A Cuckoo Search Clustering Algorithm for Design Structure Matrix

Hayam G. Wahdan, Sally S. Kassem and Hisham M. Abdelsalam

Faculty of Computers and Information, Cairo University, Cairo, Egypt

Keywords: Design Structure Matrix, Cuckoo Search, Modularity, Modular Design, Clustering, Optimization.

Abstract: Modularity is a concept that is applied to manage complex systems by breaking them down into a set of

modules that are interdependent within and independent across the modules. Benefits of modularity are

often achieved from module independence that allows for independent development to reduce overall lead

time and to reach economies of scale due to sharing similar modules across products in a product family.

The main objective of this paper is to support design products under modularity, cluster products into a set

of modules or clusters, with maximum internal relationships within a given module and minimum external

relationships with other modules. The product to be designed is represented in the form of a Design

Structure Matrix (DSM) that contains a list of all product components and the corresponding information

exchange and dependency patterns among these components. In this research Cuckoo Search (CS)

optimization algorithm is used to find the optimal number of clusters and the optimal assignment of each

component to specific cluster in order to minimize the total coordination cost. Results obtained showed an

improved performance compared to published studies.

1 INTRODUCTION

System design involves clustering various

components in a product such that the resulting

modules are effective for the company. An ideal

architecture is one that partitions the product into

practical and useful modules. Some successfully

designed modules can be easily updated on regular

time cycles, some can be made in multiple levels to

offer wide market variety, some can be easily

removed as they stay, and some can be easily

swapped to gain added functionality. The

importance of effective product modularity is

multiplied when identical modules are used in

various different products (Aguwa et al., 2012).

Modular design approach is widely used in

consumer products; machinery and software design.

In response to the changing market trend of having

large varieties within small production, modular

design has assumed significant roles in the product

development process (Gwangwava et al., 2013). The

product is represented in the form of a Design

Structure Matrix (DSM) that contains a list of all

product components and the corresponding

information exchange and dependency patterns.

DSM, working as a product representation tool,

provides a clear visualization of product design. The

transformation of Component-DSM into proposed

functional blocks of components is called

Clustering. For small problems' components, a

Component- DSM may be sorted manually. For

larger problems, this is not practical, and at some

point, computer algorithms are absolutely necessary

(Borjesson and Hölttä, 2012).

The aim of this paper is to develop a cuckoo

search (CS) optimization algorithm to find: (1) the

optimal number of clusters in a DSM; and (2) the

optimal assignment of components to each cluster.

The objective function is to minimize the total

coordination cost. In this context, the DSM will

work as a system analysis tool that provides a

compact and clear representation of a complex

system. It captures the

interactions/interdependencies/interfaces between

system elements. It also works as a project

management tool which renders a project

representation that allows for feedback and cyclic

activity dependencies (Abdelsalam et al., 2014).

The following sections of the paper are

structured as follows. Section 2 provides a brief

introduction on DSM. Section 3 reviews the

literature and introduces the previous work this

36

Wahdan, H., Kassem, S. and Abdelsalam, H.

A Cuckoo Search Clustering Algorithm for Design Structure Matrix.

DOI: 10.5220/0005693000360043

In Proceedings of 5th the International Conference on Operations Research and Enterprise Systems (ICORES 2016), pages 36-43

ISBN: 978-989-758-171-7

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

research builds on. Section 4 provides the problem

definition. Section 5 presents the proposed

algorithm. Section 6 discusses the results obtained

and, finally, Section 7 provides conclusion and ideas

for future research.

2 DESIGN STRUCTURE MATRIX

The design structure matrix (DSM) is becoming a

popular representation and analysis tool for system

modelling, A DSM displays the relationships

between components of a system or product in a

compact visualization. Such a system can be, for

example, product architecture or an engineering

design process or a project.

