The Intelligent Water Project: Bringing Understanding to Water Pumps

in Africa

Daniel Scott Weaver

1

, Brian Nejmeh

1

, David Vader

2

and Tony Beers

2

1

Department of Computer and Information Science, Messiah College, Mechanicsburg, PA 17055, U.S.A.

2

The Collaboratory for Strategic Partnerships and Applied Research, Messiah College, Mechanicsburg, PA 17055, U.S.A.

Keywords:

Intelligent Water Project, Monitor, SMS, Texting, Handpump, Hand Pump, Sensor, Remote.

Abstract:

The Intelligent Water Project (IWP), born out of an effort to increase handpump reliability, measures and re-

ports the functionality of handpumps and volume of water extracted on two-hour intervals daily. Additionally,

IWP will measure groundwater levels which can be used to evaluate well yields. Data from handpumps is

automatically collected and transmitted to a remote database. Once in the database, the data is analyzed and

distributed to stakeholders via web and mobile applications and customizable alerts. Besides monitoring water

extraction, handpump performance, and borehole health, the IWP system processes data to alert stakeholders

of failure or degrading conditions (imminent failure). Coupled with appropriate field management processes,

this information can lead to improved handpump availability and lowered cost of ownership. The key goal is to

dramatically increase the reliability of handpumps. A secondary goal is the collection of handpump data from

all IWP enabled pump sources providing a rich resource of data to enabling WASH practitioners, managers,

hydrologist and donors to make more informed decisions.

1 INTRODUCTION

Wells and handpumps in Africa fail at alarming rates

within the first two years of installation ((RWSN),

2009). Much of this failure can be attributed to a lack

of transparency into the performance of handpumps.

Existing manual methods of handpump monitoring

require manual field inspection by personnel which

is costly, untimely and superficial. Furthermore, trav-

eling long distances to reach handpumps results in in-

frequent inspections.

The advent of low cost, reliable sensor technology

coupled with the ubiquitous GSM network has the po-

tential to bring unprecedented levels of transparency

to handpump performance in rural Africa. Our project

has refined a fully automated wireless, sensor-based

mobile and web application suite to provide signif-

icant remote transparency of the overall handpump

performance.

Initial concept development of the Intelligent Wa-

ter Project (IWP) sensor technology and the software

suite began in 2012 with internal funding from the

Messiah College Collaboratory and the Department

of Computer and Information Science (CIS) with sub-

sequent funding from World Vision. This project

is being done by a coordinated group of faculty

members and students across various engineering and

computer science disciplines at Messiah College, a

Christian college based in the United States. The soft-

ware for this project has been developed using the Ag-

ile Scrum method(Nejmeh and Weaver, 2014) in two

service-learning computer science classes (database

applications, senior capstone course in CIS). Given

the Christian-faith tradition of Messiah College, we

often use Biblical references to help motivate our

work. Work on the IWP project has been inspired by

the following passage: “The poor and needy seek wa-

ter, but there is none, their tongues fail for thirst. I, the

Lord, will hear them; I, the God of Israel, will not for-

sake them. I will open rivers in desolate heights, and

fountains in the midst of the valleys; I will make the

wilderness a pool of water, and the dry land springs

of water.” Isaiah 41:17-18 (NKJ)

1.1 Related Work

Broadly speaking, there are two different types of so-

lutions to monitoring handpumps: non-sensor based

approaches and sensor based approaches. Non-sensor

based approaches use mobile apps into which hu-

mans input data for subsequent machine analysis.

This includes generic (non-water specific) mobile

Weaver, D., Nejmeh, B., Vader, D. and Beers, T.

The Intelligent Water Project: Bringing Understanding to Water Pumps in Africa.

In Proceedings of the 2nd International Conference on Geographical Information Systems Theory, Applications and Management (GISTAM 2016), pages 211-218

ISBN: 978-989-758-188-5

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

211

app toolkits such as iFormBuilder

R

(Zerion Soft-

ware, 2015), Open Data Kit (ODK) (OpenDataKit,

2015), FrontLineSMS (FrontlineSMS, 2015), de-

vicemagic (Inc., 2015), and Magpi (Magpi, 2015)

(formerly EpiSurveyor). Water specific mobile apps

include aquaya (Institute, 2015), Mwater.co (mWater,

2015), and Akvo FLOW (Akvo, 2015).

