Development of an Ontology for Aerospace Engine Components

Degradation in Service

C. Okoh

1

, R. Roy

1

, J. Mehnen

1

, L. Redding

1

and A. Harrison

2

1

EPSRC Centre for Innovative Manufacturing in Through-Life Engineering Services

Department of Manufacturing and Materials, Cranfield University, MK43 0AL, Cranfield, U.K.

2

Rolls Royce, Derby, U.K.

Keywords: Ontology, Taxonomy, Degradation Mechanisms, Aerospace Engine, Component Degradation, Information

Extraction, Knowledge Management, Service Knowledge, Through-life Engineering Service.

Abstract: This paper presents the development of an ontology for component service degradation. In this paper,

degradation mechanisms in gas turbine metallic components are used for a case study to explain how a

taxonomy within an ontology can be validated. The validation method used in this paper uses an iterative

process and sanity checks. Data extracted from on-demand textual information are filtered and grouped into

classes of degradation mechanisms. Various concepts are systematically and hierarchically arranged for use

in the service maintenance ontology. The allocation of the mechanisms to the AS-IS ontology presents a

robust data collection hub. Data integrity is guaranteed when the TO-BE ontology is introduced to analyse

processes relative to various failure events. The initial evaluation reveals improvement in the performance

of the TO-BE domain ontology based on iterations and updates with recognised mechanisms. The

information extracted and collected is required to improve service knowledge and performance feedback

which are important for service engineers. Existing research areas such as natural language processing,

knowledge management, and information extraction were also examined.

1 INTRODUCTION

In some specific domains events recorded for

knowledge capture, sharing and reuse are usually

represented in text formats. Information extraction

(Wang et al., 2006) is employed to data when

seeking to identify and capture the required

degradation mechanisms for service knowledge

(Doultsinou et al., 2009). The concept of

information extraction is essential in the respective

domains of health care, energy, power, and

aerospace where various events are encountered in

the maintenance of machines.

An understanding of knowledge management

(KM) (Dadzie et al., 2009; del-Rey-Chamorro et al.,

2003), natural language processing (NLP)

techniques (Dale et al., 2000), information extraction

(IE), taxonomy (Saleem and Bellahsene, 2008),

degradation mechanisms (DM) (Okoh et al., 2014)

and an ontology (Ahmad and Colomb, 2007; Serra et

al., 2013) is needed to improve validated results for

better decision making.

The domain corpus is a repository of

unstructured and semi-structured information. The

task to identify, extract and retrieve the relevant data

lies in the domain of natural language processing.

The extraction of specific information from natural

language is compared with the expected data.

Information extraction is part of NLP with the task

of extracting entities such as names of persons,

locations, and organisations. In this case, Named

Entities (NE), Cause and Effect causality ordering

approaches are implemented by using the verb cue

phrase (Kim et al., 2009). The data are then

structured in the ontology.

A taxonomy is a structured arrangement of terms

and concepts (Ryu and Choi, 2006). This presents a

representation of knowledge with domain specific

concepts. In populating the ontology with terms,

duplicate words are avoided to eliminate

redundancy.

In this paper, the case study focuses on

evaluating the validity of the taxonomy of the

degradation mechanisms for an existing ontology.

Sanity checks were used to manually observe and

count the number of identified and captured

108

Okoh C., Roy R., Mehnen J., Redding L. and Harrison A..

Development of an Ontology for Aerospace Engine Components Degradation in Service.

DOI: 10.5220/0005090201080119

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (KEOD-2014), pages 108-119

ISBN: 978-989-758-049-9

Copyright

c

2014 SCITEPRESS (Science and Technology Publications, Lda.)

mechanisms. The degradation mechanisms and

keywords within issues reported by service

engineers describe defects observed during

maintenance, repair and overhaul from a through-life

engineering services perspective (Roy et al., 2013).

This understanding is required to establish the

synonyms of the words to be extracted from the

corpus (Ryu and Choi, 2006). This work is based on

a case study carried out within the aerospace

maintenance domain. The contribution is the

practical use of the ‘AS-IS’ and the ‘TO-BE’

framework to validate and develop an ontology

within a service maintenance domain. Sanity checks

ascertain the effectiveness of the extractor and show

improvement in the performance of the ‘TO-BE’

ontology.

The remainder of this paper is organised as

follows. The background of related fields is

discussed in Section 2. The research methodology is

described in Section 3. Section 4 presents and

discusses the evaluation of the results and Section 5

presents the research conclusions with regard to the

benefits of the validation and identification process.

2 BACKGROUND

2.1 Knowledge Management

Knowledge Management (KM) is increasingly being

implemented in global engineering and service

organisations. Knowledge acquisition, storage,

retrieval and interaction are part of KM (Dadzie et

al., 2009). It ensures information is secure and well

managed (del-Rey-Chamorro et al., 2003) with the

purpose of information reuse and sharing. KM is an

information system strategy based on insights and

experiences of domain experts to gain competitive

advantage. KM can be used to develop taxonomies

in order to produce and manage ontologies.

2.2 Ontology

An Ontology is an explicit specification of

conceptualisation (Gruber, 1993). Recent work has

shown the importance of ontology as a problem

solving tool of conceptualisation of entities

(Maedche and Volz, 2001). The concepts and

relations are used to reason and describe domain

knowledge. This is a hierarchical arrangement which

represents a more natural means of information

management in a unique domain.

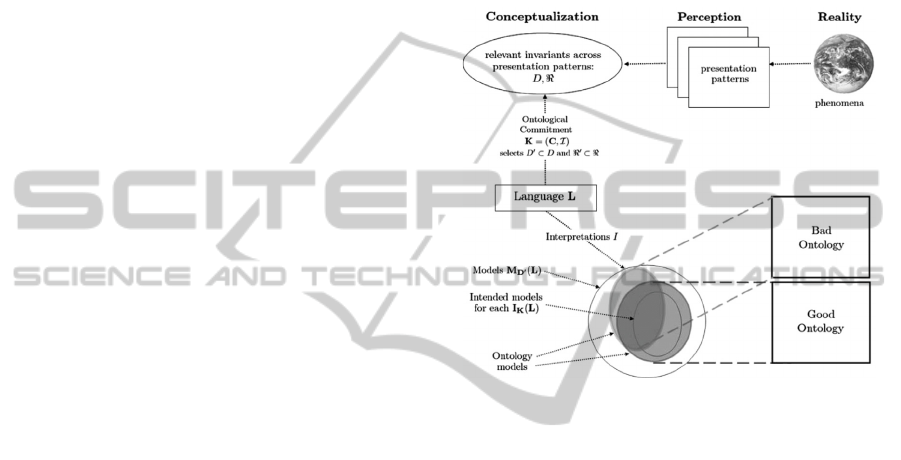

Ontology assists in developing models of a

domain based on reality, perception, conceptual-

lisation, communication and interpretation (see

Figure 1). Axioms (reasoning about the meaning)

are described by means of asymmetric and

intransitive can be related to symmetric, irreflexive

and intransitive. It is aimed at capturing specific

intended and excluding non-required concepts by

reason of conceptualisation (Guarino et al., 2009). It

defines terms and relationships inside the domain.

Types of ontology include domain, representational,

application and generic.

