DECENTRALIZED NEURAL BACKSTEPPING CONTROL FOR

AN INDUSTRIAL PA10-7CE ROBOT ARM

R. Garcia-Hernandez

1

, E. N. Sanchez

2

, M. A. Llama

3

and J. A. Ruz-Hernandez

1

1

Facultad de Ingenieria, Universidad Autonoma del Carmen, Av. 56 No. 4, Cd. del Carmen, Campeche, Mexico

2

Centro de Investigacion y de Estudios Avanzados del IPN, Unidad Guadalajara, Guadalajara, Jalisco, Mexico

3

Division de Estudios de Posgrado, Instituto Tecnologico de la Laguna, Torreon, Coahuila, Mexico

Keywords:

High-order neural network, Extended Kalman filter, Backstepping, Trajectory tracking, Robot arm.

Abstract:

This paper presents a discrete-time decentralized control strategy for trajectory tracking of a seven degrees

of freedom (DOF) robot arm. A high order neural network (HONN) is used to approximate a decentralized

control law designed by the backstepping technique as applied to a block strict feedback form (BSFF). The

neural network learning is performed online by extended Kalman filter. The local controller for each joint use

only local angular position and velocity measurements. The feasibility of the proposed scheme is illustrated

via simulation.

1 INTRODUCTION

Nowadays, industrial robots have gained wide pop-

ularity as essential components in the construction

of automated systems. Reduction of manufacturing

costs, increase of productivity, improvement of prod-

uct quality standards, and the possibility of eliminat-

ing harmful of repetitive tasks for human operators

represent the main factors that have determined the

spread of the robotic technology in the manufactur-

ing industry. Industrial robots are suitable for applica-

tions where high precision, repeatability and tracking

accuracy are required.

In this context, a variety of control schemes have

been proposed in order to guarantee efficient tra-

jectory tracking and stability (Sanchez and Ricalde,

2003), (Santiba˜nez et al., 2005). Fast advance in

computational technology offers new ways for imple-

menting control algorithms within the approach of a

centralized control design.However, there is a great

challenge to obtain an efficient control for this class of

systems, due to its highly nonlinear complex dynam-

ics, the presence of strong interconnections, parame-

ters difficult to determine, and unmodeled dynamics.

Considering only the most important terms, the math-

ematical model obtained requires control algorithms

with great number of mathematical operations, which

affect the feasibility of real-time implementations.

On the other hand, within the area of control sys-

tems theory, for more than three decades, an alter-

native approach has been developed considering a

global system as a set of interconnected subsystems,

for which it is possible to design independent con-

trollers, considering only local variables to each sub-

system: the so called decentralized control (Huang

et al., 2003). Decentralized control has been applied

in robotics, mainly in cooperative multiple mobile

robots and robot manipulators, where it is natural to

consider each mobile robot or each part of the ma-

nipulator as a subsystem of the whole system. For

robot manipulators each joint and the respective link

is considered as a subsystem in order to develop local

controllers, which just consider local angular position

and angular velocity measurements, and compensate

the interconnection effects, usually assumed as dis-

turbances. The resulting controllers are easy to im-

plement for real-time applications (Liu, 1999).

In (Ni and Er, 2000), a decentralized control of

robot manipulators is developed, decoupling the dy-

namic model of the manipulator in a set of linear sub-

systems with uncertainties; simulation results for a

robot of two joints are shown. In (Karakasoglu et al.,

1993), an approach of decentralized neural identifica-

tion and control for robots manipulators is presented

using models in discrete-time. In (Safaric and Rodic,

2000), a decentralized control for robot manipulators

is reported; it is based on the estimation of each joint

dynamics, using feedforward neural networks.

In recent literature about adaptive and robust con-

trol, numerous approaches have been proposed for

82

Garcia Hernandez R., N. Sanchez E., A. Llama M. and A. Ruz-Hernandez J..

DECENTRALIZED NEURAL BACKSTEPPING CONTROL FOR AN INDUSTRIAL PA10-7CE ROBOT ARM.

DOI: 10.5220/0003684300820089

In Proceedings of the International Conference on Neural Computation Theory and Applications (NCTA-2011), pages 82-89

ISBN: 978-989-8425-84-3

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

the design of nonlinear control systems. Among

these, adaptive backstepping constitutes a major de-

sign methodology (Krstic et al., 1995). The idea be-

hind the backstepping approach is that some appro-

priate functions of state variables are selected recur-

sively as virtual control inputs for lower dimension

subsystems of the overall system. Each backstepping

stage results in a new virtual control design from the

preceding stages; when the procedure ends, a feed-

back design for the true control input results, which

achieves the original design objective.

In this paper, the authors propose a decentral-

ized approach in order to design a suitable controller

for each subsystem. Afterwards, each local con-

troller is approximated by a high order neural network

(HONN) (Ge et al., 2004). The neural network (NN)

training is performed on-line by means of an extended

Kalman filter (EKF) (Alanis et al., 2007), and the con-

trollers are designed for each joint, using only local

angular position and velocity measurements. Simu-

lations for the proposed control scheme using a Mit-

subishi PA10-7CE robot arm are presented.

