Embedded Sensors System Applied to Wearable Motion Analysis in

Sports

Aurélien Valade

1

, Antony Costes

2

, Anthony Bouillod

1,3

, Morgane Mangin

4

, P. Acco

1

,

Georges Soto-Romero

1,4

, Jean-Yves Fourniols

1

and Frederic Grappe

3

1

LAAS-CNRS, N2IS, 7, Av. du Colonel Roche 31077, Toulouse, France

2

University of Toulouse, UPS, PRiSSMH, Toulouse, France

3

EA4660, C3S - Université de Franche Comté, 25000 Besançon, France

4

ISIFC – Génie Biomédical - Université de Franche Comté, 23 Rue Alain Savary, 25000 Besançon, France

Keywords: IMU, FPGA, Motion Analysis, Sports, Wearable.

Abstract: This paper presents two different wearable motion capture systems for motion analysis in sports, based on

inertial measurement units (IMU). One system, called centralized processing, is based on FPGA +

microcontroller architecture while the other, called distributed processing, is based on multiple

microcontrollers + wireless communication architecture. These architectures are designed to target multi-

sports capabilities, beginning with tri-athlete equipment and thus have to be non-invasive and integrated in

sportswear, be waterproofed and autonomous in energy. To characterize them, the systems are compared to

lab quality references.

1 INTRODUCTION

Electronics in sports monitoring has been a growing

field of studies for the last decade. From the heart rate

monitors to the power meters, sportsmen are using

them every day to monitor their trainings (Bouillod et

al., 2014). ). However those data are not enough to

help the sportsmen to improve their performances,

they only measure overall output parameters that are

the consequence of the effort, and thus, lack on the

important mechanical elements: including the pose

and gesture, which are crucial basic parameters

(Oggiano et al., 2008).

In the meantime, motion capture systems have

been developed, based on vision (Vicon, Dartfish,…)

or inertial measurement units (IMU) (Xsens,

Inertia,…) (Brigante et al., 2011) (Marin-Perianu et

al., January 2013) and massively used in robotics,

movies and games industries. However, these

systems require a heavy calibration process and need

controlled environment (ambient light, restricted

zone, no obstacles…) and/or massive equipment, and

thus are unusable for on-field measurements. Our

approach is to integrate common IMU, which are

nowadays large scale produced micro-electro-

mechanical systems integrated in everyday

electronics (smartphones, game controllers...), in an

autonomous embedded system to monitor the

sportive activity, even in field conditions.

Our IMU based monitoring system allows

embedded data logging for post-processing motion

analysis, which is not possible with commercially

available solutions, where the wireless connection

can be lost due to the limited range (allowing only

short loop training monitoring) or attenuation (due to

the water in swimming conditions).

On-the-field high level sportsmen monitoring

implies the system to be wearable and non-invasive

to limit the loss of performances. It has moreover to

be waterproof due to sweat during the effort, and, of

course, for swimmers monitoring.

Our wearable system allows embedding relatively

low complexity algorithm in order to add postural and

specific motion patterns real-time feedback to already

existing indicators (hear-rate, powermeter...).

In this paper, we will expose the currently

available systems in sports and motion capture. Then

we will discuss about our approach on the embedded

motion analysis development. In a third part, we will

present the selected applications field, the

experiments we have been working on, and the results

we have obtained. Finally, we will develop some of

our project perspectives.

170

Valade, A., Costes, A., Bouillod, A., Mangin, M., Acco, P., Soto-Romero, G., Fourniols, J-Y. and Grappe, F.

Embedded Sensors System Applied to Wearable Motion Analysis in Sports.

DOI: 10.5220/0005699001700175

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 1: BIODEVICES, pages 170-175

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 AVAILABLE SYSTEMS

Sports equipment manufacturers offer a large panel of

dedicated sensing devices to monitor parameters

(Heart rate, oxygen consumption, mechanical power,

etc) during an activity. Some of them are easy to use

outdoor, we will call them embeddable equipment;

some others are more dedicated to lab tests.

2.1 Embeddable Sports Equipment

Referring to the majority of large scale distribution

sports equipment, such as HRM, speed and distance

measurement (on bikes, or via GPS for runners),

stepping cadence measurement, brain activity

(Comani et al., 2013)…

The main characteristics of these devices are:

They provide low frequency information (0.5 to

3Hz),

Data are pre-processed to be easily understood by

the user, even with low specific skills (a bike

computer displays the distance and speed

although it measures the wheel rotation count and

frequency),

They don’t need external power supply, they work

on batteries.

