Design of Customised Orthodontic Devices by Digital Imaging and

CAD/FEM Modelling

Sandro Barone, Alessandro Paoli, Armando Viviano Razionale and Roberto Savignano

Department of Civil and Industrial Engineering, University of Pisa, Largo Lucio Lazzarino 1, 56126, Pisa, Italy

Keywords: Orthodontic Aligner, Finite Element Model, Aligner Thickness.

Abstract: In recent years, the public demand of less invasive orthodontic treatments has led to the development of

appliances that are smaller, lower profile and more transparent with respect to conventional brackets and

wires. Among aesthetic appliances, removable thermoplastic aligners gained instant appeal to patients since

able to perform comprehensive orthodontic treatments without sacrificing comfort issues. The aligner must

deliver an appropriate force in order to move the tooth into the expected position. However, at present, the

relationship between applied force and aligner properties (i.e., aligner’s thickness) is poorly understood. In

this paper, a patient-specific framework has been developed to simulate orthodontic tooth movements by

using aligners. In particular, a finite element model has been created in order to optimise the aligner’s

thickness with regard to the magnitude of the force-moment system delivered to a mandibular central incisor

during bucco-lingual tipping.

1 INTRODUCTION

Orthodontic treatments are performed to achieve the

correct occlusion with the best functional and

aesthetic features. The correction of irregular bites is

obtained by applying mechanical actions that move

teeth into their proper position within the dental

arches. The growing interest for adult orthodontic

corrections has accelerated the use of aesthetic

alternatives to conventional fixed devices. For this

reason, the use of transparent tooth correction

systems is becoming common for minimally

invasive treatments. In particular, treatments based

on clear removable thermoplastic appliances

(aligners) are increasingly used (Boyd, 2008).

This system consists of a set of thermoformed

templates, made of transparent thermoplastic

material, which are sequentially worn by the patient.

The orthodontic three-dimensional force-moment

system on each tooth is generated by a pre-

determined geometrical mismatch between the

aligner shape and the dentition geometry. This

condition is determined by using virtual 3D models

of the patient’s dentition and computer-aided design

(CAD) methodologies (Beers et al., 2003). Each

single template, which corresponds to the new

required tooth placement, is programmed to perform

only a small part of the complete tooth movement.

Therefore, a full treatment consists of a set of

templates with varying shapes from the initial

anatomical geometry to the target tooth position.

The possibility to simulate and identify appropriate

moment-to-force ratios is a key issue in order to

predict and control tooth movements. At this

purpose, the Finite Element Analysis (FEA) is one

of the most used tools to evaluate the effectiveness

of dental devices and has been widely used in

dentistry since the 70’s (Farah et al., 1973).

In this paper a patient-specific framework has

been developed in order to make feasible a

customized simulation of orthodontic tooth

movements by using thermoplastic aligners. A Finite

Element (FE) model is created to design optimised

appliances leading to more efficient orthodontic

treatments. Even if the use of aligners is becoming

an effective solution to treat malocclusion conditions

(Boyd, 2008), few attempts have been made to

develop FE models describing the aligner’s

behaviour in delivering forces (Cai et al., 2015,

Gomez et al., 2015).

Tooth movements with aligners may be more

complex with respect to fixed appliances since there

is no specific point of force application. Many

parameters are certainly involved in determining the

clinical outcome: tooth anatomy, aligner’s material

properties, amount of mismatch between aligner and

dentition geometries, slipping motions between

44

Barone, S., Paoli, A., Razionale, A. and Savignano, R.

Design of Customised Orthodontic Devices by Digital Imaging and CAD/FEM Modelling.

DOI: 10.5220/0005821000440052

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 2: BIOIMAGING, pages 44-52

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

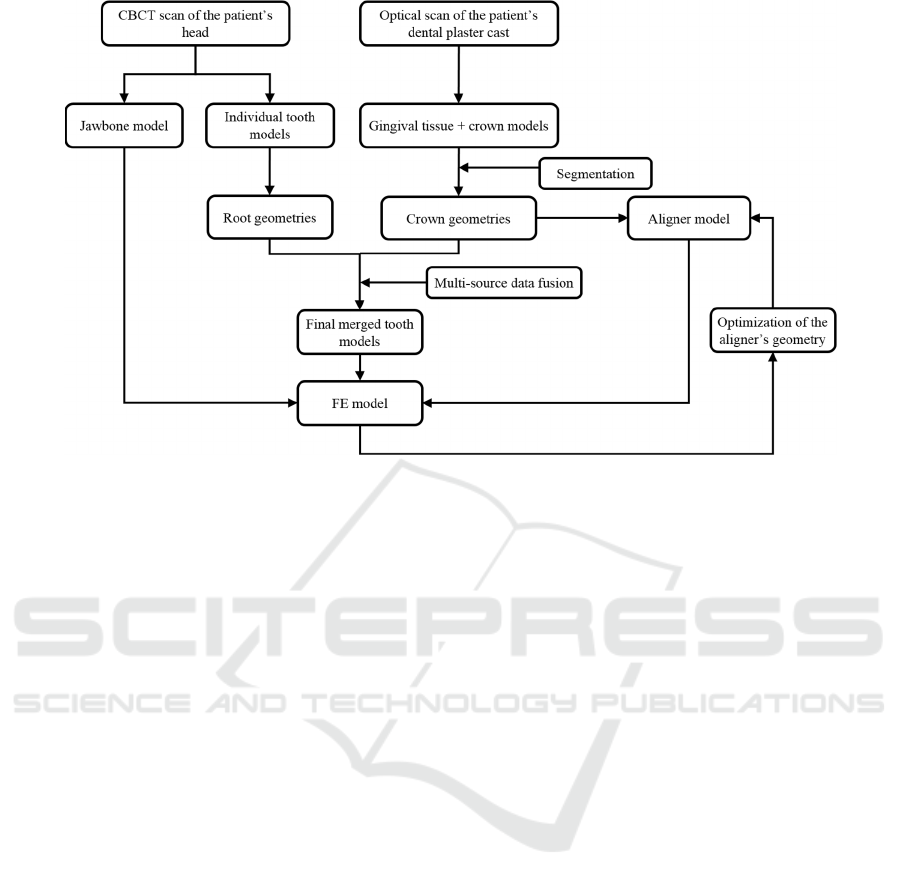

Figure 1: Overall workflow.

contact shapes. In particular, the aligner’s thickness

has demonstrated to have a great influence on the

magnitude of the force produced by the appliance

(Hahn et al., 2009, Kwon et al., 2008). In this work,

the authors have used the developed FE model to

study the influence of non-uniform aligner’s

thickness on the amount and quality of the force

system delivered to a central incisor during tipping.