2 DISCRETE-TIME

DECENTRALIZED SYSTEMS

Let consider a class of discrete-time nonlinear per-

turbed and interconnected system which can be pre-

sented in the block strict feedback form (BSFF)

(Krstic et al., 1995) consisting of r blocks

χ

1

i

(k+ 1) = f

1

i

χ

1

i

+ B

1

i

χ

1

i

χ

2

i

+ Γ

1

iℓ

χ

2

i

(k+ 1) = f

2

i

χ

1

i

,χ

2

i

+ B

2

i

χ

1

i

,χ

2

i

χ

3

i

+ Γ

2

iℓ

.

.

.

χ

r−1

i

(k+ 1) = f

r−1

i

χ

1

i

,χ

2

i

,.. ., χ

r−1

i

(1)

+B

r−1

i

χ

1

i

,χ

2

i

,.. .,χ

r−1

i

χ

r

i

+ Γ

r−1

iℓ

χ

r

i

(k+ 1) = f

r

i

χ

i

+ B

r

i

χ

i

u

i

+ Γ

r

iℓ

where χ

i

∈ ℜ

n

i

, χ

i

=

χ

1⊤

i

χ

2⊤

i

... χ

r⊤

i

⊤

and χ

j

i

∈

ℜ

n

ij

×1

, χ

j

i

=

χ

j

i1

χ

j

i2

... χ

j

il

⊤

, i = 1,.. .,N; j =

1,.. . ,r; l = 1,... , n

ij

; N is the number of subsystems,

u

i

∈ ℜ

m

i

is the input vector, the rank of B

j

i

= n

ij

,

∑

r

j=1

n

ij

= n

i

, ∀χ

j

i

∈ D

χ

j

i

⊂ ℜ

n

ij

. We assume that

f

j

i

, B

j

i

and Γ

j

i

are smooth and bounded functions,

f

j

i

(0) = 0 and B

j

i

(0) = 0. The integers n

i1

≤ n

i2

≤

··· ≤ n

ij

≤ m

i

define the different subsystem struc-

tures. The interconnection terms are given by

Γ

1

iℓ

=

N

∑

ℓ=1, ℓ6=i

γ

1

iℓ

χ

1

ℓ

Γ

2

iℓ

=

N

∑

ℓ=1, ℓ6=i

γ

2

iℓ

χ

1

ℓ

,χ

2

ℓ

.

.

. (2)

Γ

r−1

iℓ

=

N

∑

ℓ=1, ℓ6=i

γ

r−1

iℓ

χ

1

ℓ

,χ

2

ℓ

,.. ., χ

r−1

ℓ

Γ

r

iℓ

=

N

∑

ℓ=1, ℓ6=i

γ

r

iℓ

χ

ℓ

where χ

ℓ

represents the state vector of the ℓ-th sub-

system with 1 ≤ ℓ ≤ N and ℓ 6= i.

Interconnection terms (2) reflect the interaction

between the i-th subsystem and the other ones.

3 HIGH-ORDER NEURAL

NETWORKS

3.1 Discrete-time HONN

Let consider the HONN described by

φ(w,z) = w

⊤

S(z)

S(z) = [s

⊤

1

(z),s

⊤

2

(z),··· ,s

⊤

m

(z)]

s

i

(z) =

"

∏

j∈I

1

[s(z

j

)]

d

j

(i

1

)

···

∏

j∈I

m

[s(z

j

)]

d

j

(i

m

)

#

⊤

i = 1,2,·· · ,L

(3)

where z = [z

1

,z

2

,·· · ,z

p

]

⊤

∈ Ω

z

⊂ ℜ

p

, p is a positive

integer which denotes the number of external inputs,

L denotes the neural network node number, φ ∈ ℜ

m

,

{I

1

,I

2

,·· · ,I

L

} is a collection of not ordered subsets of

{1,2,·· · , p}, S(z) ∈ ℜ

L×m

, d

j

(i

j

) is a nonnegative in-

teger, w ∈ ℜ

L

is an adjustable synaptic weight vector,

and s(z

j

) is chosen as the hyperbolic tangent function:

s(z

j

) =

e

z

j

− e

−z

j

e

z

j

+ e

−z

j

(4)

For a desired function u

∗

∈ ℜ

m

, assume that there

exists an ideal weight vector w

∗

∈ ℜ

L

such that the

smooth function vector u

∗

(z) can be approximated by

an ideal neural network on a compact subset Ω

z

⊂ ℜ

q

u

∗

(z) = w

∗⊤

S(z) + ε

z

(5)

where ε

z

⊂ ℜ

m

is the bounded neural network approx-

imation error vector; note that kε

z

k can be reduced

by increasing the number of the adjustable weights.