There are a few sensor-based approaches to auto-

mate handpump data collection. Among them are the

Sweetlab project (Thomas, 2013) and the Oxford Uni-

versity Smart Water project (Rob Hope, 2011). The

Oxford project performed a proof of concept study to

determine the feasibility of using low cost accelerom-

eters to estimate handpump extractions. Our work ex-

pands on this work to develop a sophisticated system

that monitors not only handle movement but water

flow and well water level. Our system is differenti-

ated by the following attributes:

• it provides support for automated, sensor-based

handpump data collection over the ubiquitous

GSM network,

• it provides full transparency and access to all of

the underlying sensor data via the website,

• it supports configurable, periodic status alerts on

user defined events of interest,

• it leverages the work of the Messiah College In-

dia MKII and Afridev Sustainability Studies that

gives unique insight and focus to the sensor de-

sign (Anthony Q. Beers, 2013),

• it provides full integration with Google Maps

R

and ESRI (GIS cloud environment) systems,

• it is a cloud-based application suite which runs on

desktops and mobile devices,

• it is being developed by an interdisciplinary team

of hydrologists, mechanical engineers, electrical

engineers and computer scientists.

2 PROBLEM STATEMENT

Approximately 184 million people living in Africa

depend on handpumps for their daily water sup-

ply (MacArthur, 2015) with an estimated 50,000 new

handpumps shipped to Africa each year (Sansom

and Koestler, 2009). Despite efforts to improve ru-

ral water service delivery, handpumps serving ru-

ral communities often fall into disrepair. According

to data compiled by Rural Water Supply Network

(RWSN) ((RWSN), 2009) from 20 African nations

covering 345,071 wells in 2009, 36% of handpumps

are non-operational. This results in a loss of capi-

tal investment in infrastructure and a negative impact

on rural communities. When a community handpump

breaks down, families are forced to find alternative

water sources. Alternative sources may include car-

rying water a greater distance from a handpump in

a neighboring community, or less protected sources

such as hand dug scoops or surface water. The lat-

ter sources carry increased risk of water born disease.

The increased time and energy spent collecting water

and the potential for illness detract from more eco-

nomically empowering activities.

Logistical challenges and costs hamper effective

and efficient handpump monitoring and evaluation

efforts in rural areas. To determine the condition

of a handpump, water authority representatives must

travel to each handpump location and perform a man-

ual inspection. This process can result in lengthy

down-times and high labor and transportation costs

incurred by the community and/or sponsoring NGO

or government organization. As a consequence, hand-

pumps may go weeks without necessary repairs and

Water and Sanitation Hygiene (WASH) managers are

forced to make critical program decisions on incom-

plete data.

Given the critical importance of clean water, it fol-

lows that an accurate, reliable and low-cost tool to

assess handpump performance efficiency and effec-

tiveness would be valuable to many stakeholders. Im-

proved handpump transparency can lead to better visi-

bility and early warning of handpump problems. This

will enable timely handpump remediation, thereby

leading to improvements in overall pump efficiency

and effectiveness in service to rural African commu-

nities.

3 SOLUTION OVERVIEW

The primary goal of IWP is to develop a system to

automatically capture and organize data about hand-

pump functionality and performance from both sen-

sor and human sources. This allows the IWP to alert

stakeholders via web and mobile applications, email,

and text messaging of pump failure or degrading con-

ditions. Coupled with appropriate field response pro-

cesses, the information the system provides can lead

to improved handpump availability with a lower cost

of ownership. A secondary goal is the collection of

handpump data from all IWP enabled pump sources

providing a rich resource of data to enabling WASH

practitioners, managers, hydrologists and donors to

make more informed decisions.

The IWP team decided on the following design

goals and desired outcomes to drive our process:

GISTAM 2016 - 2nd International Conference on Geographical Information Systems Theory, Applications and Management

212

3.1 Design Goals

• Design a solar-powered, GSM-enabled, pump

monitor with a network of sensors to communi-

cate with a cloud-based database application,

• Design a web-based application suite to produce

actionable information about handpumps,

• Design a mobile application that exploits

location-aware and other mobile capabilities for

local field technology workers.

3.2 Desired Outcomes

• Improved visibility of handpump performance

and ease of maintenance and reporting,

• Improved understanding of water extraction for

each handpump (how much and when),

• Improved understanding of well water level fluc-

tuations,

• Single, unified source for storage, access, and

analyses of handpump related data.

