A Microfluidic-based Tactile Sensor for Palpating Mice Tumor

Tissues

Yichao Yang

1

, Garett Johnson

2

, Dean Krusienski

2

, Siqi Guo

3

, Cheng Lin

4

and Zhili Hao

1

1

Department of Mechanical and Aerospace Engineering, Old Dominion University, Norfolk, VA, U.S.A.

2

Department of Electrical and Computer Engineering, Old Dominion University, Norfolk, VA, U.S.A.

3

Center of BioElectrics, Old Dominion University, Norfolk, VA, U.S.A.

4

Department of Engineering Technology, Old Dominion University, Norfolk, VA, U.S.A.

Keywords: Microfluidics, Tactile Sensor, Transducer Array, Tumor Localization, Minimally Invasive Surgery.

Abstract: In light of the need of tissue palpation for Robotics-assisted Minimally Invasive Surgery (RMIS), this paper

presents a microfluidic-based tactile sensor for palpating mice tissues for tumor localization. The core of the

sensor is a 33 sensing-plate/transducer array built into a single polydimethylsiloxane (PDMS)

microstructure, with a transducer spacing of 3.75mm1.5mm. Mounted on a robot, the sensor is pressed

against a tissue region with a pre-defined indentation depth pattern, and consequently the stiffness

distribution across the tissue region translates to the deflection distribution of the sensing-plate array and is

captured by the transducer array underneath as resistance changes. Thus, the recorded data on a tissue

region is the sensor deflection as a function of the indentation depth. While the continuous manner of the

sensor interacting with a tissue region alleviates the error resulting from non-ideal normal contact between

the sensor and the tissue region, the error related to uncertainty in contact point is removed by interpreting

the palpation results in terms of the slope of the sensor deflection versus the indentation depth. Two mice

tumor tissues are palpated using the sensor. After their noise being removed, the raw data on the two tissues

are processed to obtain their slope distribution, the slope error and the percentage error in the slope. The

slope distribution of each tissue clearly illustrates the location of a tumor. The palpation results also indicate

that this sensor can be integrated into a robotic-assisted system for tumor localization.

1 INTRODUCTION

Offering many advantages over open surgeries,

Robotic-assisted Minimally Invasive Surgery

(RMIS) has gained great popularity over recent

years (Girão et al., 2013; Konstantinova et al., 2014;

Schostek et al., 2009; Tiwana et al., 2012 ). With a

RMIS system such as the da Vinci

TM

Surgical

System, (Guthart et al., 2000) and the ZEUS™

Surgical System (Uranues et al., 2002), a surgeon

gets access to an operation site and performs an

operation via robotic-assisted laparoscopic tools

through a small incision. Thus, direct manual

palpation to a tissue region is lost in RMIS. The lack

of tissue palpation not only increases the chance of

tissue trauma/damage, but also limits the application

of RMIS in many complex procedures (Beccani et

al., 2015; Puangmali et al., 2008). Thus, tactile

sensors are resorted to for adding tissue palpation to

RMIS (Puangmali et al., 2008; Trejos et al. 2009).

Up to date, various tactile sensors have been

developed for tissue palpation (Anastassopoulos et

al., 2001; Beccani et al., 2015; Panteliou et al.,

2000). Since a tumor exhibits a much higher

stiffness than its surrounding healthy tissue

(Krouskop et al., 1998), tissue palpation via tactile

sensors translates to acquiring the stiffness

distribution of a tissue region. A tactile sensor is

typically comprised of a mechanical structure to

convert a force to a deflection and a transducer to

register the deflection as an electrical/optical signal.

A tissue region is often considered to have the same

thickness across it and is much larger than the

mechanical structure of a tactile sensor. Thus, the

measured stiffness distribution of a tissue region is

representative of its elasticity distribution

(Anastassopoulos et al., 2001; Konstantinova et al.,

2014). Acquiring the stiffness distribution of a tissue

region can be achieved either by sliding a tactile

sensor over the region or employing a sensor array

Yang, Y., Johnson, G., Krusienski, D., Guo, S., Lin, C. and Hao, Z.

A Microfluidic-based Tactile Sensor for Palpating Mice Tumor Tissues.

DOI: 10.5220/0005705600830092

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 1: BIODEVICES, pages 83-92

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

83

to concurrently map out the stiffness distribution of

the region (Girão et al., 2013; Konstantinova et al.,

2014; Schostek et al., 2009; Tiwana et al., 2012).

In recent years, quite a few MEMS/microfluidic-

based tactile sensors and sensor arrays have been

incorporated into surgical instruments to enable

surgeons to measure mechanical properties (Dargahi

and Najarian, 2003; Lanfranco et al., 2004; Ottermo

et al., 2006; Su et al., 2012; Talasaz and Patel,

2013;). These studies have greatly advanced the

tactile sensing technology and led to a better

understanding of its application for tissue palpation.

However, two unavoidable misalignment issues

(Wanninayake et al., 2013; Zhao et al., 2013)

(uncertainty in contact point and non-ideal normal

contact) associated with an indiviudal sensor and a

sensor array for tissue palpation severely distort the

genuine stiffness distribution of a tissue region,

yielding false identification of tumors.

To address the misalignment issues, we have

developed a two-dimensional (2D) microfluidic-

based resistive tactile sensor for tissue palpation

(Yang et al., 2015a). The core of the 2D tactile

sensor is one whole PDMS microstructure

embedded with a 3×3 sensing-plate/transducer array.

The distributed deflection acting on the top of the

sensing-plate array translates to geometrical changes

of the transducer array underneath and further

registers as resistance changes. The 2D sensor

features ease of fabrication and performance

robustness (Yang et al., 2015a). Previously, this

sensor has successfully been demonstrated to

measure tissue phantoms with embeded dummy

tumors. As compared with our previous related work

(Yang et al., 2015a), the unique contributions of this

paper are 1) the motion of the sensor is controlled by

a robot to examine the effect of mounting the sensor

on a robot on the palpation results, and 2) two true

animal tumor tissues are palpated to examine

whether the sensor is suitable for tumor localization

of true tumor tissues, instead of well-prepared tumor

tissue phantoms.