The basic DSM is a simple square matrix, where

n is the number of system elements. The DSM has m

non-empty elements, where m is the number of

couplings among different system elements. An

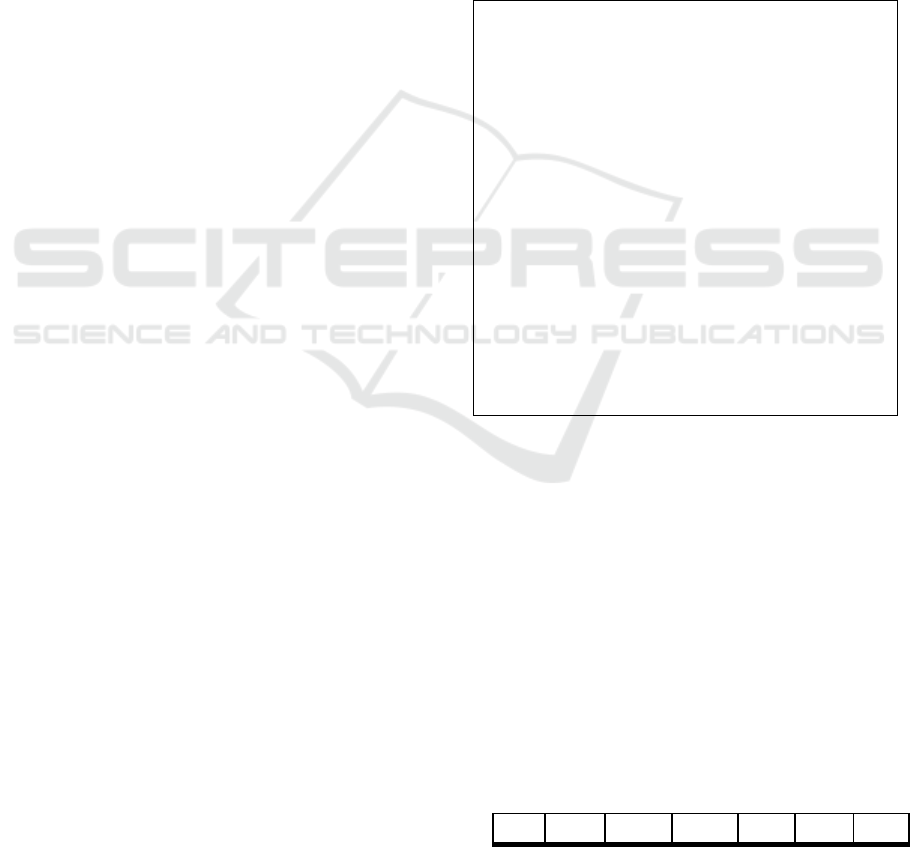

example of a DSM is shown in Figure 1. Element

names are placed on the left hand side of the matrix

as row headings and across the top row as column

headings in the same order of their execution. A

common DSM assumption is that elements are

undertaken in the order listed from top to bottom.

An off-diagonal mark (x) represents dependency

between two elements. If an element i depends on

element j, then the matrix element i j (row

i

, column

j

)

contains an off diagonal mark (x), otherwise the cell

is empty (Abdelsalam and Bao, 2006).

Once the DSM for a product is constructed, it

can be analyzed for identifying modules, a process

referred to as clustering. The goal of DSM clustering

is to find a clustering arrangement where modules

minimally interact with each other while

components within a module maximally interact

with each other. As an example, consider the DSM

shown in Figure 1(a). One can see from Figure 1(b)

that the DSM is rearranged by permuting rows and

columns to contain most of the interactions within

two separate modules: {A, F, E} and {D, B, C, G}.

However, three interactions are left out of any

modules.

Figure 1: Design Structure Matrix.

3 RELATED WORK

The idea of maximizing interactions within modules

and minimizing interactions between modules within

a DSM was proposed by (Eppinger et al., 1994). A

stochastic clustering algorithm using this principle

operating on a DSM was first found in (Idicula,

1995), with subsequent improvements presented by

(Gutierrez, 1998). The proposed algorithm can find

clustering solutions to architecture and organization

interaction problems modelled using DSM method.

Gutierrez, (1998) developed a mathematical model

to minimize the coordination cost to find the optimal

solution for a given number of clusters. A Simulated

annealing algorithm was performed by (Thebeau,

2001) to find clustered DSM with cost minimization

as an objective.

Yassine et al. (2007) used the design structure

matrix (DSM) to visualize the product architecture

and to develop the basic building blocks required for

the identification of product modules. The clustering

method was based on the minimum description

length (MDL) principle and a simple genetic

algorithm (GA).

Borjesson (2009) proposed a method for

promoting better output from the clustering

algorithm used in the conceptual module generation

phase by adding convergence properties, a collective

reference to data identified as option properties,

geometrical information, flow heuristics, and

module driver compatibility.

Van Beek et al. (2010) developed a

modularization scheme based on the functional

model of a system. The k-means clustering was

adopted for DSM based modularization by defining

a proper entity representation, a relation measure

and an objective function. A novel clustering

method utilizing Neural Network algorithms and

Design Structure Matrices (DSMs) was introduced

by (Pandremenos and Chryssolouris, 2012). The

algorithm aimed to cluster components in DSM with

predetermined number of clusters and clustering

efficiency as an objective function.

Borjesson and Hölttä (2012) used IGTA (Idicula-

Gutierrez-Thebeau Algorithm) for clustering

Component-DSM as the basis for their work. They

provided some improvement named IGTA-plus.

