Direct Detection of Bacteria on Fresh Produce

Shin Horikawa

1

, Yating Chai

1

, Howard C. Wikle

1

, James M. Barbaree

2

and Bryan A. Chin

1

1

Materials Research and Education Center, Auburn University, Auburn, Alabama 36849, U.S.A.

2

Department of Biological Sciences, Auburn University, Auburn, Alabama 36849, U.S.A.

Keywords:

Direct Detection, Bacteria, Fresh Produce, Magnetoelastic Biosensor, Phage, Surface-Scanning Detector.

Abstract:

This paper presents a revolutionary method of bacterial detection that directly detects and quantifies the pres-

ence of specific bacteria on the surfaces of fresh produce without sample preparation (water rinse, soak, stom-

aching) and/or enrichment. The speed of detection is from 2 to 10 minutes with a limit of detection in a

range of 10

2

to 10

4

cfu/mm

2

. The specificity of detection is 2 in 10

6

background bacteria. This technology

was awarded a $20,000 prize in the first United States Food and Drug Administration (FDA) Food Safety

Challenge. The method combines wireless magnetoelastic (ME) biosensors and a surface-scanning detector

for rapid determination of bacterial contamination. Tests were conducted on tomatoes and grapes spiked with

different concentrations of Salmonella Typhimurium. The resonant frequency changes of the biosensors were

found to be dependent on the surface concentration of Salmonella. Detection limits were found to be affected

by the surface roughness of the food. A 90-second video of a test for Salmonella on tomato can be viewed at

http://eng.auburn.edu/food-safety. The method presented in this paper is envisioned for use at ports of entry

for the swift screening of foods.

1 INTRODUCTION

The past decades have been marked by a global in-

crease in the outbreaks of food poisoning and asso-

ciated illnesses. These public health problems are

caused by the accidental supply and consumption of

contaminated food, largely due to improper safety

knowledge, perspectives, and practices of food pro-

ducers as well as insufficient consumer awareness.

Although substantial progress on food safety reg-

ulations has been made worldwide, up to 30% of

the population even in industrialized countries suffer

from foodborne illnesses each year (WHO, 2007). In

the United States, approximately 48 million cases of

foodborne illnesses are estimated to occur annually,

resulting in 128,000 hospitalizations, 3,000 deaths,

and $51.0 to $77.7 billion economic losses (Scallan

et al., 2011a; Scallan et al., 2011b; Scharff, 2012).

Salmonella is one of the most pervasive food prob-

lems today. In the past years in the United States,

$1.1 billion was lost, and over 3,000 individuals were

confirmed sick due to Salmonella food contamination

(2008 tomato, 2009 peanut butter, and 2010 egg out-

breaks). Since foodborne illnesses spread so easily,

rapid, on-site detection can play an important role

in preventing the spread of contamination. However,

current detection methods of Salmonella can take up

to several days, causing delays in contacting con-

sumers, removing food items from the marketplace,

and preventing producers from selling products while

the commodity remains stored in warehouses. In this

work, we present a revolutionary bacterial detection

method that allows for testing of contamination to be

completed in only a matter of minutes without sample

preparation (water rinse, soaking, stomaching, con-

centration, etc.) and/or enrichments in the testing pro-

cess. The method combines phage-coated magnetoe-

lastic (ME) biosensors and a surface-scanning detec-

tor, which can be used on site at ports of entry, food

processing facilities and in agriculture fields for food

inspection and outbreak investigation.

2 MATERIAL AND METHODS

2.1 Fabrication of ME Biosensor

Platforms

Strip-shaped ME biosensor platforms (length × width

× thickness: 1 mm × 0.2 mm × 30 µm) were fab-

ricated by dicing a commercially available Metglas

2826MB ribbon (Metglas, Inc.). The diced biosensor

platforms were, then, coated successively with thin

48

Horikawa, S., Chai, Y., Wikle, H., Barbaree, J. and Chin, B.

Direct Detection of Bacteria on Fresh Produce.

