Risk Driven Analysis of Maintenance for a Large-scale Drainage System

Yujie Chen

1

, Fiona Polack

1

, Peter Cowling

1

, Philip Mourdjis

1

and Stephen Remde

2

1

YCCSA, Computer Science Department, University of York, York, U.K.

2

Gaist Solutions Limited, Lancaster, U.K.

Keywords:

Simulation, Maintenance, Risk Management.

Abstract:

Gully pots or storm drains are located at the side of roads to provide drainage for surface water. We consider

gully pot maintenance as a risk-driven maintenance problem. Our simulation considers the risk impact of

gully pot failure and its failure behaviour. In this paper, we focus on two factors, the issue of parked cars

and up-to-date gully pots status information, that may affect the scheduling of maintenance actions. The aim

is to discover potential investment directions and management policies that will improve the efficiency of

maintenance. We find that the “untimely system status information” is a dominant factor that weakens the

current maintenance. Low-cost sensor technique could be a good development.

1 INTRODUCTION

Gully pots are designed to prevent solids and sedi-

ment from flushing into sewers and causing block-

ages in the underground system (Butler et al. (1995)).

Regular cleaning is required for gully pots to func-

tion effectively (Karlsson and Viklander (2008); Scott

(2012)). Usually, gully pots in a city are cleaned

once or twice a year. Partial or complete blockages of

the gully pots increases the likelihood of surface wa-

ter flooding. In extreme situations such as intensive

rainfall, a clogged drainage system may cause serious

property loss (i.e. BBC (2011, 2012); Shieldsgazette

(2012); Leylandguardian (2015)).

Our gully pot maintenance problem is based on

Blackpool, UK. Blackpool’s gully pot maintenance

system records 28,149 gullies in an area of about 36.1

km

2

. On any day, the maintenance team either car-

ries out the normal cleaning action, categorised as

the preventative maintenance, or responds to emerg-

ing events such as gully broken and blockage reports

(i.e. the corrective maintenance). Depending on the

local risk, these emerging events should be scheduled

5 to 20 days from when they are recorded. For broken

gully pots, a different vehicle equipped with a spe-

cialist machine is required. Due to limited human re-

source, only one vehicle works each day.

Each day there is a schedule of gully pots to visit,

starting and ending at the depot. The maintenance ve-

hicle departs the depot at 09:00 and returns no later

than 17:00. During servicing, some gully pots are in-

accessible due to parked vehicles. Historical mainte-

nance records show that this is a striking issue: about

8.3% of gully pots are not serviced each year because

of parked cars.

Apart from the parking issue, we also notice an-

other weakness of current maintenance scheduling

strategy – untimely system status information. Cur-

rently, all the broken or blocked gully pots are either

reported by local residents or found through preventa-

tive maintenance. Historically, the records show that

reporting of gully pot issues by local residents is high-

est in autumn, when leaf-fall and higher rain causes

many blockages; and lowest in winter, when short

daylight and cold weather reduce footfall. This pas-

sive situation potentially leads to uncontrolled surface

water flooding.

In order to discover techniques or policy that could

improve current gully pot maintenance, this paper

considers the gully pot maintenance as a risk-driven

problem. In our analysis, we take account of each

gully pot’s failure behaviour and the risk impact of

its failure, which varies across the city. The current

widely used maintenance strategy, including both pre-

ventative and corrective actions, is evaluated by our

risk model across various scenarios.

The remainder of this paper is organized as fol-

lows. Section 2 reviews maintenance techniques and

concept. We then introduce our simulation in Sec-

tion 3. Section 4 shows our results and conclusions.

A summary of investment suggestions based on our

simulation is provided in Section 5.

296

Chen, Y., Polack, F., Cowling, P., Mourdjis, P. and Remde, S.

Risk Driven Analysis of Maintenance for a Large-scale Drainage System.

DOI: 10.5220/0005749102960303

In Proceedings of 5th the International Conference on Operations Research and Enterprise Systems (ICORES 2016), pages 296-303

ISBN: 978-989-758-171-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 RELATED WORKS

Maintenance is generally categorised into corrective

and preventative maintenance (Duffuaa et al. (2001);

Ahmad and Kamaruddin (2012)). Corrective mainte-

nance (CM) usually happens after failures occur. It

includes actions such as repair and replacement. Pre-

ventative maintenance (PM) is an alternative strategy.

In industry, preventative maintenance typically takes

place at regular time interval, based on experience.

Operational research on PM introduces decision

making, based on data analysis, with techniques such

as time-based (TBM) (e.g. Scarf and Cavalcante

(2010); Wu et al. (2010)) and condition-based main-

tenance (CBM) (e.g. Carnero Moya (2004); Cam-

pos (2009)). TBM can be applied when the failure

rate is predictable, whilst CBM is employed where

conditions are continuously monitored by sensors or

any appropriate indicators. A similar approach, track-

ing real-time operation information, is also applied

in dynamic scheduling (e.g. Cowling and Johansson

(2002)). There is a little research combining PM and

CM strategies: Kenne and Nkeungoue (2008) intro-

duce a PM/CM rate control strategy, obtaining a near-

optimal maintenance policy for a manufacturing sys-

tem.