IGTA-plus represented a significant improvement in

speed and quality of the solution obtained.

Borjesson and Sellgren (2013) presented an

efficient and effective Genetic clustering algorithm,

with the Minimum Description Length measure. To

significantly reduce the time required for the

algorithm to find a good clustering result, a

A Cuckoo Search Clustering Algorithm for Design Structure Matrix

37

knowledge aware heuristic element is included in the

GA process. The efficiency and effectiveness of the

algorithm is verified with four case studies.

Yang et al. (2014) provided a systematic

clustering method for organizational DSM. The

proposed clustering algorithm was able to evaluate

the clustering structure based on the interaction

strength.

Jung and Simpson (2014) introduced simple new

metrics that can be used as modularity indices

bounded between 0 and 1, and also utilized as the

objective functions to obtain the optimal DSM. The

optimum DSM was the one with the maximized

interactions within modules and the minimized

interactions between modules.

Kim et al. (2015) provided a new approach for

product design by integrating assembly and

disassembly sequence structure planning.

We conclude from all the above that there are

few techniques to cluster DSM for modularity which

differ mainly in the clustering objective. Cost

minimization is one of the first clustering objectives

in which each DSM element is placed in an

individual cluster and components are then,

coordinated across modules to minimize the cost of

being inside and outside a cluster. The maximum

number of components in a cluster is predetermined

to prevent forming large clusters. A clustered DSM

can be compared to a targeted DSM topology using

another objective function called Minimal

Description Length (MDL). MDL finds

mismatching elements between the two topologies.

The objective of clustering is to minimize MDL. The

number of clusters is determined a priori based on

the DSM structure. Clustering Efficiency (CE) index

is another clustering objective that evaluates a

weighed count of zero elements inside clusters and

non-zero elements outside clusters with a predefined

number of clusters.

In this research, a new optimization algorithm,

called the cuckoo search algorithm (CS) algorithm,

is introduced for solving the clustering problem of

DSM. To the best of our knowledge, this is the first

time CS is used to design products under modularity

with variable number of clusters, while prohibiting

overlapping between clusters.

4 PROBLEM DEFINITION

The problem presented in this work considers two

decision variables: (1) the number of clusters to be

formed and (2) the optimal assignment of elements

to each cluster. The objective function is to

minimize the total coordination cost. The total

coordination cost of the DSM to be clustered is

based on IntraClusterCost and ExtraClusterCost as

shown in equations 1 and 2,

intraClusterCost

ClusterSize

j

DSM

,∈

DSM

(1)

ExtraClusterCost

DSM

,∉

DSM

DSMSize

,

j1…ncluster

(2)

where DSM

ik

is the coupling between elements i

and k, DSMSize is the number of elements (rows) in

the matrix, powcc is the exponent used to penalize

the size of clusters, and ncluster is the total number

of clusters. clustersize is the number of elements in

cluster j (Borjesson and ltta, 2014).

Total coordination Cost = ExtraClusterCost +

IntraClusterCost

Subject to the constraint that each element is

assigned only to one cluster, in other words, overlap

between clusters is not allowed. Prohibiting overlap,

or multi-cluster elements, is important for the

following reasons: when allowing elements to be

assigned in multiple clusters, the importance and

usefulness of the clustering algorithm will be

diminished or eliminated. If elements exist in more

than one cluster, this forces interactions between

these clusters on multi levels. We would like the

elements to be placed with other elements that are

very similar (Pandremenos and Chryssolouris,

2012).

Modularity affects both the profit and the

sustainability of the product. A modular product

contains modules that can be removed and replaced.

The manufacturer can develop new modules instead

of entirely new products. Therefore, customers

buying upgraded modules only dispose of a portion

of the product, thus reducing the total amount of

waste. Hence, a customer upgrading a module does

not have an entirely new product.

5 PROPOSED ALGORITHM

Yang and Deb (2009) proposed a new Meta heuristic

algorithm called cuckoo search (CS). They tried to

simulate the behaviour of cuckoos to examine the

solution space for optimization. The algorithm was

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

38

inspired by the obligate interspecific brood

parasitism of some cuckoo species that lay their eggs

in the nests of host birds of other species. The aim is

to escape the parental investment in raising their

offspring. This strategy is also useful to minimize

the risk of egg loss to other species, as the cuckoos

can distribute their eggs amongst a number of

different nests.

Of course, sometimes it happens that the host

birds discover the alien eggs in their nests. In such

case, the host bird takes different responsive actions

varying from throwing such eggs away, to simply

leaving the nest and building a new one elsewhere.