2 MATERIALS AND METHODS

The patient anatomical geometries as well as the

aligner shape have been reconstructed by computer-

aided scanning and digital imaging techniques.

In particular, multi-source data are used to obtain

tooth anatomies including crown and root shapes.

Ideal tooth movements can be achieved through

orthodontic appliances that are designed by taking

into account not only tooth crowns but also root

geometrical features. For this reason, in this work,

accurate crown geometries, obtained from high-

precision optically scanned data, are merged with

approximate representations of root geometries

which are derived from a raw and fast segmentation

of Cone Beam Computed Tomography (CBCT)

data.

The aligner geometry has then been modelled by

exploiting CAD tools in order to create a layer,

which closely mates the tooth crown surfaces except

for the area corresponding to the tooth to be moved.

In this region, a penetration between crown and

aligner surfaces is introduced to generate the loading

condition. In particular, in this work, the influence of

both thickness and shape of the aligner has been

investigated in order to optimize the effectiveness of

the orthodontic treatment and reduce the patient

discomfort. Figure 1 summarizes the overall

framework.

2.1 Creation of the Patient Anatomical

Model

The patient’s anatomical model, composed of

alveolar bone, teeth and periodontal ligament (PDL),

is obtained by exploiting information derived from a

CBCT patient’s scan and an optical scan of the

relative dental plaster cast. The CBCT scan is used

to obtain complete geometries of each individual

tooth along with its relative spatial arrangement

within the jawbone. An optical scanner, based on a

coded structured light approach, has been used to

acquire the plaster model created from the patient’s

mouth impression. The aim of the optical scanning

procedure is to reconstruct an accurate digital model

composed of tooth crowns.

CBCT volumetric data are used to reconstruct

the jawbone structure as well as the complete and

individual tooth geometries. A CBCT scan yields a

stack of slices corresponding to cross-sections

through a maxillofacial volumetric region. CBCT

data are stored in a sequence of Digital Imaging and

Communications in Medicine (DICOM) images. An

imaging slice is a 2D matrix of grey intensity values

Design of Customised Orthodontic Devices by Digital Imaging and CAD/FEM Modelling

45

representing the x-ray attenuation of different

anatomical tissues.

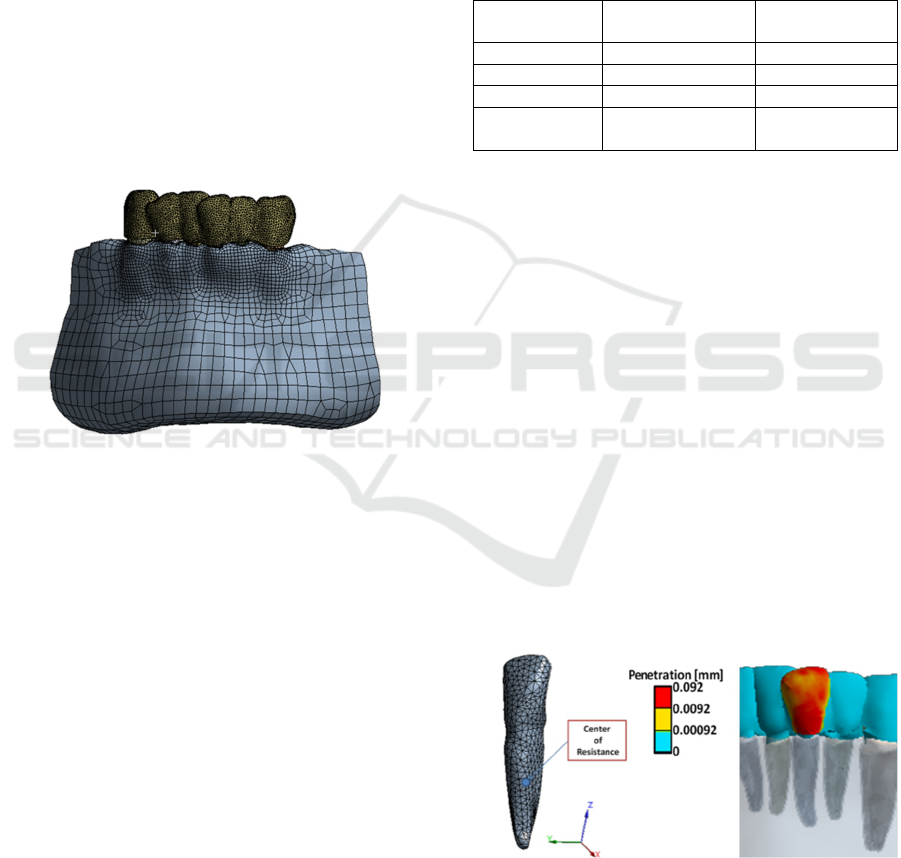

The three-dimensional model of the jawbone has

been obtained by exploiting tools provided by an

open-source software for medical image analysis

(3DSlicer, 2014). A triangular mesh of the

isosurface representing the bone shape (Figure 2)

has been obtained by segmenting the volumetric

CBCT data set with a specific grey intensity value

(isovalue).

Figure 2: Jawbone geometry used in the FE model.

