A Perspective on Industry 4.0: From Challenges to Opportunities in

Production Systems

Ateeq Khan and Klaus Turowski

Magdeburg Research and Competence Cluster, Faculty of Computer Science,

University of Magdeburg, Magdeburg, Germany

Keywords:

Industry 4.0, Digital Manufacturing, Industrie 4.0, Smart Systems, Smart Factory, Future Factory, Cyber

Physical Systems, IoT.

Abstract:

Industry 4.0 and smart factory are the terms frequently used for next generation production systems. Advance-

ment of Information technologies paved the way for evolution of production systems. To remain competitive

in the market, enterprises want to utilize these technological advancements in order to solve current challenges

and serve customers in new ways which were not imagined before. In order to provide new services quickly,

new methods and technologies have to be introduced at manufacturing level. The paper briefly discusses

industry 4.0 and settings (arrangements) for co-innovation. This paper also describes what are the current

challenges faced by companies with the help of a survey. The paper proposes an approach from strategical

to operational level for the implementation of industry 4.0. In this paper, we also provide new opportunities,

scenarios, and applications enabled by introducing new tools and technologies for industry 4.0. At the end,

the paper provides summary and glimpse of the future work.

1 INTRODUCTION

Advancement in Information Technology (IT) made

it possible to bring production systems at new levels.

These new developments enable organizations to im-

prove current environment and allow them to serve

the customers in new ways by using new business

models to create value for customers and revenue for

themselves.

Companies are eager to introduce new technolo-

gies to improve quality, efficiency and effectiveness

of resources, reduce risks, and to remain competi-

tive in the market (Falk et al., 2015; Tassey, 2014).

A company which fails to cope the technology chal-

lenges also face the challenge of introducing new

products/services, innovation, and business models.

This places the company in fierce competition where

costs have to be reduced each year.

New business models have been introduced by

various companies in order to provide more value and

services for customers (Kallenbach, 2015; Figalist,

2015). These new business models not only bonded

majority of the customers but also created new cus-

tomers (and their segments) to whom value-added ser-

vices can be provided. An innovative business model

coupled with the latest technical tools guarantees the

success of a company. There are many successful ex-

amples of big companies and start-ups. For example,

Amazon (originally, a book-selling company) under-

stood what are the demands of customers and poten-

tial markets, now become one of the major IT services

provider challenging the position of the IT companies

which are in business over many decades.

Technology has been advanced at the rapid pace

on enterprise level. However, these technological de-

velopments are not applied on industrial level and it

still stands as old as the start of the third revolution

with basic IT functionalities and monolithic structure.

There are solutions on enterprise level which can be

applied at production or shop-floor level. However,

organizations are hesitant to use them on the shop-

floor level. This is due to critical nature of the systems

and their potential economic impact on operations of

organization. If a manufacturing system stops, the

whole production line may have to be stopped which

costs the loss to company (items produced per hour).

Therefore, Technology used at production level is still

quite old and has not gained much attention in com-

parison to enterprise level.

In this paper, we discuss about industry 4.0 and

settings for co-innovation in future manufacturing.

We describe the current challenges faced by compa-

Khan, A. and Turowski, K.

A Perspective on Industry 4.0: From Challenges to Opportunities in Production Systems.

DOI: 10.5220/0005929704410448

In Proceedings of the International Conference on Internet of Things and Big Data (IoTBD 2016), pages 441-448

ISBN: 978-989-758-183-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

441

nies at production systems with the help of a question-

naire. These companies belong to diverse segments

of industry. We also provide promising future scenar-

ios that can improve the efficiency of production sys-

tems. We present an approach for industry 4.0 which

will guide us for the steps needed to be taken for in-

dustry 4.0. It will also describe how we can enable

future scenarios (discussed in this paper) and simulta-

neously help to solve current challenges in production

systems. At the end we provide a summary of the pa-

per and outlook.

