A SOFTWARE PRODUCT LINE FOR ENERGY-EFFICIENT

CONTROL OF SUPPLEMENTARY LIGHTING IN

GREENHOUSES

Hans Martin Mærsk-Møller and Bo Nørregaard Jørgensen

The Maersk Mc-Kinney Moller Institute, University of Southern Denmark, Campusvej 55, 5230 Odense M, Denmark

Keywords: Software product line engineering, Software development, Software reuse, Energy-efficient production.

Abstract: In 2009, the industrial-size greenhouses in Denmark consumed 0.8 percent of the national electricity

consumption. The increasing energy costs for heating and supplementary lighting have bankrupt many

growers in 2010 causing an urgent need for remaining growers to reduce the consumption while preserving

production quality. This paper presents a novel approach addressing this issue. We use weather forecasts

and electricity prices to compute cost- and energy-efficient supplementary light plans that achieve the

required plant growth defined by the grower. Experiments performed during the winter of 2009 – 2010

showed 25 percent savings with no negative effect on plant quality. To accelerate the impact of our

approach, we chose to use Software Product Line Engineering, as it enables a greater variety of related

software tools to be created faster. We have created a web-based analysis tool, DynaLight Web, for

computing potential savings of our approach, and a desktop version, DynaLight Desktop, that computes an

optimal supplementary light plan and controls the supplementary lighting accordantly. DynaLight Desktop

is currently being field-tested at five industrial-size greenhouses. The development of these two tools is

described together with the lessons learned from using Software Product Line Engineering in the domain of

greenhouse software development.

1 INTRODUCTION

In 2009, the industrial-size greenhouse growers were

responsible for 0.8 percent of the Danish electricity

consumption, which is equivalent to 256 GWh

(Dansk Energi, 2009). Electricity is the largest single

expenditure for the growers and the increasing prices

of electricity can very well jeopardize their existence

within a few years if they do not find ways to reduce

their consumption. An equally important reason for

reducing the consumption is the need to decrease the

CO

2

emission caused by the production of

electricity. In this paper, we present a novel

approach capable of decreasing both the cost and the

consumption, while keeping the same production

quality.

New plant-physiological research has shown

plasticity in plants to irregular light periods (Kjær &

Ottosen, 2011) and these results enable more

energy-efficient ways to grow plants. They also

disproof the perception that plant growth is harmed

by having many short periods of supplementary light

during the 24 hours of a day instead of fewer, longer

periods. This knowledge allows us to prioritize use

of supplementary lighting when plant growth, i.e.,

the photosynthesis, is highest, instead of prioritizing

consecutiveness of the light hours.

The photosynthesis is dependent on three

parameters: CO

2

level, temperature and light. The

light in the greenhouse has two contributors, the

natural light and the supplementary light. We are

most interested in the photosynthesis contributed by

the supplementary light as this consumes electricity

and is controllable.

The growers have specific daily growth goals to

meet their delivery dates – these can be expressed as

Daily Photosynthesis Integrals (DPIs). Planning the

supplementary light to meet the required DPI by

prioritizing the hours when the photosynthesis gain

is highest was investigated in a preceding project,

and is outside the scope of this paper. Changes in the

way the growers pay their electricity have changed

the applicability of this solution and led us towards

the solutions presented in this paper.

Industrial growers now buy electricity on the

37

Mærsk-Møller H. and Nørregaard Jørgensen B. (2011).

A SOFTWARE PRODUCT LINE FOR ENERGY-EFFICIENT CONTROL OF SUPPLEMENTARY LIGHTING IN GREENHOUSES.

In Proceedings of the Second International Conference on Innovative Developments in ICT, pages 37-46

DOI: 10.5220/0004471400370046

Copyright

c

SciTePress

spot market (more detailed explained in section 1.1),

which means they pay different prices per KWh

dependent on the time of use. The preceding project

did not take the price volatility into account when

creating daily supplementary light plans, but

assumed flat rates on electricity. Flat rate here means

a constant price per KWh independent of time of

use. This fact yields the former solution less

applicable to the growers as supplementary light

usage can be placed in very expensive periods. The

solutions in this paper remedy this shortcoming by

taking the fluctuation of electricity price into

account.

Our portfolio of software uses information from

the electricity spot market, local greenhouse

conditions, and light information from weather

forecasts or historic data. We combine these

information sources with a planning algorithm to

optimize the cost and efficiency of the electricity

utilization in the industrial-size greenhouses,

benefiting both the growers and the environment.

Early on, we identified a need for several

different products, both to increase our impact in the

domain but also to enable us to provide different

solutions to the growers dependent on their

involvement. We wished an option to award those

investing in the research and development with a

competitive edge. We chose to develop these

software products using a Software Product Line

(SPL), because the upfront analysis of the

envisioned products showed extensive

commonalities between the products, and we wished

to take advantage of the reuse benefits the Software

Product Line Engineering (SPLE) paradigm

promises. In this paper, we present two software

applications instantiated as product members of our

software product line and explain the consequences

of developing them using SPLE.

The application, DynaLight Web, is capable of

analyzing historical data and showing how efficient

and cheaper utilization could have been achieved

using our planning algorithm, and the cost savings it

would have given the grower. This gives incentive to

use the planning and control tool called DynaLight

Desktop. This product moves the optimization

capabilities of our algorithm verified by DynaLight

Web on historic conditions into production

conditions. Controlled greenhouse conditions,

weather forecasts and electricity prices are then used

to create a light plan for the forthcoming day.