For TBM, the accurate prediction of the current

and future condition of a system is crucial for de-

veloping appropriate maintenance schedules. Dam-

age, deterioration and degradation are important no-

tions in asset life cycle management. Literature shows

that related research has been done in bridge, pave-

ment and water pipe systems (Madanat and Ibrahim

(1995); Morcous et al. (2002); Baik et al. (2006)).

Two techniques are normally applied: first, functional

based models like exponential (Shamir and Howard

(1978)) and time-powered models (Kleiner and Ra-

jani (2001)) have been used to determine the opti-

mal timing of water pipe inspection and replacement;

time-dependent Poisson (Constantine et al. (1996))

and the accelerated Weibull hazard models (Le Gat

and Eisenbeis (2000)) are also widely used. Sec-

ond, Markov chain-based deterioration models have

been well studied and applied in a number of real-

world applications (e.g. Madanat and Ibrahim (1995);

Morcous et al. (2002); Baik et al. (2006)). Differ-

ent from the functional based models, Markov chain-

based models focus on the transition probabilities be-

tween different grades, which also implies our condi-

tions are evaluated discretely. The advantage of dis-

crete methods is that clear management policies can

be addressed based on the corresponding states.

This problem is also related to the periodic vehicle

routing problem (PVRP) (Christofides and Beasley

(1984)), which is widely used in geographically dis-

tributed maintenance and on-site service applications

(e.g. Shih and Chang (2001); Gaur and Fisher (2004);

Claassen and Hendriks (2007); An et al. (2012)). Dif-

ferent from research in the above maintenance con-

cept, PVRP is based on the assumption that the opti-

mal maintenance frequency and pattern for each ob-

ject is known. The aim is to produce efficient schedule

and daily routes that satisfy maintenance frequency

and pattern constraints in a given period.

3 SIMULATION

3.1 Model for Schedule Strategy in the

Real World

Due to the large-scale of the problems and gully pot

condition changing over time, the schedule plan is

normally provided for the near future (e.g. one week

or one month). Therefore, during the planning period,

not all gully pots can be serviced.

In order to discover any methodology or policy

that could improve the current gully pot maintenance,

we would like to simulate the actual scheduling strat-

egy that is widely applied across local authorities. We

summarise the procedure as follows.

1. Construct efficient preventative maintenance

routes. In our model, This sub-problem is

considered as a vehicle routing problem (VRP).

The objective is building daily cleaning routes

that minimize the total travelling distance, with

constraints including: 1) all gully pots in the

system should be visited at least once; 2) all

routes should start and end at the depot; 3) no

route travelling time should exceed the working

hours constraint. A variable neighbourhood

search (Hansen et al. (2010)) is applied. A similar

solver is also described by Chen et al. (2014).

2. Collect recent information on emerging bro-

ken/blocked gully pots.

3. Generate schedule for the near future (e.g. one

week or one month plan). Priority is given to

broken and blockage reports. When all the re-

ported problematic gully pots are serviced, the

crew comes back to preventative maintenance. To

schedule the preventative actions, we give priority

to the routes with the highest risk estimates (de-

scribed in the following section, function 1) that

have not been scheduled in the last year.

Risk Driven Analysis of Maintenance for a Large-scale Drainage System

297

3.2 Evaluation

In order to evaluate the performance of a mainte-

nance schedule, we propose a risk-driven model.

Each day, the risk of surface water flooding due to

blocked/broken gully pots is evaluated by function 1:

N

∑

i=1

r

i

P

i

(d) (1)

Where N is the total number of gully pots in the

drainage system, r

i

is the risk impact of gully pot i

estimated by its surrounding environment, and P

i

(d)

is the probability that gully pot i is failed on day d.

3.2.1 The Risk Impact Per Gully Pot (r

i

)

A hazard (i.e. surface water flooding) could poten-

tially be exacerbated by social-related factors, which

are usually influenced by economic, demographic and

building types (Cutter et al. (2003)). A higher risk

impact here implies that if a particular gully pot is

blocked and floods happen, it results in relatively

larger economic and social losses. Co-operating with

Blackpool local council, we firstly decide a list of so-

cial concerns with awareness of their economic and

population influence. Then, each gully pot is evalu-

ated by its location and the related social concerns.

Here, social concerns are classified in to three

groups: 1) residential property; 2) commercial and

industrial areas including local and district centres,

business zones, and employment sites; 3) public ser-

vices including schools, hospitals, doctors and public

transport routes. In table 1, the estimated value of the

item in group 1 is the average residential house price

in Blackpool (UK GOV (2015)). Group 2 takes ac-

count of the footfall and critical building prices for

each item. The estimated value of items in group 3 is

based on average daily operation costs.