2.1.1 Complete Tooth Geometries by CBCT

Scanning

The reconstruction of the individual tooth anatomies

is not so straightforward because tooth root regions

cannot be easily separated from surrounding bone

tissue by only considering pixel’s grey-intensity

values. Most of the existing techniques are based on

slice-by-slice segmentation procedures, which

involve the digital processing of hundreds of slices

in order to reconstruct three-dimensional geometries,

thus resulting in time-consuming procedures. In this

paper, DICOM images are processed by adopting

the methodology introduced in (Barone et al., 2015).

This method, is based on processing a small number

(four) of multi-planar reformation images, which are

obtained for each tooth on the basis of anatomy-

driven considerations. The reformation images

greatly enhance the clearness of the target tooth

contours, which are then extracted and used to

automatically model the overall 3D tooth shape

through a B-spline representation.

Practically, four reference planar sections are

automatically extracted as passing from the tooth

axis and oriented along the buccolingual direction,

the mesiodistal direction and the two directions

disposed at 45° with respect to these two meaningful

clinical views. These reference sections are used to

outline the tooth by interactively tracing four

different 2D tooth contours (C

i

) as shown in Figure

3-a. The four contours are used to automatically

extract a B-spline curve. Each slice perpendicular to

the tooth axis (transverse slice) intersect the C

i

contours in eight points that are used as control

points to compute a parametric B-spline curve of

degree 2 (Figure 3-b). For each slice, 100 points are

evaluated on the B-spline curve in order to obtain a

point cloud representing the overall tooth shape. For

further details the reader can refer to (Barone et al.,

2015).

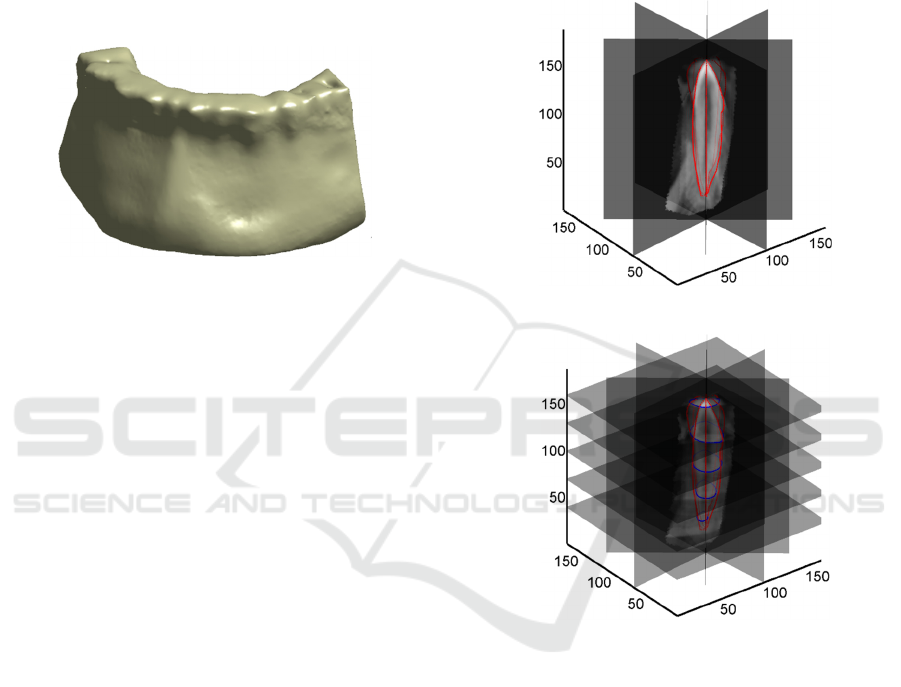

(a)

(b)

Figure 3: a) Four reference planar sections along with the

2D tooth contours, b) B-spline curves computed for the

transverse slices.

Figure 4-a shows the point clouds relative to the

incisors, canine and premolar teeth of the inferior

arch used in the present work. Figure 4–b shows the

respective StL models obtained by a tessellation of

the respective point clouds.

The greatest benefit of this methodology consists

in providing reliable approximations of individual

tooth roots, by interactively contouring a few

significant images created from the whole CBCT

data set.

The processing time is greatly reduced with

respect to standard cumbersome slice-by-slice

methods usually proposed within medical imaging

BIOIMAGING 2016 - 3rd International Conference on Bioimaging

46

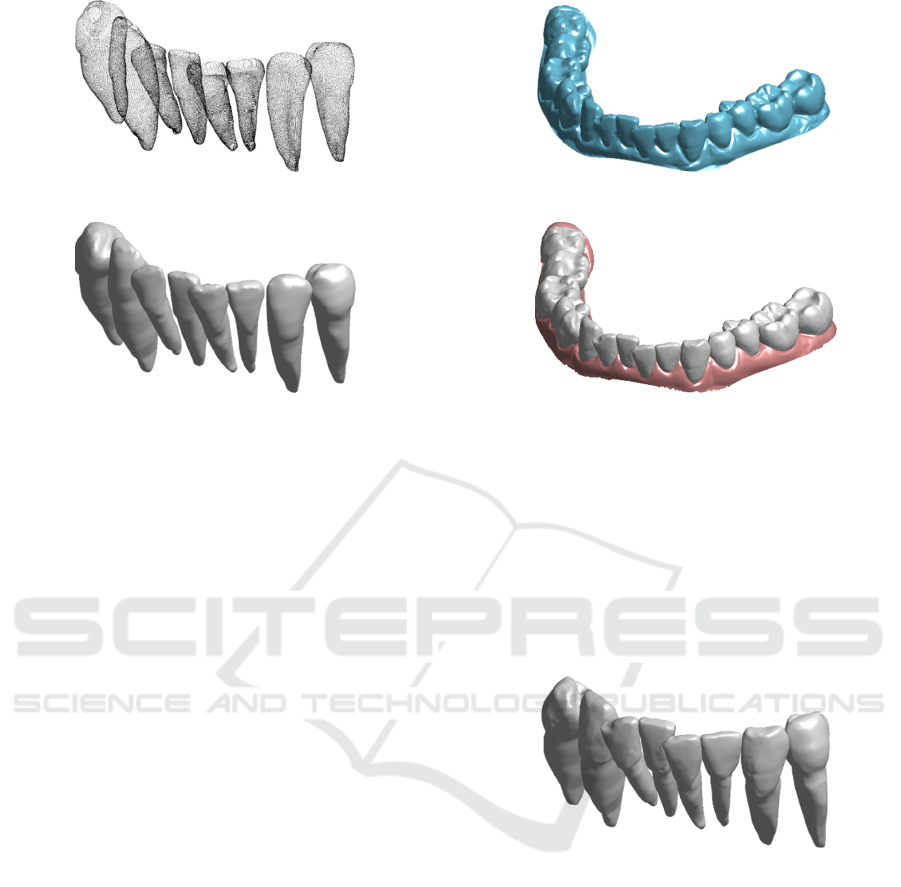

(a)