2 A MICROFLUIDIC-BASED

TACTILE SENSOR

2.1 Design and Working Principle

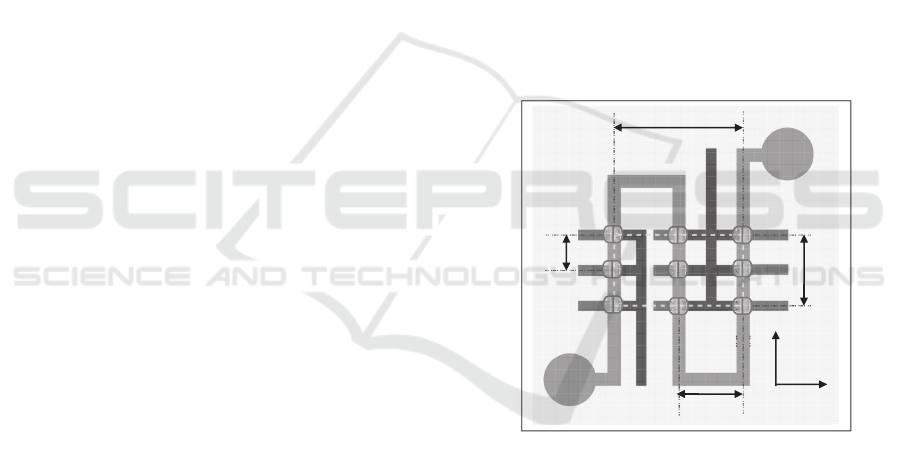

In Figure 1, the configuration of the microfluidic-

based tactile sensor is presented. It consists of a

PDMS microstructure with a 3×3 circular sensing-

plate array at its top and a serpentine-shape

electrolyte-filled microchannel at its bottom. A set

of electrode pairs are distributed along the

microchannel length. The portion of electrolyte

underneath a sensing-plate serves as a resistive

transducer, whose resistance varies with the bottom

deflection of the sensing-plate and is routed out by

the electrode pair. Thus, coincident with the sensing-

plate array, a 3×3 transducer array is realized by one

body of electrolyte in the microchannel and the set

of electrode pairs. Distributed deflection acting on

top of the microstructure translates to the bottom

deflections of the sensing-plates and consequently

causes geometrical changes of the transducer array,

which register as resistance changes. Two reservoirs

at the ends of the microchannel serve as a conduit

for electrolyte to flow in/out during the sensor

operation. The transducer spacing of the sensing-

plate/transducer array is 3.75mm along the x-axis

and 1.5mm along the y-axis, respectively. The

effective sensing region of the sensor is 7.5 mm×3

mm, defined by the distance between the centers of

the sensing-plates at the array sides.

Figure 1: Configuration of a microfluidic-based tactile

sensor: a 3×3 sensing-plate/transducer array built into a

single PDMS microstructure with transducers being

labeled (drawn not to scale for clear illustration).

A standard photolithography fabrication process

for PDMS-based microfluidic devices is employed

to fabricate the sensor. The microstructure is made

of 1:10 PDMS (mixing ratio of cross-linking agent

to base of PDMS Sylgard 184 base). Details about

the sensor fabrication process can be found in the

literature (Gu et al., 2013a). After the sensor is

fabricated, electrolyte, 1-ethyl-3-methylimidazolium

dicyanamide (EMIDCA), is injected into the

microchannel through a hole in the reservoir using a

syringe. The holes are then sealed by 1:10 PDMS to

prevent leakage of electrolyte for flipping the sensor

2d

x

=7.5mm

Input

Reservoir

Microchannel

Sensing

plate

2d

y

=3mm

d

y

A

A

A

B

B

B

C

C

C

O

x

y

d

x

Input

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

84

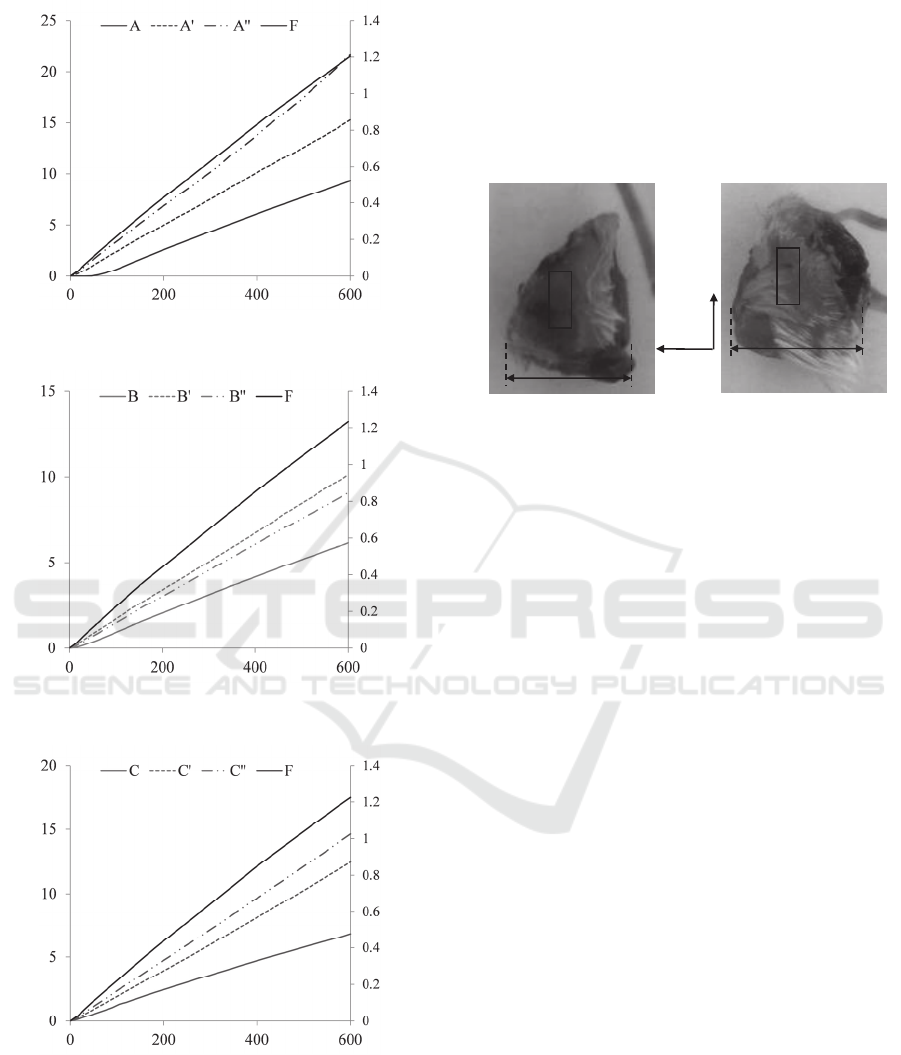

over to palpate a tumor tissue. In Figure 2, the

fabricated sensor and its sensing-plate/transducer

array are shown.