The ideal weight vector w

∗

is an artificial quantity re-

quired only for analytical purposes (Ge et al., 2004),

(Rovithakis and Christodoulou, 2000). In general, it

DECENTRALIZED NEURAL BACKSTEPPING CONTROL FOR AN INDUSTRIAL PA10-7CE ROBOT ARM

83

is assumed that there exists an unknown but constant

weight vector w

∗

, whose estimate is w ∈ ℜ

L

. Hence,

it is possible to define:

˜w(k) = w(k) − w

∗

(6)

as the weight estimation error.

3.2 EKF Training Algorithm

It is known that Kalman filtering (KF) estimates the

state of a linear system with additive state and out-

put white noises (Song and Grizzle, 1995). For KF-

based neural network training, the network weights

become the states to be estimated. In this case, the

error between the neural network output and the mea-

sured plant output can be considered as additive white

noise. Due to the fact that neural network mapping is

nonlinear, an EKF-type is required.

The training goal is to find the optimal weight val-

ues which minimize the prediction error. We use a

EKF-based training algorithm described by:

K

j

i

(k) = P

j

i

(k)H

j

i

(k)M

j

i

(k)

w

j

i

(k+ 1) = w

j

i

(k) + η

j

i

K

j

i

(k)e

j

i

(k)

P

j

i

(k+ 1) = P

j

i

(k) − K

j

i

(k)H

jT

i

(k)P

j

i

(k) + Q

j

i

(k)

(7)

with

M

j

i

(k) = [R

j

i

(k) + H

jT

i

(k)P

j

i

(k)H

j

i

(k)]

−1

(8)

where P ∈ ℜ

L×L

is the prediction error covariance

matrix, w ∈ ℜ

L

is the weight (state) vector, η is the

rate learning parameter such that 0 ≤ η ≤ 1, L is the

respective number of neural network weights, x ∈ ℜ

m

is the measured plant state, ˆx ∈ ℜ

m

is the neural net-

work output, K ∈ ℜ

L×m

is the Kalman gain matrix,

Q ∈ ℜ

L×L

is the state noise associated covariance ma-

trix, R ∈ ℜ

m×m

is the measurement noise associated

covariance matrix, and H ∈ ℜ

L×m

is a matrix, for

which each entry (H

ij

) is the derivative of one of the

neural network output (ˆx

i

), with respect to one neural

network weight (w

j

), as follows

H

ij

(k) =

∂ˆx

i

(k)

∂w

j

(k)

(9)

where i = 1, ... ,m and j = 1,... ,L. Usually P and Q

are initialized as diagonal matrices, with entries P(0)

and Q(0), respectively. It is important to remark that

H(k), K(k), and P(k) for the EKF are bounded (Song

and Grizzle, 1995).

4 CONTROLLER DESIGN

Once the system in the BSFF is defined, we apply the

well-known backstepping technique (Krstic et al.,

1995). We can define the desired virtual controls

(α

j∗

i

(k),i = 1,.. .,N; j = 1,.. .,r − 1) and the ideal

practical control (u

∗

(k)) as follows:

α

1∗

i

(k) , x

2

i

(k) = ϕ

1

i

(x

1

i

(k),x

i

d

(k+ r))

α

2∗

i

(k) , x

3

i

(k) = ϕ

2

i

(x

2

i

(k),α

1∗

i

(k))

.

.

.

α

r−1∗

i

(k) , x

r

i

(k) = ϕ

r−1

i

(x

r−1

i

(k),α

r−2∗

i

(k))

u

∗

i

(k) = ϕ

r

i

(x

i

(k),α

r−1∗

i

(k))

χ

i

(k) = x

1

i

(k)

(10)

where ϕ

j

i

(·) with 1 ≤ j ≤ r are nonlinear smooth func-

tions. It is obvious that the desired virtual controls

α

∗

i

(k) and the ideal control u

∗

i

(k) will drive the output

χ

i

(k) to track the desired signal x

i

d

(k). Let us approx-

imate the virtual controls and practical control by the

following HONN:

α

j

i

(k) = w

j⊤

i

S

j

i

(z

j

i

(k))

u

i

(k) = w

r⊤

i

S

r

i

(z

r

i

(k)), j = 1,· ·· ,r − 1

(11)

with

z

1

i

(k) = [x

1

i

(k),x

1

i

d

(k+ r)]

⊤

z

j

i

(k) = [x

j

i

(k),α

j−1

i

(k)]

⊤

, j = 1,· ·· ,r − 1

z

r

i

(k) = [x

i

(k),α

r−1

i

(k)]

⊤

where w

j

i

∈ ℜ

L

j

are the estimates of ideal constant

weights w

j∗

i

and S

j

i

∈ ℜ

L

j

×n

j

with j = 1,.. .,r. Define

the weight estimation error as

˜w

j

i

(k) = w

j

i

(k) − w

j∗

i

.