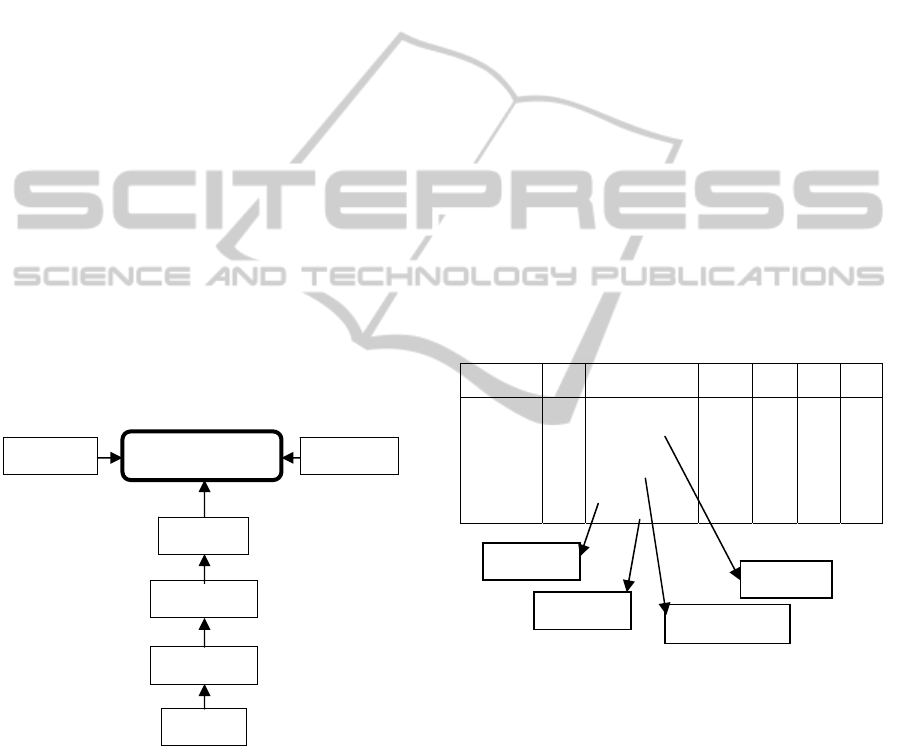

Figure 1: The relationships between perception,

conceptualisation and language for communication

(Adapted from Source: Guarino et al., 2009).

A primary focus of most ontologies is the

taxonomy of classes and subclasses (also called

concepts and synonyms) related to different

properties (roles) (see Figure 2) which describes the

attributes with the role’s restrictions defined

(Uschold and Gruninger, 2004).

A development process to identify and extract

relevant terms or keywords is proposed in this paper.

These terms are considered as taxonomy. Taxonomy

represents knowledge acquisition of similar words.

The taxonomy extracted from a service maintenance

context for different degradation mechanisms

include Fracture with synonyms as crack, tear and,

break. An ontology is a knowledge repository of the

taxonomy with inter-relationship of a

conceptualisation of terms as illustrated in Figure 2.

Both taxonomy and ontology are sometimes used

interchangeably. However, taxonomy is often used

in industry and ontology is commonly used by

academics.

Figure 2 is an extension of the ontology tree

showing a simplistic knowledge representation with

levels relating to the mechanical component. It also

DevelopmentofanOntologyforAerospaceEngineComponentsDegradationinService

109

Figure 2: Example of an Ontology (Adapted from Source:

(Uschold and Gruninger, 2004).

links the component to the feature and mechanisms

with examples of defects which can affect an asset.

Identification of image and shape feature bird

classification is based on real-world objects and

semantic-based retrieval (Liu et al., 2007). There are

critical unchanging properties such as physical bird

shapes and characteristics. These are used to manage

and model bird classification for knowledge reuse.

The ontology provides a similar shared

understanding of a specific domain in both humans

and computers. It provides a semantic starting point

for meaningful definitions. The UNAS, (2000)

describes criteria for the design of ontologies

relating to the common approaches and visualisation

used in ontological engineering. Ahmad and

Colomb, (2007) argue that a server development

should be determined by considering what the

ontology is designed for (e.g. ontologies for business

and engineering applications should vary slightly).

Jasper and Uschold, (1999) present a framework for

understanding and classifying the application of

ontologies. Scenarios have been categorised into (1)

neutral authoring of a single language, (2) common

access to information by more than one person or

computer applications and (3) indexing – ontology

as a tool for indexing information.

The applicability of ontology structure is the

conceptualisation of lexical entries. It represents

concepts, the hierarchy and lexical signs for

relations and non-taxonomic relations (Maedche and

Volz, 2001).

In ontology, maintenance is related to the

pruning of the information (Sabou et al., 2005).

Unwanted keywords are eliminated in a given

domain, whilst refinement, the recognition of the

relevant keywords which are not resident in the

ontology are removed (Maedche and Volz, 2001). In

pruning, the domain relevance is determined by the

comparison of the concepts retrieved from a specific

domain with the rate of occurrence acquired from a

general domain. In refinement, the learning phase

enhances the functional capability of the algorithm,

so that, unrecognised words can be identified as

concepts and conceptual behaviours.

2.3 Information Extraction

Information extraction is one of the important sub-

areas of NLP. Named Entities Recognition (NER)

recognises named entities from within a phrase or

clause or group of sentences. The named entities can

be classified based on pre-defined terms such as

organisation, person and location. The NER is

context-dependent and the extraction is

accomplished by string matching if the sentence is

incomplete (Wang et al., 2006).

Pre-processing is required in information

extraction to accurately retrieve a more complex

structure which contains events and relations. The

detection and characterisation of semantic relations

between entities in the text is applicable to

information extraction of relations (Jiang, 2012).

Lanfranchi et al., (2007) proposes an extraction and

search knowledge for the aerospace industry.

Correia et al., (2011) illustrates extracting ontology

hierarchies from text by tagging, extraction of

candidate classes, identification of hyponyms and

synonyms as well as identification and

representation of taxonomic relationships.

2.4 Degradation Mechanisms

In the aerospace service domain, a number of factors

lead to deterioration of mechanical components.

These components become permanently damaged

when the threshold is exceeded. Degradation

mechanisms relate the causes to the resulting

damages (see Figures 3 and 4). For instance, wear

caused by poor lubrication, fracture caused by

induced vibration of the engine vanes and crack as a

result of oxidation. The focus of the case study was

to validate the identified synonyms of the taxonomy

of wear, corrosion, fracture, and deformation, and to

develop an ontology.

Wear is the loss of material as a result of usage over

time (Ameen et al., 2011). Lack of lubrication in a

rotating engine can lead to wear. Erosion is a form

of wear, while cavitation and rub are the causes of

Mechnical Component

Pump

Engine

Jet Engine

Fuel Pump

Gear Pump

Fuel System Fuel Filter

Gasket

O’ring

Tear

Rust

Supplies-fuel-to

Has-component

Connected-to

Part-of

Has-feature-of

Ontolo

gy

Domain

Fracture

Crack

Tear

Break

Has- mechanisms

Affected-by-mechanisms

KEOD2014-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

110

wear. Wear may lead to corrosion depending on the

operating environments.

Corrosion is a chemical deterioration process

leading to material loss. Oxidation and sulphidation

can cause components degradation under high

thermal stress (Pomeroy, 2005). An example of

corrosion is rust caused by oxidation (Figure 3).