One of the data that is currently not monitored in

embeddable equipment is the sportsman posture.

2.2 Lab Sports Equipment

Lab equipment in sports is generally more complex

equipment which is used to precisely monitor and

optimize sportsmen or hardware (bike, helmet, saddle

position…) at one point. In this category, we include

ergometers like BikeFitting (Shimano) or Cyclus 2

(RBM elektronik-automation), and wind turbines for

aerodynamic tests.

The main differences with embeddable equipment

are (one or more):

They are larger/heavier,

They use much more energy to run,

They provide high frequency data and/or raw

measurement data.

Some of these instruments are focused on the user

posture, in order to improve his global efficiency and

performance.

However, this is just a single-shot operation,

which could be improved by “on-field” real-time

feedback.

2.3 Motion Capture Equipment

This third sort of equipment is currently rarely used

for sports applications, except for some researches in

biomechanics. It consists of objects motion

measurement in a calibrated area; the main

application of this technology is for animation. The

two main kinds of system we can find to measure a

human skeleton posture are:

Computer vision base systems use reflective tags,

positioned over the subject body, and a network

of infrared cameras. The tags positions in a

calibrated volume are calculated by a central

processing unit, and post-processing is needed to

retrieve the body segment orientations,

IMU-base systems use attitude sensors attached to

the user’s body, on each monitored segments. The

global posture of the body is then computed by

fixing the segments dimensions and joints on the

skeleton. We can find wired and wireless versions

of this system.

However it always needs a computer to process the

data in a close range around the experiment.

Regarding these information, none of these

system are embeddable for real-time sportsman

feedback in real-life conditions.

3 OUR APPROACH

The growing interest in sports performances and the

lack of embedded posture analysis and feed-back,

coupled with our knowledge in embedded systems led

us to develop wearable motion analysis systems. We

based our development on IMUbased motion capture

systems, using commercially available digital 9-axis

(3-axis accelerometer, 3-axis gyroscope and 3- axis

magnetometer) IMU sensors chips (like the ones used

in smart-phones or game controllers to determine the

device orientation), which we coupled with our

reconfigurable multi-sensors embedded architecture.

As the IMU-based motion analysis of a skeleton

needs to measure the orientation of each bones, or

segment, we needed to collect and process the data

from multiple IMU sensors dispatched over the

sportsman body. To do so, we explored two kinds of

processing architectures, which we are going to

describe.