(12)

Then, the corresponding weights updating laws

are defined as

w

j

i

(k+ 1) = w

j

i

(k) + η

j

i

K

j

i

(k)e

j

i

(k)

(13)

with

K

j

i

(k) = P

j

i

(k)H

j

i

(k)M

j

i

(k)

M

j

i

(k) = [R

j

i

(k) + H

j⊤

i

(k)P

j

i

(k)H

j

i

(k)]

−1

P

j

i

(k+ 1) = P

j

i

(k) − K

j

i

(k)H

j⊤

i

(k)P

j

i

(k) + Q

j

i

(k)

(14)

H

j

i

(k) =

∂

ˆ

υ

j

i

(k)

∂w

j

i

(k)

(15)

and

e

j

i

(k) = υ

j

i

(k) −

ˆ

υ

j

i

(k)

(16)

where υ

j

i

(k) ∈ ℜ

n

j

is the desired signal and

ˆ

υ

j

i

(k) ∈

NCTA 2011 - International Conference on Neural Computation Theory and Applications

84

ℜ

n

j

is the HONN function approximation defined, re-

spectively as follows

υ

1

i

(k) = x

1

i

d

(k)

υ

2

i

(k) = x

2

i

(k)

.

.

.

υ

r

i

(k) = x

r

i

(k)

(17)

and

ˆ

υ

1

i

(k) = χ

1

i

(k)

ˆ

υ

2

i

(k) = α

1

i

(k)

.

.

.

ˆ

υ

r

i

(k) = α

r−1

i

(k)

(18)

e

j

i

(k) denotes the error at each step as

e

1

i

(k) = x

1

i

d

(k) − χ

1

i

(k)

e

2

i

(k) = x

2

i

(k) − α

1

i

(k)

.

.

.

e

r

i

(k) = x

r

i

(k) − α

r−1

i

(k).

(19)

The whole proposed neural backstepping control

scheme is shown in Fig. 1.

EKF

( )

i

u k

( )

i

kc

d

( )

i

x k

( )

i

e k

( )

i

w k

References

Robot Manipulator

NN Backstepping

Controller

Neural Network N

Neural Network 1

Neural Network 2

Link N

Link 1

Link 2

Figure 1: Decentralized neural backstepping control

scheme.

5 SEVEN DOF MITSUBISHI

PA10-7CE ROBOT ARM

5.1 Robot Description

The Mitsubishi PA10-7CE arm is an industrial robot

manipulator which completely changes the vision of

conventionalindustrial robots. Its name is an acronym

of Portable General-Purpose Intelligent Arm. There

exist two versions (Higuchi et al., 2003): the PA10-

6C and the PA10-7C, where the suffix digit indicates

the number of degrees of freedom of the arm. This

work focuses on the study of the PA10-7CE model,

which is the enhanced version of the PA10-7C. The

PA10 arm is an open architecture robot; it means that

it possesses:

• A hierarchical structure with several control lev-

els.

• Communication between levels, via standard in-

terfaces.

• An open general purpose interface in the higher

level.

This scheme allows the user to focus on the pro-

gramming of the tasks at the PA10 system higher

level, without regarding on the operation of the lower

levels. The programming can be performed using a

high level language, such as Visual BASIC or Visual

C++, from a PC with Windows operating system. The

PA10 robot is currently the open architecture robot

more employed for research (Jamisola et al., 2004),

(Kennedy and Desai, 2003).The PA10 system is com-

posed of four sections or levels, which conform a hi-

erarchical structure:

Level 4: Operation control section (OCS); formed

by the PC and the teaching pendant.

Level 3: Motion control section (MCS); formed

by the motion control and optical boards.

Level 2: Servo drives.

Level 1: Robot arm.