2 INDUSTRY 4.0 AND

CO-INNOVATION IN FUTURE

The first industrial revolution started in the end of

the 18th century with the introduction of mechanical

machines. The second industrial revolution started

in the beginning of the 20th century with electricity

and mass production. The third industrial revolution

started in early 1970s with introduction of electron-

ics and Information Technology (IT). This was the

beginning of automation of manufacturing processes

and programmed machines to take the production re-

sponsibilities. In order to compete with other uprising

countries (like India, China) and offer more value to

the customers, developed countries started to apply

advance technologies on production level. In USA

and some other countries, such initiatives are termed

as fourth industrial revolution, Internet of Things

(IoT), or next generation systems. Whereas in Ger-

many, this initiative is driven by German government

(Bundesministerium f

¨

ur Bildung und Forschung), and

referred as Industry 4.0 (industrie 4.0) (MacDougall,

2014). The industrial revolutions are depicted in the

Figure 1.

There are various definition exists for industry 4.0.

Various groups and companies define the term accord-

ing to their understanding and perspective of discus-

sion. There are also inter-relating terms like IoT, Cy-

ber Physical Systems (CPS), Smart Systems, Digital-

ization, and Digital Factory.

We define Industry 4.0 as a revolution enabled by

application of advanced technologies (like IT) at pro-

duction level to bring new values and services for cus-

tomers and organization itself. The will also bring

flexibility and quality in production systems to fulfill

demands of new innovative business models and ser-

vices quickly (service oriented architecture and net-

work communication at production level). The digi-

talization and virtualization are tools to bring end-to-

end services throughout a product life-cycle (design

till recycle) and in a cost effective way for customers.

A formal definition of industry 4.0 is defined

in (Kagermann et al., 2013) as follows:

”Industry 4.0 will involve the technical integration of

CPS into manufacturing and logistics and the use of

the Internet of Things and Services in industrial pro-

cesses”.

Various terms are used in above definition. Here

we briefly explain these terms. Powerful autonomous

physical systems connected with one another and

environment will perform operations intelligently

(smart systems). These interconnected systems re-

ferred as CPS (Lee et al., 2008; Tseng and Hu,

2014) communicates each other to fulfill the tasks.

Cyber-Physical Production Systems comprise smart

machines, warehousing systems and production facil-

ities that have been developed digitally and feature

end-to-end ICT-based integration, from inbound lo-

gistics to production, marketing, outbound logistics

and service. The IoT is a network of devices. These

devices can be small, e.g., sensor in a fridge or it can

be a robot working inside a car manufacturing fac-

tory. The No. of IoT devices till 2020 will be around

50 billion, an estimate by Cisco (Cisco, 2015). The

significant number of connected devices opens up the

door for new opportunities and new use cases in every

field. Industry and academics will find new use cases

and services which can be offered to various indus-

tries. Although currently IoT use cases at production

level are less and organizations does not know how

we can take advantage from it. Collaboration will get

more focus in future from industry 4.0 perspective as

reported in (Kagermann et al., 2013). In the follow-

ing, we present one of the future scenarios from in-

dustry 4.0 perspectives.

2.1 Co-innovation Opportunities

Recent developments in IT have paved the way for

the next industrial revolution. Next industrial revo-

lution is going to change our eco-system. As stated

in (Kagermann et al., 2013), in future manufacturing,

collaboration will be the focal point. Whether such

collaboration exists between CPS, industries or other

partners, the granularity of such collaboration can

vary from cases to cases. Services either from cloud

computing or fog computing (term initially coined by

Cisco (Bonomi et al., 2012)), will play a significant

role in this context, allowing systems and partners to

work, communicate and collaborate from anywhere

in real time.

There exists variety of collaboration possibilities

for development of future products, e.g. within com-

panies, research institutions, or combination of both.

Every collaboration requires adaptation of the strate-

IoTBD 2016 - International Conference on Internet of Things and Big Data

442

TIME

REVOLUTION

Fourth industrial revolution

21st century (20XX)

Evolution from existing

Cyber Physical Systems (Intelli – Smart)

First industrial revolution

18th century (1784)

Mechanical (Hydro - power)

Second industrial revolution

19th century (1870)

Electricity – conveyer belt

Mass production (Ford)

Third industrial revolution

20th century (1960)

Programmable units (Mechatronics)

ICT (PCs)

Figure 1: Industrial revolutions.

gies, as collaboration strategies between company-

to-academics will be different than company-to-

company collaboration strategy. For collaboration,

partners decide about the scope of the collaboration,

governance strategy, coordination, confidentiality, in-

tellectual property rights, deliverables, duration, mile-

stones, matters relating sharing of results, terms, and

termination of the collaboration.