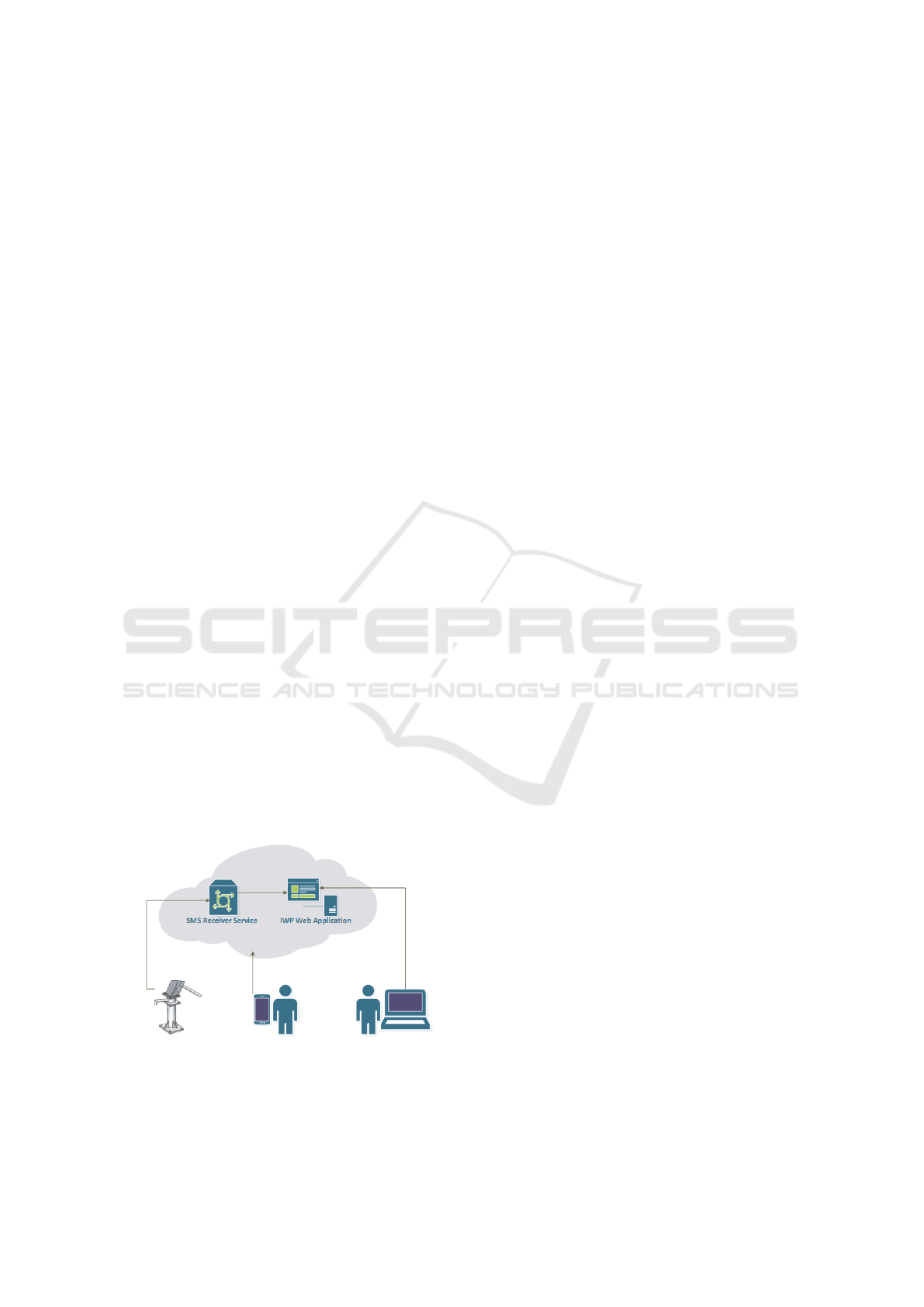

3.3 System Overview

The IWP remotely monitors handpumps, including

the Afridev and India MKII, through the use of an em-

bedded monitor installed in the handpump. The mon-

itor, connected to and collecting data from concur-

rently installed sensors, is equipped with a GSM mo-

dem to communicate with the cloud-based database

application via text messaging through an SMS re-

ceiver service. The cloud-based database application

parses the transmitted data, populates the database

and determines the performance and status of the

handpump (See Figure 1).

Figure 1: The Conceptual Overview of IWP.

Each day the IWP embedded monitor measures

and records the volume of water extracted by the

handpump in two hour intervals, the amount of effort

required to prime the pump, and the largest recorded

leakage rate. This automatically collected data is

transmitted daily to the remote database where the

information is analyzed and made available to stake-

holders via a web or mobile application. In addi-

tion to monitoring water extraction, handpump per-

formance, and borehole health, the IWP system pro-

cesses this data to predict certain degrading condi-

tions before failure occurs and notifies stakeholders

via customizable alerts. For instance, an increas-

ing amount of effort required to prime the handpump

may indicate degradation of handpump parts while

decreasing yield may indicate silting at the screened

interval.