Oxidation can also result in creep which leads to

deformation of the material and eventually causes

crack or spallation. Corrosion can be uncontrollable

and irreparable.

Figure 3: Surface corrosion of metal discs.

Fracture is the result of a separation of material due

to cracking or disintegration (see Figure 4). It

reduces the functionality of a component. Fractures

may occur as a result of chemical effects, shock or

stress and increases as strain rate increases.

However, deformation happens by reason of Creep

which is a slow growth caused by an applied stress.

Other types of fracture include crack, tear, burst,

peel and split which can either be micro-crack or

macro-crack (Medjaher et al., 2012).

(

a

)

(

b

)

Figure 4: Bearing with fracture (a) outer ring failure and

(b) inner ring failure (Source: (Medjaher et al., 2012).

Deformation is the effect of a change in the

geometry or shape of a component such as

shrinking, stretching, bending, and twisting due to

cumulative strain on a component when force is

applied. Deformation is either time dependent or

time independent mechanisms (Norman, 2013). In

Creep deformation the component gradually

accumulates over time with the presence of high

temperature and thermal cycles stress until the

product fails. Elastic deformation results from

applied stress on an asset which returns to its

original condition when the stress is removed.

Plastic deformation occurs when a component

exceeds its elastic limit (threshold) and results in a

permanent change to the physical structure of the

item even when stress is removed.

Degradation mechanisms result from a

combination of mechanical, electro-chemical,

operational, and environmental conditions. In

grouping the identified concepts, an understanding

of failure modes and effects analysis (FMEA) as a

measure for qualitative analysis is required (Rausand

and Høyland, 2004). The FMEA is a procedural

method to identify possible failures in a design, an

assembly or a manufacturing process, a product or a

service. Failure modes are means by which things

fail or defects occur and can be potential or actual.

Effects analysis examines and helps to understand

the consequences of the failures. The aim of the

FMEA is to take actions to reduce failures,

beginning with the highest-priority failures. Failures

can be prioritised by analysing the severity of the

consequences, the frequency of occurrence and ease

of detection. In this paper, classification of failures

is presented as classes and subclasses of knowledge

in the domain ontology (Figure 2).

This case study focuses on mechanisms reported

by service engineers in the form of text in MS word,

Excel, etc. The goal of this validation process is to

ensure the mechanisms or damage recorded in the

event reports are recognised by the information

extraction tool.

Current and future research activities in these

areas include evaluation of these applications in

large scale datasets assuming an increased

requirement for KM (Dadzie et al., 2009) which

include the study of different methods of concept

mapping and analysis to identify differences

between feature combination and integration (Zhang

et al., 2011). This includes investigative approaches

for automatic mapping (Liu et al., 2007).

3 METHODOLOGY

This paper is based on the validation of taxonomy

of the degradation mechanisms which is a list of

terms. This is essential in deciding allocation of the

mechanisms to create a robust data collection hub.

The data collected are required to enrich Service

Knowledge and performance feedback to policy

makers. The methods used in addressing this work

include literature research, observations, and

interview with domain experts.

This study shows how to extract concepts for

ontology development to aid knowledge sharing and

DevelopmentofanOntologyforAerospaceEngineComponentsDegradationinService

111

reuse. The information will be pre-processed and

filtered from the raw ‘on-demand’ data sets of

textual information. These data contain various

keywords (terms and concepts) which will be

systematically and hierarchically arranged for use in

the engineering service domain.

The data will be grouped into classes of

degradation mechanisms which include fracture,

wear, corrosion, deformation and causes. The ‘AS-

IS’ and ‘TO-BE’ framework using an iterative

process before, during, after updates and sanity

check technique will be implemented.

The case study is essential to enhance Service

Knowledge by equipping service engineers with

tested, trusted and approved ontology whilst

analysing a vast amount of textual failure data. This

is important because the relevant failure data will be

validated against history information to ascertain

through-life performance of the components. This is

useful for service engineers when reporting failures

encountered in engine maintenance.

This work examines events associated with

engine component testing and the means by which

the records are processed. A series of trials and

processing updates were introduced to a framework

to deliver a proposed solution to capture concepts

from observed failure. The failure information

examined contains the engine name and type, events

or issues encountered by the component, year of

manufacture and date, and mechanism stating the

type of degradation experienced during the test.

An acquisition of a large amount of data from

engine information recorded various types of failure

modes, mechanisms and types of component feature.

The mechanisms and causes of degradation were

assessed and analysed in order to understand how

the data would be extracted. The FMEA will be used

to gain an understanding and assessment of the type

of damage present in the textual information. The

dataset is a collection of recorded issues observed,

evaluated, decided, tracked and closed by service

engineers in the maintenance domain. Mechanisms

such as bent, shrink, and crack are considered

keywords (synonyms). The synonyms of

mechanisms are manually identified, extracted from

the text and entered onto the ontology.

The taxonomy refers to the synonyms of

degradation mechanisms for existing ontology. The

procedure to modify the ontology requires an

understanding of the process, meaning of the types

of damage and under what class it should be. The

keywords are uploaded onto the system for a rerun

and re-analysis with an embedded recognition tool.

This paper shows the method to identify and collect

concepts and synonyms using the recognition tool.

3.1 Keywords Grouping

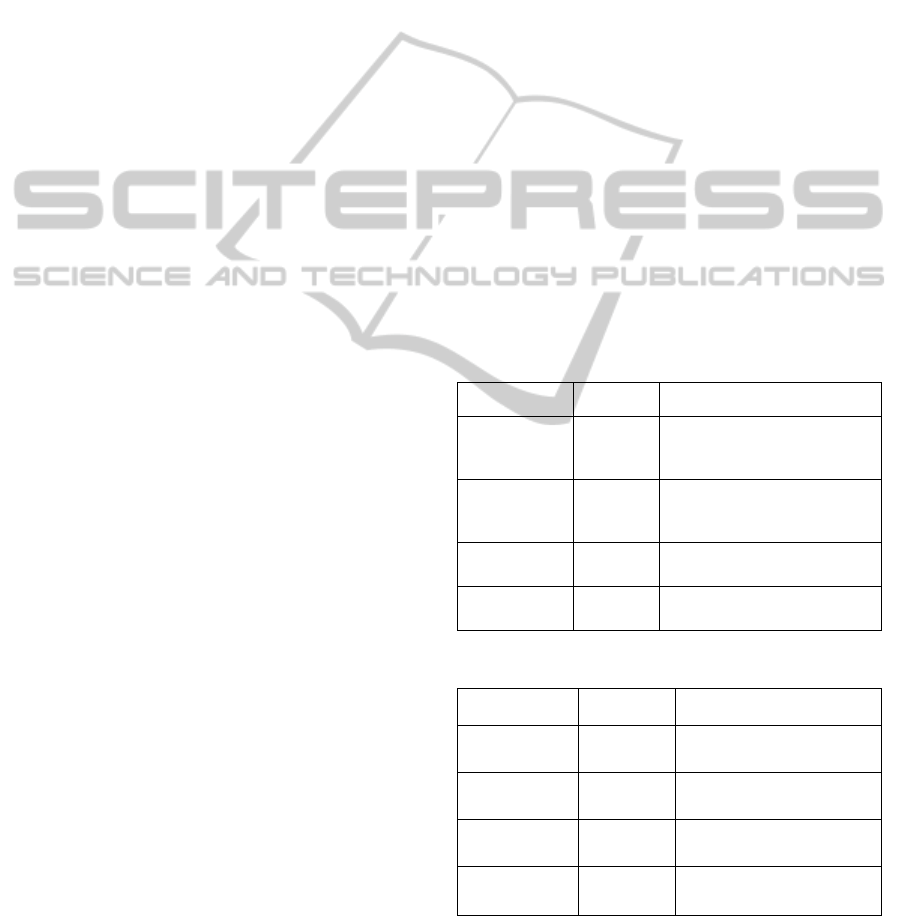

This case study illustrates the process of keyword

identification and grouping. The identification

process includes:

