An Overset Mesh Approach for Valve Closure: An LVAD Application

Mohammed G. Al-Azawy

1,2

, A. Turan

1

and A. Revell

1

1

School of Mechanical, Aerospace and Civil Engineering, The University of Manchester, Manchester, U.K.

2

Mechanical Engineering Department, College of Engineering, Wasit University, Wasit, Iraq

Keywords:

Computational Fluid Dynamics (Cfd), Left Ventricular Assist Device (Lvad), Overset Mesh, Non-Newtonian

Flow, Turbulence Modelling.

Abstract:

A comprehensive Computational Fluid Dynamics (CFD) simulation of transient, non-Newtonian, and tur-

bulent blood flow through a positive displacement pump, left ventricular assist device (LVAD), is executed.

Non-Newtonian blood flow is conducted to investigate the flow through a pulsatile pump LVAD by using com-

mon blood viscosity model: Carreau. The numerical results of non-Newtonian fluid with a turbulence model,

Elliptic Blending Reynolds Stress Model (EB-RSM) are presented. The computational domain that has been

selected is a pulsatile pump, which includes valves and a moving pusher plate. An overset mesh zero gap

technique was employed to capture the cyclic motion of pusher plate and valves rotation to mimic the scenario

of a natural heart. The use of this technique to rotate the valves and ensure full valve closure presented a good

agreement results with the experimental data.

1 INTRODUCTION

Fluid mechanical studies inside artificial heart pumps

have been ongoing since the 1970s in an attempt to in-

vestigate and understand the flow behaviour of blood

inside the device in order to predict and mitigate the

blood damage caused by the device.

Artificial heart valves have been used widely in or-

der to assist or replace the natural damage valves. Pre-

viously, the researchers observed that serious prob-

lems associated with the flow around the valves such

as separated and secondary flow, high pressure and

large turbulence shear stress (Kiris et al., 1997; Sti-

jnen et al., 2004). The main causal risks associated

with heart devices, especially with the valves, are

thrombosis and haemolysis, both of which are directly

related to the flow field within the devices.

In simulating the blood flow inside the cardiovas-

cular systems, one of the important issues that needs

to be taken into account is how to treat the nature of

blood flow as a fluid in order to accurately predict and

evaluate the wall shear stress and strain rate. Local

haemodynamics are not only affected by the geome-

try of artificial heart assist devices, properties of flow

as pulsation or not, but also by the natural proper-

ties of blood. Therefore, in the current study, a non-

Newtonian Carreau model has been used to investi-

gate the blood flow within a left ventricular assist de-

vice (LVAD).

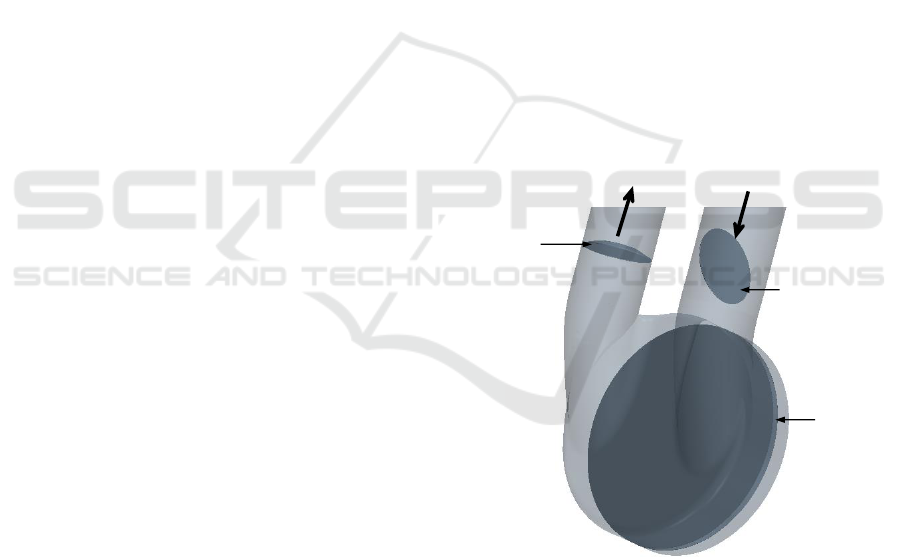

Outlet port

Inlet port

Aortic

valve

Mitral

valve

Pusher

plate

Figure 1: Model Geometry.

A study in 2004 by Yin et al. (Yin et al., 2004) was

performed experimental and numerical study to mea-

sure in vitro the procoagulant properties of platelets

induced by flow through Carbomedics bileaflet and

Bjork-Shiley monoleaflet mechanical heart valves in

a left ventricular assist device. A modified prothrom-

binase method was used to measure the platelet ac-

tivation states during circulation. Wilcox k −ω tur-

bulence model and platelet shear-stress histories were

used to simulate the CFD model of turbulent, transient

Al-Azawy, M., Turan, A. and Revell, A.