In the event of an immediate handpump failure or

degrading condition, the system automatically gen-

erates email and text message notifications to com-

munity members and area handpump mechanics, mo-

bilizing them to inspect the handpump and make re-

pairs. Certain known failure modes are detected and

reported by IWP, enabling repair teams to carry the

needed parts, supplies, and tools to the site. Commu-

nity members and area handpump mechanics will also

have the ability to report data such as cost of repairs

or other visible handpump problems using the mobile

app. Once a handpump is repaired, sensor data will

verify handpump performance and close the failure

reporting loop.

4 FUNCTIONAL OVERVIEW

The main subsystems of IWP include the monitor

hardware, database, data transport, mobile app, and

web interface.

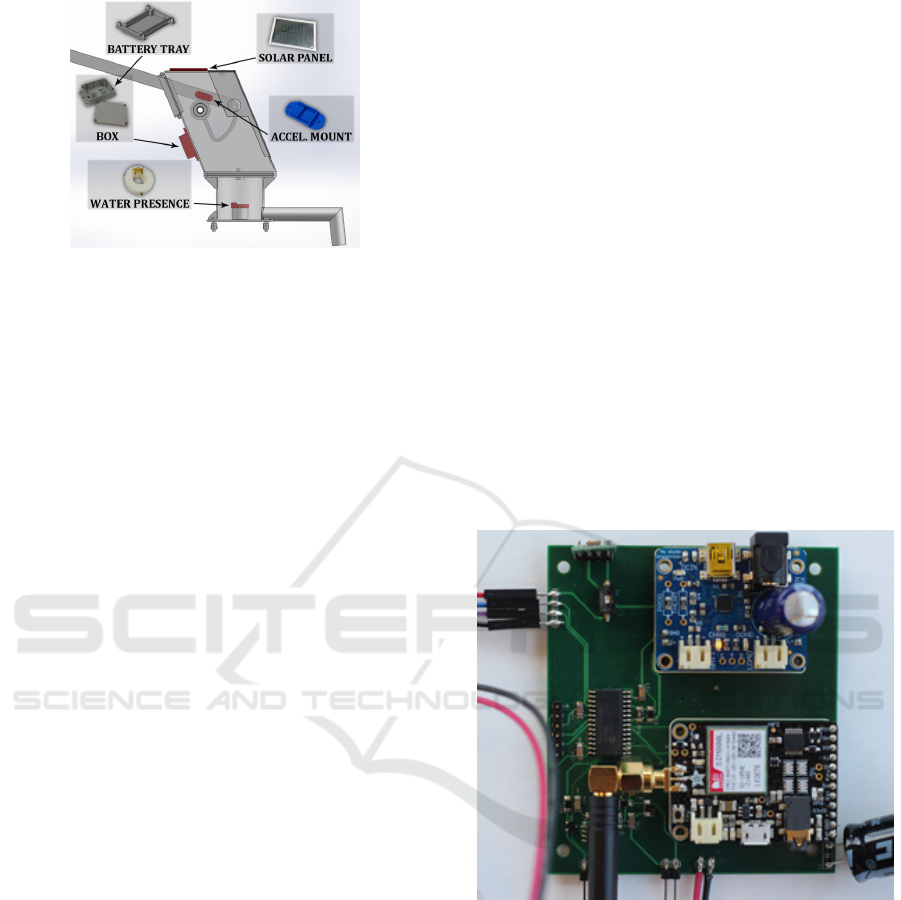

4.1 Monitor Hardware

The IWP system hardware consists of a solar-

powered, GSM cellular-enabled sensor node that

mounts inside of India MKII and Afridev handpumps.

See Figure 2 for the mechanical layout of IWP on

the India MKII platform. The system monitors the

motion of the handpump handle and the presence or

absence of water in the mouth of the rising main to

(a) ascertain the amount of upstroke required to prime

the pump, (b) the amount of water extracted from the

pump and (c) the rate of leakage in the rising mains.

This information is summarized and sent daily to the

IWP database.

Since characteristics of handpumps such as the In-

dia MKII and Afridev include an open channel, a non-

steady flow and low flow rates, standard off-the-shelf

The Intelligent Water Project: Bringing Understanding to Water Pumps in Africa

213

Figure 2: Mechanical Layout of IWP on the India MKII

Handpump.

flow meters were found to be unsuitable for our ap-

plication. Instead, we employ an indirect system of

measurement that takes advantage of the mechanics

of positive displacement pumps. Knowing the amount

of upstroke experienced by the pump rod and the vol-

umetric efficiency of the pump, the amount of water

that would have been extracted from the well under

ideal conditions can be calculated. For the India MKII

handpump this is given by the equation:

Volume = 0.0075∆θ × Volumetric Efficiency (1)

Where volume is in Liters, 0.0075 is a constant

derived from the geometry of the India MKII hand-

pump, θ is the angular displacement of the handle,

and the volumetric efficiency is the ratio of the vol-

ume of water extracted per stroke to the volume of

water swept by the piston (Beyer and Bryan, 1984).