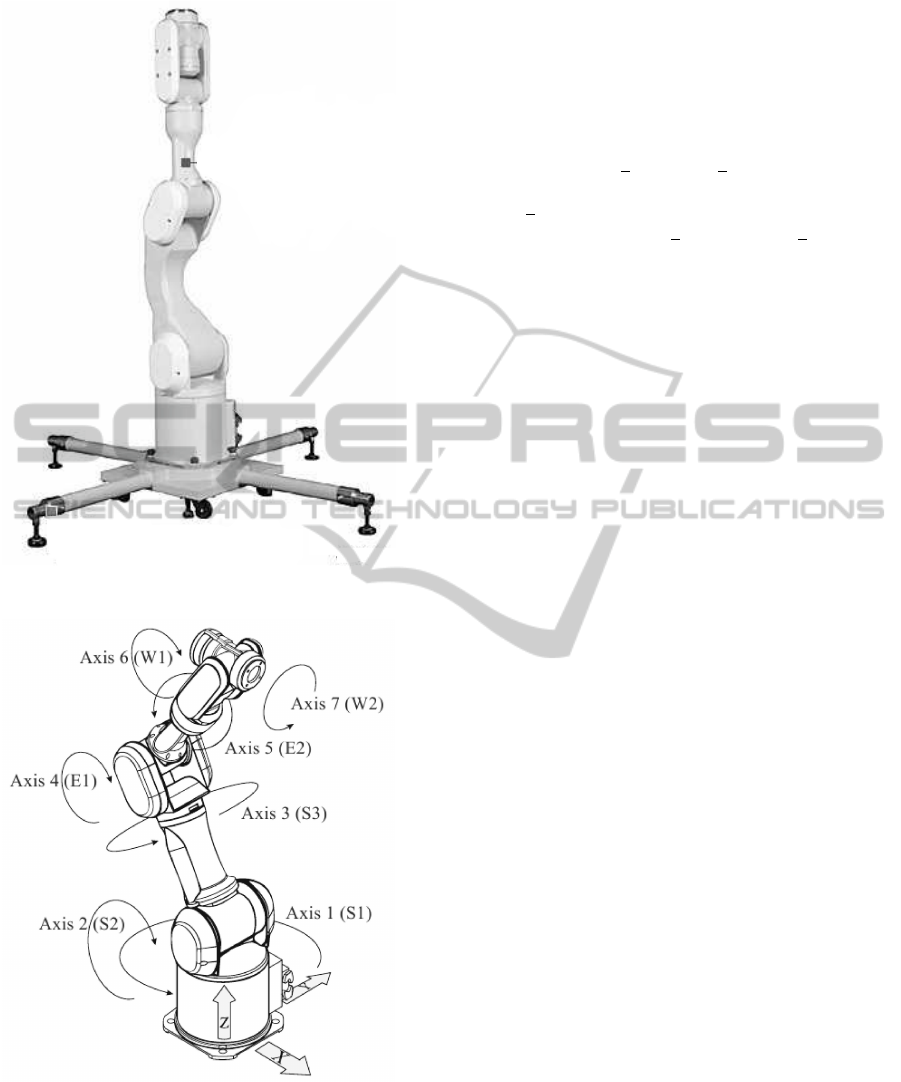

Figure 2 shows the PA10-7CE robot arm. The

PA10 robot is a 7-DOF redundant manipulator with

revolute joints. Figure 3 shows a diagram of the PA10

arm, indicating the positive rotation direction and the

respective names of each of the joints..

5.2 Control Objective

The decentralized discrete-time model for a seven

DOF robot arm can be represented as follows

χ

1

i

(k+ 1) = f

1

i

(χ

1

i

) + B

1

i

(χ

1

i

)χ

2

i

+ Γ

1

i

χ

2

i

(k+ 1) = f

2

i

(χ

1

i

,χ

2

i

) + B

2

i

(χ

1

i

,χ

2

i

)u

i

(k) + Γ

2

i

(20)

where i = 1,.. .,7; χ

1

i

(k) are the angular positions,

χ

2

i

(k) are the angular velocities, u

i

(k) represents the

applied torque to i-th joint respectively. f

j

i

(·) and

B

j

i

(·) depend only on the local variables and Γ

j

i

are

the interconnection effects.

Let define the following states:

x

1

(k) =

h

χ

1

1

χ

1

2

χ

1

3

χ

1

4

χ

1

5

χ

1

6

χ

1

7

i

⊤

x

2

(k) =

h

χ

2

1

χ

2

2

χ

2

3

χ

2

4

χ

2

5

χ

2

6

χ

2

7

i

⊤

DECENTRALIZED NEURAL BACKSTEPPING CONTROL FOR AN INDUSTRIAL PA10-7CE ROBOT ARM

85

Figure 2: Mitsubishi PA10-7CE robot arm.

Figure 3: Mitsubishi PA10-7CE robot axes.

u(k) =

h

u

1

u

2

u

3

u

4

u

5

u

6

u

7

i

⊤

x

1

d

(k) =

h

x

1

1

d

x

1

2

d

x

1

3

d

x

1

4

d

x

1

5

d

x

1

6

d

x

1

7

d

i

⊤

χ

1

i

(k) = x

1

i

(k)

(21)

where x

1

1

d

(k) to x

1

7

d

(k) are the desired trajectory sig-

nals. The control objective is to drive the output χ

1

i

(k)

to track the reference x

1

i

d

(k). Using (21), the system

(20) can be represented in the block strict feedback

form as

x

1

i

(k+ 1) = f

1

i

(x

1

i

(k)) + g

1

i

(x

1

i

(k))x

2

i

(k)

x

2

i

(k+ 1) = f

2

i

(x

2

i

(k)) + g

2

i

(x

2

i

(k))u

i

(k)

(22)

where x

2

i

(k) =

x

1

i

(k) x

2

i

(k)

⊤

, i = 1,... ,7,

f

1

i

(x

1

i

(k)), g

1

i

(x

1

i

(k)), f

2

i

(x

2

i

(k)) and g

2

i

(x

2

i

(k)) are

assumed to be unknown. To this end, we use a

HONN to approximate the desired virtual controls

and the ideal practical control described as

α

1∗

i

(k) , x

2

i

(k) = ϕ

1

i

(x

1

i

(k),x

1

i

d

(k+ 2))

u

∗

i

(k) = ϕ

1

i

(x

1

i

(k),x

2

i

(k),α

1∗

i

(k))

χ

1

i

(k) = x

1

i

(k).