Flooding impact analysis involves large uncertain-

ties. We do not expect a precise assessment of im-

pact. Instead, we aim to find values that are able to

guide gully pot maintenance actions in decision mak-

ing. Here, we mainly focus on direct economic losses

using a damage function which relates to property

type and water level. Thieken et al. (2008) propose

the impact from a range of flood water levels on dif-

ferent building types. After consulting the UK Envi-

ronment Agency and Blackpool Council, we decide to

focus on the impact of flood water levels of less than

21 cm. This gives the value-loss figures shown in ta-

ble 1. For public transport we focus on bus routes,

estimating the cost of road section closure due to sur-

face water flooding.

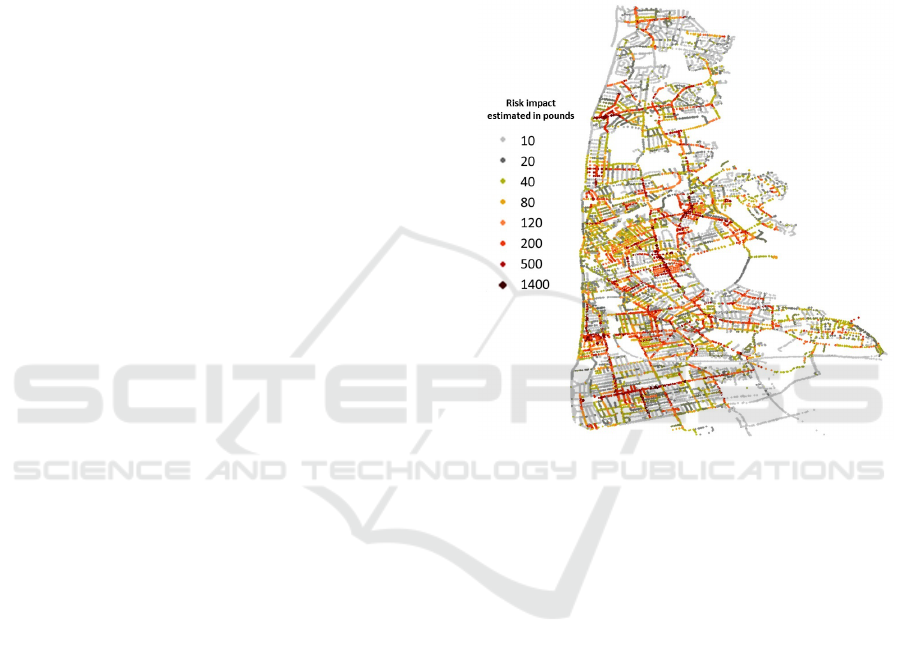

By analysing Blackpool’s historic flooding fre-

quency (Blackpool (2009)), the probability of flood-

ing events is used to map the flooding value loss to the

daily risk impact per gully pot according to its loca-

tion (last column of Table 1). We assume that gullies

in the same section of a street evenly share the respon-

sibility for the risk impact evaluated in that area. Fig-

ure 1 illustrates the geographic distribution of gully

pot risk impact in Blackpool.

Figure 1: Gully pot risk impact in Blackpool.

3.2.2 Estimating the Process of a Gully Pot

Blocking

Ahmad and Kamaruddin (2012) suggest that time-

based maintenance is the normal strategy in situations

where equipment has a fixed lifespan or predictable

failure behaviour. After analysis of historic gully pot

records, we model the gully pot blocking process us-

ing the Weibull distribution model (Weibull (1951);

Ebeling (2004)), from reliability theory. The parame-

ters of this form of Weibull distribution are the scale

parameter λ, and the shape parameter k. In our study,

all values applied are based on our statistical analysis

of the Blackpool data. We first define k = 6, which

captures a realistically increasing blocking rate over

time. The scale parameter λ, capturing lifetime be-

haviour, is affected by location and seasonal factors,

according to a simple linear function:

λ =

10 ... if gully pot recorded as broken

E

calling

... a calling event

max(90, E −

∑

f ∈F

n

f

∗ s

f

) ... normal state

E

calling

represents the expected number of days

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

298

Table 1: Social factor evaluation.

Group Social Concerns

Estimated

value

Value loss

from flooding

Risk

impact

1 Residential £113,000 3% £34

2

Local center £1,130,000 5% £580

District center £1,695,000 5% £870

Business area £565,000 5% £290

Employment sites £226,000 5% £116

3

School £5,168 4% £71

Large hospital £917,808 4% £377

Doctors £9,178 4% £73

Bus route £220 100% £37

from a report on a gully pot to its servicing. E is the

expected number of days that it would take a normal

gully pot to become blocked since its last services.