Figure 2: Pictures of (a) the fabricated microfluidic-based

sensor (a black paper is put underneath the sensing-plate

/transducer array for clear illustration) and (b) close-up

view of its sensing-plate/transducer array and electrodes.

2.2 Performance Characterization

The experimental setup (Gu et al., 2013b) used for

characterizing the one-dimensional tactile sensor is

utilized in this work to characterize the performance

of the sensor. The whole experimental setup is

implemented on an optical table. The sensor is first

mounted on a printed circuit board (PCB) for

electrical connections and further fixed on a five-

axis manipulator for better position alignment.

Mounted on a micropositioner, a cylinder probe of

11mm-in-length and 0.8mm-in-diameter is used to

generate distributed deflection on each column of

the transducer array, respectively. Note that the

applied displacement from the cylinder is the same

as the deflection acting on the top of the

microstructure, which translates to the bottom

deflection of the sensing-plate array and is registered

as resistance changes by the transducer array. A six-

axis force/torque sensor (NANO 17, ATI Industrial

Automation) is incorporated into the experimental

setup to monitor the overall force experienced by the

tactile sensor, in response to a deflection input.

To monitor the resistance changes of the

transducer array, a 100 kHz AC voltage with a peak-

to-peak value of 200mv is applied as the common

input to all the transducers. The outputs of the

transducers are connected to their own electronics

with the same design and are converted to DC

voltage outputs, which are recorded by a LabVIEW

program. The resistance changes can be extracted

from the recorded DC voltage outputs (Gu et al.,

2013a). Afterward, the resistance changes can be

used to find out the bottom deflection of the sensing-

plate array (Yang et al., 2015b).

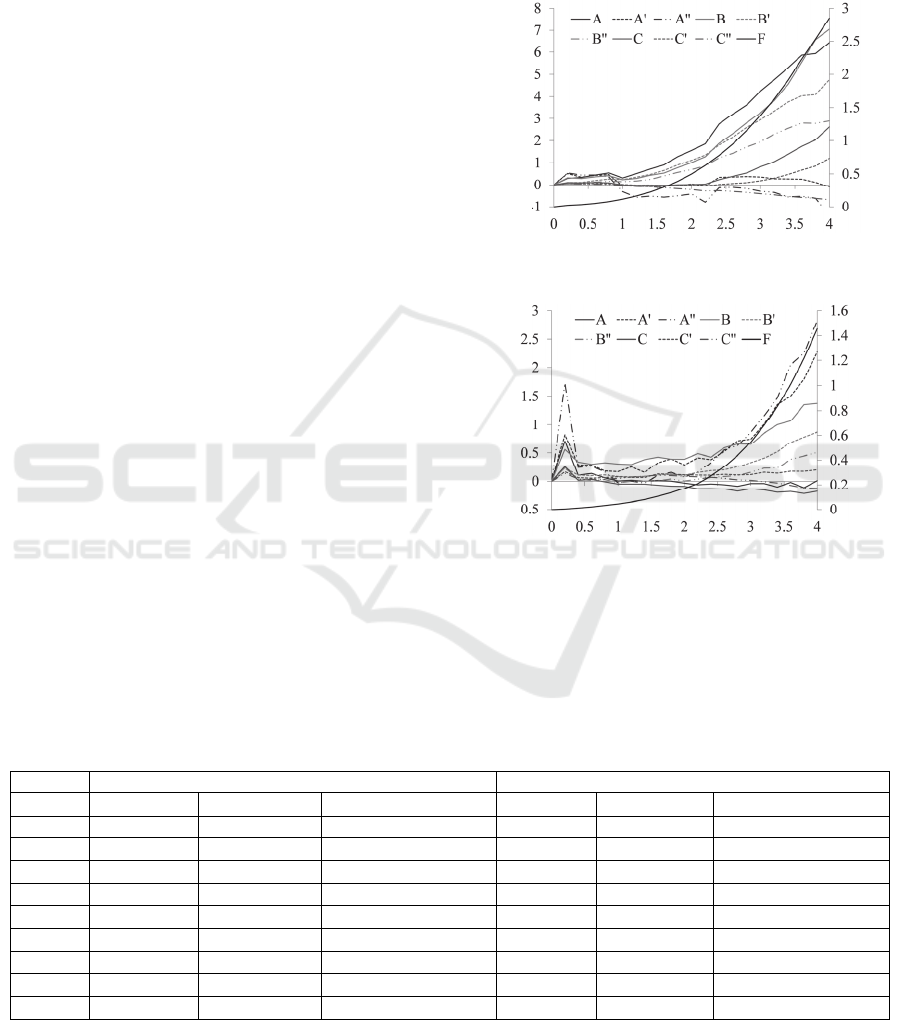

In Figure 3, the average bottom deflection of five

measurements of each sensing-plate column as a

function of the deflection acting at their tops are

presented. A 600µm-indentation depth, z

in

, exerted

on the top of the i

th

sensing-plate translates to a

roughly 12µm-deflection, z

s-i

, at its bottom (As will

be seen in Figure 6). Based on the average slope

relation of the top deflection, z

top-i

, and bottom

deflection, z

s-i

, of the 3×3 sensing-plate array, the

deflection at the top of the sensing-plate, z

top-i

(equal

to z

in

) is approximately related to its bottom

deflection by equation (1).

top i s i

z58z

(1)

The variation in bottom deflection among the

sensing-plates is believed to result from in-plane

misalignment between the sensor and the cylinder

probe, since the fabrication variation in transducer

height and the out-of-plane misalignment between

the sensor and the probe (the probe being tilt toward

one transducer in each column) has been corrected

(Yang et al., 2015b). Consequently, the distributed

deflections, z

top-i

, over the contact surface between

the sensor and the cylinder probe are captured by the

sensor deflection, z

s-i

. Accompanying the applied

distributed deflection, the overall reaction force of

the sensor can be obtained from the readout of the

six-axis force/torque sensor. The relation (F-z

s-i

)

between the overall reaction force, F(N), and the

sensor deflection, z

s-i

(m), is obtained from the

slope value of F and z

s-i

, from a sensing-plate

column and is given by equation (2),

.

s

i

F

0116 z

(2)

the equation can be used to relate the sensor

deflection to the corresponding contact force at a

transducer, which is important for avoiding the

possible damage to a tumor tissue during palpation.