An Overset Mesh Approach for Valve Closure: An LVAD Application.

DOI: 10.5220/0005663901450151

In Proceedings of the 9th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2016) - Volume 1: BIODEVICES, pages 145-151

ISBN: 978-989-758-170-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

145

and non-Newtonian blood flow. The results from the

platelet activation states measurements showed that

the bileaflet MHV activated platelets at a rate more

than twice that observed with the monoleaflet MHV.

For simplicity, most numerical simulations as-

sumed the flow around the heart valves to be two di-

mensional (Bluestein et al., 2000) flow and fixed fully

open position such as (Medvitz et al., 2009). The

techniques that can be used for valve simulation is

discussed in this work. Kreider et al. (Kreider et al.,

2006) conducted an experimental work (planer parti-

cle image velocimetry) to analysis the flow field asso-

ciated with the Bjork-Shiley mechanical heart valve

of the 50cc Penn State ventricular assist device. The

authors noticed that there was longer duration wall

washing motion occurring at 45 degree. In most re-

cent study by the authors (Al-Azawy et al., 2016;

Al-Azawy et al., 2015), the valves were assumed

in the fully open position. The authors investigated

unsteady flow inside a 50cc LVAD Penn State, de-

sign V2. The authors tested the laminar and turbu-

lent flow to assess the sensitivity to a range of com-

monly used turbulence models. In this study, six tur-

bulence models have been used: shear stress transport

(SST) k −ω, transition SST, Spalart-Allmaras, k −ε,

Reynolds stress model (RSM), and laminar model.

The CFD model includes valves and a moving pusher

plate, the valves were simulated in their fully open po-

sition and a layering method was employed to move

the pusher plate and capture the cyclic motion. The

results were validated with the numerical and exper-

imental data and showed that the RSM provided the

best agreement with the experimental data over much

of the flow. In parallel with this work, the authors in

this study extended the investigation to use the over-

set mesh technique to rotate the valves and pusher

plate movement. The overset mesh zero gap approach

has been employed to incorporate full valve open-

ing/closing, instead of assuming full opening position

as illustrated in the previous work. The aim of this

study is to evaluate the impact of the overset mesh

approach on the flow around the valves.

2 NUMERICAL MODELLING

In the current study, a model of a ventricular assist de-

vice is constructed. The model to be investigated is a

50cc LVAD test rig V2 design, as described in previ-

ous studies (Medvitz, 2008; Al-Azawy et al., 2016).

