Development of Techniques for the Fabrication of Micro- and

Nano-batteries for Biomedical Applications

Hayley Osman

1

, V. S. Sandeep Akkanapragada

1

, Jacob Conner

2

and Saibal Mitra

1

1

Dept. of Physics, Astronomy and Materials Science, Missouri State University,

901 S. National Avenue, Springfield, MO, U.S.A.

2

US Photonics Inc., 2241 Kearney Street, Springfield, MO, U.S.A.

Keywords: Microbatteries, Nanobatteries, Femtosecond Laser, iCVD, Biomedical Applications.

Abstract: Future bio-medical devices with dimensions in the nanoscale region will need independent energy sources

to power them. Lithium-ion micro- and nano-batteries are excellent candidates for these power sources. Our

proposed nanobattery design ensures that these batteries remain lightweight and safe with fast rechargeable

times. We have used femtosecond laser for precision machining. Intense electric fields produced by the laser

beam induces electrical breakdown due to avalanche ionization. For femtosecond pulses, this breakdown

threshold remains fairly deterministic thereby allowing the use of femtosecond lasers for micro- and nano-

machining. The nanobattery consisted of an anode, cathode and separator. The anode was made of graphite

or molybdenum oxide while the cathode was made of LiCoO

2

. The separator was a Kapton membrane with

an array of n x n holes micro- or nano-scale holes machined into it which were then filled with Li-based

electrolyte. For biomedical applications these batteries must be packaged with bio compatible polymers.

Initiated chemical vapor deposition is an attractive technique where polymeric films are deposited by

activating a mixture of gas of monomers and initiators. This solventless technique is substrate independent

and should lead to the deposition of biocompatible films that can be used to coat and package electronic

devices.

1 INTRODUCTION

As technology progresses there is an increasing

demand to shrink biomedical electronic devices to

the micro- and nano-scale. These nanoscale

biomedical devices will need bio-compatible energy

sources to provide power on demand. Thus,

development of micro- and nano-batteries is of great

interest to the biomedical instrumentation

community.

Ideally, a nanobattery is envisioned as a single

battery cell with nanoscale dimensions that can be

integrated on to a nanodevice. However, given the

current status of technology, it is difficult to

fabricate a single nanobattery with assured reliable

performance. Thus the first logical step to achieve

this goal is to develop a macrobattery with an array

of micro- or nano-cells. Each cell is itself a battery

and they are electrically connected in parallel so that

the total power drawn from this device is the sum of

power from this array of micro- or nano-cells. Once

this battery is fabricated then bio-compatible

coatings need to be developed to package the

nanobattery systems so that they may be implanted

safely in biological systems.

The nanobattery system developed by our group

also has the following advantages. While

conventional batteries are typically heavy and this

limits their use in a number of applications,

nanobatteries are lightweight and hence versatile.

Runaway thermal failure is eliminated since each

nanocell is electrically isolated from the rest of the

nanocells. Also, since the volume of each cell is

small, any thermal runaway reaction is contained in

a nanocell and will produce limited heat that the

battery can easily withstand.

Given their high energy density, Lithium ion

(Li

+

) based battery cells have become most accepted.

A survey of literature shows that there are numerous

papers that describe either the use of very thin films

of electrolyte materials to construct battery systems

or describe the potential of these films to be used in

batteries (Park et al., 2000a); (Park et al., 2000b);

(Dudney et al., 2000); (Humble et al., 2003);

127

Akkanapragada V., Conner J., Osman H. and Mitra S..

Development of Techniques for the Fabrication of Micro- and Nano-batteries for Biomedical Applications.

DOI: 10.5220/0004234601270131

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2013), pages 127-131

ISBN: 978-989-8565-34-1

Copyright

c

2013 SCITEPRESS (Science and Technology Publications, Lda.)

(Humble et al., 2001). However, recent papers by

number of researchers have described the

construction of micro- and nano-batteries with

diameters up to 200 nm across and 60μm deep

(Brazier et al., 2008); (Zhang et al., 2004); (Dewan

et al., 2003); (Stephan et al., 2003); (Vorrey and

Peters, 2003); (Layson et al., 2003). Individual

growth and use of nanoelectrodes using carbon

nanotubes were also described (Jogelkar et al.,

2004). However, these nanobatteries had some

serious drawbacks. The size and arrangement of

individual nanocells, which were fabricated porous

alumina, varied substantially. Only a small fraction

of the cells were electrically active and the outcome

was completely stochastic.