The following subsections introduce the

electricity market in Denmark, the photosynthesis

model and the optimization algorithm. The

introduction of product-specific elements e.g.

weather forecasts, will be found in the section

belonging to the respective product.

1.1 The Electricity Market

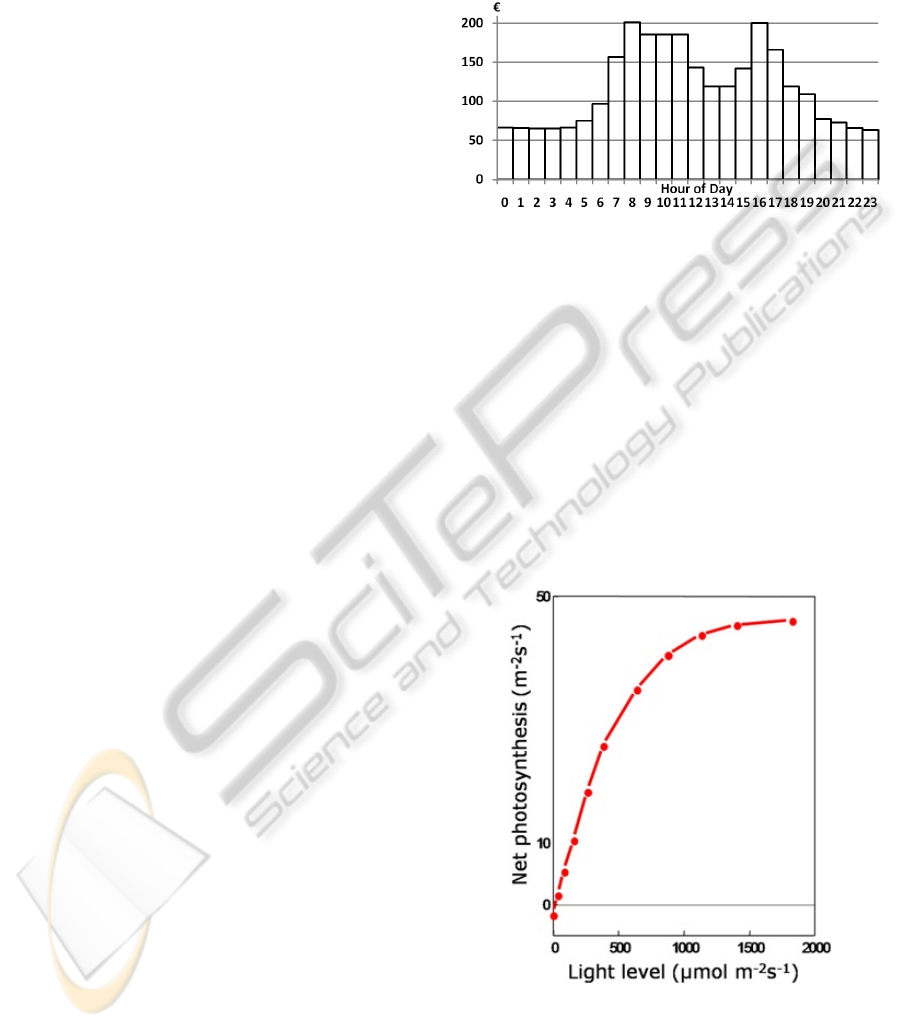

Figure 1: Electricity Price Example.

The industrial-size growers in Denmark, who

consume more than 100,000 KWh, can buy at a flat

rate or buy on the electricity spot market of Nord

Pool Spot (Nord Pool Spot A/S, Lysaker, Norway).

Norway, Finland, Sweden, Estonia and Denmark all

participate on this market. Four of our partners buy

on the spot market while the last buys flat rate.

The electricity prices on the spot market are

settled every day at 1 pm for each of the

forthcoming day’s 24 hours. The prices may vary

significantly from hour to hour (see Figure 1).