DOI: 10.5220/0005670100480053

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 1: BIODEVICES, pages 48-53

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

layers of chromium (90 nm in thickness) and gold

(150 nm in thickness) by electron-beam induced de-

position. The chromium layer acts as an adhesive in-

terlayer. The gold layer provides corrosion resistance

as well as a ready surface for the immobilization of

a phage probe. Before and after the metal deposi-

tion, annealing was performed in vacuum at 220

◦

C

for 2 hrs to relieve residual internal stresses and cor-

rect any surface defects from the fabrication processes

(Chai et al., 2012; Chai et al., 2013c; Chai et al.,

2013b; Chai et al., 2013a; Li et al., 2010; Horikawa

et al., 2011; Horikawa et al., 2014b; Horikawa et al.,

2014a).

2.2 Preparation of E2 Phage and

Salmonella Typhimurium

E2 phage was derived from a landscape f8/8 phage

library (Sorokulova et al., 2005) and used as the

biomolecular recognition element for the ME biosen-

sor. E2 phage possesses 10- to 1,000-fold greater

binding affinity for S. Typhimurium over other bacte-

ria. The specificity of detection has been reported to

be 2 in 10

6

background bacteria (Lakshmanan, 2008).

Suspensions of E2 phage (1 × 10

12

virions/ml

in TBS) and S. Typhimurium cells (ATCC 13311,

5 × 10

8

cfu/ml in sterile distilled water) were pre-

pared and provided by Dr. James Barbaree’s group

at Auburn University, Auburn, Alabama, U.S.A. The

concentrated Salmonella suspension was diluted with

sterile distilled water as desired prior to use.

2.3 Phage Immobilization and Surface

Blocking

The fabricated biosensor platforms were individually

immersed in 330 µL of the E2 phage suspension in a

polypropylene PCR tube. The tubes were, then, ro-

tated with a Barnstead LabQuake tube rotator (Fisher

Scientific, Inc.) at 8 rpm for 1 hr. In this way, the

phage was allowed to uniformly attach to the biosen-

sor platforms via physical adsorption. Finally, a wa-

ter rinse was performed to remove loosely attached

phages and TBS buffer residues from the platform

surfaces.

In order to reduce non-specific binding of S. Ty-

phimurium on biosensor surfaces, surface blocking

was performed. The phage-coated biosensors, or

what we call ”measurement sensors,” were individ-

ually immersed in a 330-µl solution of SuperBlock

Blocking Buffer (Thermo Fisher Scientific, Inc.) in a

PCR tube. After 2 hrs of tube rotation at 8 rpm, the

biosensors were collected from the solution and thor-

oughly rinsed with sterile distilled water to be ready

for use. ”Control sensors,” which are not coated with

E2 phage but only surface-blocked with the blocking

buffer, were also prepared and used for determination

of the limits of detection.

∆f ≈ −

∆m

4L

2

WT

s

E

ρ

3

(1− ν)

, (1)

2.4 Principle of Detection

The ME biosensor used in this work is made of

Metglas 2826MB, a magnetostrictive alloy (Li et al.,

2012). Hence, the biosensors can be placed into me-

chanical resonance when subjected to an externally

applied time-varying magnetic field at the right fre-

quency. In this study, the fundamental resonant fre-

quency of longitudinal vibration, f, is of interest, and

thus, an external magnetic field was applied in the di-

rection parallel to the length of the biosensor to excite

such a mode of vibration. For a freestanding, strip-

shaped biosensor, f can be expressed by (Liang et al.,

2007)

f =

1

2L

s

E

ρ(1− ν)

, (2)

where L, E, ρ, and ν denote the length, modulus of

elasticity, density, and Poisson’s ratio of the biosen-

sor, respectively. When this biosensor comes into

contact with S. Typhimurium, E2 phage that is coated

on the biosensor binds specifically with the bacteria,

thereby increasing the total mass of the biosensor by

∆m. This change in mass causes a corresponding

decrease in the biosensor’s resonant frequency. The

mass-induced resonant frequency change, ∆ f, can be

approximated by (Grimes et al., 2011)

where W and T represent the width and thickness

of the biosensor, respectively. By recording ∆ f as a

function of time, real-time monitoring of the presence

of Salmonella on food surfaces can be performed.

Unlike a measurement sensor (with E2 phage), a con-

trol sensor (without E2 phage) does not bind specifi-

cally with S. Typhimurium, which gives a background

resonant frequency shift in the testing environment.