(b)

Figure 4: Incisor, canine and premolar tooth models of an

inferior arch as obtained by segmenting CBCT data. (a)

Point clouds, (b) StL models.

software. However, the accuracies obtained for

crown geometries, especially for multi-cusped

shapes, cannot be considered adequate to simulate

orthodontic treatments based on the use of

customized appliances.

2.1.2 Crown Geometries by Optical

Scanning

In this work, an optical scanner, based on a coded

structured light approach, has been used to acquire

the patient’s plaster model. An accurate digital

mouth reconstruction composed of both crown

shapes and gingival tissue is then obtained as shown

in Figure 5-a. The overall surface is then segmented

into disconnected regions, representing the

individual crown geometries and the gingiva (Figure

5-b) through a semi-automated procedure, which

exploits the curvature of the digital mouth model.

2.1.3 Multi-Source Data Fusion

For each tooth, the multi-source data obtained by

using optical and tomographic scanning must be

merged in order to create accurate multibody dental

models. The crown surfaces obtained by optical

scanning are aligned with the corresponding crown

geometries segmented from the CBCT data set.

The meshes from the two sets of data are

coarsely aligned into a common reference frame by

manually selecting at least three common points. A

refinement of the initial alignment is then

(a)

(b)

Figure 5: (a) Digital mouth model as obtained by using the

structured light scanner and (b) individual tooth crowns

and gingival geometries as obtained by segmenting the

model.

performed by a fine registration procedure based on

the Iterative Closest Point (ICP) technique. The

crown geometries obtained by processing DICOM

images are then removed by means of a disk vertex

selection algorithm.

Figure 6: Final merged tooth geometries (optical crowns +

CBCT roots) used in the FE model.

Each vertex of the optic crown is projected into a

point on the CBCT mesh. This point describes the

center of a sphere, which is used to select the points

of the CBCT mesh to remove. The final tooth

models (Figure 6) are then obtained by a Poisson

surface reconstruction approach (Kazhdan et al.,

2006). This allows for fully closed models

composed of the most accurate representation for

tooth crowns.

2.1.4 PDL Modelling

PDL geometries cannot be easily visualized and

reconstructed since usually the slice thickness is

Design of Customised Orthodontic Devices by Digital Imaging and CAD/FEM Modelling

47

similar or even greater than the ligament space

(about 0.2 mm) (Dorow et al., 2003). For this

reason, in this work the PDL has been modelled for

each tooth by detecting the interface area between

bone and tooth models to which a 0.2 mm thick shell

has been added. The volume shell is then subtracted

from the alveolar bone in order to define the PDL

volume (Liu et al., 2013). The obtained PDL solid

models are shown in Figure 7.

Figure 7: PDL geometries used in the FE model.

2.1.5 Orthodontic Aligner Modelling

Process

The aligner geometry has been created by defining a

layer completely congruent with the tooth crown

surface. The individual teeth are firstly joined, root

geometries are deleted and undercut volumes

manually removed in order to create a unique layer.

The layer is thickened to create a 0.5 mm thick

volume. Finally, the merged tooth geometries

(shown in Figure 6) are subtracted from the volume

and the most external surface of the remaining

geometry is removed with the aim at modelling the

inner shape of the aligner. This procedure is carried

out to guarantee an optimal fit between the mating

surfaces of the tooth crowns and the appliance

(Barone et al., 2014). The aligner is supposed to

have a uniform 0.7 mm thickness which originates

from the mean thickness of the thermoplastic

material disk (0.75 mm thick) before the

thermoforming process (Ryokawa et al., 2006). For

this reason, a shell has been created by thickening

the inner shape of the aligner by 0.7 mm along the

direction normal to the surface. Figure 8 shows the

overall modelled geometries used to create the FE

model.

In this work, a further modelling strategy has

been followed to test the influence of non-uniform

aligner thickness values on the effectiveness of the

orthodontic treatment. The idea is based on varying

the appliance geometry by thickening the appliance

in correspondence of highly deformed regions while

thinning the model in correspondence of low

deformed regions. This would allow to optimize the

forces delivered to any tooth in the arch.

Figure 8: Overall geometries used to create the FE model.

In particular the aligner displacement values

have been used to pinpoint adjust the aligner’s

thickness. The procedure can be schematized as

follows:

1. Evaluation of the displacement value (d) for

each FE mesh node of the inner surface of the

0.7 mm thick aligner;

2. Determination, for each node, of the normal

direction with respect to the surface. The mean

of the normal unit vectors of the triangles

having that node as vertex is used;

3. Computation, for each node, of a new point

along the normal direction having distance t

from the node linearly defined as:

min

min max min

max min

( )

( )

d d

t s s s

d d

(1)