Here, E = 10.3 years. F is a set of factors that may

affect gully pot lifetime, such as street type, number

of trees nearby, and blown sand effect: n

f

represents

the effect level from a specific factor f ∈ F to a gully

pot; s

f

adjusts the effect from factor f according to

seasonal information. For example, if a gully pot is on

a street with five deciduous trees nearby, then n

f

= 5

with s

f

= 93, 1, 389, 433 in spring, summer, autumn

and winter respectively. If a gully pot location is not

affected by factor f , we simply assign n

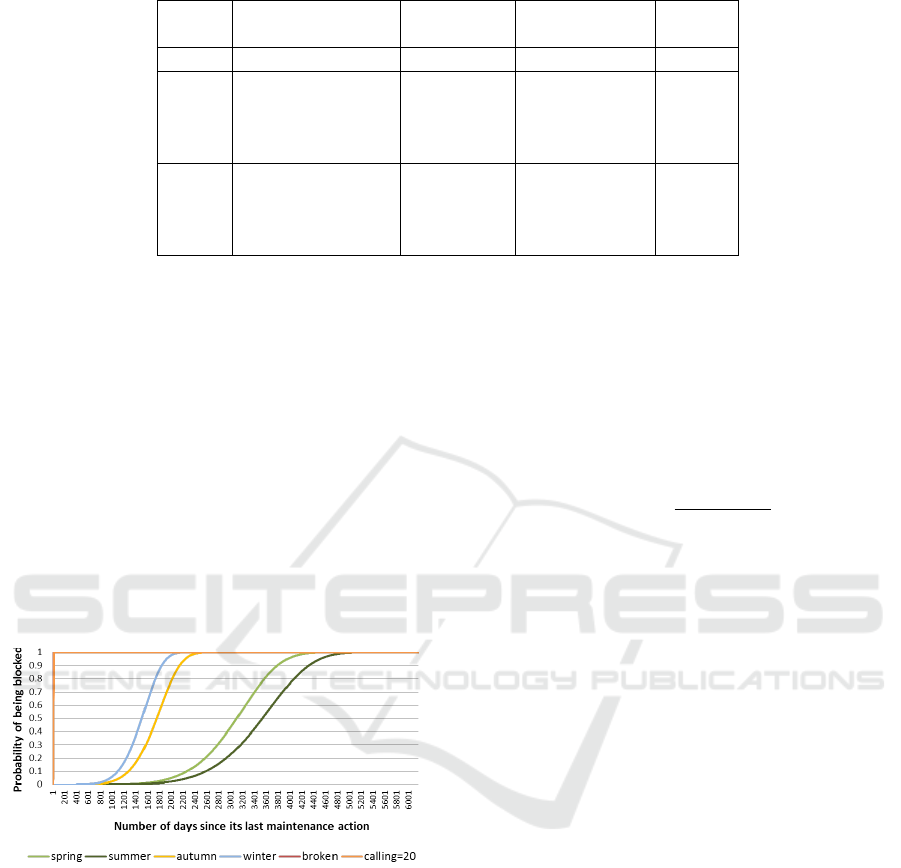

f

= 0. Fig. 2

illustrates one example of a gully pot lifetime estima-

tion taking account of the surrounding environment.

Figure 2: Probability of being blocked since last mainte-

nance action (Example of a gully pot lifetime with 5 tree

nearby at different seasons).

4 EXPERIMENT

In this section, we firstly summarise the background

of our problem and simulation. All simulations

were implemented in C# and executed on a cluster

composed of 8 Windows computers, each with 8

cores, Intel Xeon E3-1230 CPU and 16GB RAM.

Simulation Settings

1. Total number of gully pots in the system: 28,149.

2. Broken events: Blackpool council estimates about

1.1% of gully pots are broken every year. This is

represented by each gully pot becoming broken

randomly with probability 0.00003 per day in our

simulation.

3. Blocking probability: a gully pot lifetime is esti-

mated by a Weibull distribution described in Sec-

tion 3.2.2. Every day, each gully pot has a proba-

bility of becoming blocked according to its failure

rate function h

i

(d) =

R

i

(d−1)−R

i

(d)

R

i

(d−1)

, where R

i

(d) =

1 − F

i

(d) is the reliability function.

4. Seasonal factors F: the Blackpool data only al-

lows us to include trees and leaf-fall in our sim-

ulation. Seasonal factors related to the number

of trees nearby highly affect the lifetime of gully

pots, and on average, each gully pot is affected by

0.4 trees in Blackpool.

5. Resident calling behaviour: about 1700 calls

are received every year by the Blackpool gully

maintenance team, and most of the calls con-

cern blocked or damaged gully pots. Over

50% of all calls occur during the autumn, as

shown in Figure 3. Our statistical analysis de-

termined that, to match the resident calling be-

haviour in our simulation, on any given day,

the probability of receiving a call if a gully

pot is already broken or blocked is p

calls

(i) =

{0.0033, 0.005, 0.0056, 0.002} for spring through

winter, respectively. If a gully pot is not broken,

there is still a small chance that a call is received,

related to its current condition. The simulation

probability is p

calls

(i) = P

i

(d)∗γ, where γ = 10.62

has been measured experimentally to adjust the

calling probability to match the real data.

Simulation Assumption

1. Planning horizon: In the real world, maintenance

schedules are generated at varying levels of gran-

ularity, from long term (yearly) to short term

(weekly). Here, we only consider the procedure

Risk Driven Analysis of Maintenance for a Large-scale Drainage System

299

described in Section 3.1, where the maintenance

schedule is updated every week according to the

most recent system status reports.