We have developed a laser machining technique

using a femtosecond laser that allowed us to

successfully fabricate array of nanocells in a Kapton

membrane. The cells are isolated and are connected,

in parallel, by the cathode and anode.

2 EXPERIMENTAL DETAILS

2.1 Development and Construction of

the Battery

All materials are susceptible to damage by a focused

laser beam when the induced electric field produced

by the laser beam is comparable to the Coulomb

field an electron sees in the proximity of the atomic

nucleus leading to the creation of an avalanche

process for the free electrons. This process also

occurs in transparent materials which become

opaque when the free electron density approaches

the critical density for that particular light. It is

important to note that this optical breakdown has a

non-linear dependence on intensity and this allows

for the damage to be restricted to the subdiffraction

limit by “thresholding” allowing the fabrication of

nanoscale features (Squier et al., 1991); (Jogelkar et

al., 2003). Though, optically induced dielectric

breakdown scales as t

1/2

, where t is the pulse width

for pulse durations longer than 10 ps, the damage

threshold remains fairly constant (and deterministic)

for shorter pulses (Stuart et al., 1996). For ultra-short

pulses, polarization of the beam also plays an

important part. For linear polarization, a machined

hole becomes a narrow groove in the direction of the

polarized beam. This effect was pronounced at low

pulse energy close to the threshold of the material

(Venkatakrishnan et al., 2002). At low energies, only

the central part of the beam has enough energy to

ablate the material and thus, in this energy regime,

polarization plays an important part. For laser pulses

with a Gaussian spatial beam profile, the diameter D

of the ablated area is given by

2

(1)

Here ω

0

is the beam radius and φ

0

and φ

th

are the

laser fluence and the threshold modification

fluences, respectively. The laser pulse energy E

pulse

is related to laser fluence by

2

(2)

Combining the above two expression, we have

(3)

where and are fitting parameters ( gives the

threshold energy). It is clear by controlling the

energy of the laser pulse the diameter of the ablated

area can be controlled.

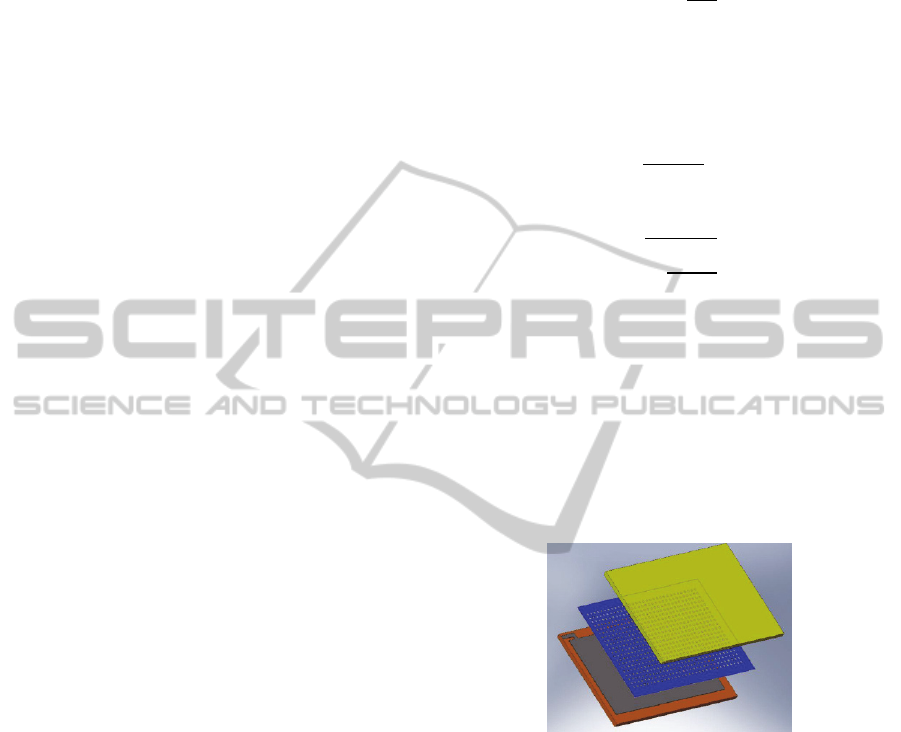

The basic battery design is shown below in

Figure 1. The battery consists of three layers. The

middle layer is made of Kapton with an n x n array

of micro- or nano-cells machined into it. The bottom

and top layers are the two electrodes.