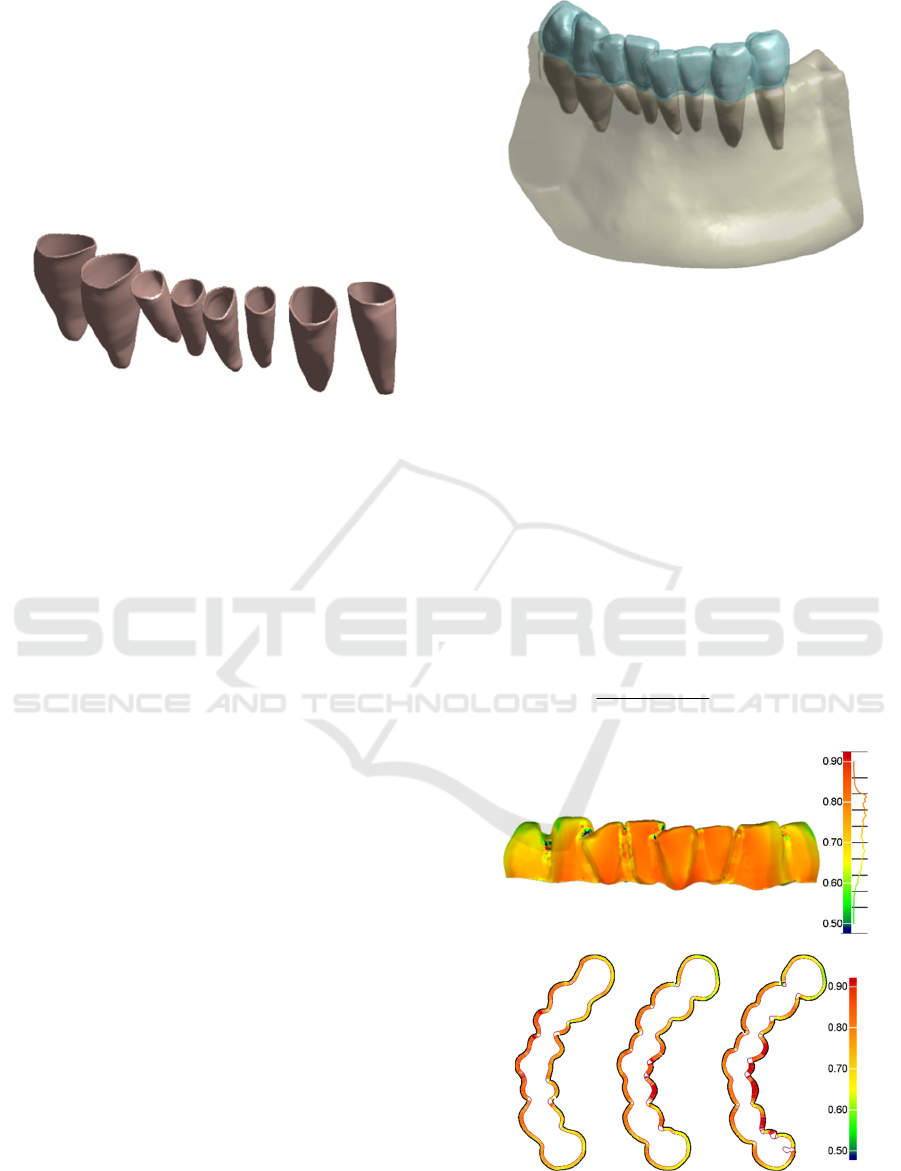

(a)

(b)

Figure 9: a) Full-field map of the aligner thickness values

(expressed in mm) and three cross sections (b).

BIOIMAGING 2016 - 3rd International Conference on Bioimaging

48

where s

min

and s

max

are, respectively, the

minimum and maximum values which define the

aligner’s thickness range, while d

min

and d

max

respectively represent the minimum and maximum

displacement values computed for the 0.7 mm thick

aligner. The thickness range has been defined

between 0.5 mm and 0.9 mm. Figure 9 shows a full-

field map of the aligner thickness values (Figure 9-a)

and three different cross sections (Figure 9-b).

2.2 Generation of the FE Model

The different bodies were imported in Ansys

®

14.

Each body was modeled with solid 10 nodes

tetrahedrons. The approximate number of elements

and nodes for each simulation was 134000 and

226000 respectively. Figure 10 shows the meshed

models for the simulation performed with a uniform

0.7 mm thick aligner.

Figure 10: Meshed model used for the simulation with 0.7

mm uniform thick aligner.

2.2.1 Material Properties

A linear elastic mechanical model was assigned to

each body as shown in Table 1. Moreover, teeth and

bone were supposed as made by a homogenous

material, without discerning in enamel, pulp, dentin

for the teeth and cortical and cancellous for the

bone. This simplification does not affect the

simulation results as shown in previous studies

(Penedo et al., 2010). In technical literature, many

are the biomechanical models that simulate the tooth

ligament properties (Fill et al., 2012). The

investigation of the ligament in-vivo behavior is not

a trivial task due to its small size (about 0.2 mm

thickness). For this reason, most of the scientific

literature has investigated the mechanical properties

of the PDL through experimental analyses, thus

developing five different models: linear elastic,

bilinear elastic, viscoelastic, hyperelastic and

multiphase (Fill et al., 2012). However, the complex

non-linear response of the PDL does not need to be

addressed while performing an analysis about the

first phase of the orthodontic reaction as in the

present study (Cattaneo et al., 2005).

The thermoplastic aligners are usually made

from a polyethylene terephthalate glycol-modified

(PETG) disc, whose mechanical properties can be

retrieved from the manufacturer's datasheet. Its

mechanical behavior has been approximated as

linear elastic.

Table 1: Material properties used for the FE analyses.

Young Modulus

[MPa]

Poisson's ratio

Bone

13000 0.3

Teeth

20000 0.3

PDL

0.059 0.49

Aligner

(PETG)

2050 0.3

2.2.2 Loading and Boundary Conditions

A bucco-lingual tipping of a mandibular central

incisor was simulated. The initial load configuration

for the FE analysis was generated by the penetration

between the aligner and the target tooth. The initial

models do not present any penetration between teeth

and aligner since the aligner is modelled onto the

teeth surfaces. The tooth must be rotated around the

Center of Resistance in order to create the initial

penetration. The coordinates of tooth Center of

Resistance were determined by using the method

proposed by (Viecilli et al., 2013). The reference

axes were defined accordingly to the occlusal plane.