2. Parking issues: inaccessibility during mainte-

nance due to parking usually appears in preventa-

tive maintenance. For corrective actions, includ-

ing servicing for both resident reports and broken

gully pots, we assume the team always has access

in our simulation.

3. Others: as well as broken gullies reported by res-

idents, damage is also found during preventative

maintenance. In this case, the simulation registers

the broken gully and schedules it on a later day.

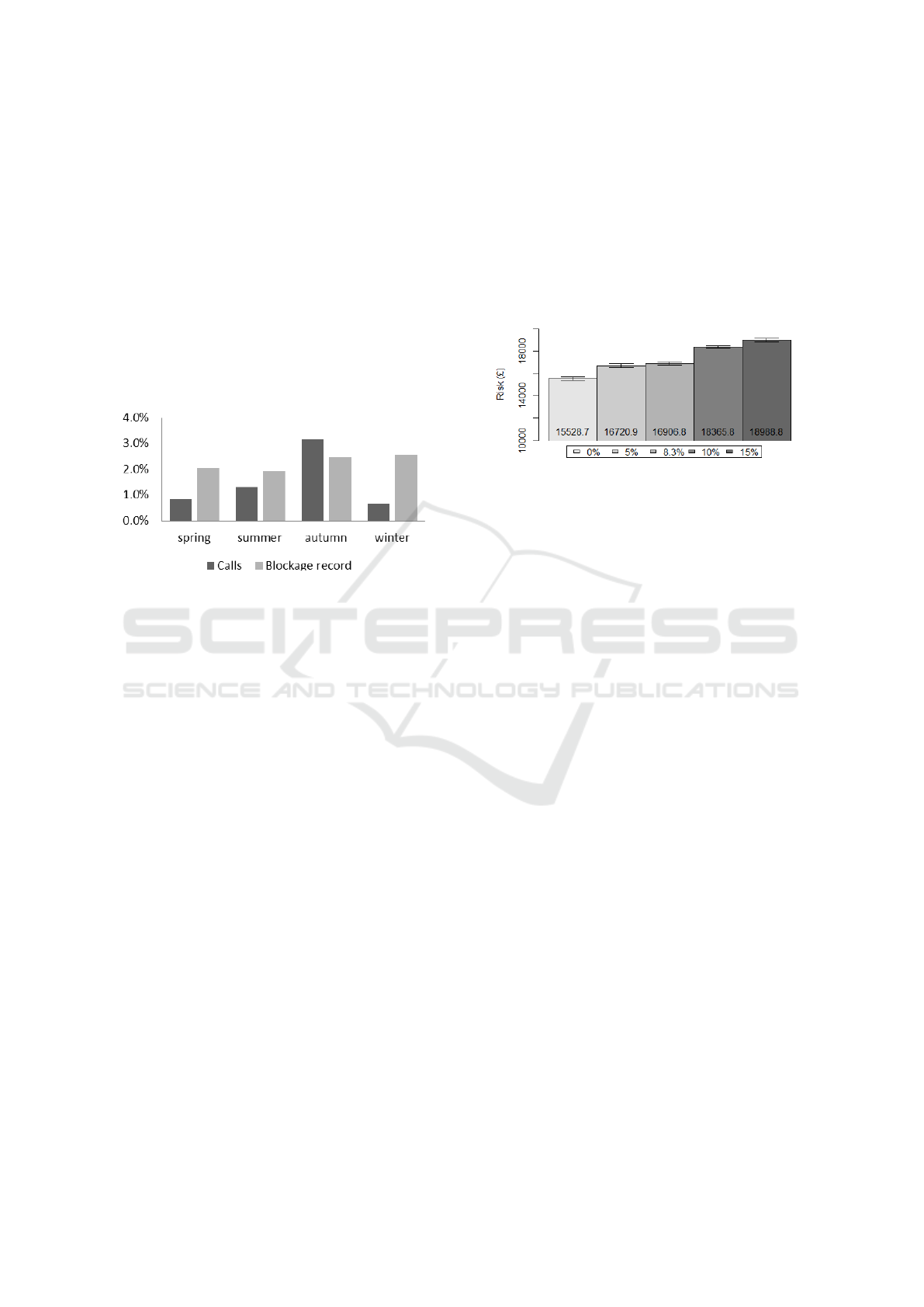

Figure 3: Seasonal calls and blockages as a percentage of

the total number of gully pots in Blackpool.

These parameters and assumption have been dis-

cussed with Gaist Solutions Ltd. and agreed to be

a realistic representation of gully-pot behaviour in

Blackpool.

4.1 The Impact of Parking Issues

According to the maintenance records, the parking

issue has been identified as a major problem that

decreases the maintenance working efficiency, espe-

cially in the old town, where no extra space was de-

signed for parked cars. The number of parked private

vehicle also increases significantly. Our simulation

helps us to understand the impact of parking on gully-

pot maintenance performance. Therefore, potential

strategies can be proposed such as banning parking

when a maintenance visit for a certain street is sched-

uled.