By monitoring the angle of the handle with a low

cost accelerometer and performing a numerical inte-

gration in software, the total upstroke for each phase

of a pumping event can be determined and converted

into the theoretical volume of water extracted.

Real handpumps are more complicated than this

model suggests due to leakage, therefore, a second

sensor is employed. This sensor, located in the throat

of the rising main with probes protruding into the riser

pipe, relies on the difference in resistivity between air

and ground water to sense water flowing in the pump.

It transforms IWP from a system calculating theoret-

ical yields to one producing realistic data regarding

handpump performance and yield.

To compute the actual volume of water extracted,

the priming effort is first assessed by recording the

amount of upstroke measured in meters from the start

of the pumping event until the water presence sensor

detects water. This is stored as another indicator of

overall pump health. The theoretical volume of wa-

ter is then determined using the volume calculation

(See Equation 1) from the time the water was sensed

until the pumping event is complete. At the end of

the pumping event, the monitor starts a timer to de-

termine how long it takes for the water presence sen-

sor to cease detecting water. The time, in conjunc-

tion with the cross sectional area of the riser pipe, is

used to calculate the current leakage rate of the pump.

This leakage rate is then used to deduct the appro-

priate amount of volume from the theoretical yield,

producing a more realistic volume of water extracted.

The monitor records water extracted in two-hour in-

tervals, the maximum priming effort, and the leakage

rate each day.

While the sensor suite described in detail above

is application specific, the rest of the IWP system

is applicable to the needs of any solar powered,

GSM-enabled monitoring application. As a result

it was possible to incorporate several open source

and off-the-shelf solutions to decrease development

time. GSM Cellular communications and solar bat-

tery charging are handled by open source hardware

from Adafruit Industries while system power regula-

tion is managed by a commercial boost/buck regulator

circuit from Pololu Robotics (See Figure 3).

Figure 3: Current Working Prototype Monitor.

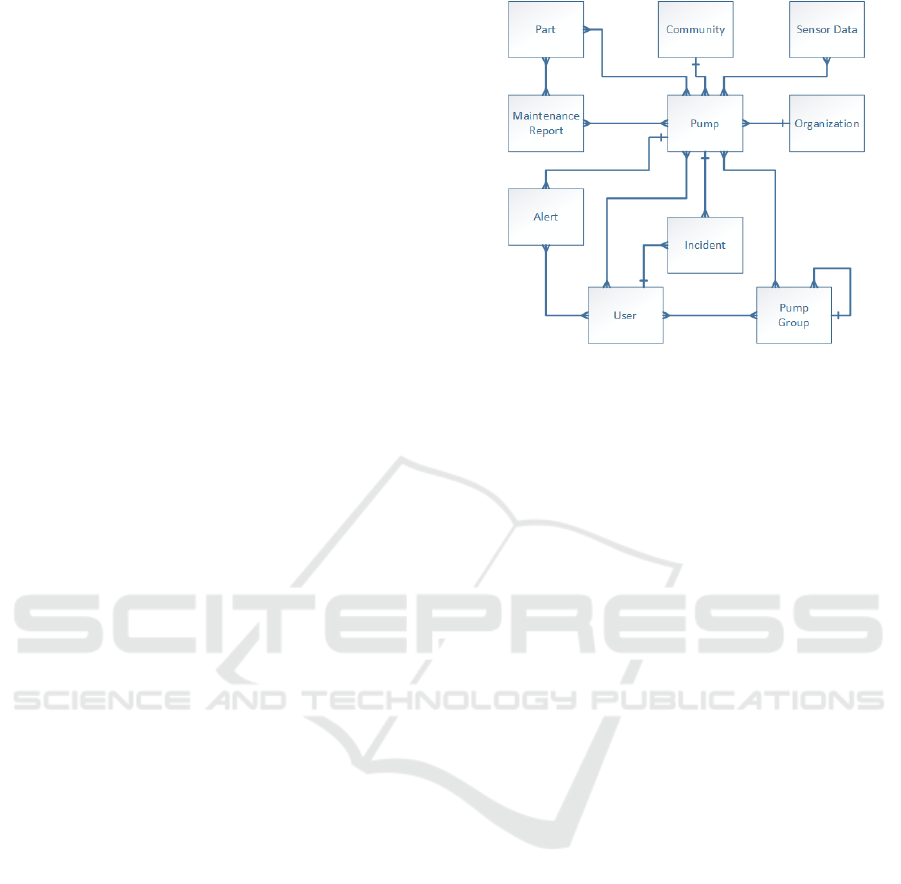

4.2 Database and Analytics

The IWP data is housed in a secure, cloud-based

database. The main components of the database are

depicted in Figure 4.