3.1 Centralized Processing

Our first approach was to position micro sensors tags

over the body, all wired to a central processing unit

Embedded Sensors System Applied to Wearable Motion Analysis in Sports

171

(called “Reconfigurable Multi-sensors Embedded

Architecture”, AREM in French) composed of a Field

Programmable Gate Array (FPGA), which is

essentially a programmable logic circuit, to handle

the sensors interconnections, and a microcontroller,

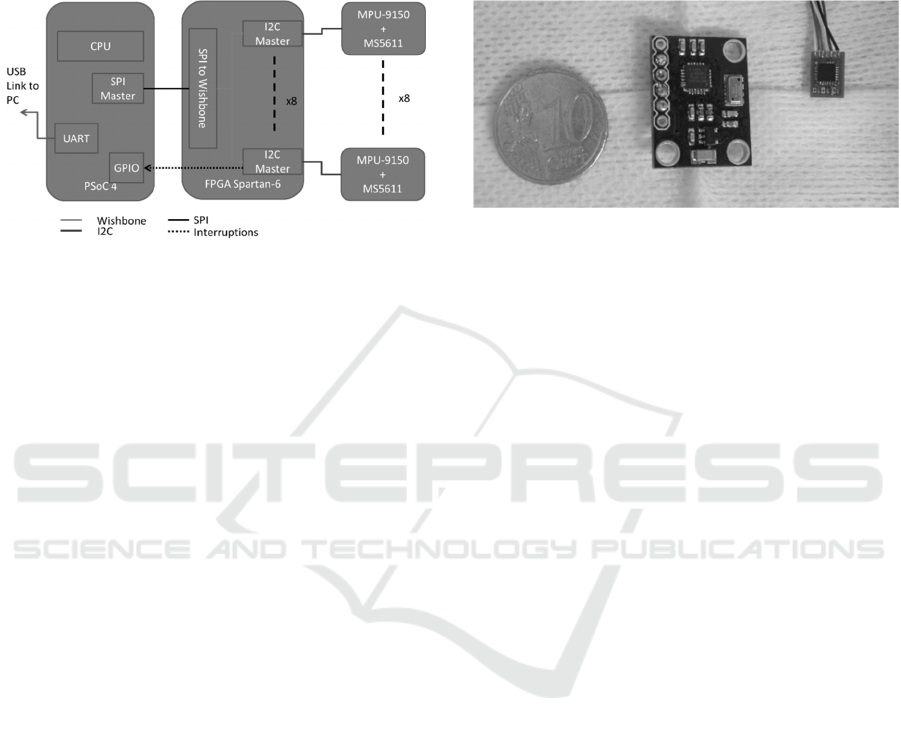

to handle the data-processing (Figure 1).

Figure 1: Centralized embedded motion system synopsys.

3.1.1 First Design

On the first version of AREM architecture, we used

common IMU sensors using Inter-Integrated Circuit

(I2C) communication standard, MPU9150 from

Invensense as sensor tags. Each one of these sensors

was connected to the FPGA via wires (Figure 2

middle). The FPGA was programmed to handle one

I2C bus master per tag, which allows to

synchronously, and simultaneously poll each sensor.

Finally, a microcontroller was connected to the FPGA

as a master to control the process, get the sensors data,

process them, and send the results back to a computer

via USB cable.

This architecture was not properly an embedded

system as it wasn’t working on batteries, nor

communicating wirelessly.

However, it was a first prototyping step to

integrate multiple motion measurement sensors in

one system.

3.1.2 Integrating the Design

In order to fulfil the wearable constraints, the design

had to be improved in several ways:

The sensors had to be smaller and integrated into

a textile,

The central processing unit had to be smaller, to

communicate wirelessly with an external device

(eg. computer, smartphone…) and to work on

batteries.

The first step was to reduce the size of the sensors

tags. In order to improve the measurement and reduce

the chip size, we change the sensor tag to the MPU-

9250, which package is smaller, handles faster

acquisition and is able to communicate via Serial

Peripheral Interface (SPI) bus. We designed smaller

support Printed Circuit Boards (PCB), and replaced

the standard cable wiring with ultra-thin wires (Figure

2right, Figure 3a).

Figure 2: AREM v0 sensor tag (middle), AREM v1 sensor

tag (right).

Then, we have tried different methods to integrate

the sensors into textiles. The first one was to sew wire

guides to the t-shirt, then maintaining the tags with a

piece of Velcro (Figure 3b). In a second time, we

integrated the whole sensor + wire into the t-shirt

using silicon coated heat transfer film (Figure 3c).

About the processing unit, we have switched from

a microcontroller + FPGA solution to an all-

embedded solution based on the Xilinx Zynq

programmable system on-chip (PSoC) which offers a

better communication between the two parts,

processing power (with an ARM Cortex A9 dual-core

processor) and an improved energy efficiency.

3.2 Distributed Processing

Our second though was to work on a distributed

sensors network: each sensor is equipped with a

battery, a microcontroller and a wireless

communication module. This design targets a lower

local computational power as each tag only has to

process its data and send the results to the network.

Consequently, the processor frequency could be

lower, and each tags power consumption, which

enables to use smaller batteries. With this

architecture, we place one unit per sensed bone, and

an access point to collect all the data.

We built our system around another IMU, the ST

iNemo-M1, which is composed of a 6-axis IMU

(Accelerometer + Magnetometer), a 3-axis gyroscope

and an ARM STM32 microcontroller which is used

to handle all the computation and to handle the whole

tag (with communication and battery management).

To transmit the processed data wirelessly, we

chose to use ESP8266 WiFi modules, working in

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

172

station mode, and connecting to a standard WiFi

Access-Point. The system is equipped with a USB

connector to charge the battery and communicate

with a computer (during debug, or to transfer data), a

Serial-ATA connector connected to a SPI bus, to

enable extension capabilities, and a programming

connector for the STM32 microcontroller.

The designed PCB (Figure 4) is 31 x 44mm, and

the circuit is 13mm high, including the battery and

connectors, for a 15g weight with a 300mAh battery.

In normal operation mode, the battery lasts 2h30.