3 MATERIALS AND METHOD

3.1 Tumor Tissue Preparation

Tumor tissues used in this work were stored at -80°C

freezer. The orthotopic mouse breast cancer model

was established by injection of 106 4T1-luc cells in

50µL PBS into the left abdominal mammary gland.

Tumors were measured every 3 to 4 days by a

Caliper and were harvested after one dimension of

tumor reached 15 mm diameter then kept at -80°C

Sensing-plates

2d

x

=7.5mm

C

C

C

B

B

B

A

A

A

0.5mm

(a)

(b)

2d

y

=3mm

0.5mm

A Microfluidic-based Tactile Sensor for Palpating Mice Tumor Tissues

85

Figure 3: Sensor deflections, z

s-i

, as a function of

indentation depth, z

in

, with a 11mm-long and 0.8mm-in-

diameter cylinder probe above the transducer column (a)

A, A and A (b) B, B and B, (c) C, C and C,

respectively.

freezer. The frozen tumor tissues defrosted at room

temperature for 2 hours to recover tissue flexibility

before the experiment was performed. As shown in

Figure 4, the two prepared mice tumor tissues are

labelled as tumor tissue #1and tumor tissue #2,

respectively. Coincident with the sensing region of

the sensor, the tissue region highlighted in each

tumor tissue is the palpated region.

(a) (b)

Figure 4: Pictures of the prepared mice tumor tissues (a)

tumor tissue #1 and (b) tumor tissue #2.

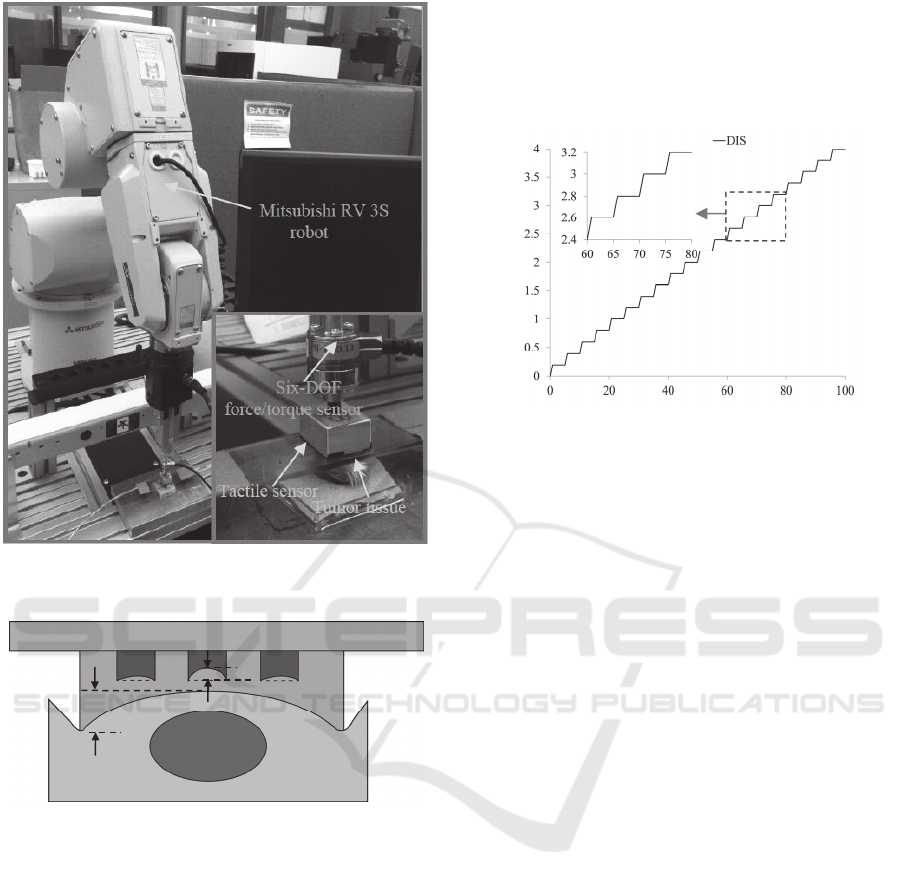

3.2 Palpation Rationale

The experimental setup for palpating a tumor tissue

using the tactile sensor is shown in Figure 5. With

the sensor mounted on its end effector, a Mitsubishi

RV 3S robot is used to control the motion of the

sensor during palpation. With a displacement

repeatability of 20m, the robot offers the

capability of position control and 6 DOFs of the

sensor. The rest of the setup is the same as the setup

for characterizing the sensor. Additionally, the six-

axis force/torque sensor is incorporated into the

setup for monitoring the accompanying reaction

force of a tumor tissue, in response to an indentation

depth input.

As shown in Figure 6, after being aligned on a

tissue region of a tumor tissue, the tactile sensor is

pressed against the tissue with an indentation depth,

z

in

, and the distributed deflection, z

s-i

, of the sensor

is acquired concurrently. Based on the characterized

relation between the deflection on top of a sensing-

plated and the deflection at its bottom, the top

deflection, z

top-i

, is obtained. Since the sensing-plates

are designed to have the same stiffness, the variation

in bottom deflection among the sensing plates

originates from the stiffness distribution of a tissue

region. Since a tumor is stiffer than its surrounding

healthy tissue, a large deflection at a sensing-plate

indicates the location of the tumor in a tissue.