Define and seek specific meaning to a

degradation mechanism to ensure better

understanding of the taxonomy of the

degradation and causes (Table 1)

Attempt to ask and answer questions to ascertain

whether the identified keyword is relative to a

specified category of degradation mechanisms

(Table 3)

Identify, assess and filter degradation

mechanisms based on material loss, separation,

geometry change and property maintained in

order to predict or determine (using a flowchart)

whether the material under investigation is

affected by either corrosion, wear, deformation

or fracture. The meaning of the mechanisms

must be understood (Figure 5)

Table 1: Sample concepts and meanings.

Class Subclass Definitions

Deformation

Change

geometry

Bent

Altered from an originally

straight or even condition

Fracture

Material

separation

Cracked

Damage showing lines on

the surface of having split

without coming apart.

Wear

Material loss

Abraded

Scrape or wear away by

friction or erosion

Corrosion

Material loss

Blistered

A raised bubble, as on a

painted or laminated surface

Table 2: Sample of concepts and questions.

Class Subclass Questions

Deformation

Bent

Is the material altered from

its original condition?

Fracture

Cracked

Is there a separation within

the material?

Wear

Abraded

Is there a scrape on the

material?

Corrosion

Blistered

Are there raised bubbles

on the material?

As shown in Figure 5, the process starts with

observing the issue with the material in terms of

loss, change in shape and properties, and questions

to classify the defects.

KEOD2014-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

112

Figure 5: Flowchart to determine degradation mechanisms.

3.2 Risk Matrix with Failure Modes

In order to build a robust ontology that can deliver

better performance, various probable states of events

and their consequences should be considered. These

events are described within the FMEA. Performance

of materials is affected by some event which are

termed critical. The critical events are differentiated

by the keywords used. The keywords are identified

and extracted from the FMEA.

To achieve an increased understanding of the

concepts and classification within the ontology, risk

factors applied to the identified keywords are based

on the level of seriousness of the damage and

severity of consequences of failure. The severity of

the mechanisms results from the understanding of

the FMEA procedure in analysing failures. Hence, a

relationship was created between the taxonomy of

degradation mechanisms and the severity of the

failure modes to generate an ontology for problem-

solving and decision making.

The identification of potential failure modes on

the lowest level of damage and upward hierarchy is

a representation of the ontology. The severity of

failure modes is classified into minor, major, critical

and catastrophic. Minor failure does not degrade the

overall performance beyond acceptable limits. Major

failure will degrade the system beyond acceptable

limits, but can be adequately controlled by alternate

means. Critical failure will degrade the component

further than the acceptable limits and create a safety

threat. A catastrophic failure could result in

preventing performance of the intended operations

(Rausand and Høyland, 2004).

Physical or chemical processes can lead to

events which cause the lowest level of arrangement

of failure mechanisms such as deformation, fracture,

corrosion and wear represented in Figure 6. Failure

rates for each failure mode are recorded. The failure

rates are further classified according to frequency of

occurrence to give a better understanding of

causality for informed decision making (Table 3).

Table 3: Failure rate categorisation (adapted from source:

(Rausand and Høyland, 2004).

No Failure Rate Occurrence

1 Very unlikely Once per 1000 years / more

2 Remote Once per 100 years

3 Occasional Once per 10 years

4 Probable Once per year

5 Frequent Once per month / more often

The Failure rate is different for various

operational domains with respect to a failure mode.

DevelopmentofanOntologyforAerospaceEngineComponentsDegradationinService

113

The FMEA contains information useful for

operation and maintenance. The risk is the severity

of the consequences mapped against failure rate.

Table 4: Risk matrix showing different failure modes

(adapted from source: (Rausand and Høyland, 2004).

Severity Categories (Consequences)

Failure rate

Very

unlikely

Remote Occas-

ional

Probable Frequent

Catastrophic

X

Critical

X

Major

X

Minor

X

As indicated in Table 4, however, a minor damage

(e.g a Spall) to a critical component (bearing) can be

catastrophic, in that it hinders the performance of the

entire system. The failure rate and the severity

categories show that the catastrophic failure is very

unlikely to occur because the relationship within the

ontology is properly developed and utilised by

reason of the system, subsystem and component

levels Figure 6.

System

Level

(PumpingStation)

Subsystem

Level

(Pump)

Component

Level

(Seal)

NoTotal

Shutdown

Internal

Leakage

Leakage

fromsealing

‐ Corrosion

‐ Wear/Erosion

‐ PoorLubrication

‐ Usageoutsidespecifications

‐ WrongmaterialsSpecifications

Failuremechanisms

RootCauses

Failurecause

Leakagefromsealing

FailureMode

Failure

Effects

Internal

leakage

Failurecause

Internalleakage

FailureMode

Nototal

Shutdow

Failure

Effects

FailureMode

Ontology

Figure 6: The relationship between failure cause, failure

mode and failure effect. (Adapted from Source: (Rausand

and Høyland, 2004).

This analysis informs decision making when seeking

to consider the choice to either scrap or continue to

use the component under investigation. This link is

created to assist in detecting failure mechanisms

easily based on the approved and agreed threshold. It

relates to the use of the monitored operating and

maintenance information as inputs to determine

through-life performance in terms of remaining

useful life of the component under investigation by

observing geometry, property loss and material loss

(Okoh et al., 2014).