This design includes Bjork-Sheily valves and pusher

plate. The valves were simulated without supported

struts for the sake of simplicity; see Figure 1, which

shows the mitral valve (23 mm) in its fully open posi-

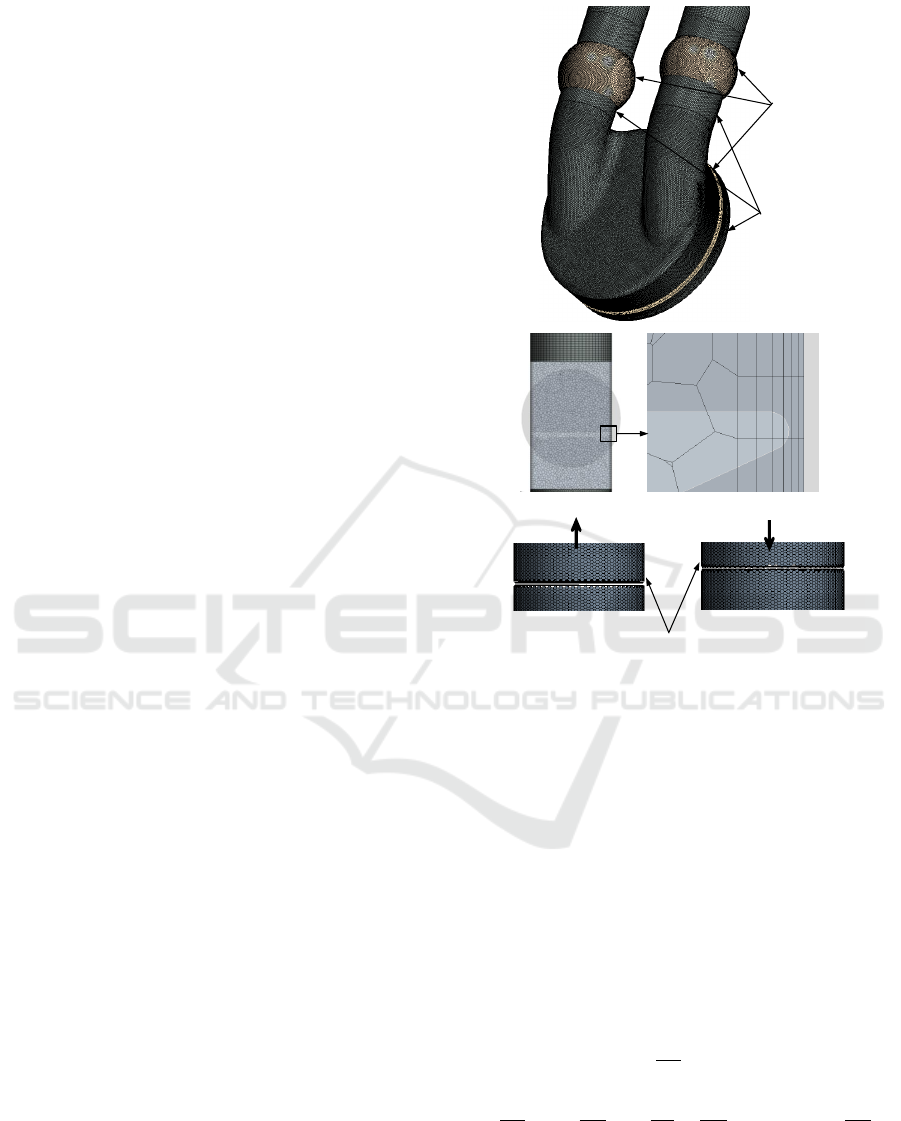

(a)

Overset

region

Background

region

(b)

Inactive cells in

the small gap

(c)

Figure 2: Snapshots of (a) mesh configuration showing the

overset and background regions, (b) the gap between the

background and valve showing the cells and (c) the space

after initialisation.

tion (70 deg) and the aortic valve (21 mm) in its fully

closed position (0 deg). The model was examined

under physiological operating conditions at 4.2 LPM

(litres per minute) and 86 BPM (beats per minute).

All the simulations employed unsteady compu-

tational flow for a full pumping cycle of the three-

dimensional analysis. The simulations were imple-

mented using a finite volume code STAR-CCM+

10.02, a commercially available CFD package (Star-

CCM, 2015), to solve the Navier-Stokes equations:

∂u

i

∂x

i

= 0 (1)

ρ

∂u

i

∂t

+ ρu

j

∂u

i

∂x

j

= −

∂p

∂x

i

+

∂

∂x

j

(µ(|S|) + µ

t

)

∂u

i

∂x

j

(2)