For collaboration between companies, companies

can collaborate for a common shared goal to gain mu-

tual benefit. Such collaboration can exists between

companies to design a new product, using other com-

pany infrastructures based on new business models,

or between partners to optimize logistics in manufac-

turing. There are also challenges involved, e.g., find-

ing and sparing suitable resources for such collabora-

tion from their routine operations. Although it is quite

possible that companies fear to participate in such col-

laboration project because of the fear that they may

disclose their business knowledge or companies com-

petitive advantage will be compromised.

Industries want to collaborate with academic in-

stitution to increase the research and development in

the companies. By collaborating with research insti-

tution, companies gain access to current innovative re-

search areas from academics and can use the knowl-

edge to co-innovate products for future or introduce

new flexible processes in their organizations.

Research institutions gain access to sources of

business relevant innovations and work on real world

problems and case studies. Academic institution stu-

dents will find placement opportunities for internships

and potential employers afterwards. Industrial part-

ners can help the academic partners to get the propri-

etary state of the art technology in terms of hardware

and software licenses. Industries can transfer the in-

novation from research prototype or proof of concept

to commercial realization of a product or deployment

in a real environment. Companies will attract new po-

tential employees in form of students by hiring them

as internees or research students who already know

about the processes of the company.

Such a collaboration exists between our institu-

tion and our partners. We perceive the challenges

of our partners facing and better guide what services

they can offer in future in diverse topics. An exam-

ple of such collaboration in the context of industry

4.0 is to find-out what are the requirements of next

generation manufacturing systems and services (like

seamless integration, secure services, and smart sys-

tems) and conduct the research on industry 4.0 with

the help of industrial partners. We investigate solu-

tions for current problems and how new and innova-

tive services/systems can be created and evaluated for

next industrial revolution.

3 APPROACH

As in real industrial context, all issues can not be ad-

dressed at once, therefore, an approach is needed to

accomplish the goals. This approach should address

the current problems, and pave the way for industry

4.0.