1.2 The Photosynthesis Model

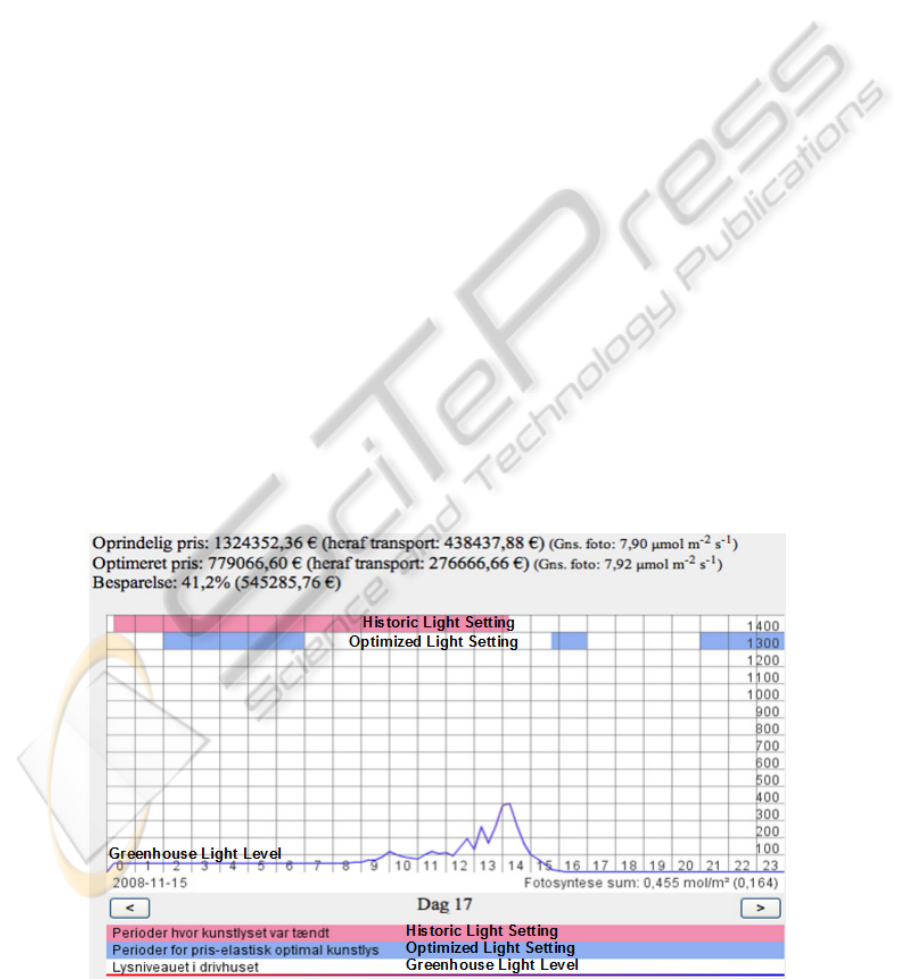

Figure 2: Photosynthesis to Light level.

The growth of the plants can be described using a

photosynthesis model. We currently use one

provided by the Faculty of Agricultural Science at

Aarhus University. This model takes light level, CO

2

INNOV 2011 - Second International Conference on Innovative Developments in ICT

38

level and temperature as inputs and outputs the

photosynthesis as CO

2

assimilation (μmol m

-2

s

-1

).

The photosynthesis is not directly proportional to

the variation in light level even when the CO

2

and

temperature levels are kept constant as the

photosynthesis model is non-linear (see Figure 2);

therefore we introduce the term photosynthesis gain.

We define the photosynthesis gain as the difference

between the photosynthesis caused by the natural

light exclusively and photosynthesis caused by the

combination of the natural and the supplementary

light. In other words, it is the growth caused by the

supplementary lighting at a given natural light level.

1.3 The Optimization Algorithm

The semantics of the core in the optimization

algorithm is described in pseudo code in Figure 3.

1.Split period into Days

2.For each Day:

3.Split into hourly Timeslots

4.For each Timeslot:

5.Add Price, CO2, Light Level,

Temperature.

6. Calculate Photosynthesis,

Photosynthesis Gain, Price per

unit of Photosynthesis Gain.

7.Select the hours with the

lowest price per gain until

the DPI is reached or no more

timeslots are available.

Figure 3: Algorithm in Pseudo Code.

The core algorithm uses electricity prices and the

photosynthesis model to create a supplementary

light plan, which fulfils a growth goal chosen by the

grower for the period in scope. This goal is referred

to as the Daily Photosynthesis Integral (DPI).

The algorithm is used in different ways in

DynaLight Web and DynaLight Desktop. For

example DynaLight Desktop does not require

splitting the period into days, as only one day is

analyzed at a time. Other variabilities are hidden

behind abstractions e.g. the light level which is

calculated from weather forecasts in DynaLight

Desktop while extracted from logs in DynaLight

Web.

1.4 Structure of the Paper

Section 2 describes SPLE and relates it to our

context. Section 3 describes the first product,

DynaLight Web and its position as a SPL member.

DynaLight Desktop and its relation to the SPL are

described in Section 4. Section 5 describes the

experimental validations. Our discussion is found in

Section 6 followed by our conclusion in Section 7.

2 SOFTWARE PRODUCT LINE

ENGINEERING

Software Product Line Engineering (SPLE) is the

paradigm dealing with development, maintenance

and evolution a software product line (SPL). It is a

well established field with research being conducted

for more than 15 years. Fundamentally, SPLE builds

on planned reuse contrary to opportunistic reuse,

which empirically has been shown ineffective (Pohl,

van der Linden, & Böckle, 2005).

We agree on the definition of a SPL to be “a set

of software-intensive systems sharing a common,

managed set of features that satisfy the specific

needs of a particular market segment or mission and

that are developed from a common set of core assets

in a prescribed way”(Clements & Northrop, 2001).

The reusable parts are in SPLE terminology

called core assets. These assets are not limited to

source code, but encompass everything from domain

analysis documents, feature graphs, manuals etc.

The variable parts are called variabilities.

The high degree of commonality together with

the assembly plan enable the effective reuse of

SPLE, which causes decreasing development effort,

maintenance cost and time-to-market, while causing

increasing software quality compared to single-

product development. This is to a wide extent only

possible if the SPL is well-managed as the added

complexity of simultaneously developing multiple

products quickly becomes uncontrollable. This

increase in complexity comes from adding one more

level on top of conventional software development

as multiple products need to be designed, developed,

maintained and evolved in coexistence.

Contrary earlier beliefs that only large companies

were able to benefit from applying SPLE,

experiences have shown that small companies can

gain these benefits from adopting the SPLE

paradigm as well (Verlage & Kiesgen, 2005);

(Gacek et al, 2001). That said, SPLE is not ideal for

all as it is very dependent on the degree of

commonality and the possibilities to exploit this. It

is, therefore, important to perform a careful analysis

beforehand.