(23)

The HONN proposed for this application is as fol-

lows:

α

1∗

i

(k) = w

1⊤

i

S

1

i

(z

1

i

(k))

u

i

(k) = w

2⊤

i

S

2

i

(z

2

i

(k))

(24)

with

z

1

i

(k) = [x

1

i

(k),x

1

i

d

(k+ 2)]

z

2

i

(k) = [x

1

i

(k),x

2

i

(k),α

1

i

(k)].

(25)

The weights are updated using the EKF (13) - (19)

with i = 1, 2 and

e

1

i

(k) = x

1

i

d

(k) − χ

1

i

(k)

e

2

i

(k) = x

2

i

(k) − α

1

i

(k).

(26)

The training is performed on-line using a series-

parallel configuration. All the neural network states

are initialized in a random way.

6 SIMULATION RESULTS

For simulation, we select the following discrete-time

trajectories (Ramirez, 2008)

x

1

1

d

(k) = c

1

(1− e

d

1

kT

3

)sin(ω

1

kT)[rad]

x

1

2

d

(k) = c

2

(1− e

d

2

kT

3

)sin(ω

2

kT)[rad]

x

1

3

d

(k) = c

3

(1− e

d

3

kT

3

)sin(ω

3

kT)[rad]

x

1

4

d

(k) = c

4

(1− e

d

4

kT

3

)sin(ω

4

kT)[rad]

x

1

5

d

(k) = c

5

(1− e

d

5

kT

3

)sin(ω

5

kT)[rad]

x

1

6

d

(k) = c

6

(1− e

d

6

kT

3

)sin(ω

6

kT)[rad]

x

1

7

d

(k) = c

7

(1− e

d

7

kT

3

)sin(ω

7

kT)[rad]

(27)

NCTA 2011 - International Conference on Neural Computation Theory and Applications

86

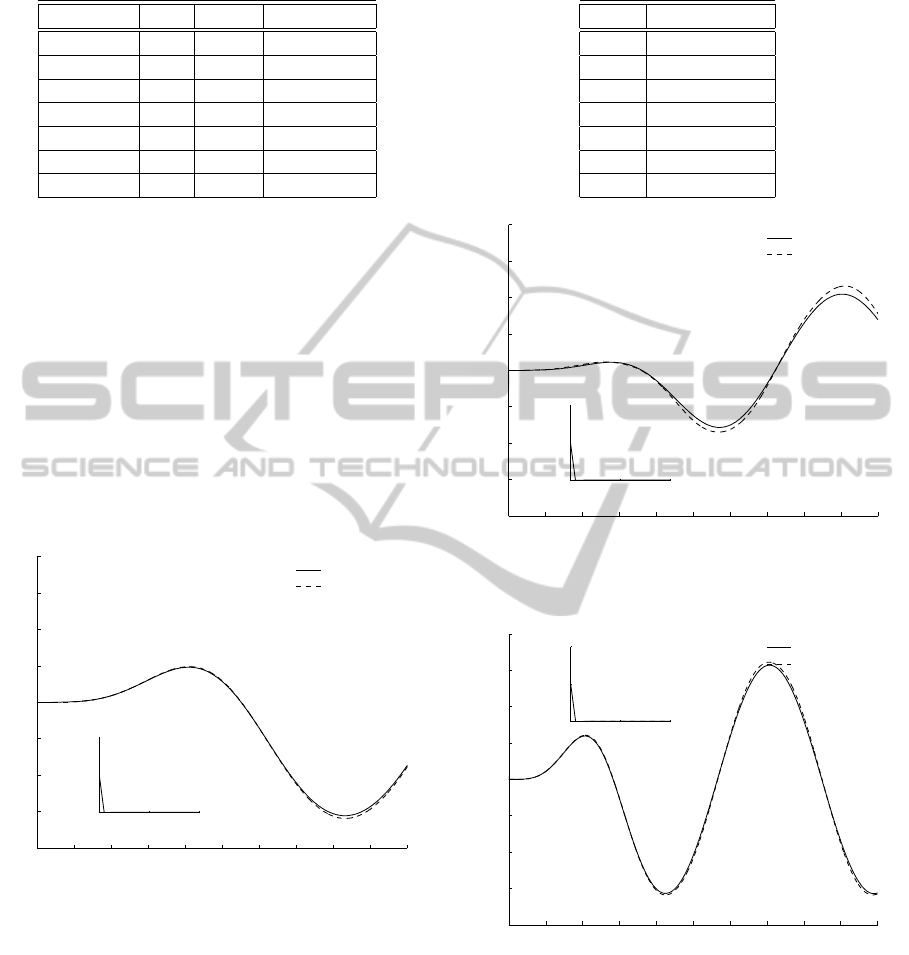

Table 1: Parameters for desired trajectories.