Additionally, the overall reaction force acting on the

tissue can be used to avoid possible damage to the

tissue during palpation.

Sensing region

(3mm×7.5mm)

16 mm

x

y

O

Sensing region

(3mm×7.5mm)

18 mm

Sensor deflection, z

s

(m) Force, F (N)

Indentation depth, z

in

(m)

(c)

Sensor deflection, z

s

(m)

Force, F (N)

Indentation depth, z

in

(m)

(b)

Sensor deflection, z

s

(m) Force, F (N)

Indentation depth, z

in

(m)

(

a

)

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

86

Figure 5: Picture of experimental setup for robotic-assisted

tumor localization.

Figure 6: Schematic of palpation on a tumor tissue via a

2D microfluidic-based tactile sensor (drawn not to scale

for clear illustration).

3.3 Tissue Palpation Protocol

Prior to palpation, the sensor is visually aligned on

the surface of a tissue region with the best

achievable normal contact, via the robotic arm. The

resistances of the sensor after being aligned are

measured and are treated as the initial resistances.

Later on, the resistance change is calculated relative

to the initial resistance for each palpation to

compensate for the performance variations among

the transducers resulting from fabrication variation

and the misalignment. Afterward, the sensor

palpates a tissue region with a pre-defined

indentation pattern. The position of the sensor after

being aligned is treated as its initial position. As

shown in Figure 7, each time the sensor is brought

down to an indentation depth of 0.2mm at a speed of

0.25mm/s and is held at the position for 5s, until

reaching the final indentation depth of 4mm.

Figure 7: Pre-defined indentation pattern, z

in

, for palpating

a tumor tissue via the tactile sensor.

4 MEASURED RESULTS

4.1 Noise Removal

The raw transducer outputs are visibly corrupted

with significant noise. A spectral analysis is

performed on these signals, which reveals broadband

noise that is uncorrelated across the transducers.

Additionally a significant amount of main noise

(60Hz) and its harmonics is also present. To remove

the presence of broadband interference from the

transducer DC voltage outputs, in addition to

removing the mains noise and its harmonics, a 4th

order Chebyschev Type II low pass filter is created

in MATLAB. The Type II filter is chosen as this

minimizes ripples in the passband. A passband

corner frequency of 10Hz is selected because the

robotic arm is not expected to apply a changing

pressure at a rate greater than ten times per second.

A 40dB decrease in the stopband power was

specified. In order to minimize the edge effects

inherent in any digital filtering, the first sample is

used to initially populate the entire filter structure.

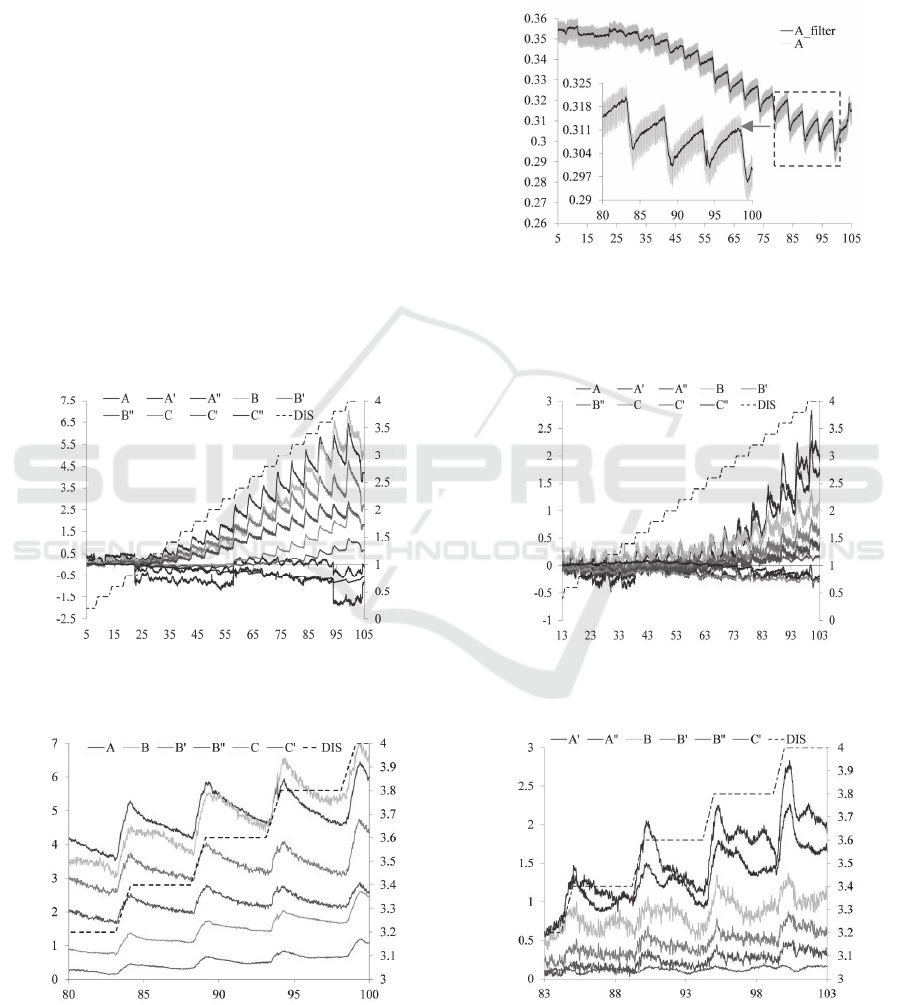

For illustrating the effectiveness of the low pass

filter, comparisons of the raw signal of DC voltage

output of transducer A, denoted as “A”, with the

signal after filtering, denoted as “A_filter”, from the

measured results on tumor tissue #1 are presented in

Figure 8. The signal appears significantly cleaner

after employing the low pass filter. The originally

recorded transducer voltage outputs on the two

Indentation depth, z

in

(mm)

Substrate

Microstructure

Tumor

Tissue

C B A

z

top-i

z

s-i

Time, t (s)

A Microfluidic-based Tactile Sensor for Palpating Mice Tumor Tissues

87

tumor tissues are all processed by the same noise

removal algorithm.