2.1 SPLE Applied

We analyzed the envisioned product candidates for

A SOFTWARE PRODUCT LINE FOR ENERGY-EFFICIENT CONTROL OF SUPPLEMENTARY LIGHTING IN

GREENHOUSES

39

our SPL using elements of the PuLSE™

methodology (Bayer et Al, 1999) and decided on a

strategy matching our context. We chose an

Extractive Approach leading to a Reactive Approach

(Krueger, 2002). Our strategy was to extract already

existing assets and domain knowledge from a legacy

application called Climate Monitor and use this to

seed our SPL. Afterwards reactively implement the

missing parts to enable instantiation of our products.

Climate Monitor was continuously developed

during the transition to SPL development, which

resulted in the decision to restructure the Climate

Monitor to fit the modular platform architecture we

wanted to use as SPL architecture. This decision was

promoted by the fact that Climate Monitor was

implemented using NetBeans™ Rich Client

Platform (RCP) and that our SPL architecture was

based on the same infrastructure. This facilitated

keeping production online during the transition

process.

All modules needed to be part of a suite from

where the different products could be instantiated.

The first milestone consisted of porting and

refactoring Climate Monitor into the module suite,

called Green Components. The second milestone

was the implementation of custom parts for

DynaLight Web after its core modules could be

instantiated from the suite. The third milestone was

implementation of new modules and refactoring of

old modules to create DynaLight Desktop.

Proceeding milestones and products are planned.

Experiences show that unexpected variability

may arise throughout the life of a software product

line especially in new unstable domains like ours.

We have taken all foreseeable needs for variability

into account, but we have also tried to create a

modular architecture that can handle introduction of

unexpected variability without major restructuring.

3 DYNALIGHT WEB

DynaLight Web uses historical data from

environmental climate computers (ECCs) to analyze

the actual and optimized costs of using

supplementary lighting. The intention is to make the

growers aware of the potential savings, and

indirectly promote DynaLight Desktop.

There are two main vendors of environmental

climate computers (ECCs) in the Danish greenhouse

domain: Senmatic (Senmatic A/S, Søndersø,

Denmark) and Priva (Priva, De Lier, The

Netherlands) and both log all the necessary data to

calculate the historical photosynthesis. They also

store previous set points for the supplementary light,

thereby telling us which hours the light was on and

off. The data can be exported to proprietary text files

for both types of climate computers. DynaLight

Web performs its analysis based on these data,

archived electricity prices and some production

parameters provided by the grower. The analysis is

performed in the following way on the server side.

First the exported text files are cleaned, formatted

and transformed into one standardized data format.

Figure 4: DynaLight Web Screen Flow.

INNOV 2011 - Second International Conference on Innovative Developments in ICT

40

The DPI of days of the past is calculated using the

photosynthesis model and stored. The DPIs are

thereafter used as new DPI goals in the algorithm

described in section 1.3. This returns an optimized

light plan for each of the days of the past. The

historical light set points are then displayed side by

side the virtual setpoints for comparison (see Figure

4). This enables the grower to see the differences

hour by hour between the historical management and

the optimized one. The electricity price of the

historical period is calculated by using the historical

light set points and an electrical price archive. This

result is displayed for the grower together with the

price of optimized set points. The possible savings

are then calculated and displayed (see Figure 4).

DynaLight Web thereby provides an opportunity to

analyze how much the optimization algorithm could

have saved the grower while reaching the same level

of growth.

The solution functions as a website

(http://softwarelab.sdu.dk/DynaLight/) and the

growers are guided through the following five steps.

First, the growers are welcomed and told how to

proceed. Second, the growers are asked for the type

of climate computer they use in order for DynaLight

Web to clean, format and standardize the historical

data correctly, but also to display the correct

guidelines on the next step. The third step displays a

visual guide to the growers on how to export the

data from their particular climate computer. After

the data are exported correctly to a file, the grower

can move on to the next step of the wizard. In this

fourth step, the grower is told to select the path for

the export file and asked whether they belong to the

eastern or western region of Denmark (as it

influences the electricity prices). The growers are

asked for the power consumption of their lamps per

m

2

, their greenhouse size in m

2

and how close the

grower needs the optimization algorithm to match

the historical DPI. The grower uses this last option

to see the effect of using less artificial lighting than

used in the past. The grower clicks ‘Next’ and the

calculations are done on the server side before the

last page is displayed to the grower. This last page

displays the results of the analysis (see Figure 4).

There are eight different totals shown on the top

of the webpage. These cover the whole period being

analyzed. The first line shows the original electricity

price, the part of the price that was used on grid fees

and the average photosynthesis obtained. The second

line shows the price of the optimized light plan, the

included grid fee, and the average photosynthesis

during the period. The third line displays the savings

accomplished by the optimization algorithm both in

percentage and in euro. The grower can navigate

through the days of the past and for each day inspect

the hours the supplementary light was on (the

uppermost coloration), the hours where the

optimization algorithm would have turned the light

on (the coloration just below) and the natural light

level inside the greenhouse (the thin chart line).

The specific results shown in Figure 4 are

calculated on real climate-computer data from an

industrial-size greenhouse. The price of the

historical light set points was 1,324,352.36 €. The

next line shows the price that the optimization

algorithm would have obtained reaching the same

photosynthesis. The price of the optimized plan is

779,066.60 €. Thus the savings would have been

545,285.76 € or equivalent to 41.2 percent. The

resulting average photosynthesis overshoots the

historical result a little bit (7.92 µmol m-2 s-1), so

even with the reduced cost, the algorithm achieves

more growth.

DynaLight Web is instantiated as a SPL member.