i-th Joint c

i

d

i

ω

i

1 π/2 0.001 0.285 rad/s

2 π/3 0.001 0.435 rad/s

3 π/2 0.01 0.555 rad/s

4 π/3 0.01 0.645 rad/s

5 π/2 0.01 0.345 rad/s

6 π/3 0.01 0.615 rad/s

7 π/2 0.01 0.465 rad/s

the selected parameters c, d and ω for desired trajecto-

ries of each joint are shown in Table 1. The sampling

time is selected as T = 1 millisecond.

These selected trajectories (27) incorporate a si-

nusoidal term to evaluate the performance in presence

of relatively fast periodic signals, for which the non-

linearities of the robot dynamics are really important.

Simulation results for trajectory tracking using the

decentralized neural backstepping control (DNBS)

scheme are shown in Figs. 4 to Fig. 10. The ini-

tial conditions for the plant are different that those of

the desired trajectory. According to these figures, the

tracking errors for all joints present a good behavior

and remain bounded as shown in Fig. 11.

0 2 4 6 8 10 12 14 16 18 20

−2

−1.5

−1

−0.5

0

0.5

1

1.5

2

Time (s)

Position (rad)

↑ Initial condition

x

1

1d

Desired trajectory

χ

1

1

Plant

0 0.01 0.02

0

0.05

0.1

← x

1

1d

(0)=0.05

Time(s)

Position (rad)

Figure 4: Trajectory tracking for joint 1 x

1

1

d

(k) (solid line)

and χ

1

1

(k) (dashed line).

The applied torques to each joint are always inside

of the prescribed limits given by the actuators manu-

facturer (see Table 2); that is, their absolute values are

smaller than the bounds τ

max

1

to τ

max

7

, respectively.

7 CONCLUSIONS

In this paper a decentralized neural control scheme

based on the backstepping technique is presented.

The control law for each joint is approximated by a

Table 2: Maximum torques.

Joint Max Torque

1 232 N-m

2 232 N-m

3 100 N-m

4 100 N-m

5 14.5 N-m

6 14.5 N-m

7 14.5 N-m

0 2 4 6 8 10 12 14 16 18 20

−2

−1.5

−1

−0.5

0

0.5

1

1.5

2

Time (s)

Position (rad)

↑ Initial condition

x

1

2d

Desired trajectory

χ

1

2

Plant

0 0.01 0.02

0

0.05

0.1

← x

1

2d

(0)=0.05

Time(s)

Position (rad)

Figure 5: Trajectory tracking for joint 2 x

1

2

d

(k) (solid line)

and χ

1

2

(k) (dashed line).

0 2 4 6 8 10 12 14 16 18 20

−2

−1.5

−1

−0.5

0

0.5

1

1.5

2

Time (s)

Position (rad)

↑ Initial condition

x

1

3d

Desired trajectory

χ

1

3

Plant

0 0.01 0.02

0

0.05

0.1

← x

1

3d

(0)=0.05

Time(s)

Position (rad)

Figure 6: Trajectory tracking for joint 3 x

1

3

d

(k) (solid line)

and χ

1

3

(k) (dashed line).

high order neural network. The training of each neu-

ral network is performed on-line using an extended

Kalman filter. Simulations results for trajectory track-

ing using a seven DOF PA10-7CE Mitsubishi robot

arm show the effectiveness of the proposed control

scheme.