When an organization installs an IWP Monitor

in a handpump within a community, the information

necessary to track that handpump is stored in Orga-

nization, Pump, Community, and Part. The system

administrator is then able to link that handpump to

authorized Users who then have the ability to view

information about that pump anywhere in the world.

As soon as the Monitor is installed and operational, it

GISTAM 2016 - 2nd International Conference on Geographical Information Systems Theory, Applications and Management

214

begins its collection and transmission of sensor data

to be stored in Sensor Data (the process of collection

and transport is discussed later).

The insertion of sensor data into the database trig-

gers a process that calculates health indicators, such

as leakage rate and, based on configurable parame-

ters, determines the current status of the handpump.

If the status of the pump changes, the system creates

an Incident report (SIR), which in turn generates an

Alert. The user, having the capability to indicate how

he/she would like to be notified, will receive the alert

on login to the web or mobile application, email, or

via text message.

Any authorized user may also create an Incident

report based on their observation of the handpump.

These human-generated incident reports (HIRs) are

included in the calculation of the pump status. Alerts

are generated based on the worse of the two types of

incident reports (HIRs or SIRs).

IWP provides a mechanism for grouping hand-

pumps together using Pump Groups. Pump groups

allow for aggregate analysis, reporting, and search-

ing across pumps in that group. Pumps can belong

to more than one group. A pump group has a unique

name and a brief description and allows pumps to be

grouped by location, field technician, type of pump,

or any user-define grouping. There are groups that

are automatically formed by IWP based on defined

attribute-pair configuration parameters. For example,

the system may be instructed to create a group con-

taining all handpumps within an x-kilometer radius

on a given GPS location, or those assigned to a given

field technician, or within a certain geographic bound-

ary such as a country. The system also allows users to

define their own pump groups, or to add groups within

groups.

When handpump technicians perform mainte-

nance on a handpump, they complete a Maintenance

Report, identifying their incurred travel, part, and la-

bor costs.

4.3 Data Transport

The Sensor data collected by the monitor is stored on

both an SD Card, installed in the monitor, and resident

memory. Every twenty-four hours the monitor pack-

ages the collected data as a JSON formatted string

and creates an SMS message. The system transmits

the SMS message over a GSM (voice grade) wireless

network to an SMS Receiver Service. It is commonly

known and field studies in Africa have shown (Ne-

jmeh and Dean, 2010) that voice grade GSM network

service is much more widely available than 3G net-

work service. Given the desire to field IWP in remote

Figure 4: Database Conceptual Model.

areas of Africa, the decision was made to only assume

a voice-grade GSM network in our design.

The SMS Receiver Service forwards the message

to the parser module in the cloud-resident database

application. The parser module posts the raw message

in the database, parses the message and (if error-free)

stores the parsed sensor data in the database.

These SMS messages are equipped with unique

sequence identifiers (USI). Once a message has been

successfully processed and added to the database, an

ACK message is sent to the monitor. Once received,

the monitor will remove the message from its queue

based on the USI.

If a message is missing data or the data does not

conform to the defined data format, an ERR message

is sent to the monitor. The monitor will then attempt

to re-transmit the message.

When a duplicate message is encountered, a DUP

message is sent to the monitor. In response, the mon-

itor deletes the message from the queue.

The insertion of the data into the database trig-

gers a process that determines the current status of the

handpump based on the current sensor data and stores

the status in the database. A handpump will have

the status of Green (running fine), Yellow (concerns

exist about the handpump), Orange (significant prob-

lems exist with the handpump), Red (pump failure),

or Grey (handpump has not been heard from). This

status will be displayed on an authorized user’s dash-

board and the handpump location depicted on Google

Maps

R

. If the status of the handpump changes, the

alert system notifies the appropriate authorized users

of the change. Handpump status is a configurable

function defined for a given set of handpumps based

on the values of daily volume extraction, leakage rate

and maximum well level.

The Intelligent Water Project: Bringing Understanding to Water Pumps in Africa

215

4.4 Mobile App

A mobile app is an important element of the overall

IWP system. It serves as a lightweight tool for work-

ers to use while in the field, thereby enabling them

to take advantage of mobile services such as location

awareness and offline modes.

Figure 5: IWP Mobile App.

User Authentication: Mobile app users login to

the mobile app using the same user name and pass-

word credenials of the web application. The mobile

app authenticates users using the same web backend

system that authenticates web users. Furthermore,

the mobile app limits user access to handpump data

and functionality identical to the security and access

model imposed by the web application.