The z-axis was perpendicular to the occlusal plane,

while the y and x-axis were parallel to the occlusal

plane and congruent respectively with the

mesiodistal and bucco-lingual tooth directions

(Figure 11-a). Finally, the tooth is rotated around its

C.Res. along the y-axis.

(a) (b)

Figure 11: Target tooth's Center of Resistance (a) and

initial penetration between teeth and aligner (b).

Design of Customised Orthodontic Devices by Digital Imaging and CAD/FEM Modelling

49

The resultant initial penetration turned out to be

about 0.09 mm as shown in Figure 11-b. The bone

extremities were fixed in all directions. An

augmented Lagrangian formulation was used to

simulate contact. Bonded contact surfaces were

considered between bone and PDL and between

PDL and teeth. Corresponding nodes cannot separate

each other and a perfect adhesion between contact

surfaces, without mutual sliding or separation, can

be assumed. The aligner-teeth contact was set as

frictionless, with a maximum allowed penetration of

0.01 mm which provided the best accuracy-

computational time ratio. Because of the meshing

process, an undesired initial penetration can occur

between the aligner and the non-target teeth. For this

reason the "adjust to touch" option was used for

those contact couples in order to remove all the

undesired initial penetrations.

2.2.3 Analysis Settings

Different scenarios were simulated to compare the

influence of the aligner's thickness onto the

orthodontic movement:

uniform 0.7 mm thickness;

uniform 0.6 mm thickness;

non-uniform thickness (average value = 0.62

mm) obtained as described in section 2.1.5.

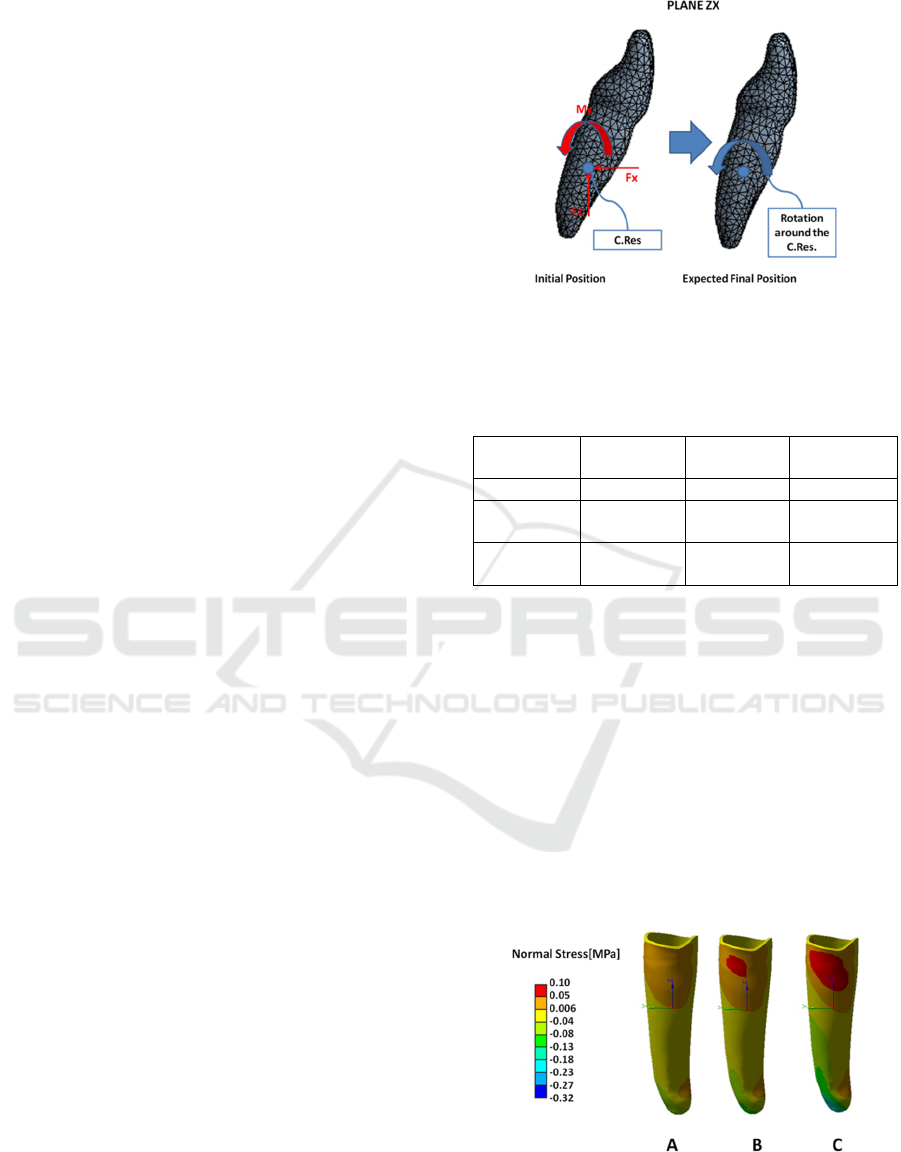

For each simulation, the resulting force-moment

system delivered by the aligner to the target tooth

was calculated at the Center of Resistance (Figure

12). Computational time resulted in about 2 hours

for each simulation, using a Workstation based on

Intel Xeon CPU E3-1245 v3@3.40 GHz and 16 GB

RAM.

3 PRELIMINARY RESULTS

The results obtained for each scenario were analysed

by comparing the moment along y-axis and the

resulting moment-to-force-ratio (M:F) delivered to

the tooth on the plane ZX (Table 2). The M:F values

describe the quality of the force system (Savignano

et al., 2015), while M

y

defines the amount of

orthodontic movement. Moreover, the stress in the

PDL, along the x-axis, and the tooth displacement

were compared (Figure 13). The magnitude of the

PDL stress values directly affects the bone

remodelling process, which is the main responsible

of the orthodontic movement (Penedo et al., 2010).

Figure 12: Initial tooth position and Force System on the

plane of interest (left). Expected final tooth position

(right).