where u

i

is the velocity in i direction (i =

1,2,and3), u

i

= (u,v,w), correspond to the coordi-

nate system, x

i

= (x,y,z), respectively; p is the pres-

sure; and ρ is the density. In the current study we

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

146

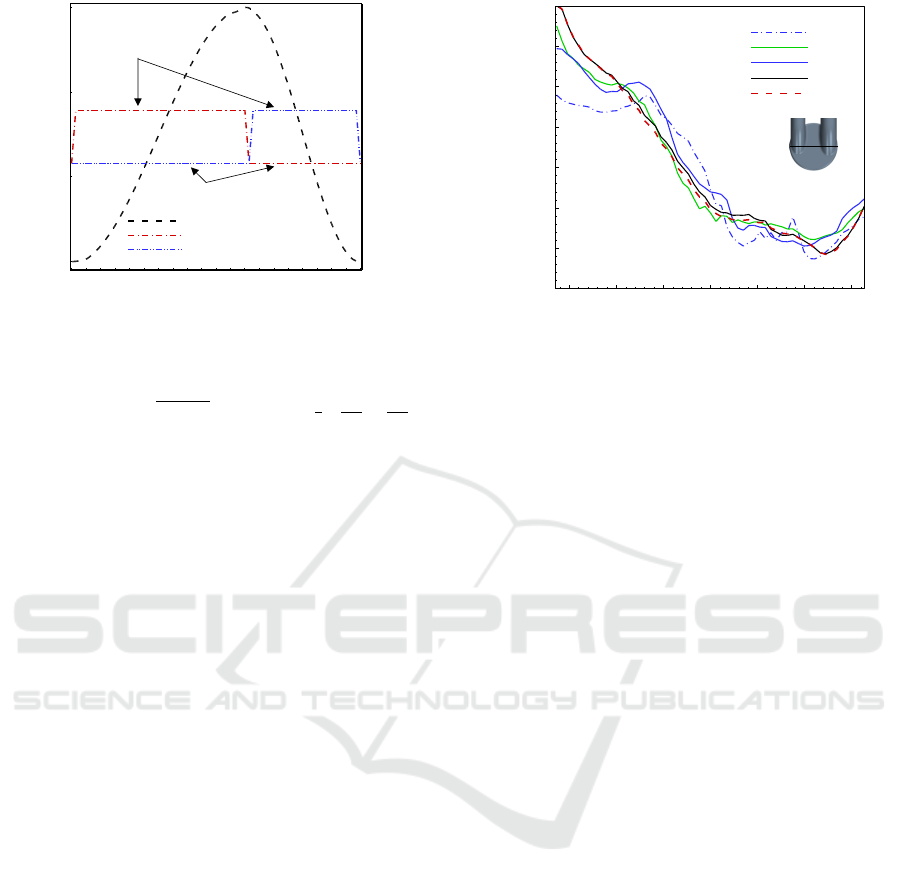

0 0.2 0.4 0.6 0.8 1

0

5

10

15

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

3

Pusher plate movement

Mitral valve movement

Aortic valve movement

Pusher plate displacement(mm)

Fully opened

Fully closed

Valve movement (deg)

t/T

0

70

Figure 3: Valves and pusher plate movement.

have used the non-Newtonian Carreau models, µ(|S|)

is the blood viscosity that depends on the shear rate

magnitude,|S|=

p

2S

i j

S

i j

where S

i j

=

1

2

∂u

i

∂x

j

+

∂u

j

∂x

i

.

The turbulent viscosity, µ

t

, calculated via additional

transport equations representative of the turbulence.

The following expression has been given for the

Carreau model (Carreau, 1972; Johnston et al., 2004):

µ(|S|) = µ

∞

+ (µ

0

−µ

∞

)(1 + (λS)

2

)

(n−1)/2

(3)

where λ is the relaxation time constant (λ =

3.313s), n = 0.3568, µ

0

is the viscosity of blood at

zero shear rate (µ

0

= 0.056pa.s) and µ

∞

is the infinite

shear viscosity (µ

∞

= 0.00345pa.s).

The transport equations are solved by using a seg-

regated flow approach and the SIMPLE algorithm for

pressure-velocity coupling. A second order implicit

unsteady scheme is applied in time, while the spatial

discretisation utilises a second-order upwind scheme

along with a hybrid Gauss-LSQ method is used for

gradient reconstruction. In the present work, the to-

tal and static pressures were set according to in vitro

measurements which indicated a device mean static

pressure rise of 80 mm Hg (Medvitz, 2008). There-

fore, the total and static pressures were set to zero at

the inlet and 80 mm Hg at the outlet respectively.

3 DESCRIPTION OF THE

VALVES AND PUSHER PLATE

MOVEMENT

In positive displacement pump problems, in order to

acquire the desired scenario for the diastolic and sys-

tolic phases, it is necessary to model the valve closure

and the pusher plate movement to maintain unidirec-

tional flow. The times of the valve closing and open-

ing are short compared to the duration of diastole and

Position(m)

Y-velocity (m/s)

-0.03 -0.02 -0.01 0 0.01 0.02 0.03

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

MO1

MO2

MO3

MO4

MO5

Figure 4: Time-averaged y-velocity located on the plane

z/z

c

= 0.53 along a horizontal centreline at time t/T =

0.614.

systole phase. Therefore, in previous study by (Al-

Azawy et al., 2016) the mitral and aortic valves were

fixed in the fully open position during the pump cycle

and to mimic the closed valve as in a natural heart.

Further to this, an interface was fixed above the valves

and introducing it as a wall on one occasion and as

an open interface on another, depending on the cycle

phase. However, there are various methods to model

the valves; either a dynamic mesh, immersed bound-

ary (Peskin, 2002) or a binary flow model (where the

flow is either fully closed or fully open). A variable

viscosity model was implemented by Medvitz (Med-

vitz et al., 2007) to model the valve closing, as used

by Avrahami (Avrahami, 2003) and Stijnen (Stijnen,

2004). In the present study the authors extended the

investigation and used the overset mesh technique to

model the valve rotation, as the authors believe this

will give more accurate results and more insight anal-

ysis for shear stress and strain rate near the valves.

The overset mesh technique (Chimera) has been

successfully used to simulate the flow among the

moving regions with zero gap between the moving

and stationary zones. The overset mesh zero gap in-

terface method has been employed to simulate the

pusher plate movement inside the chamber and valve

rotation with full closure of the valve, as shown in

Figure 2a, which illustrates the background and over-

set regions. In the background zone, where the ac-

tive cells are found, the regular discretised governing

equations are solved, while in the overset mesh, which

contains the inactive or passive cells (these cells will

be active during the movement) no equation is solved.

The inactive cells that separate active and passive are

called the acceptor cells and the active cells along the

interface with the inactive cells are called donor cells.