On the other hand, the brood parasites have their

own sophisticated characteristics to ensure that the

host birds will care for the nestlings of their

parasites. Examples of these characteristics are

shorter egg incubation periods, rapid nestling

growth, and egg coloration or pattern mimicking

their hosts (Li and Yin, 2015).

Many testing functions are used to prove the

effectiveness of the algorithm, for example,

Michaelwicz function, Rosenbrock’s function, etc.

They prove that the CS algorithm is efficient. When

comparing results with existing GA and PSO’s,

cuckoo search performs better (Yang and Deb,

2010). Another major advantage of CS when

compared to other metaheuristic algorithms, is its

simplicity since it requires only two parameters.

This feature reduces the effort of adjustment and

fine tuning of parameter settings.

In cuckoo search, each egg can be regarded as a

solution. In the initial process, each solution is

generated randomly. When generating the i

th

solution in t + 1 generation, denoted by X

i

t+1

a levy

flight is performed as shown in equation 3,

X

i

t+1

= X

i

t

+ α ⨁ Levy(λ)

(3)

Where α > 0 is a real number denoting the step size,

which is related to the sizes of the problem of

interest, and the⨁ product denotes entry-wise

multiplications. A Levy flight is a random walk

where the step-lengths are distributed according to a

heavy-tailed probability distribution as shown in

equation 4.

Levy ∼ u = t −λ, (1 < λ ≤ 3)

(4)

The CS algorithm is based on three idealized

rules (Navimipour and Milani, 2015).

(1) Each cuckoo lays one egg at a time and

dumps it in a randomly chosen nest.

(2) The best nests with high quality eggs

(solutions) will be carried over to the next

generations.

(3) The number of available host nests is fixed,

and a host can discover an alien egg with a

probability

∈

[0, 1]. In this case, the host bird

can either throw the egg away or abandon the nest to

build a completely new nest in a new location.

For simplicity, the third assumption can be

approximated by a fraction of the nests being

replaced by new nests (with new random solutions at

new locations). For a maximization problem, the

quality or fitness of a solution could be proportional

to the objective function. However, other more

sophisticated expressions for the fitness function can

also be defined.

Based on these three rules, the basic steps of the

CS algorithm are summarized in the pseudo code in

Figure 2.

Objective function f(x), x = (x1, ..., xd)

T

;

Initial population of n host nests xi (i = 1, 2, ..., n);

while (t <MaxGeneration) or (stop criterion);

Get a cuckoo (i) randomly using Levy flights;

Evaluate its quality/fitness Fi;

Choose a nest among n (j) randomly;

if (Fi > Fj),

Replace j with the new solution;

end

Abandon a fraction (pa) of worse nests

and build new ones at new locations via Levy flights;

Keep the best solutions (or nests with quality solutions);

Rank the solutions and find the current best;

end while

Postprocess results and visualisation;

Figure 2: pseudo code of CS (Yildiz, 2013).

5.1 Solution Representation

The CS algorithm will be used to solve the problem

defined in Section 4. Solution representation of the

problem is a vector of size equals to the number of

elements in the DSM. Each cell in the vector takes

an integer value between 1 and the number of

clusters, as show in Figure 3. The vector in Figure 3

with size 7 represents a solution, where the DSM

Contains 7 elements. Elements 1 and 7 belong to

cluster 1, elements 2, 3, 4 belong to cluster 2, and

elements 5, 6 belong to cluster 3. This solution

representation forces the element to be a member of

only one cluster.

13 3 2 2 2 1

Figure 3: Solution representation vector.

A Cuckoo Search Clustering Algorithm for Design Structure Matrix

39

Assume that we start with the maximum possible

number of clusters, which equals to the number of

elements in the DSM. The next step is to try to find

the optimal number of clusters after deleting empty

clusters. Such representation of the problem will not

allow multi-clustering, which means each element

will be assigned to only one cluster.

This problem will be solved using Cuckoo search

algorithm (CS). CS solves continuous types of

variables. Since the problem in hand is categorized

as a discrete variable problem, the solutions should

be converted from continuous to discrete. This is

done by the discretization of the continuous space by

transforming the values into a limited number of

possible states. There are several discretization

methods available in the literature, for example:

random key technique is used to transform from

continues space to discrete integer space, to decode

the position, the nodes are visited in ascending order

for each dimension (Chen et al., 2011). The smallest

position value (SPV) method maps the positions of

the solution vector by placing the index of the lowest

valued component as the first item on a permutated

solution, the next lowest as the second, and so on

(Verma and Kumar, 2012). The nearest integer

method is another technique, to transform

continuous variables to integer variables. In the

nearest integer method, a real value is converted to

the nearest integer (NI) by rounding or truncating up

or down (Burnwal and Deb, 2012).