Table 2: Force system delivered to the target tooth for

each scenario on the plane ZX.

Aligner 0.6 mm 0.7 mm

Non-

uniform

M

y

[Nmm]

1.51 2.26 3.96

M

y

/F

x

[mm]

1.81 2.24 2.83

M

y

/F

z

[mm]

-2.96 -3.42 -3.06

The amount of moment delivered to the tooth

increased by 50% from the 0.6 mm to the 0.7 mm

thick aligner. While the non-uniform aligner elicited

a moment 75% higher than the 0.7 mm and 173%

higher than the 0.6 mm. The same trend was

observed also for the stress values in the PDL. All

different scenarios showed a positive stress value on

the higher part of the anterior region and a negative

stress value on the posterior, in agreement with the

expected bucco-lingual movement of the tooth. The

maximum stress value was almost double for the

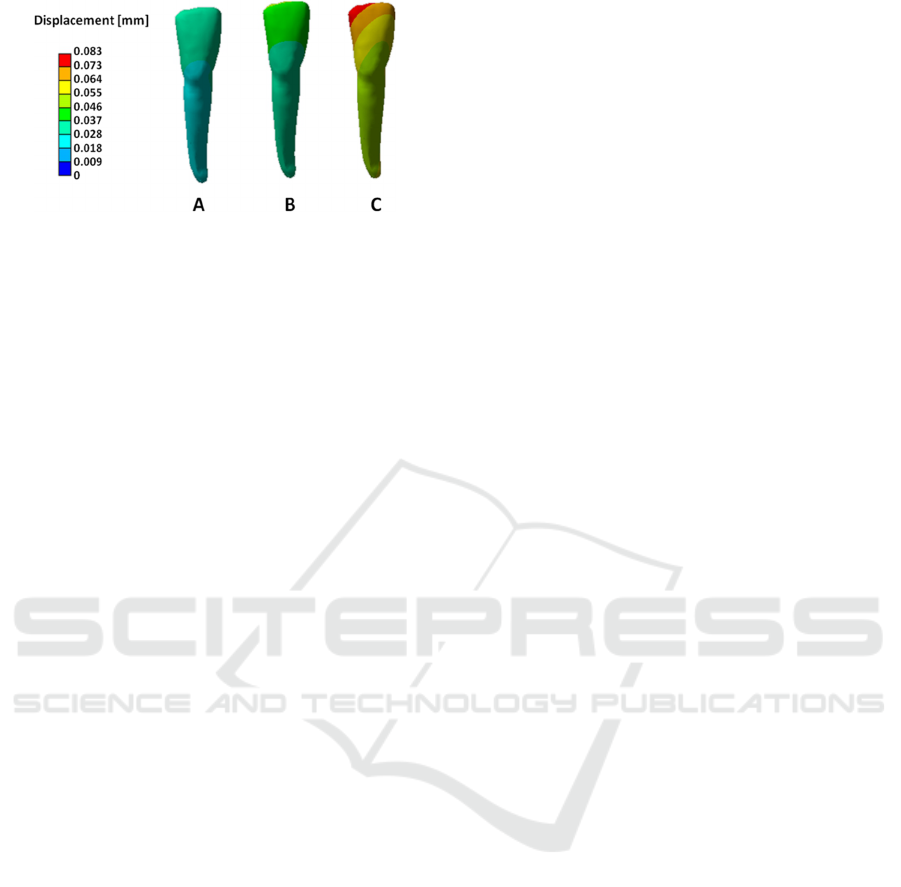

non-uniform aligner. Figure 14 shows the

displacement occurring on the target tooth for the

different configurations.

Figure 13: PDL stress values along the x-axis of the target

tooth for the different simulations: A) uniform 0.6 mm, B)

uniform 0.7 mm, C) non-uniform thickness.

BIOIMAGING 2016 - 3rd International Conference on Bioimaging

50

Figure 14: Displacement of the target tooth for the

different simulations: A) uniform 0.6 mm, B) uniform 0.7

mm, C) non-uniform thickness.

4 DISCUSSION AND

CONCLUSIONS

Thermoformed plastic aligners have demonstrated

limitations in exerting complex force systems

(Kravitz et al., 2009). In particular, extrusion of

central incisors and rotation and inclination of

canine and premolar teeth are obtained in clinical

practice by using composite elements as

attachments, bonded to the crowns surface, or divots

and power ridges, which enhance the biomechanical

effectiveness. However, the aligner thickness

represents an additional critical element that should

be optimized since the aligner material itself is the

only element that imparts the force system. Minimal

aligner thickness values would minimize patient

discomfort. However, forces delivered by thick

appliances are higher than those of thin materials

(Hahn et al., 2009).

Typically, aligners are obtained by a vacuum

thermoforming process performed onto 3D physical

moulds of the teeth manufactured by RP

methodologies for each single step of the

orthodontic treatment. A single thermoplastic

polymer resin sheet (about 0.75 mm-thick) is

stretched over each prototyped mould and trimmed

to extract the final configuration. For this reason, a

constant thickness is usually considered for the

aligners.

In this paper, the influence of non-uniform

aligner’s thickness for the tipping of a mandibular

central incisor has been investigated by exploiting

FE analyses. Preliminary results have evidenced a

more effective force system delivered to the central

incisor by pinpoint modulating the aligner thickness

in order to vary its stiffness. The non-uniform

appliance elicited a higher magnitude of the desired

moment M

y

and a better quality of the movement as

attested by the higher values obtained for the M:F

parameter.

These findings clearly call upon some

considerations about the aligner’s manufacturing

process. Currently, the standard production

processes are strictly constrained by the

thermoforming procedures, which provide only

constant thickness aligners. An alternative method

for the direct manufacturing of the aligner should be

used. For instance, milling by CNC machines or

layer-by-layer printing of a single or multiple

polymeric materials, would allow to obtain non-

uniform thin-walled polymeric orthodontic aligners.