Figure 1: Basic design of a nanobattery. The middle layer

is laser-machined Kapton with an n x n array of nanocells.

The top and bottom layers are the electrodes.

In this work, we used commercially available

lithium cobalt oxide (LiCoO

2

) as the cathode and

molybdenum oxide (MoO

2

) as an anode. Lithium

hexafluorophosphate (LiPF

6

) was used as an

electrolyte. Details of the construction of these

micro- and nano-batteries are given elsewhere

(Conner and Mitra, 2011a; 2011b). In addition to the

micro- and nano-batteries, control batteries were

also constructed. Control batteries had the same

electrodes and electrolytes but polyolefin separators

were used instead of laser-machined Kapton

membrane.

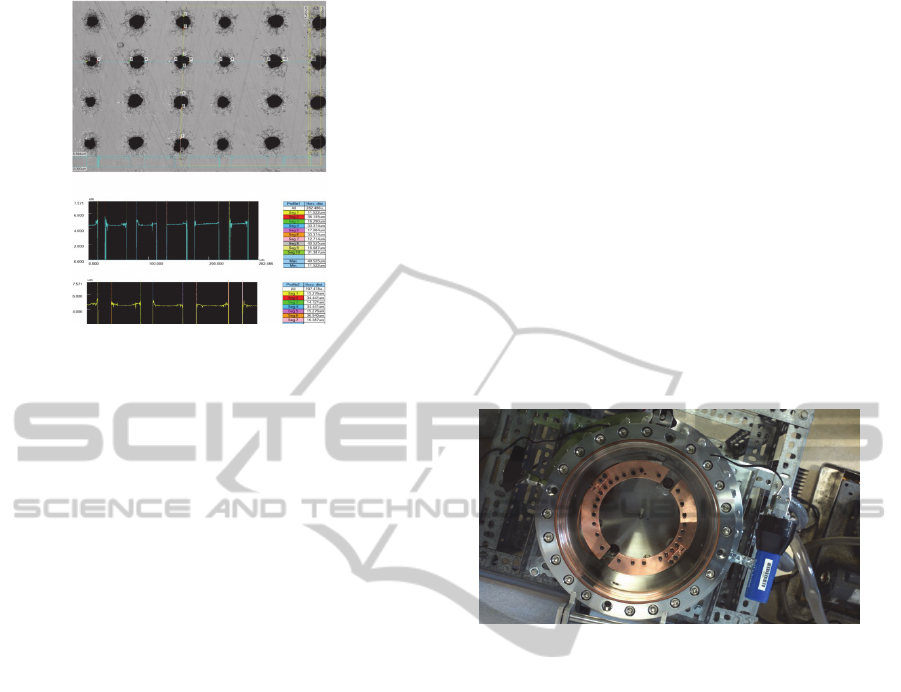

Figure 2 shows the arrangement of micro-cells in

a laser-machined Kapton membrane.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

128

Figure 2: Array of cells machined in a Kapton membrane.

A 12 mm thick Kapton membrane was placed on a mask

and ablated with the laser. Note the near vertical cell

walls.

Once constructed, the current (I) versus potential

(V) was tested for these nanobatteries on an

electrochemical workstation CHI 660C. The open

circuit voltage (V

oc

) for each battery was measured

before each scan. For each battery, the first scan was

started from V

oc

and increased to 4.1 volts. The step

size was 0.001 volts and the scan rate was 0.01

volts/s. The potential for subsequent segments would

be cycled from 4.1 volts to 2.5 volts. Each battery

was cycled five times.

The performance of a micro-battery with Kapton

separator and LiCoO

2

and graphite and MoO

3

electrodes were analyzed and compared with the

control batteries. The performance of the

micro/nanobatteries is superior to the control

batteries with polyolefin separators. When a battery

is cycled through 2.5 volts and 4.1 volts, a certain

amount of charge the cycled charge is given by the

enclosed curve. In all cases, the micro-batteries

showed superior performance compared to the

control batteries. Taking into account the fact that

only 58% of the area in micro-batteries are active

compared to the control batteries, the performance

of micro- and nano-batteries is estimated to be at

least better by 40%. This is an important observation

for the use of micro- nano-batteries in nanoscale

devices for biomedical applications.