The core of DynaLight Web is the three modules:

Electricity Prices, Photosynthesis Model and

Supplementary Light Analysis. All of these are part

of Green Components.

The website part was developed as a NetBeans™

Web-Project and as this project type is not able to be

included in a NetBeans™ module suite it had to be

kept outside Green Components. The Web-Project

includes the html, jsp-server pages and the servlet

that shows the website to the grower, retrieves the

data, delegates the data and shows the results. All

the data processing as well as the optimization

algorithm are implemented as reusable modules. The

reusable modules are also used in Climate Monitor

(which is being phased out) and DynaLight Desktop.

The current instantiation of DynaLight Web works

by building the modules and referencing the

resulting jar-files as external dependencies from the

DynaLight Web Web-Project.

4 DYNALIGHT DESKTOP

DynaLight Desktop is a computer-aided planning

tool for optimizing supplementary light use in

industrial-size greenhouses. The optimization is

based on expected photosynthesis and electricity

prices of the forthcoming day’s 24 hours. The

optimization algorithm (section 1.2) is given the DPI

goal for the day, and the algorithm placed the

supplementary light hours where the cost-

effectiveness is highest. The CO2 and temperature in

step 5 of the algorithm is controlled by the ECC and

A SOFTWARE PRODUCT LINE FOR ENERGY-EFFICIENT CONTROL OF SUPPLEMENTARY LIGHTING IN

GREENHOUSES

41

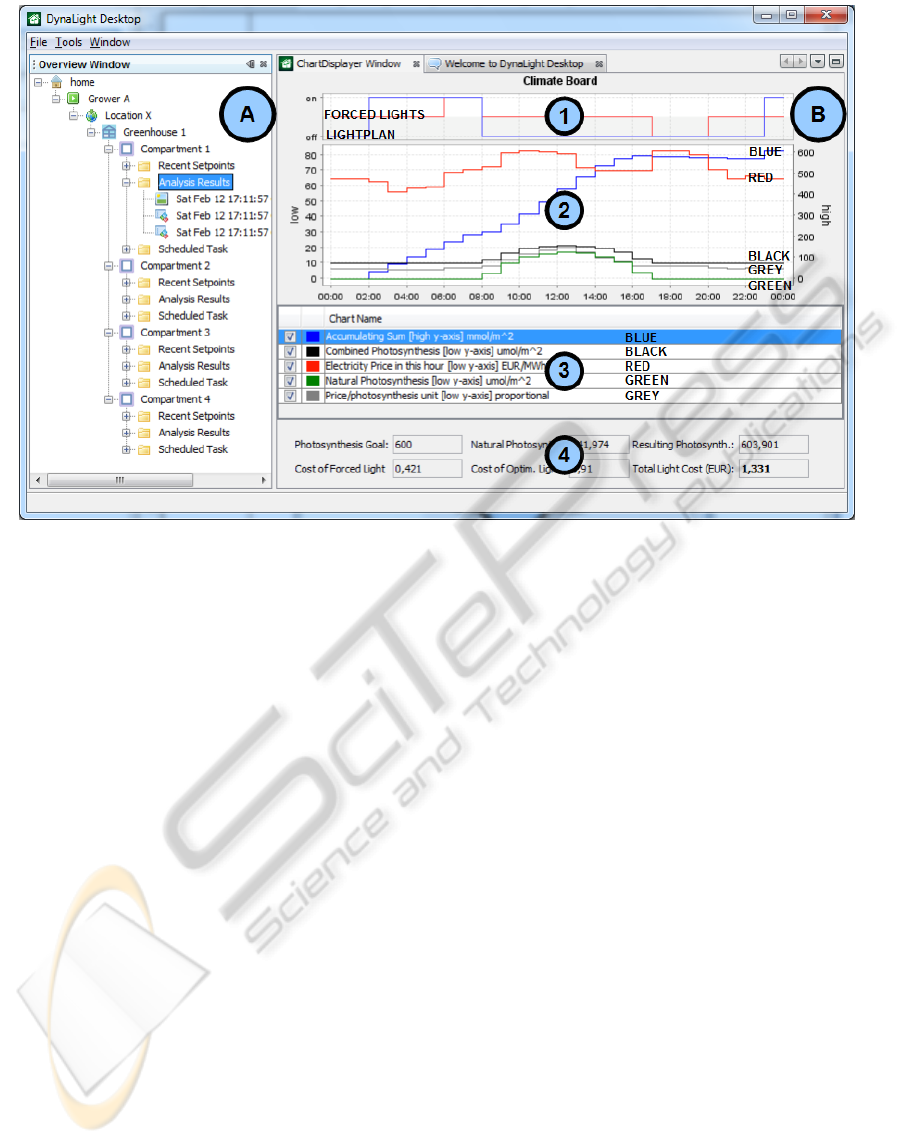

Figure 5: DynaLight Desktop Main Screen.

therefore set to constant levels according to the ECC

settings, while light level is calculated based on

weather forecasts (sun irradiation) and a

mathematical model of the light penetration of the

greenhouse glass. The electricity prices of the

upcoming day are retrieved from the webpage of

Nord Pool Spot. The algorithm thereby has the

necessary inputs to create a supplementary light plan

for the forthcoming day. The software also has the

capability to control the supplementary light in the

greenhouse according to plans using the ECC. The

whole process of creating light plans can be

automated to run every day and write set points.

The optimization algorithm saves money on the

electricity bill and reduces the electricity

consumption by placing the supplementary light

hours where cost-effectiveness is highest.