Considering the above mentioned methods, SPV,

and random key methods, are not suitable for the

problem presented in this work. This is because

integer value(s) need to be repeated, while these

methods result in unique values. Therefore, the

suitable method for the problem in hand is the

nearest integer method since it allows the repetition

of values by truncating to the higher or lower value.

In CS, we start with a set of nests; each nest is a

vector of length that equals to the number of

elements in the DSM. This vector contains random

numbers following uniform distribution in the range

from lower and upper limits, these random numbers

are converted to integer values using the nearest

integer method. Each one of these integer numbers

represent a solution that could be sent for the

evaluation function. The evaluation function returns

the total coordination cost.

5.2 Solution Evaluation

The total coordination cost of the DSM to be

clustered is based on IntraClusterCost and

ExtraClusterCost as explained in section 4.

Regarding intracluster cost, if interaction DSM

ik

belongs to cluster j, then calculate intra cluster cost.

On the other hand, if interaction DSM

ik

does not

belong to cluster j, calculate the extra cluster cost.

The first step in calculating the total coordination

cost is to start with the total number of interactions

in the DSM multiplied by the size of the DSM raised

to the power powcc. This is the highest value of total

coordination. This value will be minimized in

subsequent steps of the algorithm after forming

clusters. After completion of the evaluation step,

select the best solution and go to the next best

solution using Levy flight carrying the best nests

with high quality of eggs (solutions) over to the next

generations. Continue till the stopping condition is

reached.