2.5 Construction of the

Surface-Scanning Detector

The surface-scanning detector is a microelectroni-

cally fabricated planar coil that serves as: (1) a driving

coil to magnetically excite the longitudinal vibration

of the biosensor and (2) a pick-up coil to read the res-

onant frequency of the biosensor. The detector was

fabricated using standard microelectronic fabrication

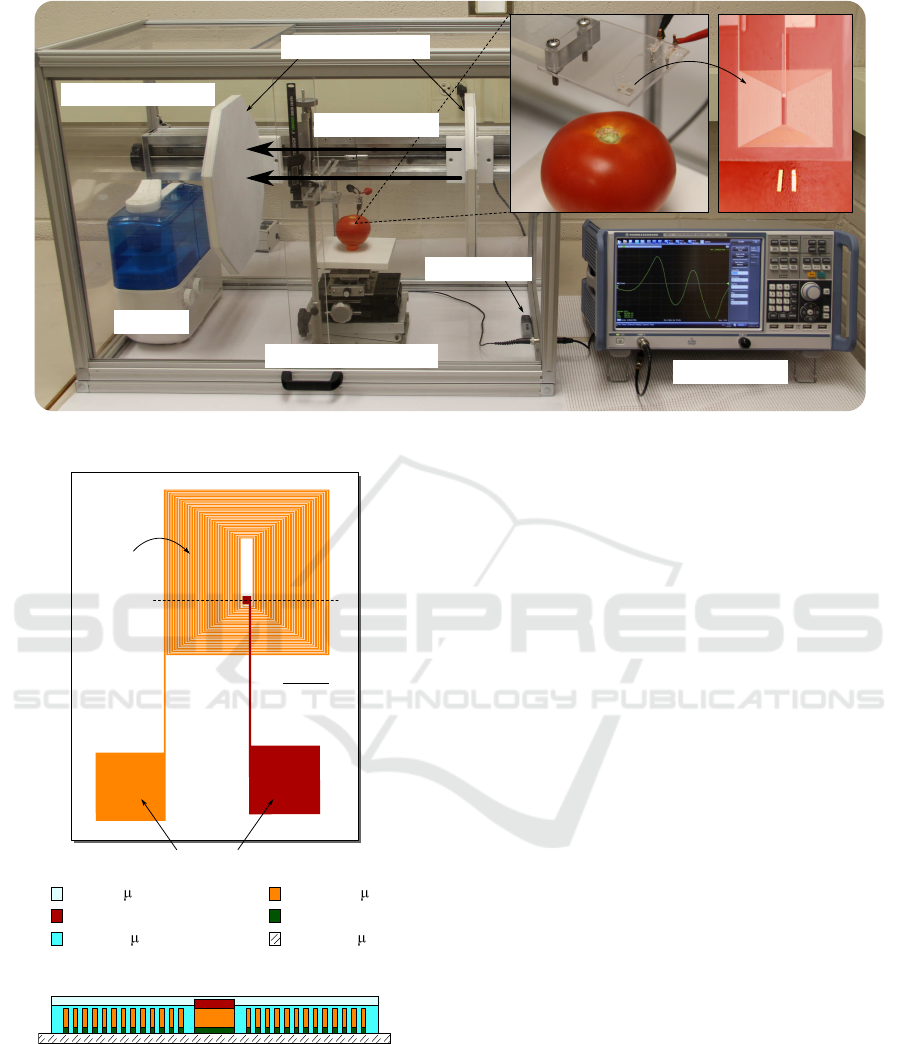

techniques. As shown in Fig. 1, the coil turns, leads,

Direct Detection of Bacteria on Fresh Produce

49

Network analyzer

Humidifier

Environmental chamber

Three-axis translation stage

Humidity sensor

Bias magetic field

Detector

Sensors

Pair of magnetic plates

Figure 2: Measurement setup for the direct detection of S. Typhimurium on food.

Glass (500 m)

Cu turns (8 m)

Ti (10 nm)

SU-8 (5 m)

SU-8 (10 m)

Cu lead and pad (200 nm)

Section AA'

(schematic, not to scale)

A'A

1 mm

Contact pads

Coil turns

Figure 1: Design of the surface-scanning detector.

and contact pads are made of copper, and they reside

on a glass substrate. To promote good adhesion of the

coil to the substrate, titanium was used as the inter-

layer. In addition, SU-8 3005 (MicroChem Corp.), an

epoxy-based photoresist, was used as the insulating

filler and topmost layer.