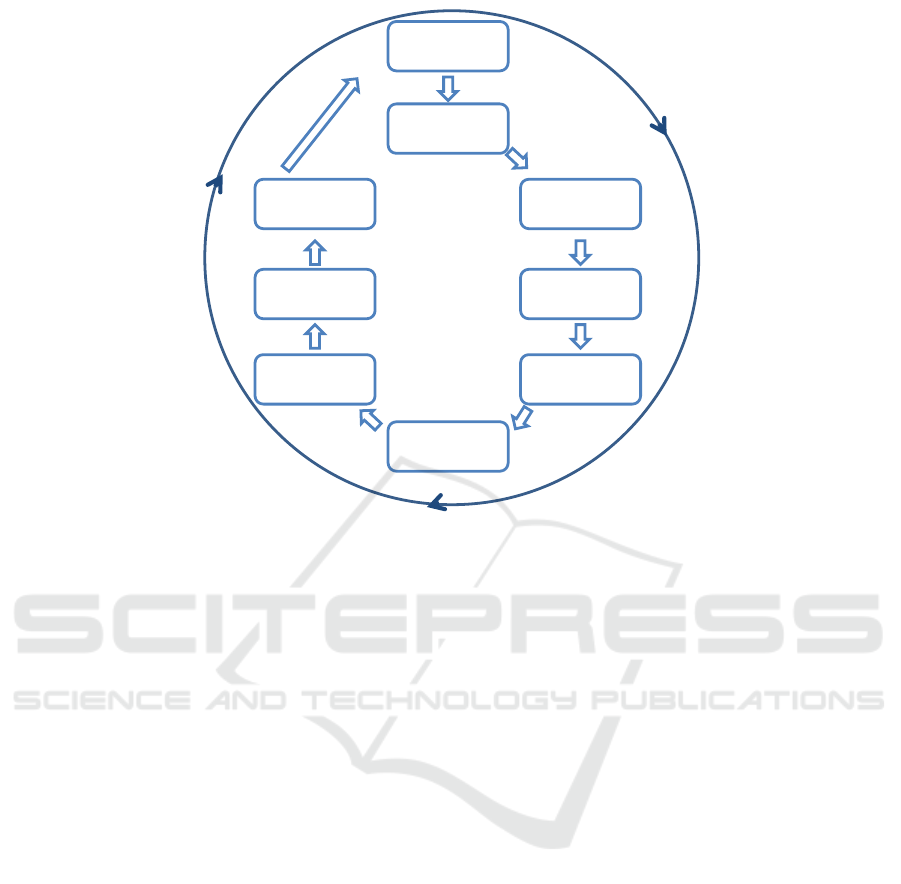

In this section, we propose a high-level approach

which consists of nine phases. This approach can be

used for any pilot project. The approach is iterative

in nature. The overall approach is depicted in the Fig-

ure 2. For the detailed understanding of our approach,

we describe its phases as follows:

In Goals and objective phase, organization set the

goals and objectives what an organization want to

achieve in a project. All steps made in a project

should help to achieve the objectives of the project

A Perspective on Industry 4.0: From Challenges to Opportunities in Production Systems

443

Goals &

Objectives

Identification

Landscape

investigation

Design &

analyze

Solution

proposals

Proof of

Concept

Evaluation and

comparison

Feedback loop

lesson learned

Strategy

selection

Figure 2: An approach for Industry 4.0

and therefore the goals of company.

In strategy selection phase, organizations decide how

they want to proceed and select which strategy they

want to apply. What are concrete steps needed to

be taken in order to achieve goals and objectives

described in previous phase. New business models

can be introduced or developed in this phase (Madu,

2013).

In identification phase, high-level requirements

will be collected. Partners and stakeholders will be

identified for the project. Collaborative workshops

will be conducted to identify pain points and oppor-

tunities. From stakeholders perspective, the purpose

is to identify roles, responsibilities, and tasks in the

project.

In landscape investigation phase, detailed infor-

mation about the current landscape will be collected.

In design and analyze phase, gathered information

will be analyzed. This step will also bring better un-

derstanding of landscape and helps to design the so-

lution.

In solution proposal phase, solution will be pro-

posed. Various solutions are possible for a project

which will be compared and finalized in this phase.

For the selected solution specific guidelines will be

prepared. Here sanity check is also performed to re-

alize the project, whether the organization have re-

quired capabilities or not.

In this phase, proof of concept of the selected so-

lution will be executed.

The evaluation phase is to review the outcomes of

the project. Here post implementation situation will

be evaluated whether the defined objective and goals

are achieved or not.

Feedback loop phase is for the continuous im-

provement purpose. Experience gained will be doc-

umented and suggestion will be prepared in case of

rolling out project on larger scale. It also includes

suggestions or guidelines to improve overall process

for other projects.

In this part, we will describe strategy selection

phase in detail. There are various perspectives and

methods available and organizations can choose from

them depending on the nature of problem. As for in-

dustry 4.0 changes are required at various levels, so it

is important for an organization to decide where they

want to focus first in a project. One of the strategies is

to address the areas where company is currently fac-

ing challenges or having problems. There are vari-

ous perspectives, namely outside-in or inside-out per-

spective (Day and Moorman, 2010). In outside-in

perspective, customers are focal point. Organiza-

tions look for what are customer trends and require-

ment, which innovative services or value added bene-

fit they can provide to customers and on basis of such

questions and requirements they design their strat-

egy and build business models. Typical examples of

outside-in perspective are offering new business mod-

els, products, and services e.g. which data companies

or external customers required from production useful

IoTBD 2016 - International Conference on Internet of Things and Big Data

444

for mutual benefit (without losing competitive advan-

tage).

In inside-out perspective, organizations look in-

side the organization for opportunities how can they

better utilize resources and processes to provide new

services and products to meet customer’s require-

ments. In inside-out perspective, organizations focus

on organization itself and to solve internal challenges

first, e.g., solving data silos issues, providing real-

time data access, standardization, and process opti-

mization, which afterwards, will help to enable in-

dustry 4.0 scenarios and benefits. Organizations also

have to decide which strategy they want to employ in

projects top-down, bottom-up or hybrid one. In fu-

ture, we plan to describe activities (conducting work-

shops, interviews) in each phases in detail with the

help of a case study.