6 EXPERIMENTAL RESULTS

AND ANALYSIS

In this section we examine the CS algorithm on

different problems. We use 2 small size and 1 large

size problem. The first small size problem has a

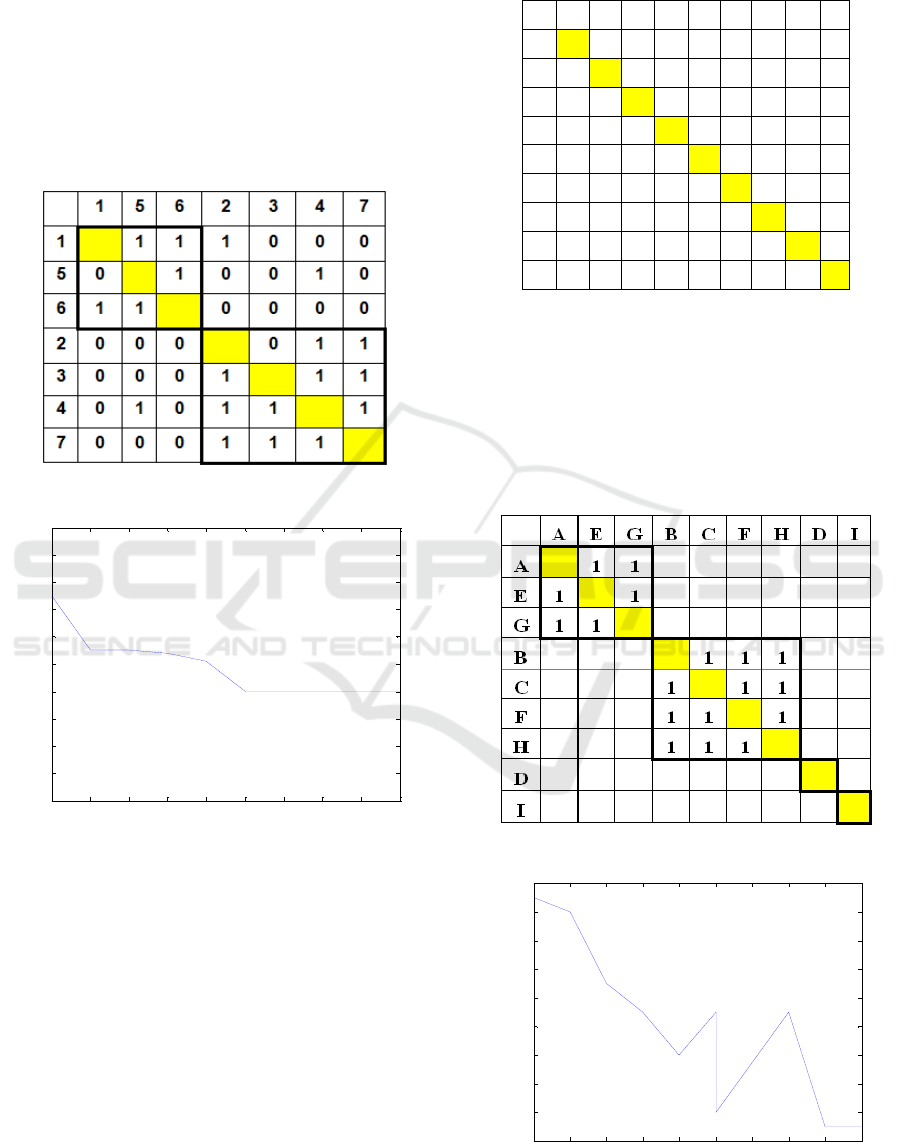

DSM that contains 7 elements as shown in figure

4.The DSM starts initially with a total coordination

cost of 68. This cost is based on assigning each

element in it is own cluster. No clusters are formed

yet, and powcc=0.65.

Figure 4: Original DSM.

After applying the CS clustering algorithm, the

clustered DSM is as shown in Figure 5. The Total

coordination cost is reduced to 48. Thebeau (2001)

solved the same problem and obtained a total

coordination cost of 53, hence, our proposed CS is

able to obtain better results. The minimum number

of clusters using the proposed CS algorithm is 2.

Figure 6 shows the total cost as it changes with

every iteration. The best solution is obtained in

iteration number 575. The CPU run time ranges

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

40

from 0.07 seconds to 0.39 seconds for 100 to 1000

iterations, respectively.

It is noticed that, in the clustered DSM two

clusters are formed and most interactions are

included in clusters. This means that, similar

elements are grouped in the same cluster. In this

case intracost is larger than the extracost which

improves the objective function value. Only 3

interactions are placed outside clusters (number of

1's).

Figure 5: Clustered DSM.

Figure 6: Cost history for CS algorithm-best solution.

We examined the developed algorithm on

another problem presented in (Yassine et al., 2007).

The DSM of the problem has 9 elements as shown in

Figure 7.

Figure 8 shows the clustered DSM after using CS

algorithm. The total coordination cost after

clustering with CS is 41.8. The corresponding

number of clusters is 4. The resulting DSM clustered

using our proposed CS algorithm is the same as the

one obtained in (Yassine et al., 2007). Figure 9

shows the total cost as it changes with every

iteration. The best solution is obtained in iteration

number 880. The CPU run time ranges from 1.07

seconds to 7.52 seconds for 100 to 1000 iterations,

respectively.

A B C D E F G H I

A 1 0 0 0 1 0 1 0 0

B 0 1 1 0 0 1 0 1 0

C 0 1 1 0 0 1 0 1 0

D 0 0 0 1 0 0 0 0 0

E 1 0 0 0 1 0 1 0 0

F 0 1 1 0 0 1 0 1 0

G 1 0 0 0 1 0 1 0 0

H 0 1 1 0 0 1 0 1 0

I 0 0 0 0 0 0 0 0 1

Figure 7: Original DSM.

We notice from Figure 8 that, in the clustered

DSM four clusters are formed, cluster 1 with the

most similar 3 elements , cluster 2 with the most

similar 4 elements, cluster 3 with 1 element and

cluster 4 with 1 element. All interactions are

included in clusters. In this case, there are no extra

costs because no 1's are outside clusters.

Figure 8: Clustered DSM.

Figure 9: Cost history for CS algorithm-best solution.