Mobile App Interface: Figure 5 displays the

main screen of the mobile app. The core IWP mo-

bile app functions are handpump initialization, filing

maintenance reports, filing incident reports and view-

ing handpump alerts.

Handpump Initialization: This function allows

a user to initialize a handpump into the IWP system.

The function records the field technican assigned to

the handpump, the GPS coordinates of the handpump

(either automatically recorded (default) or inputted by

the user), the phone number on the SIM card installed

in the handpump monitor, the date/time of the ini-

tialization and other descriptive information about the

handpump.

Maintenance Reports: This function allows a

user to create and submit handpump maintenance re-

ports (as previously described), including the iden-

tity of the handpump, the user filing the maintenance

report, date and time of the maintenance report, a

brief description of the maintenance performed on the

handpump and the total cost of the maintenance re-

port broken down by travel costs, part costs and labor

costs.

Incident Reports: This function allows a user to

create and submit handpump incident reports (as pre-

viously described), including the identity of the hand-

pump, the user filing the incident report, date and time

of the incident report, a brief description of the inci-

dent being reported on the handpump and the nature

of the incident.

Alerts: This function allows a user to view the

alerts (as previously described) associated with the

handpumps for which the user has been granted ac-

cess.

Offline and Synchronization Modes: The mo-

bile app requires a data grade connection to transmit

data, and since there will be times when such a con-

nection is not available, an offline and synchroniza-

tion mode is necessary. In such cases, the mobile app

will locally persist the data (i.e. yet to be filed main-

tenance reports and incident reports) on the mobile

device. Upon the mobile app sensing a data grade

connection, the persisted data will be transmitted to

the IWP system.

4.5 Web Interface

The data from the monitor is collected and stored au-

tomatically in the database which can be accessed by

authorized users via a secure web application or mo-

bile app. The status of individual handpumps can

be viewed on a map interface powered by Google

Maps

R

. Each handpump on the map is represented

by the pump status indicator (green, yellow, orange,

red, or grey) depending on the level of functionality

of the handpump.

The reporting module allows users to select a

time period, single or multiple handpumps, or pump

groups for further investigation, and provides either

detailed or aggregated information. Selection can be

accomplished via the map interface by selecting in-

dividual handpumps or pump groups. The IWP web

application can export these queries as printable PDF

reports or MS Excel Spreadsheets for further investi-

gation or reporting purposes.

Notifications are handled automatically by the

IWP software in the event of a change in a handpump

status indicator. These are sent to appropriate stake-

holders via email or text message depending on their

preferences. The notifications are sent in the case of

degradation, such as a status change from green to

yellow or red, and in the case of an improvement, such

as a status change from red to yellow or green. This

allows stakeholders to know not only when a pump is

broken, but also when and to what extent it has been

repaired.

GISTAM 2016 - 2nd International Conference on Geographical Information Systems Theory, Applications and Management

216

5 RESULTS TO DATE

Throughout the development of the IWP hardware,

intimate knowledge of the inner working of hand-

pumps and their failure modes and frequent field de-

ployment of prototypes have been crucial to the de-

sign of a functional system. The IWP project was

born out of a prior project (Anthony Q. Beers, 2013)

that identified the most common failures in India

MKII handpumps in West Africa which resulted in

a redesign of several failure prone components. This

initial study provided the mechanical understanding

necessary to develop a sensor suite tailored to mon-

itoring positive displacement handpumps. IWP also

benefited from the availability of complete blueprints

and 3D models of both the India MKII and Afridev

handpumps and full knowledge that the handpumps in

the field are rarely within the tolerances in the speci-

fication drawings.

The prototype IWP system has been through four

design iterations, including laboratory testing in the

US and field testing in northern Ghana. The field tri-

als occurred throughout 2014 and 2015. In our early

trials, we discovered that several key dimensions on

the MKII often fell well outside MKII design spec-

ifications. The IWP geometry and installation pro-

cedures were modified to facilitate installation in ac-

tual field conditions. Our early field trials also re-

vealed that noise effected the accelerometer data so

that deviation between actual and measured water ex-

tracted was unacceptable. Our most recent field trial

completed in October 2015. This iteration incorpo-

rates more robust sensor housings, a theft resistant

solar installation design, a software filtering solution

for noise in the accelerometer data, and a few minor

changes to the printed circuit board design. The water

presence sensor was moved out of the throat of the ris-

ing main to avoid any proximity with the handpump

rod. This sensor is now in a T fitting attached to the

top of the rising main. A ten-point moving average

algorithm has also proven an effective low pass filter

for accelerometer noise. Testing to date indicates wa-

ter extraction measurements are within ten percent of

actual.