The interpolation is used to express variable values at

acceptor cells via variable values at donor cells (Star-

An Overset Mesh Approach for Valve Closure: An LVAD Application

147

CCM, 2015).

The closing and opening time of the valves was

short, taking approximately 10 ms (Medvitz, 2008).

Figure 3 illustrates the movements of the pusher plate

and valves; during the diastole the flow enters after

opening the mitral valve as the pusher plate expands

to fill chamber. The mitral valve then closes at the

end of diastolic, whereas during the systole the aor-

tic valve will open and the pusher plate will pump

the flow towards the outlet port and the aortic valve

will close at the end of the systolic period. The cy-

cle is then repeated. The thickness of the chamber

was varied cyclically from a minimum of z/z

c

= 0.21

to a maximum of z/z

c

= 1, where z was the distance

from the front face of the chamber and the chamber

thickness z

c

was 18.8mm corresponding to a maxi-

mum volume of approximately 50cc.

The time of the diastolic phase is (0 ≤t < 0.43s)

while the time of the systolic phase is (0.43 ≤ t <

0.7s), with the velocity of the wall introduced as fol-

lows:

For the diastolic phase:

V

diastole

wall

= A

2π

T

sin

2π

T

t

(4)

For the systolic phase:

V

systole

wall

= A

2π

T

cos

2π

T

t

(5)

where V

wall

is the velocity of the moving wall, the

pusher plate is represented as a function of time, t

is the flow time (sec), A is the distance between the

moving wall and the mid-stroke position, and T is a

one-cycle period (T = 0.7s).

Cycle

0 1 2 3 4 5

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Velocity (m/s)

0 1 2 3 4 5

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Cycle

Velocity (m/s)

Figure 5: Evolution of velocity magnitude at point in the

chamber.