2.2 Challenges for Packaging

For use as a bio-medical power supply that can be

implanted in a biological system, the nanobatteries

need to be packaged in a safe and reliable way.

Given the small size of these devices, an attractive

packaging method is to use bio-compatible polymer

coatings. It is important to keep the overall size of

the system in the nanoscale region.

An attractive method is initiated chemical vapor

deposition (iCVD) of polymers. While CVD is a

mature technology, application of iCVD for

packaging of nanobatteries with polymer films

remains at a conceptual stage. In this process,

polymers are deposited from vapor phase monomers.

The reaction rate is greatly enhanced upon

introducing initiator molecules (Baxamusa et al.,

2009). Typically, a volatile initiator molecule is

mixed with the monomer and activated over a heated

filament in a vacuum chamber. iCVD is a one-step

film growth method which mimics the free-radical

chain growth polymerization. Figure 3 below shows

the top view of the iCVD reactor that is under

construction in our laboratory.

Figure 3: Top view of the iCVD reactor under

construction.

The reactor is stainless steel chamber with an

array of nickel-chrome filaments. The copper

electrodes allow the placing of evenly spaced

filaments across the substrate (which sits below the

filament). This geometry allows for the even

distribution of temperature. The filaments are

resistively heated and the temperature of the

filaments can be raised to 400

0

C. The substrate will

be placed about 2.5 cm from the filament array and

will be cooled actively to maintain a temperature of

50

0

C.The monomer and the initiator will be

premixed and introduced over the filaments. The

initiator molecules will decompose either on the

surface of the filaments or in the hot zone near the

filament. The iCVD method has several advantages.

First, the ability to conformally coat surfaces will

allow the coating of nanostructures and objects of

irregular shape. Second, the associated temperatures

needed for film deposition is low. This will allow

deposition on fabricated electron devices like

nanoscale batteries and biological systems without

causing damage.

Lastly, one can use a variety of commercially

available monomers to grow a variety of polymeric

DevelopmentofTechniquesfortheFabricationofMicro-andNano-batteriesforBiomedicalApplications

129

materials. There are a number of candidates for

biocompatible and biopassive surfaces. For example,

organosilicone coatings are electrically insulating

and biopassive.

Poly(trivinyltrimethylcyclotrisiloxane) (PV

3

D

3

)

films have been deposited by using iCVD

(O’Shaughnessy et al., 2006); (Murthy et al., 2002).

PV

3

D

3

has a highly crosslinked structure that makes

it insoluble in both polar and non-polar solvents.

This makes the structure also very stable. Another

possible monomer is Poly (tetrafluoroethylene)

(PTFE). It has been found that the rate of deposition

of PTFE films is dramatically increased with the

addition of perfluorooctane (PFOS) in the gaseous

mixture (Baxamusa et al., 2009). PTFE films can be

conformally coated. They are also hydrophobic and

biocompatible and are used in the medical device

industry and hence are expected to be a good

candidate material as a nanobattery packaging

system.

The iCVD films can be deposited rapidly and the

technology is scalable. Hence, iCVD is a very

attractive technique for packaging of nanobatteries

and any other nanoscale medical devices.

3 CONCLUDING REMARKS

In this work we report the fabrication of micro- and

nano-batteries using femtosecond laser machining.

Though the first batteries are array of n x n micro-

cells, laser machining is clearly a technology that

would allow the fabrication of a single nanobattery.

Though the field of nanobatteries is still in its

infancy, we have outlined methods that should lead

to the fabrication of an array of nanobatteries or

even a single nanobattery appropriately packaged in

biopassive and biocompatible coatings. This, then,

could be the first step to the development of power

sources for future nanodevices that can be directly

implanted in biological systems.

ACKNOWLEDGEMENTS

The authors would like to thank the National

Science Foundation and Missouri State University

for financial support.

REFERENCES

Baxamusa, S. H.; Im, S. G.; and Gleason, K., 2009.