Superfluous light hours are removed by being better

to predict the resulting daily photosynthesis. The

reduced electricity consumption reduces the CO

2

footprint of the production.

The software product is a desktop application

implemented in Java™ able to run on different

operating systems. DynaLight Desktop is currently

used by leading industrial-size growers in Denmark,

by the Faculty of Agricultural Science of Aarhus

University’s test facility at Aarslev and has been

showcased by U.C. Berkeley.

The Danish Metrological Institute provides us

with forecasts of the sun-irradiation levels, 36 hours

into the future, twice daily in hourly resolution. The

first forecast is provided at 5:45 am and covers only

until afternoon the next day, thus the next day is first

fully covered when the second forecast arrives,

preventing any analysis before 5:26 pm. The

weather forecasts provide the outdoor sun

irradiation, and the algorithm expects the indoor

light level. Therefore, we use a mathematical model

of the greenhouse windows to convert the outdoor

light level to indoor light level before using it in the

optimization algorithm (described in section 1.3).

The main screen of DynaLight Desktop is shown

in Figure 5. The explorer window (A) displays a tree

structure with greenhouses and compartments. The

compartments are one of the central concepts of

DynaLight Desktop. Compartments are separately

controlled areas within the greenhouses. The

properties of these compartments are configured

based on the real-life counterparts. Next to the

explorer window is the editor window called Chart

Displayer (B). All the analyses results are shown in

this window. It contains the light plan chart (1),

where the resulting light plan is shown (marked

LIGHTPLAN) and indications of forced on or off

light conditions (marked FORCED LIGHTS). We

will return to this later. The main chart area (2)

shows different kinds of data. These are described

by the legend below (color names for B/W prints)

INNOV 2011 - Second International Conference on Innovative Developments in ICT

42

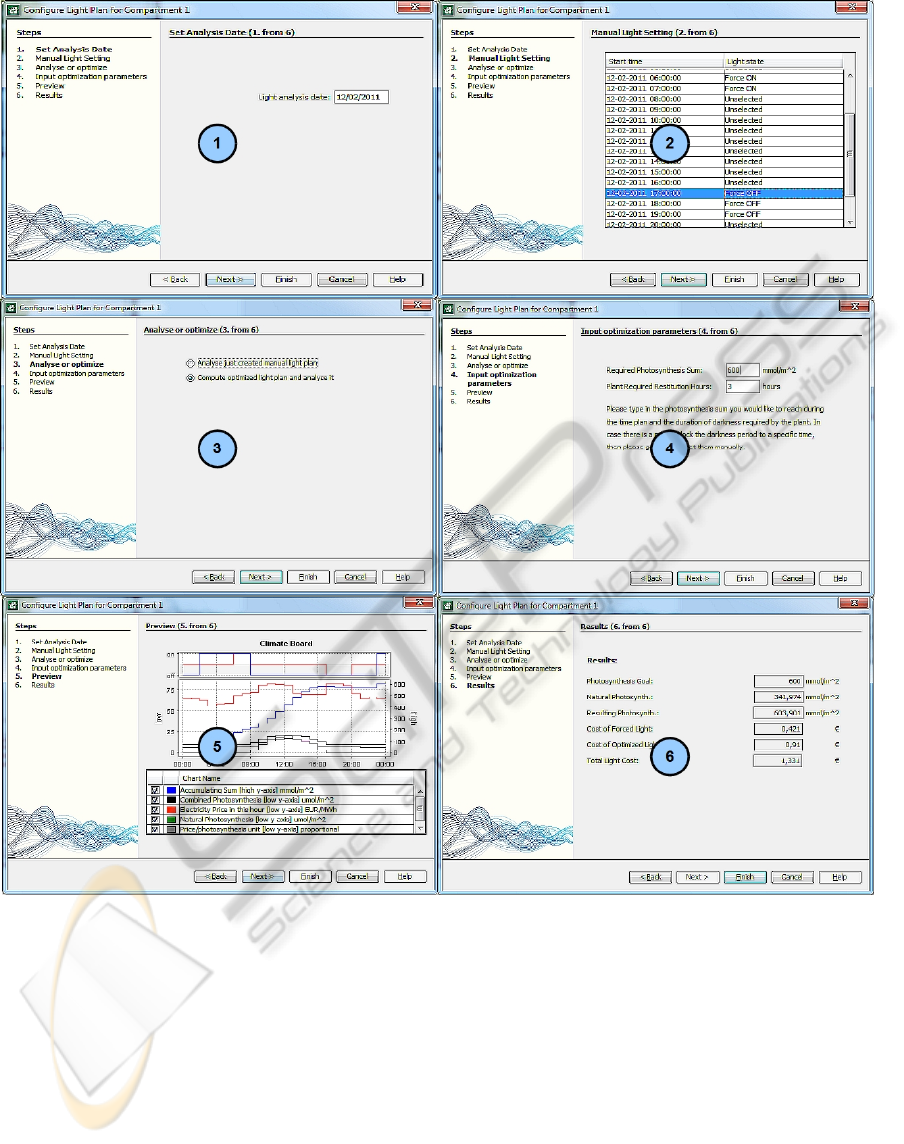

Figure 6: DynaLight Desktop Wizard Flow.

(3) e.g. the line (marked RED) shows the electricity

prices over the day. At the bottom of the Chart

Displayer is (4) the numeric results displayed,

among these the total electricity cost, the DPI goal

and the resulting DPI.