4 CURRENT CHALLENGES AND

METHODOLOGY

For our research in this paper, we use one of the qual-

itative techniques called case research strategy. As in-

dustry 4.0 and smart manufacturing is relatively new

research area, practice based problems, and poses new

challenges, case research strategy is a best candidate

for it as discussed in (Benbasat et al., 1987; Eisen-

hardt, 1989; Eisenhardt and Graebner, 2007). In this

paper, we want to know and understand the stake-

holder’s expectations, requirements and the potential

challenges industry 4.0 poses in the natural settings.

Since current challenges, future expectations from in-

dustry 4.0 have been limited investigated and lack of

case data in production environment from companies.

To find-out, what the top challenges manufacturing

industry is facing, we prepare a short questionnaire

and distributed it in an information technology exhi-

bition. We also get insights by informal interviews,

various company’s documents, and talks with indus-

trial experts and consultants regarding current prob-

lems and challenges in production environment. Al-

though due to different industry segments and com-

plex nature of their business, challenges are also di-

verse but there are also some common challenges.

We describe top five current challenges faced by

companies at production level in this paper. These

challenges are also relevant to the evolution of indus-

trial automation and manufacturing.

4.1 Data Challenge

In our data-driven world, we generate data in various

ways. In production environment, data is generated

and collected from different machines sensors, pro-

cess data, product data, quality data, plant data, logis-

tics data, data from partners, and infrastructure data;

all contribute into explosion in data size.

Such data poses various challenges and demands

new methodologies for storing, processing, and man-

agement of such data. New algorithms, models, prod-

ucts, and visualizations techniques are required to use

and gain the actual benefits from the data. Data engi-

neers are required to analyse such data and to find cor-

relation between data streams and to gain new insights

from the data which were not thought earlier. Specif-

ically, there is a problem in which plethora of inter-

mediate solution exists for data management within

a company; it ranges from storing and exchanging

data in form of printouts, emails, excel sheets, propri-

etary applications, and using heterogeneous database

solutions between various departments or production

halls. Lack of standardized approach for data man-

agement is still one of the concerns in big compa-

nies. For example, redundant data is stored in var-

ious departments of the company, in different data

formats with minor extensions or enrichments. Such

data silos raise the amount of data redundancy, in-

consistency, and different interpretation of data. Soft-

ware licenses, updates, hardware, and skilled person-

nel costs to manage such data landscape heterogeneity

are a burden in a competitive production environment.

Decision made on inconsistent data leads to incorrect

decision.

4.2 Data Exchange with Partners

Companies have to exchange data within their fac-

tories or departments and make sure the availability

of data for other processes in time. External part-

ners also share their data with companies to keep pro-

cesses optimized, e.g. material logistics data to keep

the stock level as minimum as possible. There is also

trend that instead of selling manufactured products,

companies share their infrastructure or production fa-

cilities with other companies for revenue gain. Data

transparency is also required in this case where other

companies uses infrastructure as a service. Compa-

nies have to share the progress status of such prod-

ucts manufactured at their production facilities with

other companies and for further processes carried out

on products if needed. There is a gap between pro-

duction level and ERP level. A close integration be-

tween shop floor and ERP level is often missing. Tra-

ditionally, data is not exchanged between shop floor

and ERP level in real time and independently. Trans-

ferring of data between various systems at production

level causes delay. In some scenarios, physical prod-

A Perspective on Industry 4.0: From Challenges to Opportunities in Production Systems

445

uct is transferred on the conveyer belt but updated in-

formation was not loaded to carry out operations on

the product which results in higher costs. Production

status of a product is missing and often not in real

time; hence status transparency lacked. Normally,

even in state of the art factories, they have only three

states to update the status of the product, namely pro-

duction started, in progress, and finished, and are not

well integrated with ERP systems. So, a monitoring

solution from factory is needed considering which in-

formation to provide, in which granularity, user roles,

as same information or process may be applied on the

other products. There are also issues due to data ex-

change with partners in a collaborative environment,

e.g. sharing the process status of products and cur-

rent state of the processes applied on products. Com-

panies also have to consider that sharing information

with partners does not result to lose competitive ad-

vantage or sharing critical insights. Similarly, in case

of machine faults at production level are not reported

at ERP level and current state of the production does

not reflected. Necessary measures for machine repairs

cannot be initiated because of delay in reporting.