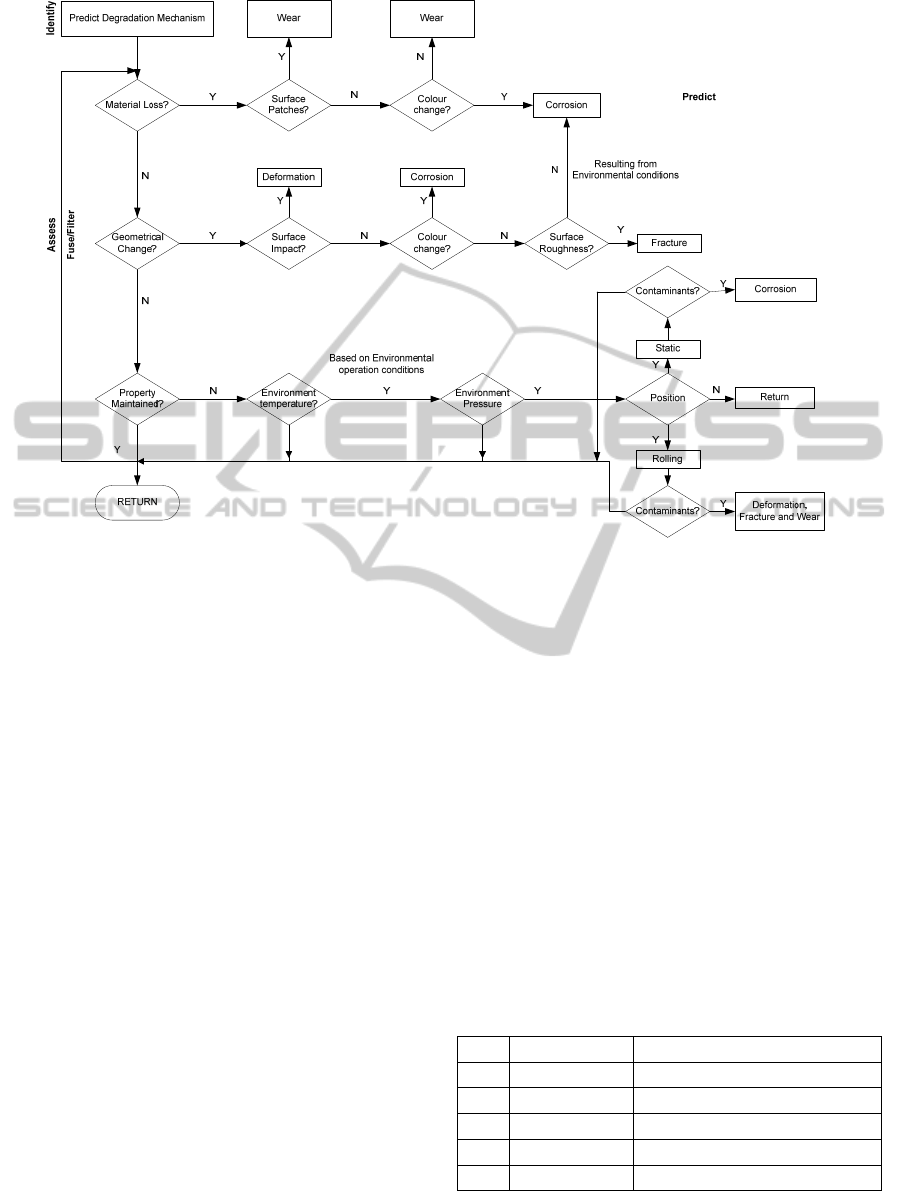

3.3 AS-IS and TO-BE Framework

The ‘AS-IS’ and ‘TO-BE’ state is a business process

model adapted from (Q-BPM, 2014). It serves as a

guide to help understand where we are, where we

need to be and how to get there. Applying the

framework of this research – it is the current state of

the ontology, the desired robust ontology and what

to do to get the ontology to the desired robust state.

This systematic process is iteratively executed.

The findings are feasible using the proposed

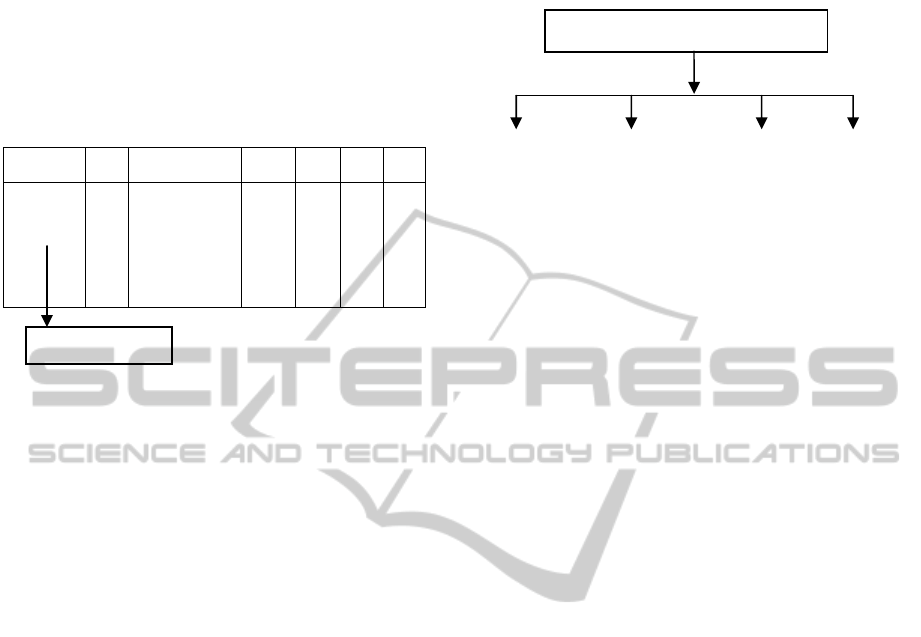

‘AS-IS’ and ‘TO-BE’ process model (Figure 7). The

model was chosen based on the knowledge of the

proposed and agreed solution.

This model is implemented to bridge the gap

between ‘AS-IS’ and ‘TO-BE’ by way of process

improvement. Advantages of the framework include

planning, continuous improvement, knowledge

retention and learning, process visualization,

training, audit and compliance (Q-BPM, 2014).

The original data set (knowledge representation)

is the ‘AS-IS’ which needs to be updated and

maintained. The proposed knowledge representation

is the ‘TO-BE’. The ‘AS-IS’ model will be updated

with the identified entries (new additional concepts)

and the results presented - the amount of concepts

returned in terms of success rate.

As indicated in Figure 7, each stage addresses a

task. The process is planned, to know exactly what

to extract and how it should be addressed, check by

comparing both current and future states for the

taxonomy of degradation mechanisms, then act by

agreeing and implementing the results.

Figure 7: The AS-IS and TO-BE Framework.

3.3.1 Procedure for Analysis

The existing records are event reports presented in

Excel. In order to analyse the records, the concepts

must be identified. The procedures to analyse

information in line with the architecture in Figure 8

are as follows:-

BEFORE

DURING

AFTER

SANITY

CHECK

AS-IS

TO-BE

Ontology

KEOD2014-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

114

1. Before Update - when results and degradation

process are initially processed to capture

mechanisms (see Figure 9)

2. During Update - current state when the results

and the degradation process are manually checked to

find the number of precise and accurate mechanisms

captured.

3. After Update – when the results and the

degradation processes are checked against event

information to identify mechanisms in ‘during

update’. The concepts which the recognition tool

failed to capture are updated within the ontology and

then uploaded to take effect for the next ‘trial run’.

Note: The Excel file should be closed and reopened.

The recognition tool automatically runs in the

background to effectively update changes.