In simulation, we can test the effect of inaccessi-

ble gully pots using a parameter, x, to represent the

percentage of gully pots that cannot be accessed dur-

ing preventative maintenance each year. The values

of x are 0, 5, 8.3 (the actual value), 10 and 15 per-

cent. Each parameter setting is run over 4 simulated

years, with corresponding seasonal factors and resi-

dential report behaviours.

The results of simulation are shown in Figure 4.

There is an increase in flooding risk as the percentage

of inaccessible drains increases. This suggests that a

policy of suspending parking on streets to be serviced

might improve maintenance efficiency by 8%, which

translates to about £1,400 risk decrease every day. If a

“suspending parking” policy only partially decreases

the number of parked cars (to 5%), little difference

can be observed in risk. When the impact of parking

increases up to 15%, the surface flooding risk increase

significantly by 12%.

Figure 4: The average daily risk of applying maintenance

schedule described in Section 3.1, with different accessibil-

ity settings during preventative maintenance. The bar with

the setting of 8.3% is the current real-world situation. Error

bars show 95% confidence interval.

4.2 What if we Could do

Condition-based Maintenance

(CBM)?

Aside from parking issues, seasonal changes and un-

timely system status information are identified as

other factors that affect the efficiency of drainage sys-

tem maintenance. Seasonal change is an uncontrol-

lable factor. On the other hand, improving low-cost

sensor techniques make it potentially feasible to con-

tinuously monitor gully-pot condition. This would

allow our schedule strategies to be combined with

CBM, discussed in Section 2. Currently, we only find

out that a gully pot is blocked or broken either during

preventative maintenance or if it is reported; because

of this incomplete system information, it is difficult to

produce any optimal schedules.

In simulation, we can test the importance of real

time failure monitoring by varying the proportion of

gully pot failures that are known immediately, as if the

gully pot had a real-time sensor. As shown in Table

2, we use two parameters, “since last maintenance ac-

tion θ” and “percentage of broken gully pots” to con-

trol the system’s initial state. The stable state assumes

that the entire system is well maintained and the num-

ber of days since the last maintenance action for each

gully is uniformly distributed across 1.1 years. Fur-

thermore, there are about 0.4% broken gullies in the

system when it is in the stable situation. The other two

scenarios assume that the system is recovering from a

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

300

natural disaster such that a large number of gullies are

broken or blocked initially regardless of prior mainte-

nance. Both a well maintained gully-pot system (see

Figure 2, recover-1) and a system that has had bad

maintenance (see Figure 2, recover-2) are tested.

Table 2: “since last maintenance” and “percentage of bro-

ken gully pots” set the system’s initial state: for all gully

pots, the days since their last service are evenly distributed

in θ years. We randomly assign a percentage of gully pots

to be in the broken state.

Stable

Recover

1

Recover

2

Since last

maintenance θ

1.1 1.1 3

Initial broken

gully pots

0.4% 2% 2%

Figure 5: Performance of maintenance in stable with sen-

sors of different install capacity. Error bars show 95% con-

fidence intervals.

Figure 5 presents the average daily risk in four

seasons over a set of four-year simulations. In com-

parison to the simulation of current blockage report-

ing, the instant information simulation shows a re-

duction in risk of about 92%. For the case where

all gully pots have instant (sensor) information, the

results clearly show the impact of seasonal factors:

falling leaves in autumn increase risk by about two

times compared to other seasons. Interestingly, we

can not observe the clear risk difference between sea-

sons when no sensors are installed. This is because

the different residents’ reporting behaviour strongly

affects the responding time of broken/blocked gullies.

The dependence on local residents’ reports bury big

hidden dangers for the entire system.

To provide further insight into how the availabil-

ity of information on gully pots affects flooding risk,

we adapt the simulation to provide instant information

from only some locations, simulating the localised in-

stallation of sensors. Setting 10% of gullies to have

sensors, allows us to compare an even distribution of

sensors to the results when sensors are focused on

critical areas of the city. We find that focusing on

high risk areas reduces the daily risk, on average, by

about 28%. When monitoring is increased to cover

30% gullies, the comparable saving is a 75% risk de-

crease.

Figure 6 illustrates the daily risk change over

two years in recovery states. In scenario recovery-

1, the system with full sensoring performs the best

in terms of recovering speed, followed by 30% high-

risk-impact and 70% random strategies. The faster

recovery also implies lower total surface water flood-

ing risk through the recovery period. In scenario

recovery-2, due to the previous poor system mainte-

nance, the recovery period is significantly longer in

all cases compared to scenario 1. Also, the peak point

uncovers the vulnerability of a badly maintained sys-

tem during the high-risk season. However, the sen-

soring still helps the maintenance team to produce a

more informed schedule, which results in less total

risk during the recovery period.

4.2.1 Discussion

The above simulations show the contribution of

timely information to improving the gully-pot system

maintenance quality. However, the proposed sensor

system also increases the management complexity,

where extra cost and manpower are needed to ensure

that the system is always working correctly. Further-

more, we assume in our simulation that instant gully-

pot condition information can be received with no er-

rors, which is hypothetical. In practice, current sen-

sor techniques can achieve up to 85% reliability (See

et al. (2012)). More research is needed into both the

hardware aspect and the optimization of scheduling

strategies.