2.6 Spiking of Fresh Produce with S.

Typhimurium

Fresh tomatoes and grapes were purchased from a lo-

cal grocery store (Kroger) and used as-received. 20-µl

drops of S. Typhimurium with various concentrations

(5 × 10

5

to 5 × 10

8

cfu/ml) were spot-inoculated on

the surfaces of the foods. Salmonella were, then, al-

lowed to dry in air for 2 hrs. Finally, the area of

the Salmonella-spiked spots were measured, which

allows conversion of cfu/ml into cfu/mm

2

(i.e., sur-

face density of S. Typhimurium).

2.7 Measurement Setup and

Experimental Procedure

The measurement setup for the direct Salmonella de-

tection on food consists of a surface-scanning detec-

tor, a 3-axis translation stage, a network analyzer (Ro-

hde & Schwarz ZNC3), a humidifier, a pair of mag-

netic plates, and an environmental chamber as shown

in Fig. 2. ME biosensors were first placed on a

Salmonella-spiked spot on food. The food was, then,

placed between the magnetic plates in the environ-

mental chamber. At this time, the biosensors on the

food can spontaneously align parallel to the direction

of the external magnetic field, which is perpendicular

to the magnetic plates. The 3-axis translation stage

was next used to position the biosensors under the

surface-scanning detector. The detector is connected

to the ZNC3 network analyzer, operated in the S

11

reflection mode. An incident AC power is applied

across the detector to magnetically excite the longi-

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

50

Time (seconds)

Resonant frequency shift, Δf (kHz)

0 50 100 150 200 250 300

0

-0.5

-1

-1.5

-2

-3

-2.5

-3.5

-3

-4

Measurement sensor

Control sensor

Measurement sensor

Control sensor

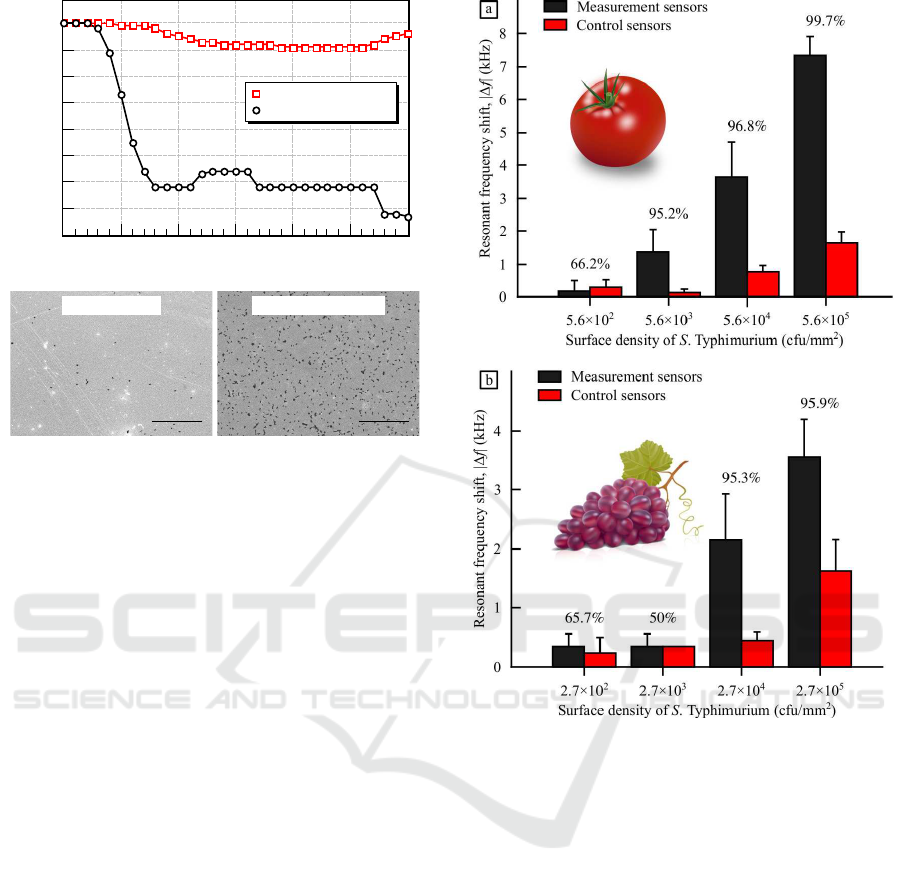

Figure 3: Resonant frequency shifts of biosensors on a

tomato that is spiked with 5.6 × 10

4

cfu/mm

2

S. Ty-

phimurium (open squares: control sensor and open circles:

measurement sensor). Scanning electron micrographs con-

firm the resonant frequency shift results. Salmonella cells

are shown as the black spots in the micrographs (scale bars:

50 µm).

tudinal vibration of the biosensor, and the resultant

reflected power is compared to the incident power

over a selected range of frequencies. In this man-

ner, frequency-dependant reflection coefficient, S

11

,

can be determined for the circuit. At the resonant fre-

quency of the biosensor, the largest change in the re-

flected power of the circuit occurs, which is visible

as a downward peak in the network analyzer output.