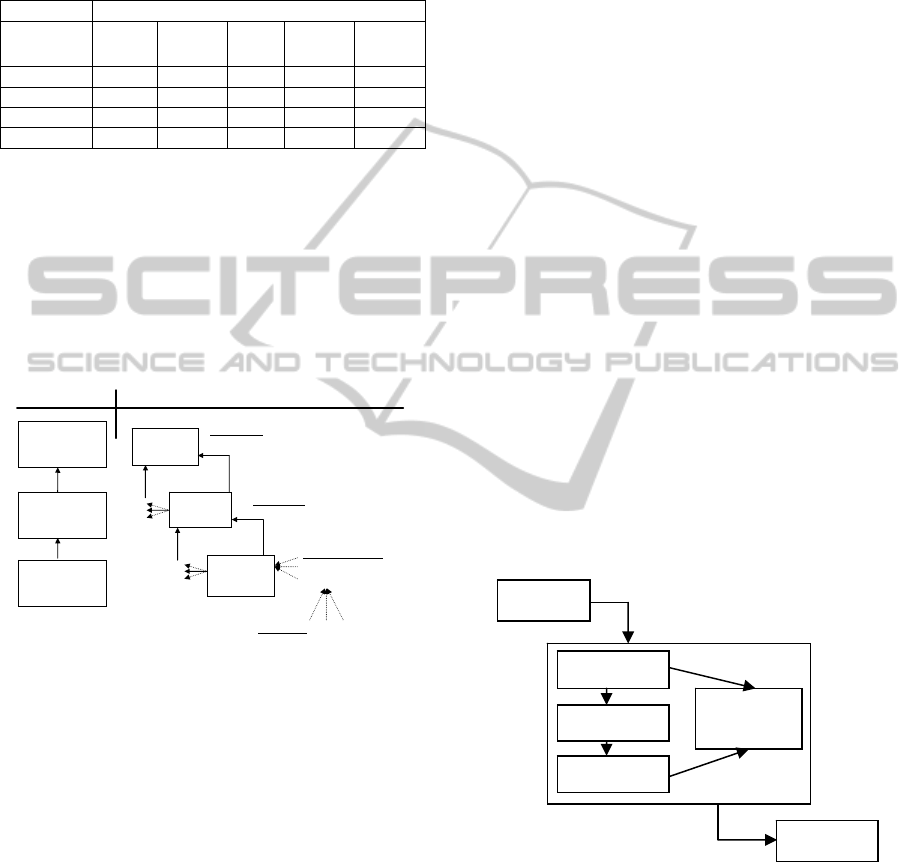

As illustrated in the architecture in Figure 8, the

Corpus is the application domain in Excel. The

metadata (information about the identified data),

Concept (similar or alternate keyword (synonym) in

the metadata) to feature (the specific data) and

Message (the selected information to extract from)

are represented in the event information section with

the related mechanisms / defect types. The mining of

data with the recognition tool is done in the Data

Extraction section. The section returns the results,

while the update is when the ontology is amended

with any newly found concepts.

Figure 8: The architecture to extract and analyse data.

3.3.2 Sanity Check Procedure

This sanity check ensures data integrity (Boritz,

2005). The sanity check technique in this context is

the manual count of concepts identified, captured

and stored as a taxonomy in the ontology. The data

extracted from the event information should be

accurate and consistent irrespective the number of

times the tool is implemented as long as the

ontology is updated accordingly with captured

concepts. The audit is done on the update section as

presented within the architecture in Figure 8.

The sanity check is physically counting the

concepts and by running the embedded Recognition

tool. The procedures for the technique are as

follows:-

1. TR Right - when the extracted concepts from the

event information are correct. An example is ‘fret’.

2. TR Miss - refers to the concepts not captured by

the recognition tool but are correct. The concepts are

identified from failure events and fixed by adding

the same onto the ontology e.g ‘frozen’.

3. False Positive (FP) - when there is an extraction

of an incorrect concept in the event information. The

fix for the FP is removal of the concept in the

taxonomy e.g ‘close’.

4. Human error - when there is a misspelling of

actual concepts. The recognition tool will not

identify and capture it. For instance ‘luse’ instead of

‘lose’, to fix this, the word ‘luse’ is added in the

ontology. The reason for this is because service

representatives report events from different locations

in the world and typing mistakes are bound to occur,

but it is advisable to train the tool to extract ‘luse’.

Figure 9: Manually identified mechanisms.

Concepts TR Missed: The number of concepts which

the recognition tool missed frozen, wetting,

degradation and overheat. As indicated in Figure 9,

the concepts missed are manually identified and

captured onto the ontology, while Figure 8 illustrate

the identification process.

Concepts False Positive (FP): The number of

concepts which returned as FP is four (4), e.g ‘mark,

markings, mark and another mark’. These words are

not concepts, hence, should not be captured by the

recognition tool.

Mechanism DP Event Information TR

Right

TR

Miss

FP HE

DP Speed validation,

shutdown made

causes a frozen of

the component

A degradation of

the rail due to

stretch resulting

from overheat

4

* FP: False Positive; HE Human; DP Deterioration process

Overheat

Degradation

Frozen

Stretch

Data Extraction

Corpus

Feature

Update Message

Concept

Metadata

DevelopmentofanOntologyforAerospaceEngineComponentsDegradationinService

115

The ontology is updated with the newly identified

concepts. The ontology is uploaded and the analysis

is repeated. The manually identified concepts were

captured by the recognition tool as indicated in

Figure 9. The number of mechanisms which

appeared in the TR right column means the sanity

check rightly identifies the concepts captured by the

tool as shown in the first and third columns.

Figure 10: Analysed data with identified mechanisms.

As indicated in Figure 10, the analysed data

returned the expected concepts. This is feasible

because the tool had been trained to identify and

capture the new concepts. That is, after update and

run of the ontology, the concepts found.

4 RESULTS

A case study in the area of taxonomy of degradation

mechanisms allows for initial evaluation of the

effectiveness of the process. Maintenance event

information was used in this research. The

recognition tool developed in Java enhanced the

extraction process.

In the first experience, one hundred rows of

records were selected and examined. The rows were

manually analysed by the researchers, who manually

identified the mechanisms. There was a manual

comparison with the results found on the

information extraction tool.

The results show the current and future states

(‘AS-IS’ and ‘TO-BE’) of the ontology. While the

‘AS-IS’ is an ill-structured presentation of keywords

anywhere in the ontology module, the ‘TO-BE’ is a

well-structured representation of the taxonomy of

the degradation mechanisms within the ontology

module. The ‘TO-BE’ is a proposed and agreed

structural arrangement by policy-makers. A high

level illustration of the ‘TO-BE’ is presented in

Figure 11 as deformation, wear, fracture and

corrosion. Table 5 shows a comprehensive final

taxonomy of the ‘TO-BE’ ontology.

Figure 11: Final Taxonomy of Degradation Mechanisms

for the TO-BE Ontology.

The presence of exclusion is needed in certain

elimination process. The exclusion is implemented

with the symbol ‘!!’. Two approaches were

attempted to fix FP issues: the first is the exclusion

of concepts in the ontology module and secondly,

classify in another ontology module. Both are good,

but in term of clear-cut representation and

performance, the latter is better.

A total 2420 event records were analysed. First,

the number of concepts ‘contained’ and ‘NOT

contained’ in the event information is based on the

existing ‘AS-IS’ structure. The event information

was interrogated with the extraction tool. The

outcome of the number of concepts and the

percentage is presented.

At the start of the process, the values were 499 as

‘contained’ concepts and 1921 as ‘NOT contained’.

That is a 21 to 79 percentage of the total records. At

this stage, the ontology was refined and updated

with concepts found in the event information.

To confirm the validity of the process, the first

97 records were selected. 31 rows ‘contained’

concepts while the 66 rows did ‘NOT contained’

concepts. The 97 records were ‘sanity checked’ to

ensure concepts were correctly recognised. The

outcome was 12 rows were blank with null

keywords. Amongst the 85 records analysed, the

domain expert identified some concepts which the

recognition tool missed and added.