(a) (b) (c)

Figure 3: (a) New MPU9250 tags with thin wires, (b)(c)

Sensors tags integrated into a t-shirt.

3.3 Architectures Comparison

These two architectures have advantages and

drawback which make them more or less suitable

depending on the application. In Table 1, we

compared the most noticeable parameters.

To summarize, for small skeleton cases (1-5

bones), the distributed computing is more interesting

in consumption and cost. For bigger systems, the

centralized processing is more efficient, though more

complex to develop.

Figure 4: AREM Gateway tag.

The main limitation for distributed processing in

large systems (more than 15 bones) could be the

wireless data throughput.

4 APPLICATIONS

We wanted this architecture to be versatile and

adapted to as many sports as possible. To begin, we

chose to design it to work on a triathlete, so to be able

to capture data for swimming, cycling and running.

The first two parts mostly consist on monitoring the

trunk and legs position during the activity, and to

work in standard conditions. The last one was more

challenging because it has to be waterproof and to

monitor the trunk and arms of the athlete, without

being intrusive or modifying the movement.

Table 1: AREM Architectures comparison.

Parameters Centralized processing Distributed processing

Batteries Only 1 battery to handle Multiple batteries in a standard application

Power consumption

One large power consumption for the central

processing unit and low power consumption

for the tags, low dependence over tags count

Each tag has a bigger consumption tough

lower than the central processing unit.

System consumption is lower from 1 to 3 tags

Sensors interconnection

Wires have to be integrated into the textile, the

positioning is hard to modify

Communication is wireless, the sensors can be

put anywhere

Sensors integration into the textile

Tags are very small and easy to integrate

without notice for the sportsman

Tags are heavier and larger, which makes the

positioning more uncomfortable

Hardware complexity

The tags are simple, only chips, but the central

processing unit is a complex mixed

hardware/software design

The complexity is dispatched over the whole

system, making the design easier

Cost

Low cost sensors and high cost central

processing unit. The system growth cost is less

important

High cost tags, and no central processing unit,

the system cost is linear with the monitored

segments count

Robustness

Low sensitivity over radiofrequency

conditions

Sensitive to WiFi radiofrequency occupation

Embedded Sensors System Applied to Wearable Motion Analysis in Sports

173

5 TESTS AND RESULTS

In order to test and validate our systems, we have

been working in collaboration with elite athletes in

lab conditions.

5.1 Centralized Processing

5.1.1 Cycling Study

The first test of our architecture was with the

centralized processing version (AREM v0). The test

was realized on a cyclist riding on a treadmill during

a standing position study about efficiency (A.

Bouillod et al., 2014). We have positioned 6 sensors

on a cyclist (1 at the middle of the spine, 1 at the top

of the spine, 1 on each hip, 1 on each clavicle) and 1

sensor under the saddle.

This version of the architecture was a proof of

concept and didn’t process any data and sent the

sensors data back to the PC at a 7Hz rate, and allowed

to monitor parameters like the bicycle lateral sways,

which increase the mechanical cost.

5.1.2 Hand Movement Analysis

We also have been working with J-D. Lemos on the

iGlove project to use our AREM centralized

architecture, with MPU9250 tiny tags, to analyse a

hand movement for surgery students training (J.D.

Lemos et al, 2014).

5.2 Distributed Processing

The first step for the distributed system validation, as

it embedded more complex algorithm, able to

compute the tag orientation in space, was to

characterize its response by comparing with a known

laboratory vision based system. Then we tested it on

multiple sports activities.