Another issue that has been noted is the commu-

nication performance of sensors, which decreases in

weather condition such as rain or snow (See et al.

(2012)). Therefore, the gully-pot system maintenance

should combine a risk estimation approach (i.e. Sec-

tion 3.2) with sensors to deliver optimized scheduling.

Our simulation shows large advantages when sen-

sors are installed in high-risk areas. However, since

sensors must be close enough to communicate wire-

lessly with each other, the network topology must be

considered (Yick et al. (2008); See et al. (2012)). In

order to successfully integrate sensors into the cur-

rent gully-pot system, further analysis is needed into

the technical feasibility and the balance between costs

and benefits (i.e. surface water flooding risk decreas-

ing) to determine if the installation and maintenance

costs of the sensors are worthwhile.

Risk Driven Analysis of Maintenance for a Large-scale Drainage System

301

(a) Daily risk tracking of scenario recovery-1. (b) Daily risk tracking of scenario recovery-2.

Figure 6: Performance of maintenance in recovery state with sensors of different install capacity.

5 CONCLUSION

This paper considers a real-world drainage system

maintenance problem. A risk-driven analysis ap-

proach is proposed to evaluate the performance of

maintenance actions. We focus on the “parking is-

sues” and “untimely system status information” that

are identified as potential weaknesses of the current

maintenance approach (see Section 3.1).

To summarise, “banning parking” could improve

gully pot maintenance to some extent. However, this

policy increases management complexity and resi-

dents’ complaints. The “untimely system status in-

formation” is the dominant factor that weakens the

efficiency of current maintenance. Our preliminary

simulation shows promise in sensor informed main-

tenance. Low-cost wireless sensor techniques could

be a good investment to help produce an informed

maintenance schedule and lower risk. Further work

is needed to form a cost/benefit analysis to discover

the optimal quantity of sensors to deploy, their loca-

tions and network topology. The technical feasibil-

ity of sensors’ topology should also be considered.

Further work is also needed to discover the potential

decrease in maintenance scheduling efficiency due to

false alarms caused by the “sensor technique”. New

scheduling approaches may be required to make best

use of the potentially large amount of data generated

by the sensors.

In practice, due to the immaturity of sensor tech-

nology, we suggest that the combination of time-

based preventative maintenance (with risk estimation)

and condition-based corrective maintenance (with

sensors) is an optimal approach.

ACKNOWLEDGEMENTS

The authors would like to thank Gaist Solutions Ltd.

for providing data and domain knowledge. This re-

search is part of the LSCITS project funded by the

Engineering and physical sciences research council

(EPSRC).

REFERENCES

Ahmad, R. and Kamaruddin, S. (2012). An overview of

time-based and condition-based maintenance in in-

dustrial application. Computers & Industrial Engi-

neering, 63(1):135–149.

An, Y. J., Kim, Y. D., Jeong, B. J., and Kim, S. D. (2012).

Scheduling healthcare services in a home healthcare

system. Journal of the Operational Research Society,

63(11):1589–1599.

Baik, H.-S., Jeong, H. S. D., and Abraham, D. M.

(2006). Estimating Transition Probabilities in Markov

Chain-Based Deterioration Models for Management

of Wastewater Systems. Journal of Water Resources

Planning and Management, 132(1):15–24.

BBC (2011). Flooding affects Pembrokeshire resi-

dents and businesses. Date accessed: 2015-09-04.

http://www.bbc.co.uk/news/uk-wales-15441912.

BBC (2012). Floods: North Wales Police travel

warning after rain. Date accessed: 2015-09-05.

http://www.bbc.co.uk/news/uk-wales-19702806.

Blackpool (2009). Blackpool strategic flood risk

assessment. Date accessed: 2015-07-05.

https://www.blackpool.gov.uk/Residents/Planning-

environment-and-community/Documents/Blackpool-

Strategic-Flood-Risk-Assessment.pdf. Technical

Report June.

Butler, D., Xiao, Y., and Karunaratne, S. (1995). The gully

pot as a physical, chemical and biological reactor. Wa-

ter Science and Technology, 31(7):219–228.

Campos, J. (2009). Development in the application of ICT

in condition monitoring and maintenance. Computers

in Industry, 60(1):1–20.

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

302

Carnero Moya, M. C. (2004). The control of the setting up

of a predictive maintenance programme using a sys-

tem of indicators. Omega, 32(1):57–75.

Chen, Y., Cowling, P., and Remde, S. (2014). Dynamic Pe-

riod Routing for a Complex Real-World System : A

Case Study in Storm Drain Maintenance. In Evolu-

tionary Computation in Combinatorial Optimisation,

pages 109–120.

Christofides, N. and Beasley, J. E. (1984). The period rout-

ing problem. Networks, 14(2):237–256.