4.3 Training and Skill Development

Normally, especially in Germany, companies are fac-

ing shortage of skilled staff due to various factors.

One of the major factors is aging population. People

used to work in production are retiring and also tak-

ing production knowledge and experience they gained

during their jobs. Other issue is to keep the hired per-

sons within organization, as younger ones wants to

have incentives, promotion or prefer to change jobs

frequently. As majority of the workforce consists of

old people who do not want to learn technologies or

hinder to have change in their routines work. Intro-

ducing new techniques, gadgets, or changing their

way is quite challenging as they resistant to such

changes. This challenge becomes manifold in case

of industry 4.0 scenarios where changes are eminent

factor.

4.4 Process Flexibility

As product life cycle in this decade is shorter than

before (Hofreiter and Huemer, 2010; Hofmann and

Bick, 2015). Individualized and customized products

also become reality. Such individualization and cus-

tomization requires flexibility at production level in a

cost effective manner. In order to provide such flex-

ibility, production environment should be adaptable

at the process level. Technology, currently used at

shop floor level is inadequate and does not support the

process flexibility (Zhang et al., 2013). Traditionally,

processes and systems at production level are devel-

oped and managed isolated over the time in various

departments. Change management at production level

is quite challenging. As processes span in various de-

partments, a clear process ownership is also missing

in case of adaptation or changes. Change structure is

also needed because sometimes it is not possible to

keep the required change in the specific area and will

impact the whole landscape due to dependencies. In

case of changes, required changes are transferred in

form of printouts or using email communication. Of-

ten these changes are handled individually in each de-

partment without any specific standards which raises

the complexity and costs of managing such changes.

There is a need to bring process standardization and

synchronizations between various company depart-

ments to provide flexibility in an effective manner.

4.5 Security

Security is also a top concern now and it will be the

major concern in future for industries. Industries want

to keep their people, products, and production fa-

cilities environment secure from security risks. The

trend of using smart devices in production is increas-

ing. On one hand connectivity of these devices pro-

vides great advantages to ease our lives. On the other

hand it poses greater risk from security perspective.

Monitoring of such devices, used in production, is

also a challenge from software and hardware perspec-

tive, which is often ignored. All devices whether in-

dustrial machines, computer, tablets, or smart phones

needs to be updated on regular basis whether to avoid

threats or due to configuration changes installed in

these devices spread across the geographical location

or inside factory. Keeping track of updates and man-

agement of such devices is a tedious task too. As

some of IoT devices used at production level have

very limited processing capabilities which requires

new tools or methods, and measurements, to keep the

devices secure instead of tradition methods. Serious

measures are needed to restrict the threats posed by

the malfunctioning or hacked devices. There are al-

ready various examples already happened where pro-

duction facilities are targeted, e.g., security holes ex-

ploited in programmable logical controllers deployed

in factories (Zetter, 2011). It is also possible that

manufactured electronic products may contain viruses

from production facility when delivered in the market,

which may result heavy fines for company or product

returns.

IoTBD 2016 - International Conference on Internet of Things and Big Data

446

5 FUTURE SCENARIOS FOR

INDUSTRY 4.0

Manufacturing industry has to cope with various chal-

lenges as mentioned in previous section. Despite of

those challenges, in the following, we present some

of the future scenarios from industry 4.0 perspectives.

The scenarios also reflect the challenges mentioned

in previous section. In first scenario, we discuss that

more integration of processes are required within en-

terprise between ERP and shop-floor level and also

across enterprise boundaries for optimal and collab-

orative environment. Second scenario highlights the

importance of real time information access to make

decision. Lastly, last scenario shows the importance

of predictive maintenance in a production environ-

ment.

5.1 Integrated Processes

Product life-cycle involves series of processes, from

design to production, service and feedback from cus-

tomers. These processes can belong within the same

enterprise or distributed across enterprise boundaries.