The use case for creating a supplementary light

plan is shown in Figure 6. The grower is first asked

for date being processed in (1). The grower is then

provided with the possibility to force specific hours

on/off in (2). The forced hours are then outside the

control of the algorithm. This can be required if the

grower is using the supplementary light as work

light, or has specific deals with the electricity

supplier not to use electricity within certain hours of

the day. Then the grower is asked if he only wants

the manually selected forced hours to be analyzed or

if the optimization algorithm should help to create a

light plan in (3). The grower is asked for the DPI

and the amount of consecutive hours of darkness

required by the plants in (4). The darkness hours

need to be placed when it is dark enough inside the

greenhouse and not in the dusk and dawn periods i.e.

the hour after sunset and the hour before sunrise.

Previews of the results are given in (5) and (6), these

resemble the results shown later in the Chart

Displayer (Figure 5 (B)).DynaLight Desktop is

A SOFTWARE PRODUCT LINE FOR ENERGY-EFFICIENT CONTROL OF SUPPLEMENTARY LIGHTING IN

GREENHOUSES

43

based on the same three core modules as DynaLight

Web: Electricity Prices, Photosynthesis Model and

Supplementary Light Analysis. This core was

extended with modules handling weather forecasts,

persistency, product branding, graphical user

interfaces, automation of the planning process and

plan execution, and connectivity for writing set

points to the ECCs for the third milestone. The three

core modules were improved by the DynaLight Web

developers during DynaLight Desktop’s

development. The improvements migrated instantly

because of our SPL and single system view. This

advantage was facilitated by well-defined

responsibilities and interfaces of the reusable

modules because we planned and designed it that

way.

5 EXPERIMENTAL VALIDATION

DynaLight Desktop has been used in production

since the winter and the program is currently

running at the Faculty of Agricultural Science of

Aarhus University’s test-facility at Aarslev and at

the companies: Rosa Danica A/S (120,000 m

2

),

PKM A/S (190,000 m

2

), Alfred Pedersen & Son

ApS and Knud Jepsen A/S. DynaLight Desktop is

considered successful based on the fact that these

companies have used the software in their

production.

DynaLight Web is publicly available at

http://softwarelab.sdu.dk/DynaLight. The service

has been tested with several datasets extracted from

ECCs of our collaborating growers to validate

functionality and it is working appropriately. This

yields a successful working solution from a software

developer’s perspective.

Measuring the benefits of using SPLE for

developing the two products is difficult, but the

perceived advantages from reusing the modules of

Photosynthesis Model, Light Analysis and

Electricity Price are big. The modules did not need

to be redeveloped for DynaLight Desktop, which

clearly reduced the development costs, and the

improvements performed by DynaLight Web’s

developers instantly made DynaLight Desktop

benefit from this. The undergoing maintenance and

evolution has not caused any code dependencies to

break or given any unexpected annoyances, which is

perceived a sign of good interface design. The

validation of SPLE as development paradigm for our

energy efficient systems might become clearer when

more of the planned products are derived.

The Department of Agriculture on University of

Aarhus performed experiments during the spring of

2010 which showed a decrease in energy

consumption of 25% without affecting the growth or

quality, compared to a reference culture. The cost

reduction on electricity was 26% (Kjær & Ottosen,

2011). These experiments, which grew plants with

three different DPIs and had one reference culture,

are thoroughly described by Kjær & Ottosen, 2011.

These experiments validate the effectiveness of the

algorithm in the dynamics of the domain. Further

validation of the algorithm is outside the scope of

this paper, as the main focus is usage of SPLE to

produce energy-efficient systems.

6 DISCUSSION

Why is the combination of SPLE and the

development of energy-efficient systems for

greenhouses interesting? Many equivalent functional

features between our previously developed

solutions, current solutions and our planned

solutions were identified and reused through SPLE

was concluded suitable. The applicability from this

perspective has more to do with the technical aspects

of the domain and less to do with energy efficiency

and greenhouses. Another good reason is that

innovative ideas for better and more energy-efficient

greenhouse production are continuously conceived

and needs to be evaluated by performing

experiments. Several of these build on the same

structure of information sources, mathematical

models, system interfaces and graphical user

interfaces. SPLE facilitates faster prototyping and

shorter time from idea conception to experimental

validations which is particular interesting for this

domain.

How does our SPL solution differ from reuse of

a library of modules? The difference is the move

away from opportunistic reuse to planned reuse. The

modules cannot be composed by coincidence, but

because we planned it. The SPL can be viewed as a

software system for producing software products – a

software factory. Thus, the work can be focused on

improving and evolving one system.

How can our system construction be extended to

other fields? The novel idea of using weather

forecasts, electricity spot market and a planning

algorithm for sculpting the electricity load is

applicable in many other domains, and is currently

being investigated for electricity savings in

computer clusters, charging of electrical cars, use of

air conditioning in buildings, and several other

fields. The quality effects of these approaches can be

INNOV 2011 - Second International Conference on Innovative Developments in ICT

44

difficult to measure e.g. change in productivity level

in offices as a result of controlling the indoor

climate. In contrast, the growth and quality are

measurable in our domain, displaying the effects of

load sculpting (planning the supplementary light).

Which refinements could be made to the

algorithm? There are several limitations that affect

the refinement of the algorithm. The prices and

weather forecasts only have hourly resolution, the

lamps currently in use can only be switched on or

off (instead of continuously as e.g. LED lamps), the

prices for the next day are not available before 1 pm,

and so forth. Refinements could be made, so the

algorithm could take several days into account. This

could result in scenarios where supplementary light

would not be switched on during a cloudy day if the

weather forecast shows sunny days at the end of the

period, or supplementary light not being switched on

if the preceding days had resulted in surplus growth.