“Initiated and oxidative chemical vapor deposition a

scalable method for conformal and functional polymer

films on real substrates”, Phys. Chem. Chem. Phys. 11,

5227 – 5240.

Brazier, A.; Dupont L.; Dantras-Laffont L.; Kuwata, N.;

Kawamura, J.; Tarascon, J.-M., 2008. “First cross-

section observation of an all solid-state lithium-ion

“nanobattery” by transmission electron microscopy”,

Chem. Mater. 20, 2352-2359.

Dewan, C. and Teeters, D., 2003. “Vanadia xerogel

nanocathodes used in lithium microbatteries”, J.

Power Sources 119-121, 310-315.

Dudney, N. J., 2000. “Addition of thin-film organic solid

electrolytes (Lipon) as protective film in lithium

batteries with liquid electrolyte”,“J. Power Sources

89, 176.

Humble, P. H. and Harb, J. N., 2003. “Optimization of

Nickel-Zinc microbatteries for hybrid powered

microsensor systems”, J. Electrochem. Soc. 150, 1182.

Humble, P. H.; Harb, J. N.; Lafolette, R., 2001.

“Microscopic nickel-zinc batteries for use in

autonomous microsystems”, J. Electrochem. Soc. 148,

1357.

Jogelkar, A. P.; Liu, H.-H.; Meyhofer, E.; Mourou, G.;

and Hunt, A. J., 2004 “Optics at Critical Intensity:

Applications to Nanomorphing”, PNAS, 101, 5856-

5861.

Jogelkar, A. P.; Liu, H.-H.; Spooner, G.; Meyhofer, E.;

Mourou, G.; and Hunt, A., 2003. J. Appl. Phys. B. 77,

23-30.

Layson, A. L.; Gadad, S.; and Teeters, D., 2003.

Electrochim. Acta 48, 2207.

Murthy, S. K.; Olsen, B. D. and Gleason, K. K., 2002.

“Initiation of cyclic vinylmethylsiloxane

polymerization in a hot-filament chemical vapor

deposition process”, Langmuir 18, 6424–6428.

O’Shaughnessy, W. S.; Gao, M. L. and Gleason, K. K.,

2006. “Ínitiated chemical vapor deposition of

trivilylmethylcyclotrisilozane for biomaterial

coatings”, Langmuir, 22, 7021–7026.

Park ,Y. J.; Kim, J. G.; Kim, M. K.; Kim, H. G.; Chung,

H. T.; Park, Y., 2000. “ Electrochemical properties of

LiMnO thin films: 24 suggestion of factors for

excellent rechargeability”, J. Power Sources 87, 69.

Park ,Y. J.; Park, K. S.; Kim, J. G.; Kim, M. K.; Kim, H.

G.; Chung, H. T., 2000. “Characterization of tin

oxide/LiMn

2

O

4

thin-film cell”, J. Power Sources 88,

250.

Squier, J.; Salin, F.; Mourou, G.; and Her, H. H., 1991.

“100-fs Pulse Generation and amplification in

Ti:Al

2

O

3

”, Opt. Lett. 16, 324-327.

Stephan, A. M. and Teeters, D., 2003. “Characterization of

PVdF-HFP polymer electrolytes confined in micor and

nanopores”, Electrochim. Acta 48, 2143.

Stuart, B. C.; Feit, M. D.; Herman, S., 1996. “Effect of

polarization on ultrashort pulsed laser ablation of thin

metal films”, J. Opt. Soc. Am, B 13, 459..

Venkatakrishnan, K.; Tan, B.; Stanley, P.; and Sivakumar,

N. R., 2002. “The effect of polarization on ultrashort

pulsed laser ablation of thin metal films”, J. Appl.

BIODEVICES2013-InternationalConferenceonBiomedicalElectronicsandDevices

130

Phys. 92, 1604-1607.

Vorrey, S. and Teeters, D., 2003. “Study of ion conduction

of polymer electrolytes confined in micro and

nanopores”, Electrochim. Acta 48, 2137.

Zhang, Z.; Dewan C.; Kothari, S; Mitra, S.; Teeters, D.,

2004. “Carbon nanotube synthesis, characteristics and

microbattery applications”, Mat. Sci. and Engg. B,

116, 293.

DevelopmentofTechniquesfortheFabricationofMicro-andNano-batteriesforBiomedicalApplications

131