4 COMPUTATIONAL DETAILS

The following five computational meshes have

been used: MO1 (957,573), MO2 (1,511,511),

MO3 (2,944,787), MO4 (4,030,158), and MO5

(5,614,830). These meshes were created by

t/T

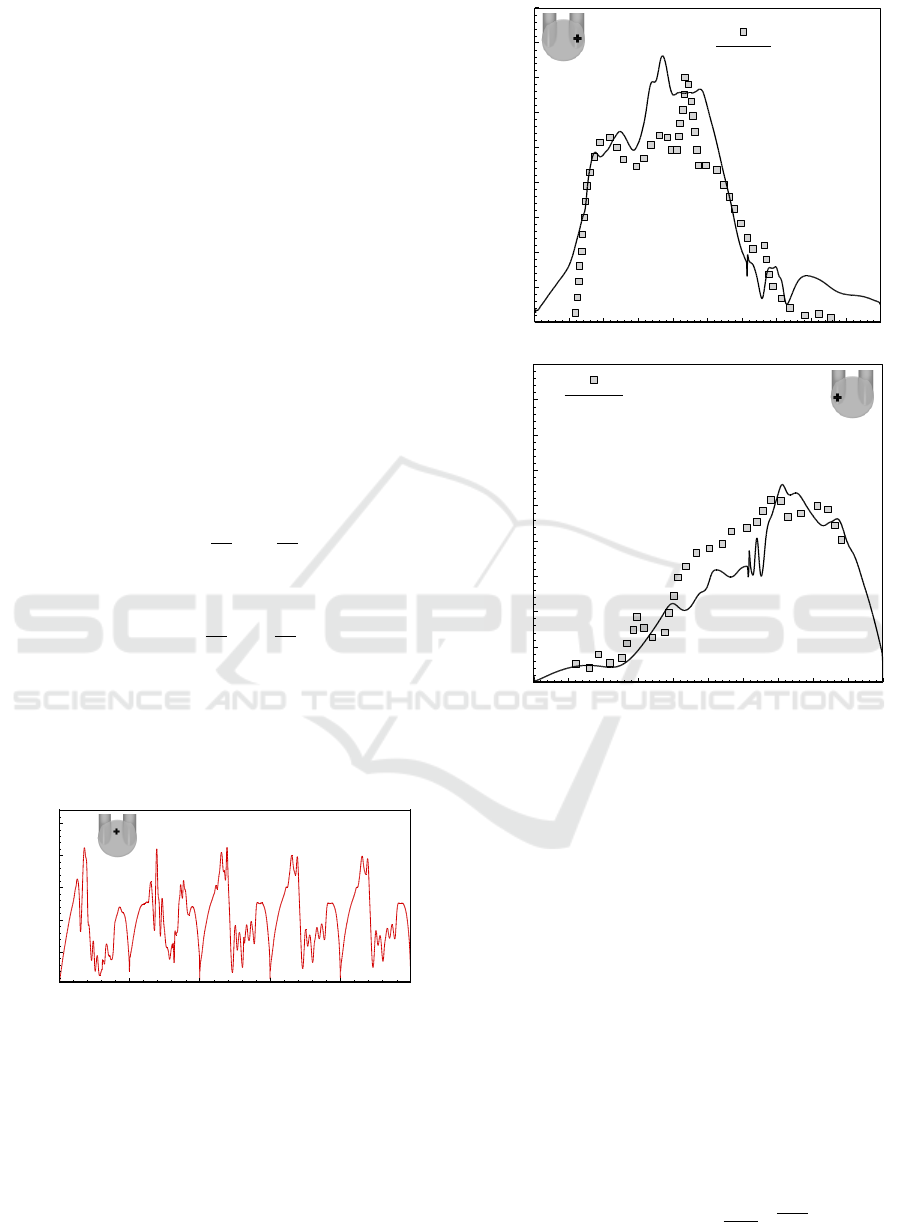

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0 0.2 0.4 0.6 0.8

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Experimental

EB-RSM : Carreau

V1

0 0.1 0.2 0.3 0.4 0 .5 0.6 0.7 0.8 0 .9 1

0 0.2 0.4 0.6 0.8

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Experimental

EB-RSM : Carreau

(b)

Velocity (m/s)

t/T

Velocity (m/s)

(a)

Figure 6: Variation of velocity magnitude at (a) mitral port

and (b) aortic port.

using Pointwise CFD mesh generation software

(V16.04R4) from Pointwise Inc. (Pointwise, 2011)

and STAR-CCM+ 10.02 (StarCCM, 2015). Figure

2a shows the overset regions in an arbitrary posi-

tion. As alluded above, the overset mesh methodol-

ogy has been employed to simulate the valve closure.

To achieve that a small gap between the background

region and the valve should be left and the number of

cells should be fewer than four. In all present work

the number of cells is two and as a result the zero

gap algorithm will apply; Figure 2b. These cells and

the overset cells outside the background region will

be inactive during the simulation, as shown in Figure

2c, which illustrates the mesh after starting the sim-

ulation. Figure 4 depicts the variation of y-velocity

with mesh size for the EB-RSM model with the non-

Newtonian Carreau model. A near wall resolution

is assessed using the non-dimensional distance to the

first near-wall grid point, y

+

=

y

µ(|S|)

√

ρτ

w

; where y is

the distance from the first cell centre to the wall, ρ is

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

148

t/T=0.3

1 2

Figure 7: Snapshots of stream lines originated from line 1

and 2.

the density of blood, µ(|S|) is the blood viscosity, and

τ

w

is the wall shear stress; where a prism mesh with

six layers was used to resolve the boundary layer. In

all simulations this value was set to the recommended

value of y

+

≈1 for all locations inside the device. The

mesh MO4 is selected for the following simulations,

which is adequate to capture the properties of the flow

within the chamber and near the valves.

For transient simulations, the sensitivity to time

step was investigated. The Courant-Friedrichs-Lewy

number CFL =

U∆t

∆x

is employed during the simula-

tion, where U is the local cell velocity and ∆x is the

characteristic cell length scale. Generally, in the zone

of interest, CFL should be of the order of unity for

unsteady analysis. In the present study, different time

steps were tested with the same conditions, as a result,

the time step ∆t = 0.001s was found to be satisfac-

tory; resulting in a maximum CFL number of around

1 inside the chamber.

The numerical simulation was allowed to continue

until a time periodic flow was obtained, in order to ob-

tain a fully converged unsteady solution. In this study,

the simulation was run for 5 complete pump flow cy-

cles and the forth cycle has been chosen to extract the

data from the simulation. Figure 5 illustrates the his-

tory of velocity magnitude at point in the chamber.

t/T= 0.00428

t/T= 0.603

t/T= 0.314

t/T= 0.8

t/T= 0.619

t/T= 0.995

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

Velocity

(m/s)

Figure 8: Contour of velocity magnitude at centre of the

valves and z/z

c

= 0.21 from the front face of the chamber.

5 RESULTS AND DISCUSSION

5.1 Velocity Distribution

The setup of the current numerical simulation was

first validated by comparing the instantaneous flow

fields in the device against the available PIV exper-

imental data (Medvitz et al., 2009). The comparisons

include traces of instantaneous velocity magnitude at

extraction points in the chamber located at 25 percent

of the chamber’s radius from the wall on the plane

z/z

c

= 0.159 from the front face of the chamber.

Figure 6 depicts the comparison of velocity mag-

nitude at two points within the chamber; proximal to

the mitral port and to the aortic port as shown. The re-

sults from the EB-RSM turbulent model for the non-

Newtonian blood viscosity model are presented in this

figure. The RSM model has been chosen because it

accounts for more realistic transport, or history, of

three-dimensional effects as reported in our previous

study (Al-Azawy et al., 2016).