Corrective behavior based on real-time local

measurements could also be an improvement, so the

light would be switched off if the level was higher

than expected and vice versa. Another improvement

could be introduction of a maximum price, so the

growers could specify the highest price they were

willing to pay. And yet another is creating models

predicting the percentage of renewable energy on the

grid, and controlling the consumption accordingly.

What are the expected savings from these

refinements? It is difficult to predict the savings

these refinements could lead to. The change to LED

lamps which can be gradually switched on/off, is

expected lead to substantial savings as the

technology uses less electricity to produce the same

photosynthesis, and that light level could be

controlled within range where the photosynthesis to

light-level gradient is highest. This is already a

planned SPL member. The other enhancement and

refinements are part of our future research.

Are there un-investigated side effects of the

planning algorithm? The algorithm places the

supplementary light where the price of the gain is

smallest; ergo when the price of an hour is low, it

receives a higher ranking. As the prices on the grid

are based on supply-demand, one would expect that

a surplus caused by renewable, non-dispatchable

energy sources would lower the prices, hence

improve the utilization of renewable energy when it

is available. This is a topic of further investigation.

Why the algorithm is considered optimizing?

Finding the optimal plan with respect to cost and

gain is a combinatorial optimization problem called

a bounded knapsack problem, which is NP-

complete. Our solution includes a greedy

approximation algorithm, which does not necessarily

find a global optimal solution. However, it is very

fast (linear time) and it performs better than standard

management with respect to electricity consumption

and cost, and this is validated by experiments. We

explain the optimization success with the dynamics

of our domain, but it is out of the scope of this paper

to prove this. We consider the algorithm optimizing,

but not optimal.

7 CONCLUSIONS

In this paper, we presented two software products

that facilitate a decrease in the electricity

consumption of the industrial-size greenhouses, thus

enabling a more environmentally-friendly

production of plants. The two applications were both

products of our Software Product Line.

DynaLight Web informs growers about possible

savings by analyzing logs from their past

production. Archived electricity prices from the spot

market and data from their environmental climate

computers (ECCs) are used for the analyses. The

information of possible savings creates both

awareness of a cheaper and greener production form

and creates an incentive to use the second product -

DynaLight Desktop.

DynaLight Desktop is a computer-aided planning

tool for supplementary light which takes weather

forecasts, predicted growth conditions and electricity

spot-market prices into account to reach a certain

growth goal (DPI) for the forthcoming day.

The two software applications are currently in

use at several industrial-size growers, and in an

experimental facility at the Faculty of Agricultural

Science of University of Aarhus. Their experiments

validate savings of 25 percent of electricity

consumption, while maintaining the same level of

production and quality. We regard the usage and

results of the software products as a success.

The challenge from a software development

perspective is how to efficiently develop, maintain

and evolve a portfolio of software products for this

domain. We addressed this challenge by shifting the

development paradigm to SPLE. The planning,

analysis and development of the SPL has been

successful and have resulted in our two product-line

members, which both are based on the same SPL

core asset modules. There are several more product

members currently planned for production.

We conclude that SPLE can be successfully

applied in the domain of greenhouse agriculture to

limit the environmental footprint and streamline the

A SOFTWARE PRODUCT LINE FOR ENERGY-EFFICIENT CONTROL OF SUPPLEMENTARY LIGHTING IN

GREENHOUSES

45

production. We believe that other similar software

organizations, both inside and outside the area of

green computing, can harvest equal benefits by

shifting to the SPLE paradigm.

ACKNOWLEDGEMENTS

The authors wish to acknowledge the European

Regional Fund, Region South Denmark for the

financial support through Intelligent Energy

Handling in Greenhouses (project number 95-410-

44060).

REFERENCES

Bayer, J., Flege, O., Knauber, P., Laqua, R., Muthig, D.,

Schmid, K., Widen, T., DeBaud, J.-M., 1999. PuLSE:

A Methodology to Develop Software Product Lines.

In Proceeding of the 1999 Symposium on Software

Reusability. ACM, New York, USA.

Clements, P., Northrop, L., 2001. Software Product Lines:

Practices and Patterns. Boston, USA: Addison-

Wesley.

Dansk Energi, 2009. Dansk Elforsyning Statistik 2009,

Dansk Energi. http://www.danskenergi.dk.

Gacek, C., Knauber, P., Schmid, K., Clements, P., 2001.

Successful Software Product Line Development in a

Small Organization A Case Study. In IESE-Repost No

013.01/E Version 1.0 March 15 2001. Fraunhofer.

Kjær, K. H., Ottosen, C., 2011. Flowering and growth of

two companula species when grown in a cost-efficient

light control system with irregular light breaks during

the night. Scientia horticulturae. In press.

Krueger, C., 2002. Eliminating the Adoption Barrier:

Point-Counter Point Column. In IEEE Software,

July/August 2002, Volume 19 issue 4. IEEE Computer

Society.

Pohl, K., van der Linden, F. ,Böckle, G., 2005. Software

Product Line Engineering: Foundation, Principles,

and Techniques. New Jersey, USA: Springer-Verlag.

Verlage, M., Kiesgen, T., 2005. Five years of product line

engineering in a small company. In Proceedings of the

27

th

International Conference on Software

Engineering. ACM.

INNOV 2011 - Second International Conference on Innovative Developments in ICT

46