The records were continually iteratively

processed by identifying new concepts and updating

the ontology. While the amended ontology was

uploaded and run, the outcome shows a massive

improvement when compared to the results of the

initial process. The outcome is based on the initial

startup of the system and software. Whereas 892

mechanisms ‘contained’ were filtered, which is

37.9%, the 1528 mechanisms ‘not contained’ were

observed, which is 63.1%. The total records of rows

analysed were 2420.

The researchers used the last 66 records to

Fracture

Corrosion

Deformation Wea

r

Mechanism DP Event Information TR

Right

TR

Miss

FP HE

Frozen

Degradation

Stretch

Overheat

DP Speed validation,

shutdown made

causes a frozen of

the component

A degradation of

the rail due to

stretch resulting

from overheat

4

* FP: False Positive

;

HE Human

;

DP Deterioration

p

rocess

Conce

p

ts found

Degradation Mechanisms

KEOD2014-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

116

‘double-check’ the validity of the techniques and the

effectiveness of the ontology. The number of

concepts identified is counted manually before the

first run of the ontology. However, based on the 66

records analysed by manually checking and

counting, 67 concepts were identified instead of 63,

including 4 false positives and 7 false negatives

missed by the recognition tool. After the update of

the AS-IS ontology, the 7 false negative concepts

which resulted in 70 identified concepts.

The results were also compared with adopting a

precision, recall and F measurement for performance

evaluation of the field of information retrieval (Liu

et al., 2007; Dellschaft and Staab, 2006). Also, in

ascertaining the extraction performance for learning

based on the manual identification regarding

Precision and Recall (Sabou et al., 2005).

Precision = mechanisms_found/All_expected

Recall = mechanisms_found/All_mechanisms_found

F = (2 x Precision x Recall)/(Precision + Recall)

where, mechanisms_found is the number of

keywords returned, All_expected is the total

expected keywords returned; All_mechanisms_found

total keywords found. The precision of 94%, recall

of 90% and F measurement of 92%.

Ontology pruning and refinement (Maedche and

Volz, 2001) are introduced at this stage. Pruning

(Sabou et al., 2005), is removing irrelevant concepts

in the ontology, that is 34 assumed old concepts

which are classified into a different ontology

module. The refinement is effective by the upload

and run of the TO-BE ontology with the relevant

concepts based on the new classification. This

refinement accurately and precisely retains the

newly identified and the existing concepts regarding

the application domain. A total of 42 concepts

returned. The success rate is based on the ‘After

Update’ of the agreed ‘TO-BE’ ontology.

In using the Ontology building support (Maedche

and Volz, 2001), the ontology precision model

would be

(Returned + found) / (Returned + found + old)

Where Returned is the concepts based on agreed

‘TO-BE’ ontology by the domain expert, found is

the concepts not considered during the building of

the ontology and old are the irrelevant concepts

Table 5: Final Taxonomy of the TO-BE Ontology.

Deterioration process

Deterioration Degradation

Chemical

deterioration

Mechanical deterioration

Corrosion Deformation Fracture Wear Cosmetic

deterioration

Deterioration

cause

Location Containment Material

property

change

Anti-corrosion Deformed Burst Worn Blueing Friction Fouls Leak Brittled

Burnt Bent Cracked Abraded Polished Fatigue De-bond Drip Embrittled

Galvanic

corrosion

Builtup Cut Brinelled Tarnished Oscillated Clashed Weep Hardened

Oxidised Deposited Perforated Cavitated Bruised Resonated Contacted Lost Softened

Pitted - corrosion Bulged Disintegrated Chaffed Burnished Hit Debonded Misfilled Coked

Stress corrosion Collapsed Ruptured Eroded Stained Bumped Ratcheted Breakout Glazed

Rusted Shingled Snapped Scrape Streaked Banged Released Spill Dealloyed

Sulphidated Compressed Divided Frayed Discoloured Wiggled Separated Melted

Microbial

corrosion

Elongated Split Fretted Discolored Vibrated Delaminate

Laquered

Scorched Extruded Flaked Lumped Strained Slipped

Transmission

Weakened

Thermal erosion Distorted Punctured Galled

Stressed Displaced Blocked

Thermal

deterioration

Flattened Spalled Picked up Fire Pooled Clogged Creeped

Shrunk Blistered Roughened Ingested Hide Starvation Frozen

Twisted Peeled Plucked Injestion Dislocated Short circuit

Stretched Wrecked Scalloped Ingress Misaligned Jammed

Burred Sheared Material transfer Misassembled Seized

Battered Lifted Plowed Damaged Misclocked

Dented Broken Exfoliation Overloaded Mismatched

Depressed Fragmented Scuffed Overspeed Misfitted

Dimpled Chipped Rubbed Overpressure

Lapped Creviced Overfill

Indented Torn Contaminated

Nicked Iced

Grooved Overheat

Gouged Bruise

Scratched

Corrosion

fatigue

Scored Unbalanced

Skewed

Foreign object

damage (fod)

DevelopmentofanOntologyforAerospaceEngineComponentsDegradationinService

117

removed from the ontology module. From this

exercise, it is observed that the higher ratio results in

better support for ontology development. The

precision reveals 55% of relevant instances

retrieved. The result shows a significant pass rate

compare with ‘AS-IS’ ontology of concepts. This is

dependent on the application domain and the

relevant concepts in the corpus is training the

software to learn.

5 CONCLUSIONS

This paper demonstrates the verification and

validation of the taxonomy of the degradation

mechanisms based on the sanity check technique.

The analysis of the framework is validated by

manual identification, capture and counting of

individual concept. The relevance of this taxonomy

is to improve service knowledge.

The iterative sanity check technique was useful

for the practical task carried out to audit and certify

the current ontology. The same technique applies to

the classification of newly identified concepts.

The case study focuses on the types of damage

observed by service engineers and classified

hierarchically in accordance with the predominant

degradation mechanisms. The validation process can

be used in the audit of information systems.

This research can help other service related

application here access to historical information is

essential, e.g. predicting system failure and spare

parts planning.

The future work within this project involves

developing a novel remaining useful life prediction

using both current health information and history of

a component.

The idea presented in this paper relies on the

PLAN, DO, CHECK and ACT (PDCA) business

process model (Q-BPM, 2014). The PDCA cycle

involves continuous management activities to

support decision making. It is an iterative operation

observed as sanity checks. Techniques such as a

workflow diagram can be used. With constant

review and the addition of new degradation

mechanisms, the efficiency, effectiveness and

performance of the ontology is improved.

This paper discussed how the ‘TO-BE’ ontology

structure was developed. Classification is on the

basis of the most common or predominant type of

degradation experienced by mechanical components.

However, a significant difference in results between

previous analysis, TO-BE’ ontology and the amount

of keywords which were categorised into another

ontology module. There is an improvement as the

precise concepts captured were retrieved.

Furthermore, compound words (‘fire detector’,

‘fire wire’) can be excluded in the ontology in order

to prevent redundancy of concepts. The iterative

process this paper can be used in parallel with the

‘AS-IS’ and ‘TO-BE’ framework for effective and

efficient execution of tasks in a sequential manner.

ACKNOWLEDGEMENTS

This work is funded by the EPSRC (Engineering and

Physical Sciences Research Council, UK), grant

number EP/I033246/1 delivered by EPSRC Centre

for Innovative Manufacturing in Through-life

Engineering Services. The authors also acknowledge

Rolls-Royce PLC for their support in this research.