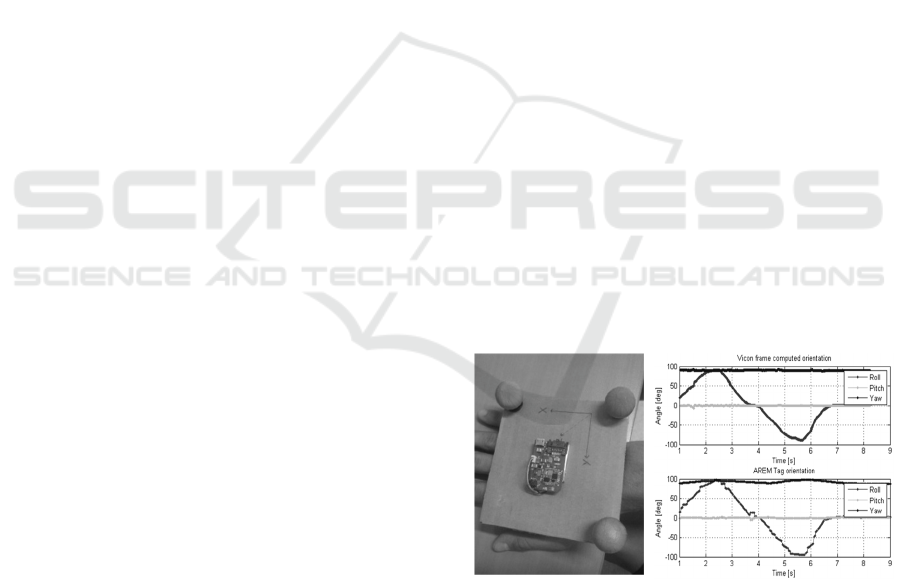

5.2.1 Comparison with Vicon

To validate the AREM Gateway (distributed

architecture), we have been comparing a tag

orientation with a Vicon capture (12 MX3+ cameras).

To do so, we fixed the tag on a cardboard frame basis

equipped with 3 Vicon reflective tags (Figure 5a) and

rotated it along X, Y and Z axis consecutively. The

data processed by the tag (25Hz) and captured by the

Vicon (200Hz) were logged to be compared in post-

processing. The frame orientation was calculated

from the markers positions, and compared to the

output data send by the tag (Figure 5b). We see that

the general aspect is good: the mean error is 2.5

degrees and the standard deviation is of 6 degrees.

In a second time, we tested the system behaviour

on a common crawl swimming movement to ensure

the functionality on complex actions.

5.2.2 Tests on Sportsmen

After this first specification, we have tried our system

on cyclists, runners and swimmers (using waterproof

bandages to protect the circuit). We have noticed that,

while suitable for bike and running, the WiFi

communication is not usable in water (since any air

path between the tag and the access-point is

obstructed by about 2cm of water, so the tag is

submerged, the sent packets are lost and the

communication is no more usable). This leads us to

reconsider the wireless communication strategy for

the distributed system.

6 PERSPECTIVES

The next step of our project will be to add an

embedded memory to log raw and processed data for

further analysis (and to allow outdoor tests, or

underwater tests, without using access-points or

computers) and to re-engineer the wireless

communication on the distributed tag to work in

water. In a second time, we will be working on the

real-time pattern recognition and feedback to the user

to enable on-field performances optimization

feedback.

(a) (b)

Figure 5: (a) AREM Gateway on a Vicon frame, (b) Roll

orientation comparison with Vicon.

ACKNOWLEDGEMENTS

The authors thanks Sylvain Laur and Compressport

International for technical discussions on this project

and future developments.

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

174

REFERENCES

A. Bouillod, J. Pinot, A. Valade, J. Cassirame, G. Soto-

Romero, F. Grappe, July 2014, Gross efficiency is

improved in standing position with an increase of the

power output. World Congress of Cycling Science,p.6.

L. Oggiano, S. Leirdal, L. Saetran, G. Ettema, 2008,

Aerodynamic Optimization and Energy Saving of

Cyclist Postures for International Elite Level Cyclists,

The engineering of Sport 7, Volume 1, pp. 597-604.

C.M.N. Brigante, N. Abbate, A. Baslie, A.C. Faulisi, S.

Sessa, August 2011, Towards Miniaturization of a

MEMS-Based Wearable Motion Capture System, IEEE

Transactions on industrial electronics, Vol. 58, No. 8,

pp 3234-3241.

Raluca Marin-Perianu et Al., January 2013, A performance

analysis of a wireless body-area network monitoring

system for professional cycling. Personal and

Ubiquitous Computing, Volume 17, Issue 1, pp 197-

209.

S. Comani, et al., 2013, Attentional focus and functional

connectivity in cycling: an EEG case study, L.M. Roa

Romero, XIII Mediterranean Conference on Medical

and Biological Engineering and Computing, IFMBE

Proceedings 41, 639.

J.D. Lemos, M. Hernandez, G.Soto-Romero, A. Valade,

Oct. 2014, Instrumented glove for skill assessment in

neurosurgical simulation. IEEE Biomedical Circuits

and Systems Conference (BioCAS), pp. 308-311.

Embedded Sensors System Applied to Wearable Motion Analysis in Sports

175