4.2 Measured Deflection/ Depth Slope

Distribution for Tumor

Localization

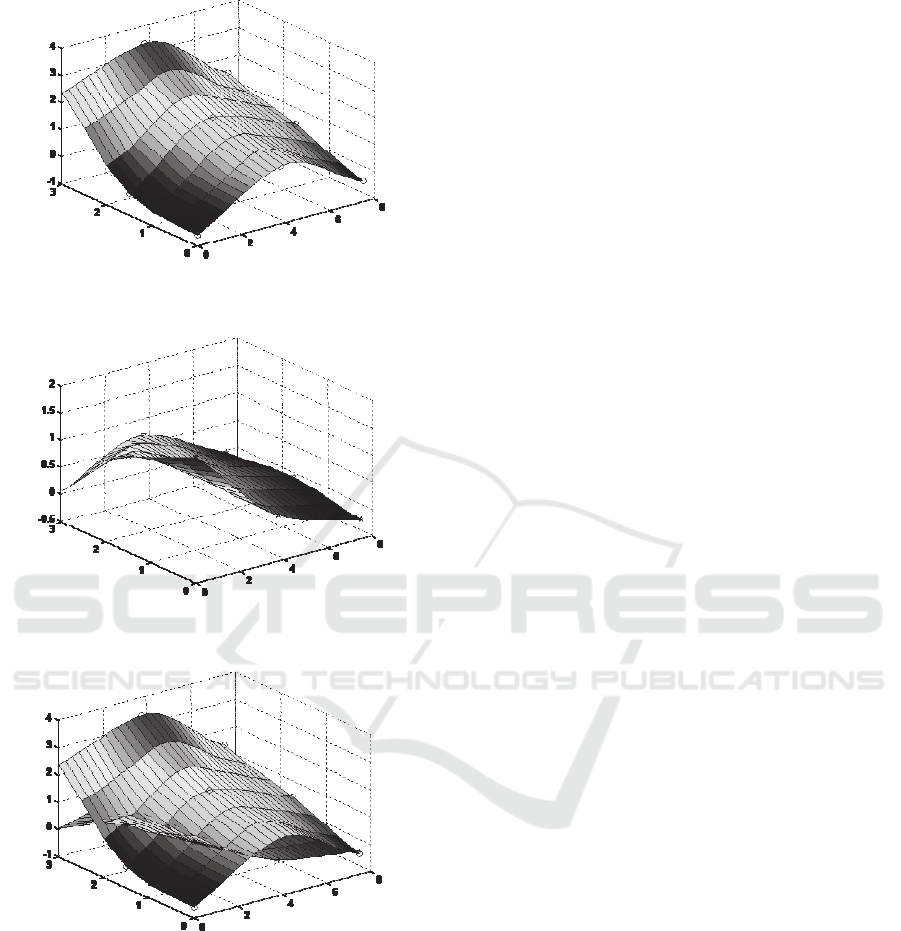

In Figure 9, the measured distributed deflection of

the sensor on the two tumor tissues as a function of

time, together with the indentation depth, are

described. Since the LabVIEW program for

collecting the data from the sensor starts prior to the

program for controlling the robot, the end time of

the data acquisition is longer than 100 seconds. As

can be seen in Figure 9(a), the transducers, A and B,

display larger deflection than the rest transducers,

while the transducers, A and A exhibit larger

deflection than the rest transducers in Figure 9(b).

Figure 9(c) and 9(d) illustrate the sensor deflection

of selected transducers in a short time span.

Evidently, the relaxation behaviour (viscosity)

during the hold time varies between the two tumor

tissues, with tumor tissue #1 being less viscous.

Although the same sensor and the same setup are

used to palpate the two tumor tissues, the results on

tumor tissue #2 are dramatically noisier than the

Figure 8: Comparison of the DC voltage, V

DC

, output of

transducer A of the 2D tactile sensor as a function of time.

(a) (b)

(c) (d)

Figure 9: Distributed defelction, z

s

, of the tactile sensor as a function of time, t, on the measured results of (a), (c)tumor #1

and (b), (d)tumor #2, respectively.

Time, t (s)

Sensor deflection, z

s

(

m)

Indentation depth, z

in

(mm)

Time, t (s)

Sensor deflection, z

s

(m)

Indentation depth, z

in

(mm)

Time, t (s)

Sensor deflection, z

s

(

m)

Indentation depth, z

in

(mm)

Time, t (s)

Sensor deflection, z

s

(m)

Indentation depth, z

in

(mm)

DC Voltage, V

DC

(V)

Time, t (s)

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

88

results on tumor tissue #1, simply because the tumor

tissue #2 is soft and thus the sensor works in its

lower end of deflection range, as will be seen later

on.

To alleviate the error associated with uncertainty

in contact point, the slope of sensor deflection, z

s

,

and indentation depth, z

in

, is used to represent the

stiffness distribution of a tissue region and

consequently localize a tumor. The measured sensor

deflection and the overall palpation force as a

function of indentation depth are shown in Figures

10(a) and 10(b). Under the same indentation depth,

the palpation force of tumor tissue #2 is much

smaller than that of tumor tissue #2, indicating that

tumor tissue #2 is softer than tumor tissue #1. The

palpation results need to be illustrated in a

convenient and straightforward manner. Toward this

end, the slope, z

s

/z

in

(m/mm), of sensor deflection,

z

s

, and indentation depth, z

in

, the slope error and the

percentage error in the slope, (z

s

/z

in

)/(z

s

/z

in

), with

the one in bold font indicating the highest slope, are

summarized in Table 1. To minimize the

measurement errors at the lower end of the sensor’s

deflection range, the indentation depth ranges of

1.5mm~4mm and 2.5mm~4mm are used to extract

the slopes for the tumor tissues #1 and #2,

respectively. Based on the slope values of the

transducer array in Table 1, color maps are

generated on the tumor tissues, as shown in Figure

11. These color maps utilize the visual color to

indicate the levels of localized slope experienced by

the sensor, with red indicating the highest slope and

blue indicating the lowest slope. As can be seen in

Figure 11(a), the transducer B displays a much

larger slope than the rest transducers, indicating that

the tumor embedded in tissue #1 is located at the site

of this transducer. In contrast, the transducer A

exhibits a much larger slope than the rest transducers

in Figure 11(b), implying that the tumor is at the site

of this transducer. Since the two tumor tissues have

similar surface profiles with similar small curvatures,

(a)

(b)

Figure 10: Distributed deflection, z

s

, and the overall

palpation force, F, of the tactile sensor as a function of the

indentation depth, z

in

, on the measurements of (a) tumor

#1 and (b) tumor #2, respectively.