Nevertheless, essential aligner’s properties are large

spring-back, high stored energy, tolerance to mouth

hostile environment, biocompatibility and low

surface roughness in correspondence of the mating

surfaces. These features should be taken into high

consideration when considering an alternative

production method. This topic certainly represents a

challenging task which should affect future research

activities.

A further parameter that influences the

effectiveness of the orthodontic treatment, besides

the aligner’s thickness, is represented by the

mechanical properties of the thermoplastic materials.

In the present study, the physical values indicated in

material manufactures datasheets have been used.

However, these values are given under standard

atmospheric conditions. Temperature, humidity, and

forming procedures may have marked effects on the

actual mechanical properties, which may differ

between the intraoral environment and room

temperature (Ryokawa et al., 2006). For this reason,

some experimental tests are currently being carried

out by simulating intraoral environment in order to

characterize the aligner’s mechanical properties in

working conditions.

REFERENCES

3DSlicer. 2014. A multi-platform, free and open-source

software package for visualization and medical image

computing [Online]. Available: http://www.slicer.org/

[Accessed 1 September 2015.

Barone, S., Paoli, A. & Razionale, A. V. 2015. CT

segmentation of dental shapes by anatomy-driven

reformation imaging and B-spline modelling.

International Journal for Numerical Methods in

Biomedical Engineering, in press, doi:

10.1002/cnm.2747.

Barone, S., Paoli, A., Razionale, A. V. & Savignano, R.

2014. Computer aided modelling to simulate the

biomechanical behaviour of customised orthodontic

Design of Customised Orthodontic Devices by Digital Imaging and CAD/FEM Modelling

51

removable appliances. International Journal on

Interactive Design and Manufacturing (IJIDeM), in

press, doi: 10.1007/s12008-014-0246-z.

Beers, A. C., Choi, W. & Pavlovskaia, E. 2003. Computer-

assisted treatment planning and analysis. Orthodontics

and Craniofacial Research, 6, 117-125.

Boyd, R. L. 2008. Esthetic orthodontic treatment using the

invisalign appliance for moderate to complex

malocclusions. Journal of Dental Education, 72, 948-

967.

Cai, Y. Q., Yang, X. X., He, B. W. & Yao, J. 2015. Finite

element method analysis of the periodontal ligament in

mandibular canine movement with transparent tooth

correction treatment. Bmc Oral Health, 15.

Cattaneo, P. M., Dalstra, M. & Melsen, B. 2005. The finite

element method: a tool to study orthodontic tooth

movement. Journal of Dental Research, 84, 428-433.

Dorow, C., Schneider, J. & Sander, F. G. 2003. Finite

Element Simulation of in Vivo Tooth Mobility in

Comparison with Experimental Results. Journal of

Mechanics in Medicine and Biology, 3, 79-94.

Farah, J. W., Craig, R. G. & Sikarski.Dl 1973.

Photoelastic and Finite-Element Stress Analysis of a

Restored Axisymmetric First Molar. Journal of

Biomechanics, 6, 511-520.

Fill, T. S., Toogood, R. W., Major, P. W. & Carey, J. P.

2012. Analytically determined mechanical properties

of, and models for the periodontal ligament: Critical

review of literature. Journal of Biomechanics, 45, 9-

16.

Gomez, J. P., Pena, F. M., Martinez, V., Giraldo, D. C. &

Cardona, C. I. 2015. Initial force systems during

bodily tooth movement with plastic aligners and

composite attachments: A three-dimensional finite

element analysis. Angle Orthodontist, 85, 454-460.

Hahn, W., Dathe, H., Fialka-Fricke, J., Fricke-Zech, S.,

Zapf, A., Kubein-Meesenburg, D. & Sadat-Khonsari,

R. 2009. Influence of thermoplastic appliance

thickness on the magnitude of force delivered to a

maxillary central incisor during tipping. American

Journal of Orthodontics and Dentofacial Orthopedics,

136.

Kazhdan, M., Bolitho, M. & Hoppe, H. 2006. Poisson

surface reconstruction. Proceedings of the fourth

Eurographics symposium on Geometry processing.

Cagliari, Sardinia, Italy: Eurographics Association.

Kravitz, N. D., Kusnoto, B., BeGole, E., Obrez, A. &

Agran, B. 2009. How well does Invisalign work? A

prospective clinical study evaluating the efficacy of

tooth movement with Invisalign. American Journal of

Orthodontics and Dentofacial Orthopedics, 135, 27-

35.

Kwon, J. S., Lee, Y. K., Lim, B. S. & Lim, Y. K. 2008.

Force delivery properties of thermoplastic orthodontic

materials. American Journal of Orthodontics and

Dentofacial Orthopedics, 133, 228-234.

Liu, Y., Ru, N., Chen, J., Liu, S. S.-Y. & Peng, W. 2013.

Finite Element Modeling for Orthodontic

Biomechanical Simulation Based on Reverse

Engineering: A Case Study. Research Journal of

Applied Sciences, Engineering and Technology, 6,

3267-3276.

Penedo, N. D., Elias, C. N., Pacheco, M. C. T. & Gouvêa,

J. P. d. 2010. 3D simulation of orthodontic tooth

movement. Dental Press Journal of Orthodontics, 15,

98-108.

Ryokawa, H., Miyazaki, Y., Fujishima, A., Miyazaki, T.

& Maki, K. 2006. The mechanical properties of dental

thermoplastic materials in a simulated intraoral

environment. Orthodontic Waves, 65, 64-72.

Savignano, R., Viecilli, R., Paoli, A., Razionale, A. V. &

Barone, S. 2015. Nonlinear Dependency of Tooth

Movement on Force System Directions. American

Journal of Orthodontics & Dentofacial Orthopedics,

in press.

Viecilli, R. F., Budiman, A. & Burstone, C. J. 2013. Axes

of resistance for tooth movement: Does the center of

resistance exist in 3-dimensional space? American

Journal of Orthodontics and Dentofacial Orthopedics,

143, 163-172.

BIOIMAGING 2016 - 3rd International Conference on Bioimaging

52