To enhance the magnitude of the resonance peak, a

proper bias magnetic field was applied to the biosen-

sor by adjusting the distance between the magnetic

plates. The measurement was conducted at 23

◦

C

and 85% relative humidity. Data were collected every

10 seconds (power: 0 dBm, bandwidth: 1 kHz, fre-

quency span: 100 kHz, number of date points: 2001,

averaging: 10 times, and smoothing aperture: 1 %).

3 RESULTS AND DISCUSSION

3.1 Direct Detection of S. Typhimurium

on Food

Resonant frequency shifts of ME biosensors placed

on the Salmonella-spiked foods were recorded every

10 seconds using the measurement setup described

in Subsection 2.7. Typical test results for a tomato

1

2

3

4

5

0

2 3 4

5

2 3

4

5

1

2

3

4

0

99.7%

96.8%

95.2%

66.2%

95.9%

95.3%

50%65.7%

Figure 4: Dose-response results for (a) tomatoes and (b)

grapes. The numbers shown above the bars are the con-

fidence levels of difference between the measurement and

control sensors at each Salmonella concentration.

spiked with 5.6 × 10

4

cfu/mm

2

Salmonella are shown

in Fig. 3. The resonant frequency shift of a con-

trol sensor (open squares) was found to be negligible

during the measurement. By contrast, a much larger

resonant frequency shift was observed for a measure-

ment sensor (open circles), due to the occurrence of

the phage-based specific binding of the bacteria on

the sensor. Depending on the surfaces of foods and

concentration of S. Typhimurium, the rates of reso-

nant frequencyshifts and detection speeds were found

to vary. In this particular example shown in Fig.

3, S. Typhimurium (5.6 × 10

4

cfu/mm

2

) was de-

tected within 2 minutes. Finally, scanning electron

microscopy was used to confirm the frequency mea-

surement results. A large cell count was found on

the measurement sensor as anticipated, indicating that

specific Salmonella binding had occurred.