Table 1: Measured deflection/depth slope (z

s-i

/z

in

), slope error ((z

s-i

/z

in

)) and percentage error in the slope ((z

s-i

/z

in

)/(z

s-

i

/z

in

)) of two tumor tissues via a 2D microfluidic-based tactile sensor.

Tumor #1 Tumor #2

z

s-i

/z

in

(z

s-i

/z)

(z

s-i

/z)/(z

s-i

/z)

z

s-i

/z

in

(z

s-i

/z) (z

s-i

/z)/(z

s-i

/z)

A 2.375 0.092 3.9% 0.030 0.046 153.8%

A

-0.232 0.057 24.7% 1.295 0.113 8.7%

A

-0.626 0.140 22.3%

1.833 0.111 6.0%

B

3.355 0.194 5.8%

0.673 0.063 9.4%

B

1.777 0.075 4.2% 0.541 0.027 5.0%

B

1.123 0.081 7.2% 0.352 0.030 8.5%

C 1.446 0.098 6.7% -0.035 0.023 63.8%

C

0.709 0.080 11.3% 0.072 0.012 16.1%

C

-0.263 0.007 2.5% -0.142 0.013 9.1%

Indentation depth, z

in

(m)

Force, F (N) Sensor deflection, z

s

(

m)

Force, F (N) Sensor deflection, z

s

(

m)

Indentation depth, z

in

(m)

A Microfluidic-based Tactile Sensor for Palpating Mice Tumor Tissues

89

(a)

(b)

(c)

Figure 11: Color maps based on the slopes, (z

s

/z

in

, m/mm)

of sensor deflection, z

s

, versus indentation depth, z

in

, on

the two tumor tissues (a) tumor tissue #1, (b) tumor tissue

#2 and (c) comparison of the two tumor tissues.

it can be concluded that the slope distribution

represents the stiffness distribution of a tumor tissue,

instead of its surface profile. In Figure 10(a),

transducer A has a larger deflection than transducer

B, but the deflection of transducer A does not

increase with the indentation depth as fast as the

deflection of transducer B. This indicates that

transducer A is located at a tissue site higher than

the rest tissue sites, but this tissue site has a lower

stiffness than that of transducer B. As such, using

the slope distribution is more accurate for tumor

localization. The comparison between the two

tissues in Figure 11(c) evidently illustrates that

tumor tissue #1 is stiffer than tumor tissue #2, which

is consistent with the conclusion drawn from the

overall palpation force difference in Figure 10.

Here, some practical concerns about using this

2D tactile sensor for tissue palpation are discussed.

First, as compared with those tactile sensor arrays or

individual sensors for tissue palpation, this 2D

sensor is much more immune to misalignment errors,

simply because one whole PDMS microstructure

with embedded transducer array palpates a tissue

region in a continuous manner and thus similar small

tilt angles are formed across the transducer array.

Second, the surface profile may introduce some

variation in the slopes across a tissue region. Both

tumor tissues contain a slightly convex surface

profile, which is not expected to yield a high slope at

the center of the tissue region. However, a convex

surface profile with a small radius of curvature may

give rise to false identification of a tumor at the

center. As such, in the future, the effect of the

surface profile of a tissue region needs to be

removed from the measured slopes. Third, to

minimize the percentage error in the slope, the

sensor design needs to be tailored so that the

stiffness of the sensor matches the stiffness of the

tissue region. Then, the difference in the slope

across a tissue region can more accurately capture

the genuine stiffness distribution of the region.

Lastly, since we know beforehand that each of the

two tissues contains a tumor, we attribute the

measured highest slope in a tissue region to the

existence of a tumor. In practice, where a tissue

region under palpation contains a tumor is not

known beforehand, both the surface profile and

experimental errors may cause a higher slope at a

site on a tissue region than the rest sites. As such, a

threshold value on the slope difference in a tissue

region needs to be established for accurate tumor

identification. This threshold value needs to factor in

the elasticity of a tissue itself and the tumor

variables (i.e., elasticity, size and depth).

5 CONCLUSIONS

In this paper, a 2D microfluidic-based tactile sensor

is mounted on a robot and utilized to palpate two

C

C

Slope, z

s

/z

in

(m/mm)

A

C

A

A

y (mm)

B

B

B

x (mm)

A

A

A

B

Slope, z

s

/z

in

(m/mm)

B

C

C

C

x (mm)

Slope , z

s

/z

in

(m/mm)

A

C

y (mm)

x (mm)

B

B

A

B

A

C

C

y (mm)

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

90

mice tumor tissues. The sensor entails a 3×3

sensing-plate/transducer array built into a single

PDMS microstructure. The distributed deflection

acting on the top of the sensing-plate array translates

to resistance changes of the transducer array

underneath. The continuity of the sensing-plate array

configuration overcomes the varying tilt angles

across a tissue region encountered by an individual

sensor or a sensor array, thus avoiding distorting the

genuine stiffness distribution of the tissue region. In

palpating a mice tissue, the input is the indentation

depth controlled by the robot and the output is the

sensor deflection at the locations of the transducer

array.

Although the robot introduces a significant

amount of noise to the recorded dada, a noise filter is

able to effectively remove the noise, indicating that

the sensor is feasible to be integrated into a robotic-

assisted system. The palpation results are interpreted

in terms of the slope distribution of the sensor

deflection versus indentation depth, with the highest

slope indicating the location of a tumor. Although

the two mice tissues have similar surface profiles,

the slope distribution varies dramatically between

them and thus is believed to arise from the existence

of tumors in them, validating the feasibility of using

this sensor for palpating true tumor tissues. Future

work will focus on improving the sensor design with

a suitable working deflection range to reduce slope

errors and reducing the sensor size for fitting in

RMIS. In addition, more tissue samples will be

measured using the presented detection method to

verify its repeatability.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial

support for this work from the National Science

Foundation, CMMI, under Grant No. 1265785.