REFERENCES

Ahmad, M. N. and Colomb, R. M., 2007. Managing

ontologies: a comparative study of ontology servers,

Proceedings of the eighteenth conference on

Australasian database-Volume 63, Australian

Computer Society, Inc., Ballarat, Australia, pp.13-22.

Ameen, H. A., Hassan, K. S. and Mubarak, E. M. M.,

2011. Effect of loads, sliding speeds and times on the

wear rate for different materials, American journal of

scientific and industrial research, vol. 2, pp. 99-106.

Boritz, J. E., 2005. IS practitioners' views on core concepts

of information integrity, International Journal of

Accounting Information Systems, vol. 6, no. 4, pp.

260-279.

Correia, J., Girardi, R. and de Faria, C. G., 2011.

Extracting Ontology Hierarchies From Text(S), SEKE,

Knowledge Systems Institute Graduate School, pp.

398-401.

Dadzie, A., Bhagdev, R., Chakravarthy, A., Chapman, S.,

Iria, J., Lanfranchi, V., Magalhães, J., Petrelli, D. and

Ciravegna, F., 2009. Applying semantic web

technologies to knowledge sharing in aerospace

engineering, Journal of Intelligent Manufacturing, vol.

20, no. 5, pp. 611-623.

Dale, R., Moisl, H. and Somers, H., 2000. Handbook of

natural language processing, CRC Press. Boca Raton,

USA.

Dellschaft, K. and Staab, S., 2006. On how to perform a

gold standard based evaluation of ontology learning,

The Semantic Web-ISWC 2006, Springer, Berlin

Heidelberg, pp. 228-241.

del-Rey-Chamorro, F. M., Roy, R., van Wegen, B. and

Steele, A., 2003. A framework to create key

performance indicators for knowledge management

solutions, Journal of Knowledge management, vol. 7,

no. 2, pp. 46-62.

KEOD2014-InternationalConferenceonKnowledgeEngineeringandOntologyDevelopment

118

Doultsinou, A., Roy, R., Baxter, D., Gao, J. and Mann, A.,

2009. Developing a service knowledge reuse

framework for engineering design, Journal of

Engineering Design, vol. 20, no. 4, pp. 389-411.

Gruber, T. R., 1993. A translation approach to portable

ontology specifications, Knowledge acquisition, vol. 5,

no. 2, pp. 199-220.

Guarino, N., Oberle, D. and Staab, S., 2009. What is an

Ontology?, in Handbook on ontologies, Springer,

Springer, Berlin Heidelberg, pp. 1-17.

Jasper, R. and Uschold, M., 1999. A framework for

understanding and classifying ontology applications,

Proceedings 12th Int. Workshop on Knowledge

Acquisition, Modelling, and Management KAW,

Stockholm, Sweden, vol. 99, pp. 16-27.

Jiang, J., 2012. Information extraction from text, in

Mining text data, Springer, Berlin Heidelberg, pp. 11-

41.

Kim, S., Aurisicchio, M. and Wallace, K., 2009. Towards

automatic causality boundary identification from root

cause analysis reports, Journal of Intelligent

Manufacturing, vol. 20, no. 5, pp. 581-591.

Lanfranchi, V., Bhagdev, R., Chapman, S., Ciravegna, F.

and Petrelli, D., 2007. Extracting and searching

knowledge for the aerospace industry, Proceedings of

1st European Semantic Technology Conference, .

Liu, Y., Zhang, J., Tjondronegoro, D. and Geve, S., 2007.

A shape ontology framework for bird classification,

Digital Image Computing Techniques and

Applications, 9th Biennial Conference of the

Australian Pattern Recognition Society, IEEE, pp.

478-484.

Maedche, A. and Volz, R., 2001. The ontology extraction

& maintenance framework Text-To-Onto, Proc.

Workshop on Integrating Data Mining and Knowledge

Management, California, USA.

Medjaher, K., Tobon-Mejia, D. A. and Zerhouni, N., 2012.

Remaining Useful Life Estimation of Critical

Components With Application to Bearings, IEEE

Transactions on Reliability, vol. 61, no. 2, pp. 292-

302.

Norman, E. D., 2013. Mechanical Behavior of Materials,

4th ed, Pearson, England.

Okoh, C., Roy, R., Mehnen, J. and Redding, L., 2014.

Overview of Remaining Useful Life Prediction

Techniques in Through-Life Engineering Services, 6th

CIRP Conference on Industrial Product-Service

Systems (IPSS 2014), Windsor, Ontario, Canada, 1-2

May.

Pomeroy, M. J., 2005. Coatings for gas turbine materials

and long term stability issues, Materials & Design,

vol. 26, no. 3, pp. 223-231.

Q-BPM, 2014. AS-IS and TO-BE Process model, available

at: http://en.q-bpm.org/mediawiki/index.php/As-is#

Overview (accessed March/18).

Rausand, M. and Høyland, A., 2004. System reliability

theory: models, statistical methods, and applications,

New Jersey, 2

nd

edition, John Wiley & Sons.

Roy, R., Shaw, A., Erkoyuncu, J. A. and Redding, L.,

2013, Through-Life Engineering Services, Journal of

Measurement and Control, vol. 46, no. 6, pp. 172-175.

Ryu, P. and Choi, K., 2006. Taxonomy learning using

term specificity and similarity, Proceedings of the 2nd

Workshop on Ontology Learning and Population:

Bridging the Gap between Text and Knowledge,

Syndey, Australia, pp. 41-48.

Sabou, M., Wroe, C., Goble, C. and Mishne, G., 2005.

Learning domain ontologies for web service

descriptions: an experiment in bioinformatics,

Proceedings of the 14th international conference on

World Wide Web, ACM, Chiba, Japan, pp. 190-198.

Saleem, K. and Bellahsene, Z., 2008. Automatic extraction

of structurally coherent mini-taxonomies, Conceptual

Modeling-ER 2008, Springer, Berlin Heidelberg, pp.

341-354.

Serra, I., Girardi, R. and Novais, P., 2013. PARNT: A

Statistic based Approach to Extract Non-Taxonomic

Relationships of Ontologies from Text, Information

Technology: New Generations (ITNG), 2013 Tenth

International Conference, Las Vagas, Navada, pp.

561-566,

UNAS, S. M., 2000. Ontological engineering: common

approaches and visualisation capabilities, Informatica,

Vilnius, Lithuania, vol. 11, no. 1, pp. 41-48.

Uschold, M. and Gruninger, M., 2004. Ontologies and

semantics for seamless connectivity, ACM SIGMod

Record, vol. 33, no. 4, pp. 58-64.

Wang, T., Li, Y., Bontcheva, K., Cunningham, H. and

Wang, J., 2006. Automatic extraction of hierarchical

relations from text, The Semantic Web: Research and

Applications, Springer, Berlin Heidelberg, pp. 215-

229.

Zhang, Z., Gentile, A. L. and Ciravegna, F., 2011.

Harnessing different knowledge sources to measure

semantic relatedness under a uniform model,

Proceedings of the Conference on Empirical Methods

in Natural Language Processing, Association for

Computational Linguistics, pp. 991-1002.

DevelopmentofanOntologyforAerospaceEngineComponentsDegradationinService

119