The IWP software is managed in a Cloud envi-

ronment at the domain www.intelligentwater.net. Ini-

tially, the data transport software layer had been ex-

tensively tested in a simulated environment with rep-

resentative sensor test data imported from a spread-

sheet. Initial smartphone tests in Africa demonstrated

successfully sent test messages through an SMS Re-

ceiver Service. The web application has been devel-

oped and tested using representative sensor test data

and is functioning properly. Finally, the mobile app

is running on the Android Operating System and in-

cludes support for handpump initialization and sub-

mission of maintenance reports. The mobile app has

been used in Africa to successfully initialize a hand-

pump. The October 2015 field trial has demonstrated

that the monitor successfully communicates with the

server, sending sensor data in JSON format. In turn,

the sensor data has been successfully parsed and pop-

ulated the database appropriately. Through a series of

three successive field trials in Africa over an 18 month

period ending October 2015, we have learned a great

deal. The IWP has accomplished significant progress

toward demonstrating proof of concept. The design of

the sensors, solar panel, charging circuit, and printed

circuit card are stable, as is their integration with the

microprocessor and cell phone modules selected for

IWP.

6 FUTURE WORK

Significant opportunities exist for advancing our

work. Sensor data collected over time will validate as-

sumptions and features such as alerts, change in hand-

pump status, etc. Ideally, we would like to see the

system deployed through the status cycle of a hand-

pump to insure that the system correctly senses the

deterioration of the handpump, issues the appropriate

alerts and senses the handpump performance improv-

ing upon being repaired by a field technician.

The IWP software will evolve based on lessons

learned from field trials. It is expected that significant

advances will be made in handpump data analytics

based on feedback from handpump field technicians.

There are a number of future directions envisioned for

the mobile app, including:

• improved support for offline functionality and

auto-synchronization upon network access,

• Geo-location tracking for locating and navigating

to handpumps,

• multi-language support for French, Spanish and

other languages,

• 3G wireless network data transport support for the

embedded monitor unit mounted within a hand-

pump.

In addition, processes and training need to be de-

veloped for local African technicians to utilize the

web/mobile app as they fix handpumps. Feedback

from theses sources will be used to enhance both the

web and mobile applications.

The Intelligent Water Project: Bringing Understanding to Water Pumps in Africa

217

ACKNOWLEDGMENTS

We acknowledge various Computer Science and Col-

laboratory students for their work on this project.

Special thanks to the extensive work of Avery de-

Gruchy, Christopher Neuman, Jacqui Young, Ken

Kok, and Makenzie Alexander.

REFERENCES

Akvo (2015). akvoflow smartphone-based field surveys.

Anthony Q. Beers, Dr. David T. Vader, D. T. V. D. D. T.

B. W. (2013). India mkii pump sustainability study

report. Technical report, Messiah College.

Beyer, M. G. and Bryan, K. (1984). Unicef and the ex-

perience in low-cost water supply and sanitation. In

World Bank Technical paper, number 48, pages 195–

215. World Bank.

FrontlineSMS (2015). Frontline sms cloud.

Inc., D. M. (2015). Collect data offline with mobile forms

and surveys.

Institute, T. A. (2015). Improving health through clean wa-

ter innovation.

MacArthur, J. (2015). Handpump standardisation in sub-

saharan africa.

Magpi (2015). Advanced mobile data collection anywhere,

on any device.

mWater (2015). Technology for water and health.

Nejmeh, B. and Weaver, D. S. (2014). Leveraging scrum

principles in collaborative, inter-disciplinary service-

learning project courses. In Frontiers in Education

Conference (FIE), 2014 IEEE, pages 1–6. IEEE.

Nejmeh, B. A. and Dean, T. (2010). The charms applica-

tion suite: A community-based mobile data collection

and alerting environment for hiv/aids orphan and vul-

nerable children in zambia. International Journal of

Computing and ICT Research, page 46.

OpenDataKit (2015). Opendatakit magnifying human re-

sources through technology.

Rob Hope, Michael Rouse, A. M. T. F. (2011). Smart water

system. Technical report, Oxford University.

(RWSN), R. W. S. N. (2009). Handpump data 2009.

Sansom, K. and Koestler, L. (2009). African handpump

market mapping study.

Thomas, D. E. A. (2013). (im)proving global impact: How

the integration of remotely reporting sensors in wa-

ter projects may demonstrate and enhance positive

change. Global Water Forum.

Zerion Software, I. (2015). iformbuilder mobile platform.

GISTAM 2016 - 2nd International Conference on Geographical Information Systems Theory, Applications and Management

218