From the figure, it can be seen that there ia good

agreement with the experimental date, especially at

the beginning of the diastolic phase at the point prox-

imal to the mitral port, where the flow is injected

into the chamber over the moving valve (see Figure

6a). This is with the notable exception of the Car-

reau model at location t/T = 0.4 where the velocity

is higher. However, the simulation with valve rotation

gives better prediction than assuming a constant open

position. Again the velocity records a closer agree-

ment with the experimental data at the aortic port,

where the flow pumps towards the outlet port, during

the systole (Figure 6b).

An Overset Mesh Approach for Valve Closure: An LVAD Application

149

Figure 7 provides streamlines seeded from the in-

let surface towards the chamber through the mitral

valve. For the sake of clarity the streamlines origi-

nated from lines 1 and 2 in order to observe the com-

plexity of the flow behaviour behind the valve (see

line 1) and inside the chamber (see line 2).

Furthermore, to provide a more quantitative as-

sessment of the blood flow within the device, the ve-

locity contour through the valves and the chamber

with streamlines are provided in Figure 8.

5.2 Clinical Issues

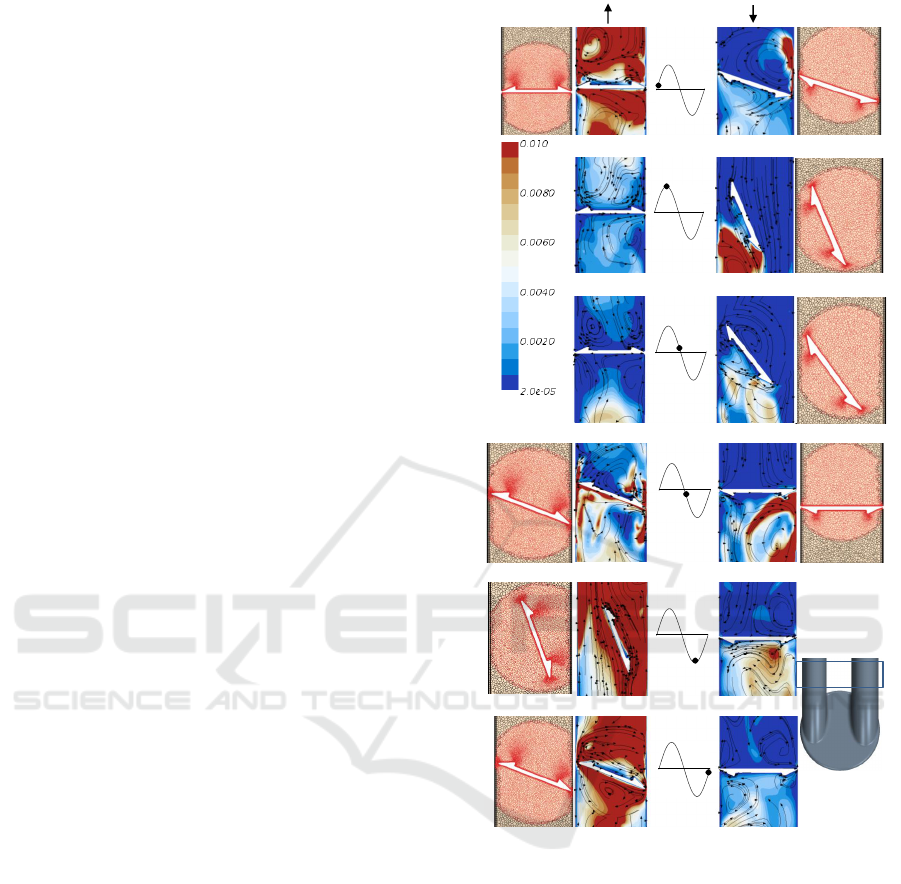

Figure 9 displays the flow behaviour and turbulent

kinetic energy (TKE) at six points during the cycle,

corresponding to early, peak and late in diastole and

then systole. In this figure, the mesh configurations

are displayed with the valve rotation, where the black

mesh represents the background while the red mesh

represents the overset mesh. It is expected that the

flow behaviour and TKE would be highly sensitive to

valve rotation. In addition, this investigation is signif-

icant as the turbulence effects cause potential damage

to the blood cells. However, this is directly related

to the thrombus and haemolysis which are the main

causal risk associated with heart pumps.

6 CONCLUSIONS

Based on the validation with the experimental avail-

able data, it can be concluded that the overset mesh

zero gap technique can be used successfully for the

CFD simulation of blood pump. The present nu-

merical study was conducted to describe the non-

Newtonian, transient, and turbulent flow through an

LVAD, using an elliptic blending Reynolds stress

model. The overset mesh approach was employed for

both pusher plate movement and valve rotation within

the positive displacement pump. The zero gap tech-

nique was used to model the valve closure in order

to mimic the natural scenario of heart pump. The

TKE and velocity with streamlines were investigated

in various positions of valve during the rotation.