REFERENCES

Anastassopoulos, G. T., Lytras, J. G., Sunaric, M. M.,

Moulianitis, V. C., Panteliou, S. D., Bekos, A.,

Kalinderis, N. and Hatzichristou, D., 2001. Optical

device for prostate cancer detection. In 6th National

Congress of Mechanics (p.381).

Beccani, M., Di Natali, C., Benjamin, C. E., Bell, C. S.,

Hall, N. E. and Valdastri, P., 2015. Wireless tissue

palpation: Head characterization to improve tumor

detection in soft tissue. Sensors and Actuators A:

Physical, 223, pp.180-190.

Dargahi, J. and Najarian, S., 2003. An integrated force-

position tactile sensor for improving diagnostic and

therapeutic endoscopic surgery. Bio-medical materials

and engineering, 14(2), pp.151-166.

Girão, P. S., Ramos, P. M. P., Postolache, O. and Pereira,

J. M. D., 2013. Tactile sensors for robotic

applications. Measurement, 46(3), pp.1257-1271.

Gu, W., Cheng, P., Ghosh, A., Liao, Y., Liao, B., Beskok,

A. and Hao, Z., 2013a. Detection of distributed static

and dynamic loads with electrolyte-enabled distributed

transducers in a polymer-based microfluidic device.

Journal of Micromechanics and Microengineering,

23(3), p.035015.

Gu, W., Cheng, P., Palmer, X. L. and Hao, Z., 2013b.

Concurrent spatial mapping of the elasticity of

heterogeneous soft materials via a polymer-based

microfluidic device. Journal of Micromechanics and

Microengineering, 23(10), p.105007.

Guthart, G. and Salisbury Jr, J.K., 2000. The intuitive™

telesurgery system: Overview and application. In

International Conference on Robotics and Automation

(pp. 618-621).

Konstantinova, J., Jiang, A., Althoefer, K., Dasgupta, P.

and Nanayakkara, T., 2014. Implementation of tactile

sensing for palpation in robot-assisted minimally

invasive surgery: A review. Sensors Journal, IEEE,

14(8), pp.2490-2501.

Krouskop, T. A., Wheeler, T. M., Kallel, F., Garra, B. S.

and Hall, T., 1998. Elastic moduli of breast and

prostate tissues under compression. Ultrasonic

imaging, 20(4), pp.260-274.

Lanfranco, A. R., Castellanos, A. E., Desai, J. P. and

Meyers, W. C., 2004. Robotic surgery: a current

perspective. Annals of surgery, 239(1), p.14.

Ottermo, M. V., Øvstedal, M., Langø, T., Stavdahl, Ø.,

Yavuz, Y., Johansen, T. A. and Mårvik, R., 2006. The

role of tactile feedback in laparoscopic surgery.

Surgical Laparoscopy Endoscopy & Percutaneous

Techniques, 16(6), pp.390-400.

Panteliou, S. D., Sunaric, M. M., Sarris, J.,

Anastassopoulos, G., Lytras, J. and Hatzichristou, D.

G., 2000. Design of a device for the objective

assessment of the mechanical properties of the prostate

gland. In International Conference on Role of

Mesomechanics for the Development of Science and

Technology.

Puangmali, P., Althoefer, K., Seneviratne, L. D., Murphy,

D. and Dasgupta, P., 2008. State-of-the-art in force

and tactile sensing for minimally invasive surgery.

Sensors Journal, IEEE, 8(4), pp.371-381.

Schostek, S., Schurr, M. O. and Buess, G. F., 2009.

Review on aspects of artificial tactile feedback in

laparoscopic surgery. Medical Engineering & Physics,

31(8), pp.887-898.

Su, Z., Fishel, J. A., Yamamoto, T. and Loeb, G. E., 2012.

Use of tactile feedback to control exploratory

movements to characterize object compliance.

Frontiers in neurorobotics, 6.

Talasaz, A. and Patel, R. V., 2013. Integration of force

reflection with tactile sensing for minimally invasive

A Microfluidic-based Tactile Sensor for Palpating Mice Tumor Tissues

91

robotics-assisted tumor localization. Haptics, IEEE

Transactions on, 6(2), pp.217-228.

Tiwana, M. I., Redmond, S. J. and Lovell, N. H., 2012. A

review of tactile sensing technologies with

applications in biomedical engineering. Sensors and

Actuators A: physical, 179, pp.17-31.

Trejos, A. L., Jayender, J., Perri, M. P., Naish, M. D.,

Patel, R. V. and Malthaner, R. A., 2009. Robot-

assisted tactile sensing for minimally invasive tumor

localization. The International Journal of Robotics

Research.

Uranues, S., Maechler, H., Bergmann, P., Huber, S.,

Hoebarth, G., Pfeifer, J., Rigler, B., Tscheliessnigg, K.

H. and Mischinger, H. J., 2002. Early experience with

telemanipulative abdominal and cardiac surgery with

the Zeus™ Robotic System. European Surgery, 34(3),

pp.190-193.

Wanninayake, I. B., Dasgupta, P., Seneviratne, L. D. and

Althoefer, K., 2013. Air-float palpation probe for

tissue abnormality identification during minimally

invasive surgery. Biomedical Engineering, IEEE

Transactions on, 60(10), pp.2735-2744.

Yang, Y., Shen, J. and Hao, Z., 2015a. A two-dimensional

microfluidic-based tactile sensor for tissue palpation

application under the influence of misalignment. In

ASME 2015 International Technical Conference and

Exhibition on Packaging and Integration of Electronic

and Photonic Microsystems collocated with the ASME

2015 13th International Conference on Nanochannels,

Microchannels, and Minichannels(pp.V003T05A001-

V003T05A001). American Society of Mechanical

Engineers.

Yang, Y., Shen, J. and Hao, Z., 2015b. A two-dimensional

(2D) distributed-deflection sensor for tissue palpation

with correction mechanism for its performance

variation. under review.

Zhao, S., Parks, D. and Liu, C., 2013. Design and

Modeling of a Wide Dynamic-Range Hardness Sensor

for Biological Tissue Assessment. Sensors Journal,

IEEE, 13(12), pp.4613-4620.

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

92