100 200 300 400 500 600 700 800 900 1000

40

42

44

46

48

50

52

54

56

58

60

Number of iterations

Total Cost

100 200 300 400 500 600 700 800 900 1000

40

42

44

46

48

50

52

54

56

58

Number of Iterations

Total Cost

A Cuckoo Search Clustering Algorithm for Design Structure Matrix

41

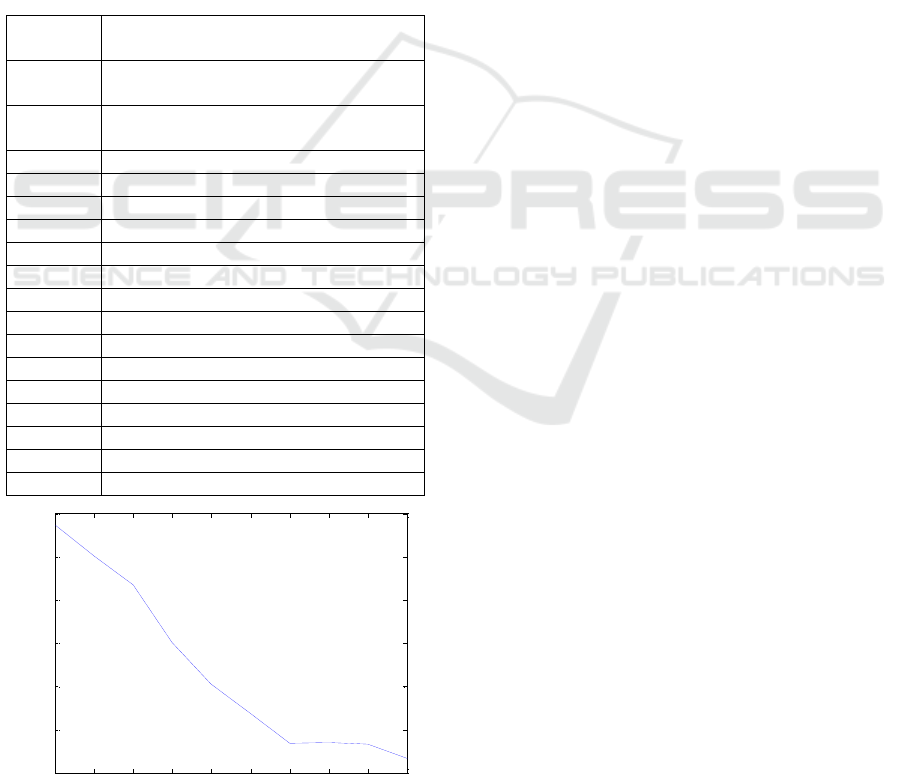

To further evaluate the proposed CS algorithm

we apply it on a large size problem, available in

(Thebeau, 2001) . The DSM contains 61 elements

and represents an elevator example. The total

coordination cost obtained using the CS algorithm is

4133.25, with a total number of 17 clusters. The

total coordination cost obtained in (Thebeau, 2001)

is 4433. Accordingly, our proposed CS algorithm is

able to obtain superior results when compared to the

results obtained by (Thebeau, 2001). Cluster

assignments of the elevator example using the CS

algorithm are shown in Table 1. The best solution is

obtained in iteration number 680. The CPU run time

5461.7 seconds after 1000 iterations.

Figure 10 shows the total cost as it changes with

every iteration.

Table 1: results obtained using CS algorithm for the

elevator example.

Cluster

N

umbe

r

Elements that cluster contains

1 1,3,5,11,15,17,18,20,22,28,34,35,37,3

9,40,41,43,47,48,50,59,60,61

2 2,8,12,16,19,21,26,27,32,33,44,46,49,

54

3 4

4 6,9,13

5 7

6 10,14,25,55

7 20

8 22,53

9 23,31

10 24

11 30

12 36

13 51

14 52

15 56

16 57

17 58

Figure 10: Cost history for CS algorithm–best solution.

7 CONCLUSION AND FUTURE

WORK

The design of products under modularity is a

problem that captured the attention of many

researchers. One method to perform modular

product design is through representation and

clustering of a DSM. Clustering of a DSM in this

work requires solving for 2 decision variables: the

number of clusters to form, and the assignment of

elements to each cluster. The objective function is to

minimize the total coordination cost, subject to one

constraint, namely, assigning each element to one

cluster and prohibiting clusters' overlap. To perform

the clustering of DSM we employed cuckoo search

(CS) algorithm. The CS algorithm has proved its

efficiency in solving many problems in terms of

simplicity, speed, and solution quality. We applied

the CS algorithm on a number of DSM test problems

available in the literature. Results show that the

proposed CS obtained superior or similar results to

those available in the literature. Future work

includes developing a model that restricts the

number of elements within each cluster,

incorporating sustainability concepts, and consider

the number of clusters as part of the objective

function.

REFERENCES

Abdelsalam, H. M., Rasmy, M. H., & Mohamed, H. G.

(2014). A Simulation-Based Time Reduction

Approach for Resource Constrained Design Structure

Matrix. International Journal of Modeling and

Optimization , 4 (1), 51-55.

Abdelsalam, H., & Bao, H. (2006). A Simulation-based

Optimization Framework for Product Development

Cycle Time Reduction. IEEE Transactions on

Engineering Management , 53 (1), 69-85.

Aguwa, C. C., Monplaisir, L., & Sylajakumar, P. A.

(2012). Effect of Rating Modification on a Fuzzy-

Based Modular Architecture for Medical Device

Design and Development. Advances in Fuzzy Systems .

Borjesson, F., & Hölttä-Otto, K. (2012). Improved

clustering algolrithm for design structure matrix.

ASME 2012 International Design Engineering

Technical Conferences & Computers and Information

in Engineering Conference (pp. 1-10). Chicago, IL,

USA: IDETC/CIE 2012.