Claassen, G. D. H. and Hendriks, T. H. B. (2007). An ap-

plication of Special Ordered Sets to a periodic milk

collection problem. European Journal of Operational

Research, 180(2):754–769.

Constantine, G., Darroch, J., and Miller, R. (1996). Pre-

dicting underground pipeline failure. WATER -

MELBOURNE THEN ARTARMON, 23(2):9–10.

Cowling, P. and Johansson, M. (2002). Using real time in-

formation for effective dynamic scheduling. European

Journal Of Operational Research, 139(2):230–244.

Cutter, S. L., Carolina, S., and Boruff, B. J. (2003). So-

cial Vulnerability to Environmental Hazards. Social

Science Quarterly, 84(2):242–261.

Duffuaa, S., Ben-Daya, M., Al-Sultan, K., and a.a. Andi-

jani (2001). A generic conceptual simulation model

for maintenance systems. Journal of Quality in Main-

tenance Engineering, 7(3):207–219.

Ebeling, C. E. (2004). An introduction to reliability and

maintainability engineering. Tata McGraw-Hill Edu-

cation.

Gaur, V. and Fisher, M. L. (2004). A Periodic Inventory

Routing Problem at a Supermarket Chain. Operations

Research, 52(6):813–822.

Hansen, P., Mladenovi

´

c, N., and Moreno P

´

erez, J. A.

(2010). Variable neighbourhood search: Methods

and applications. Annals of Operations Research,

175(1):367–407.

Karlsson, K. and Viklander, M. (2008). Polycyclic aromatic

hydrocarbons (PAH) in water and sediment from gully

pots. Water, Air, and Soil Pollution, 188(1-4):271–

282.

Kenne, J. P. and Nkeungoue, L. J. (2008). Simultaneous

control of production, preventive and corrective main-

tenance rates of a failure-prone manufacturing system.

Applied Numerical Mathematics, 58(2):180–194.

Kleiner, Y. and Rajani, B. (2001). Comprehensive review

of structural deterioration of water mains: statistical

models. Urban Water, 3(3):131–150.

Le Gat, Y. and Eisenbeis, P. (2000). Using maintenance

records to forecast failures in water networks. Urban

Water, 2(3):173–181.

Leylandguardian (2015). Blocked drain causes flooding

danger on Lancashire road. Date accessed: 2015-08-

24. http://www.leylandguardian.co.uk/news/blocked-

drain-causes-flooding-danger-on-lancashire-road-1-

7425326.

Madanat, S. and Ibrahim, W. H. W. (1995). Poisson regres-

sion models of infrastructure transition probabilities.

Journal of Transportation Engineering, 121:267–272.

Morcous, G., Rivard, H., and Hanna, A. M. (2002). Mod-

eling bridge deterioration using case-based reasoning.

Journal of Infrastructure Systems, 8(3):86–95.

Scarf, P. a. and Cavalcante, C. a. V. (2010). Hybrid

block replacement and inspection policies for a multi-

component system with heterogeneous component

lives. European Journal of Operational Research,

206(2):384–394.

Scott, K. (2012). Investigating Sustainable Solutions for

Roadside Gully Pot Management. PhD thesis.

See, C. H., Horoshenkov, K. V., Abd-alhameed, R. A., Hu,

Y. F., and Tait, S. J. (2012). A Low Power Wire-

less Sensor Network for Gully Pot Monitoring in Ur-

ban Catchments. IEEE Sensors Journal, 12(5):1545–

1553.

Shamir, U. and Howard, C. D. (1978). An analytic approach

to scheduling pipe replacement. Journal of the Amer-

ican Water Works Association, 71.

Shieldsgazette (2012). Flooding hell caused by

blocked gully. Date accessed: 2015-08-24.

http://www.shieldsgazette.com/news/local-

news/flooding-hell-caused-by-blocked-gully-1-

4761698.

Shih, L. H. and Chang, H. C. (2001). A routing and schedul-

ing system for infectious waste collection. Environ-

mental Modeling and Assessment, 6(4):261–269.

Thieken, A., Ackermann, V., Elmer, F., Kreibich, H.,

Kuhlman, B., Kunert, U., Maiwald, H., Merz, B.,

Muller, M., Piroth, K., Schwarz, J., Schwarze, R.,

Seifert, I., and Seifert, J. (2008). Methods for the eval-

uation of direct and indirect flood losses.

UK GOV (2015). Price Paid Data

2015. Date accessed: 2015-09-09.

https://www.gov.uk/government/statistical-data-

sets/price-paid-data-downloads.

Weibull, W. (1951). A statistical distribution function of

wide applicability. Journal of applied mechanics,

18:293–297.

Wu, J., Adam Ng, T. S., Xie, M., and Huang, H. Z. (2010).

Analysis of maintenance policies for finite life-cycle

multi-state systems. Computers and Industrial Engi-

neering, 59(4):638–646.

Yick, J., Mukherjee, B., and Ghosal, D. (2008). Wire-

less sensor network survey. Computer Networks,

52(12):2292–2330.

Risk Driven Analysis of Maintenance for a Large-scale Drainage System

303