Process integration is quite challenging in this

case due to various technologies, interfaces, stan-

dards, methods and unique characteristics in each en-

terprise involved. Involving customer’s feedback or

customization direct in manufacturing process will

lead to improvement in the product and higher cus-

tomer satisfaction.

Integrated processes across the enterprise will en-

able to optimize and make decisions in real time. Lo-

gistics can be well optimized and out of stock or over

production cases, both results in revenue losses can be

eliminated. Suppliers can access to live data at shop-

floor level and know when to provide the required ma-

terial for better resource planning and will reduce un-

planned outage or overstock situations. Existing pro-

cesses can be optimized and will be executed faster.

In case of companies having more than one manu-

facturing facilities, whether in same geographical lo-

cation or scattered around the globe, cross plant man-

ufacturing and planning makes more sense if data

from facilities is available and integrated. Production

load can be distributed from one plant to the other

plants for optimal resource usage. Business processes

can be analyzed across plants (Lodhi et al., 2014) to

find out which plant is performing better and what

we can learn from one plant or how we can develop

best practices for specific industry or products for the

whole organization. There is also a trend in which

instead of selling end products, companies sell their

know-how or other services.

A company can allow other companies or partners

to use state of the art manufacturing facility, compe-

tency and knowledge know-how as a service to de-

velop their own product. In this case integrated pro-

cess across enterprise boundaries is a real challenge

where companies have to exchange information and

applying processes at hired facility in a secure and

confidential way.

5.2 Real-time Data Access to/from

Shop-floor Level

Real-time data access in a production is very vital

whether it is related to products, processes, or ma-

chines operating in the factory. Traditionally, real

time information access for processes was not avail-

able at shop floor level. In case of change in processes

or actions, workers or machines have to wait until in-

structions are manually transferred or data is loaded

in the production system. Future factories demand

a close integration between ERP and shop-floor and

real time access of data at production level for real

time execution and vice versa. Data collected from

machines and business processes is filtered, analyzed,

and then delivered in required format to provide in-

sights which in return will help to give better process

control, optimize, and reduce overhead costs.

5.3 Predictive Maintenance

Maintenance of machines is an important area which

every manufacturing company has to address. Manu-

facturing companies try to carry out planned main-

tenance based on different strategies like operating

hours, number of products processed, or after a cer-

tain time. A machine condition monitoring sys-

tem can be introduced to avoid unplanned mainte-

nance. Machines equipped with sensors generates

huge amount of data and records the operating con-

dition in which machine operates. Historical data col-

lected regarding machines operating conditions can

play a vital role. Current state of the machine is com-

pared with historical data and with other data in dif-

ferent dimensions (product quality, and wastage data).

Models can be developed to predict which part of ma-

chine or machine is going to fail or vulnerable (Lee

et al., 2015; Wang et al., 2008).

Machines manufacturers can collect data from

machines to provide remote diagnostics and offer

maintenance services from their locations. Such data

can also be useful for them to know in which condi-

tions their machines are operating and what they can

learn from such data. For example, machine manu-

facturers can develop next generation of machines for

A Perspective on Industry 4.0: From Challenges to Opportunities in Production Systems

447

specific industry or buyers segments by understand-

ing their operating needs based on history. Remote

setting of parameter or operating conditions or pro-

viding early warning in case of machine is over used

or wrongly used as compared to what it is made for.

They can also send their maintenance staff to repair

or diagnose the problem. Such data can be collected

by the machines and transmitted to the machine man-

ufacturer. Other option is such data is collected by

the production facility and then those enterprises can

collaborate to produce or offer better services.

6 SUMMARY AND OUTLOOK

Industry 4.0 and smart manufacturing started to show

their importance in manufacturing industry. In our pa-

per, we provide an iterative approach for industry 4.0

projects. In our study, we investigate what are the

current challenges. We also discuss the new scenarios

which are possible in manufacturing industry to gain

the benefit from industry 4.0. Although, we listed

only current challenges but in future these new sce-

narios may also pose some challenges. In future, we

want to explain our approach in detail and to develop

a industry 4.0 project prototype (proof of concept) to

demonstrate the utility of our approach.