In order to determine the limits of detection

Direct Detection of Bacteria on Fresh Produce

51

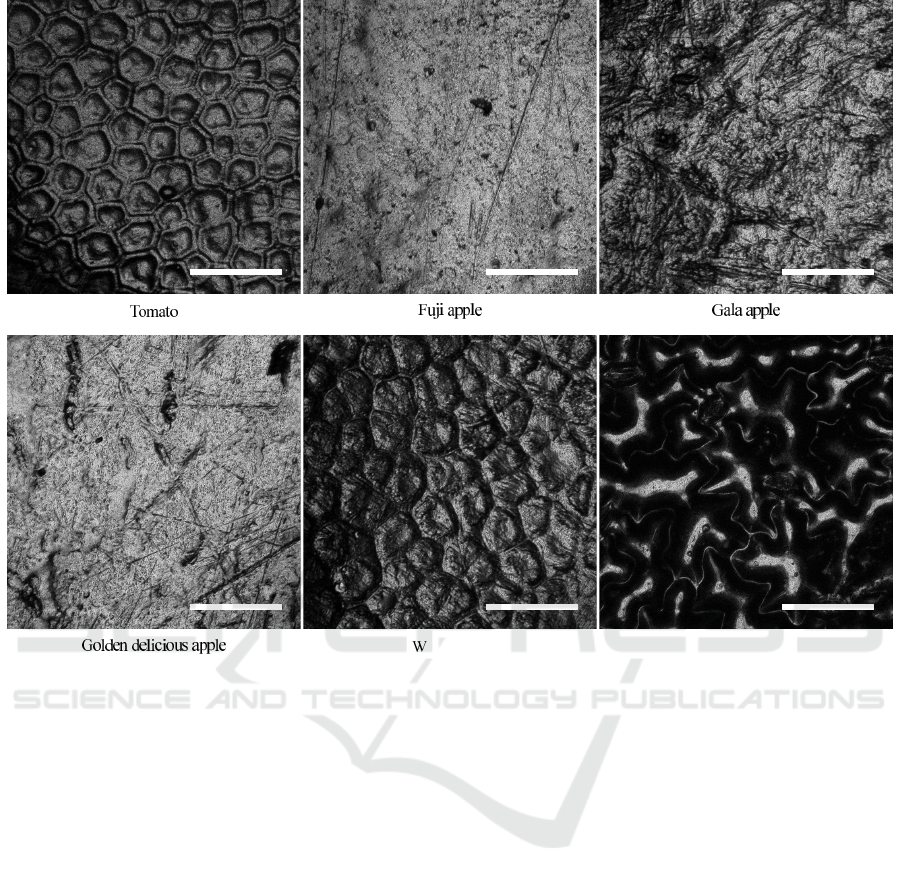

Spinach leaf

atermelon

Figure 5: Surfaces of various fresh produce (scale bars: 100 µm).

(LODs), the biosensors were tested at different

Salmonella concentrations on the food surfaces for 10

minutes. The dose-response results for tomatoes and

grapes are shown in Fig. 4. As anticipated, the reso-

nant frequency shifts of measurement sensors (black

bars) were found to be larger than those of control

sensors (red bars) at high Salmonella concentrations,

which is due to the specific binding of the bacteria

through E2 phage. By contrast, comparable sensor re-

sponses were observed at low Salmonella concentra-

tions, indicating that the limits of detection had been

reached. A one-tailed, unpaired Student’s t-test was

conducted to analyze the degree of dissimilarity be-

tween the measurement and control sensors. The con-

fidence levels of difference were calculated and pre-

sented above the bars at each Salmonella concentra-

tion in Fig. 4. With a confidence level of difference

higher than 95% (p < 0.05), the LODs were deter-

mined to be lower than: (a) 5.6 × 10

3

cfu/mm

2

for

tomatoes and (b) 2.7 × 10

4

cfu/mm

2

for grapes. The

method presented in this paper is a direct bacterial

detection method without sample preparation (con-

centration, purification, washing, etc.) and/or enrich-

ments in the testing process. The speed of detection

was found to be from 2 to 10 minutes, suited for rapid,

on-site pre-screening of food products.

4 FUTURE WORK

The current LODs can be improved by using ME

biosensors with smaller sizes. As can be seen in

Eq. 1, the mass-induced resonant frequency change,

∆f, is inversely proportional to L

2

WT, where L,

W, and T are the length, width, and thickness of

the biosensor, respectively. Smaller biosensors are,

hence, more mass-sensitive and capable of detecting

smaller amounts of pathogens that may be present on

food surfaces. The LOD is also largely dependent on

the surface topography of foods. As shown in Fig.

5, the surface pattern and roughness vary from one

food to another, which necessitates the use of appro-

priate sizes of biosensors for improved pathogen de-

tection. The authors have reported previously an ini-

tial model to calculate the LOD and probability of de-

tection as a function of the size and quantity of biosen-

sors (Horikawa, 2013). The model will be improved

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

52

and used to demonstrate a proof-in-concept in the fu-

ture.

5 CONCLUSIONS

A unique, revolutionary method of bacterial detection

on the surfaces of foods was presented. By combining

phage-coated ME biosensors and a surface-scanning

detector, S. Typhimurium was detected in a range of 2

to 10 minutes without sample preparation and/or en-

richment in the testing process. The method presented

in this paper can be used for rapid, on-site screening

of food products. The pathogen-positive foods deter-

mined by this method can then be sent to lab for con-

firmation and identification tests.

ACKNOWLEDGEMENT

This work was supported by the Auburn University

Detection and Food Safety Center and a grant from

the U.S. Department of Agriculture (USDA-2011-

51181-30642A).

REFERENCES

Chai, Y., Horikawa, S., Li, S., Wikle, H. C., and Chin,

B. A. (2013a). A surface-scanning coil detector for

real-time, in-situ detection of bacteria on fresh food

surfaces. Biosensors and Bioelectronics, 50(0):311 –

317.

Chai, Y., Horikawa, S., Wikle, H. C., Wang, Z., and Chin,

B. A. (2013b). Surface-scanning coil detectors for

magnetoelastic biosensors: A comparison of planar-

spiral and solenoid coils. Applied Physics Letters,

103(17):173510–173510–4.