Borjesson, F., & ltta-Otto, K. H. (2014). A module

generation algorithm for product architecture based on

component interactions and strategic drivers. Research

in Engineering Design , 25 (1), 31-51.

Borjesson, F., & Sellgren, U. (2013). Fast Hybrid Genetic

Clustering Algorithm for Design Structure Matrix.

100 200 300 400 500 600 700 800 900 1000

4100

4200

4300

4400

4500

4600

4700

Number of iterations

Total Cost

ICORES 2016 - 5th International Conference on Operations Research and Enterprise Systems

42

25th International Conference on Design Theory and

Methodology. Portland, Oregon, USA: ASME 2013.

Borjesson, F. (2009). Improved output in modular function

deployment using heuristics. International conferance

on engineering design, (pp. 24-27). Stanford,USA.

Burnwal, S., & Deb, S. (2012). Scheduling optimization of

flexible manufacturing system using cuckoo search-

based approach. The International Journal of

Advanced Manufacturing Technology, 64, 1-9.

Chen, H., Li, S., & Tang, Z. (2011). Hybrid gravitational

search algorithm with random-key encoding scheme

combined with simulated annealing. International

Journal of Computer Science and Mobile Computing,

11 (6), 208-217.

Eppinger, S., Whitney, D., Smith, R., & Gebala, D.

(1994). A model based method for organizing tasks in

product development. Research in Engineering Design

, 1–13.

Gutierrez, C. I. (1998). Integration analysis of product

architecture to support effective team co-location.

Cambridge: Masters thesis, Massachusetts Institute of

Technology.

Gwangwava, N., Nyadongo, S., Mathe, C., & Mpof, K.

(2013). Modular Clusterization Product Design

Support System. International Journal of Advances in

Computer Science and Technology (IJACST) , 2 (11),

8-13.

Idicula, J. (1995). Planning for concurrent engineering.

Singapore: Gintic Institute Research .

Jung, S., & Simpson, T. W. (2014). A Clustering Method

Using New Modularity Indices and Genetic Algorithm

with Extended Chromosomes. DSM 14 Proceedings of

the 16th International DSM conference: Risk and

Change management in complex systems, (pp. 167-

176).

Kim, S., Baek, J. W., Moon, S. K., & Jeon, S. M. (2015).

A New Approach for Product Design by Integrating

Assembly and Disassembly Sequence Structure

Planning. 247-257.

Li, X., & Yin, M. (2015). Modified cuckoo search

algorithm with self adaptive parameter method.

Information Sciences , 298, 80–97.

Navimipour, N. J., & Milani, F. S. (2015). Task

Scheduling in the Cloud Computing Based on the

Cuckoo Search Algorithm. International Journal of

Modeling and Optimization , 5 (1), 44-47.

Pandremenos, J., & Chryssolouris, G. (2012). A neural

network approach for the development of modular

product architectures. International Journal of

Computer Integrated Manufacturing, 1-8.

Thebeau, R. (2001). Knowledge management of system

interfaces and interactions for product development

process. Massachusetts Institute of Technology.

van Beek, T. J., Erden, M. S., & Tomiyama, T. (2010).

Modular design of mechatronic systems with function

modeling. Mechatronics , 20 (8), 850–863.

Verma, R., & Kumar, S. (2012). DNA sequence assembly

using continuous particle swarm optimization with

smallest position value rule. First International

Conference on Recent Advances in Information

Technology, (pp. 410-415 ).

Yang, Q., Yao, T., Lu, T., & Zhang, B. (2014). An

Overlapping-Based Design Structure Matrix for

Measuring Interaction Strength and Clustering

Analysis in Product Development Project. IEEE

TRANSACTIONS ON ENGINEERING

MANAGEMENT , 61 (1), 159-170.

Yang, X., & Deb, S. (2009). Cuckoo search via Levy

flights. the World Congress on Nature and

Biologically Inspired Computing (NABIC ’09) (pp.

210–214). Coimbatore, India: IEEE.

Yang, X.-s., & Deb, S. (2010). Engineering Optimisation

by Cuckoo Search. International Journal of Math

Model Numerical Optimization, 1 (4), 330-343.

Yassine, A. A., Yu, T.-L., , & Goldberg, D. E. (2007). An

information theoretic method for developing modular

architectures using genetic algorithms. Research in

Engineering Design , 18, 91-109.

Yildiz, A. R. (2013). Cuckoo search algorithm for the

selection of optimal machining parameters in milling

operations. international Journal of Advanced

Manufacturing Technology , 64 (1), 55-61.

A Cuckoo Search Clustering Algorithm for Design Structure Matrix

43