ACKNOWLEDGEMENTS

The financial support from the Higher Committee for

Education Development in Iraq and the University of

Wasit is gratefully acknowledged. The authors would

like to acknowledge the assistance given by IT Ser-

vices and the use of the Computational Shared Facil-

ity at The University of Manchester.

t/T= 0.00428

t/T= 0.603

t/T= 0.314

t/T= 0.8

t/T= 0.619

t/T= 0.995

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

V1

V2

0 2 4 6 8

-1

-0.5

0

0.5

1

TKE (m

2

/s

2

)

Figure 9: Snapshots of contour of turbulent kinetic energy

with mesh configuration.

REFERENCES

Al-Azawy, M. G., Turan, A., and Revell, A. (2015). Investi-

gating the Use of Turbulence Models for Flow Investi-

gations in a Positive Displacement Ventricular Assist

Device. 6th European Conference of the International

Federation for Medical and Biological Engineering,

45:395–398.

Al-Azawy, M. G., Turan, A., and Revell, A. (2016). Assess-

ment of turbulence models for pulsatile flow inside

a heart pump. Computer Methods in Biomechanics

and Biomedical Engineering, 19(3):271–285. PMID:

25816074.

Avrahami, I. (2003). The Effect of structure on the hemody-

namics of artificial heart pumps. PhD thesis, Tel-Aviv

University.

BIODEVICES 2016 - 9th International Conference on Biomedical Electronics and Devices

150

Bluestein, D., Rambod, E., and Gharib, M. (2000). Vortex

shedding as a mechanism for free emboli formation

in mechanical heart valves. Journal of biomechanical

engineering, 122(2):125–134.

Carreau, P. J. (1972). Rheological Equations from Molecu-

lar Network Theories. Journal of Rheology, 16(1):99–

127.

Johnston, B. M., Johnston, P. R., Corney, S., and Kilpatrick,

D. (2004). Non-Newtonian blood flow in human right

coronary arteries: steady state simulations. Journal of

biomechanics, 37(5):709–20.

Kiris, C., Kwak, D., Rogers, S., and Chang, I. (1997). Com-

putational approach for probing the flow through arti-

ficial heart devices. Journal of biomechanical engi-

neering, 119(4):452–460.

Kreider, J. W., Manning, K. B., Oley, L. a., Fontaine, A. a.,

and Deutsch, S. (2006). The 50cc Penn State left

ventricular assist device: a parametric study of valve

orientation flow dynamics. ASAIO journal (Ameri-

can Society for Artificial Internal Organs : 1992),

52(2):123–31.

Medvitz, R. B. (2008). Development and Validation of a

Computational Fluid Dynamic Methodology for Pul-

satile Blood Pump Design and Prediction of Throm-

bus Potential. PhD thesis, Pennsylvania State Univer-

sity, University Park, PA.

Medvitz, R. B., Kreider, J. W., Manning, K. B., Fontaine,

A. A., Deutsch, S., and Paterson, E. G. (2007). De-

velopment and validation of a computational fluid dy-

namics methodology for simulation of pulsatile left

ventricular assist devices. ASAIO journal (Ameri-

can Society for Artificial Internal Organs : 1992),

53(2):122–131.

Medvitz, R. B., Reddy, V., Deutsch, S., Manning, K. B., and

Paterson, E. G. (2009). Validation of a CFD method-

ology for positive displacement LVAD analysis us-

ing PIV data. Journal of biomechanical engineering,

131(11):111009 1–9.

Peskin, C. S. (2002). The immersed boundary method. Acta

Numerica, 11:479–517.

Pointwise (2011). Pointwise, Inc. Release 16.04R4 .

StarCCM (2015). CD-Adapco User Guide, STAR-CCM+

Version 10.02 .

Stijnen, J., de Hart, J., Bovendeerd, P., and van de Vosse,

F. (2004). Evaluation of a fictitious domain method

for predicting dynamic response of mechanical heart

valves. Journal of Fluids and Structures, 19(6):835–

850.

Stijnen, J. M. A. (2004). Interaction between the mitral and

aortic heart valve an experimental and computational

study. PhD thesis, Eindhoven University.

Yin, W., Alemu, Y., Affeld, K., Jesty, J., and Bluestein, D.

(2004). Flow-induced platelet activation in bileaflet

and monoleaflet mechanical heart valves. Annals of

biomedical engineering, 32(8):1058–1066.

An Overset Mesh Approach for Valve Closure: An LVAD Application

151