Chai, Y., Li, S., Horikawa, S., Park, M.-K., Vodyanoy, V.,

and Chin, B. A. (2012). Rapid and sensitive detec-

tion of Salmonella Typhimurium on eggshells by us-

ing wireless biosensors. Journal of Food Protection,

75(4):631 – 636.

Chai, Y., Wikle, H. C., Wang, Z., Horikawa, S., Best, S.,

Cheng, Z., Dyer, D. F., and Chin, B. A. (2013c). De-

sign of a surface-scanning coil detector for direct bac-

teria detection on food surfaces using a magnetoelastic

biosensor. Journal of Applied Physics, 114(10):4504.

Grimes, C. A., Roy, S. C., Rani, S., and Cai, Q. (2011). The-

ory, instrumentation and applications of magnetoelas-

tic resonance sensors: A review. Sensors, 11(3):2809

– 2844.

Horikawa, S. (2013). Real-Time, in-situ Detection of

Pathogenic Bacteria on Food Surfaces Using a

Surface-Scanning Coil Detector and Phage-Based

Magnetoelastic Biosensors. PhD thesis, Auburn Uni-

versity.

Horikawa, S., Bedi, D., Li, S., Shen, W., Huang, S., Chen,

I.-H., Chai, Y., Auad, M. L., Bozack, M. J., Barbaree,

J. M., Petrenko, V. A., and Chin, B. A. (2011). Ef-

fects of surface functionalization on the surface phage

coverage and the subsequent performance of phage-

immobilized magnetoelastic biosensors. Biosensors

and Bioelectronics, 26(5):2361 – 2367.

Horikawa, S., Chai, Y., Wikle, H. C., and Chin, B. A.

(2014a). Autonomous magnetoelastic biosentinels for

the detection and capture of invasive pathogens. ECS

Transactions, 64(1):149–155.

Horikawa, S., Zhao, R., Chai, Y., Wikle, H. C., and Chin,

B. A. (2014b). Self-propelled, phage-based magne-

toelastic biosentinels for detection of pathogens in

liquid. In SPIE Sensing Technology+ Applications,

pages 910805–910805. International Society for Op-

tics and Photonics.

Lakshmanan, R. (2008). Phage-Based Magnetoelastic Sen-

sor for the Detection of Salmonella typhimurium. PhD

thesis, Auburn University.

Li, S., Horikawa, S., Park, M., Chai, Y., Vodyanoy, V. J.,

and Chin, B. A. (2012). Amorphous metallic glass

biosensors. Intermetallics, 30(0):80 – 85.

Li, S., Li, Y., Chen, H., Horikawa, S., Shen, W., Simo-

nian, A., and Chin, B. A. (2010). Direct detection

of Salmonella typhimurium on fresh produce using

phage-based magnetoelastic biosensors. Biosensors

and Bioelectronics, 26(4):1313 – 1319.

Liang, C., Morshed, S., and Prorok, B. C. (2007). Cor-

rection for longitudinal mode vibration in thin slender

beams. Applied Physics Letters, 90:221912.

Scallan, E., Griffin, P. M., Angulo, F. J., Tauxe, R. V., and

Hoekstra, R. M. (2011a). Foodborne illness acquired

in the United States - unspecified agents. Emerging

Infectious Diseases, 17(1):16 – 22.

Scallan, E., Hoekstra, R. M., Angulo, F. J., Tauxe, R. V.,

Widdowson, M.-A., Roy, S. L., Jones, J. L., and Grif-

fin, P. M. (2011b). Foodborne illness acquired in the

United States - major pathogens. Emerging Infectious

Diseases, 17(1):7 – 15.

Scharff, R. L. (2012). Economic burden from health losses

due to foodborne illness in the United States. Journal

of food protection, 75(1):123 – 131.

Sorokulova, I. B., Olsen, E. V., Chen, I.-H., Fiebor, B., Bar-

baree, J. M., Vodyanoy, V. J., Chin, B. A., and Pe-

trenko, V. A. (2005). Landscape phage probes for

Salmonella typhimurium. Journal of Microbiological

Methods, 63(1):55 – 72.

WHO (2007). Food safety and foodborne illness. fact sheet

no. 237.

Direct Detection of Bacteria on Fresh Produce

53