REFERENCES

Benbasat, I., Goldstein, D. K., and Mead, M. (1987). The

case research strategy in studies of information sys-

tems. MIS quarterly, pages 369–386.

Bonomi, F., Milito, R., Zhu, J., and Addepalli, S. (2012).

Fog computing and its role in the internet of things. In

Proceedings of the first edition of the MCC workshop

on Mobile cloud computing, pages 13–16. ACM.

Cisco (2015). Internet of Things(IoT). http://www.cisco

.com/web/solutions/trends/iot/portfolio.html.

Day, G. and Moorman, C. (2010). Strategy from the out-

side in: Profiting from customer value. McGraw Hill

Professional.

Eisenhardt, K. M. (1989). Building theories from case study

research. Academy of management review, 14(4):532–

550.

Eisenhardt, K. M. and Graebner, M. E. (2007). Theory

building from cases: opportunities and challenges.

Academy of management journal, 50(1):25–32.

Falk, M., Klien, M., and Schwarz, G. (2015). Large man-

ufacturing firms plan to increase their investments

in 2015. results of the wifo spring 2015 investment

survey. WIFO Monatsberichte (monthly reports),

88(7):581–591.

Figalist, D. H. (2015). On the way to industrie 4.0. driving

the digital enterprise. VDMA Informationstag, Indus-

trie 4.0 Konkret.

Hofmann, J. and Bick, P. D. W. (2015). Are variant produc-

ers the pioneers? ROI Dialog, (43):6–7.

Hofreiter, B. and Huemer, C. (2010). Flexible workflow

management in service oriented environments. In

Agent-Based Service-Oriented Computing, pages 81–

111. Springer.

Kagermann, H., Helbig, J., Hellinger, A., and Wahlster,

W. (2013). Recommendations for implementing the

strategic initiative industrie 4.0: Securing the future

of german manufacturing industry; final report of the

industrie 4.0 working group.

Kallenbach, D. R. (2015). The internet of things: Con-

nected products, connected manufacturing. internet.

Bosch Software Innovations GmbH.

Lee, E. et al. (2008). Cyber physical systems: Design

challenges. In Object Oriented Real-Time Distributed

Computing (ISORC), 2008 11th IEEE International

Symposium on, pages 363–369. IEEE.

Lee, J., Bagheri, B., and Kao, H.-A. (2015). A cyber-

physical systems architecture for industry 4.0-based

manufacturing systems. Manufacturing Letters, 3:18

– 23.

Lodhi, A., K

¨

oppen, V., Wind, S., Saake, G., and Turowski,

K. (2014). Business process modeling language for

performance evaluation. In System Sciences, 47th

Hawaii International Conference on, pages 3768–

3777.

MacDougall, W. (2014). Industrie 4.0 smart manufacturing

for the future. Germany Trade and Invest.

Madu, B. C. (2013). Vision: The relationship between a

firm’s strategy and business model. Journal of Behav-

ioral Studies in Business, 6:1. Academic and Business

Research Institute (AABRI).

Tassey, G. (2014). Competing in advanced manufacturing:

The need for improved growth models and policies.

The Journal of Economic Perspectives, pages 27–48.

Tseng, M. M. and Hu, S. J. (2014). Mass customization. In

CIRP Encyclopedia of Production Engineering, pages

836–843. Springer.

Wang, T., Yu, J., Siegel, D., and Lee, J. (2008). A similarity-

based prognostics approach for remaining useful life

estimation of engineered systems. In Prognostics and

Health Management, 2008. PHM 2008. International

Conference on, pages 1–6.

Zetter, K. (2011). Serious security holes found in

siemens control systems targeted by stuxnet.

http://arstechnica.com/security/2011/08/serious-

security-holes-found-in-siemens-control-systems-

targeted-by-stuxnet/.

Zhang, Y., Huang, G., Qu, T., and Sun, S. (2013). Real-time

work-in-progress management for ubiquitous manu-

facturing environment. In Li, W. and Mehnen, J.,

editors, Cloud Manufacturing, Springer Series in Ad-

vanced Manufacturing, pages 193–216. Springer Lon-

don.

IoTBD 2016 - International Conference on Internet of Things and Big Data

448