DECENTRALIZED NEURAL BACKSTEPPING CONTROL FOR AN INDUSTRIAL PA10-7CE ROBOT ARM

87

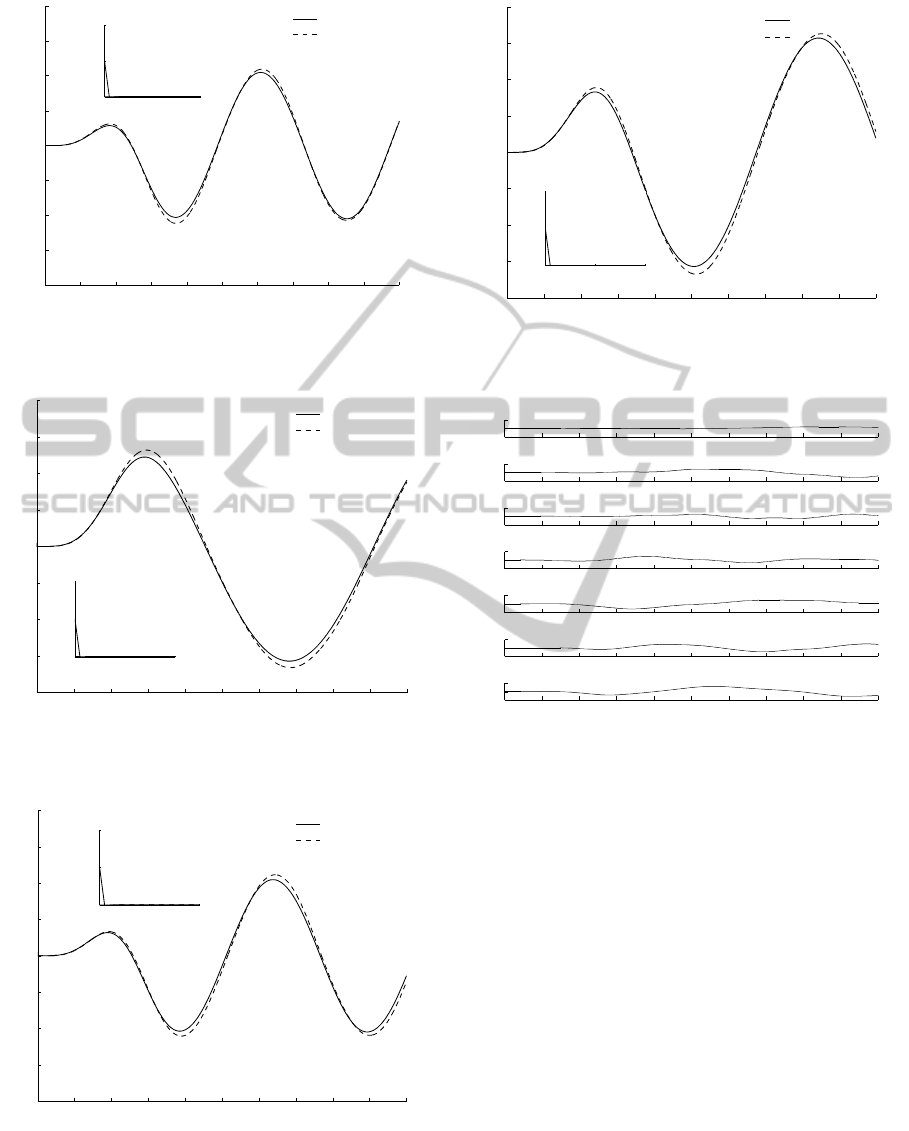

0 2 4 6 8 10 12 14 16 18 20

−2

−1.5

−1

−0.5

0

0.5

1

1.5

2

Time (s)

Position (rad)

↑ Initial condition

x

1

4d

Desired trajectory

χ

1

4

Plant

0 0.01 0.02

0

0.05

0.1

← x

1

4d

(0)=0.05

Time(s)

Position (rad)

Figure 7: Trajectory tracking for joint 4 x

1

4

d

(k) (solid line)

and χ

1

4

(k) (dashed line).

0 2 4 6 8 10 12 14 16 18 20

−2

−1.5

−1

−0.5

0

0.5

1

1.5

2

Time (s)

Position (rad)

↑ Initial condition

x

1

5d

Desired trajectory

χ

1

5

Plant

0 0.01 0.02

0

0.05

0.1

← x

1

5d

(0)=0.05

Time(s)

Position (rad)

Figure 8: Trajectory tracking for joint 5 x

1

5

d

(k) (solid line)

and χ

1

5

(k) (dashed line).

0 2 4 6 8 10 12 14 16 18 20

−2

−1.5

−1

−0.5

0

0.5

1

1.5

2

Time (s)

Position (rad)

↑ Initial condition

x

1

6d

Desired trajectory

χ

1

6

Plant

0 0.01 0.02

0

0.05

0.1

← x

1

6d

(0)=0.05

Time(s)

Position (rad)

Figure 9: Trajectory tracking for joint 6 x

1

6

d

(k) (solid line)

and χ

1

6

(k) (dashed line).

0 2 4 6 8 10 12 14 16 18 20

−2

−1.5

−1

−0.5

0

0.5

1

1.5

2

Time (s)

Position (rad)

↑ Initial condition

x

1

7d

Desired trajectory

χ

1

7

Plant

0 0.01 0.02

0

0.05

0.1

← x

1

7d

(0)=0.05

Time(s)

Position (rad)

Figure 10: Trajectory tracking for joint 7 x

1

7

d

(k) (solid line)

and χ

1

7

(k) (dashed line).

0 2 4 6 8 10 12 14 16 18 20

−0.2

0

0.2

Time (s)

Error (rad)

e

1

1Track

0 2 4 6 8 10 12 14 16 18 20

−0.2

0

0.2

Time (s)

Error (rad)

e

1

2Track

0 2 4 6 8 10 12 14 16 18 20

−0.2

0

0.2

Time (s)

Error (rad)

e

1

3Track

0 2 4 6 8 10 12 14 16 18 20

−0.2

0

0.2

Time (s)

Error (rad)

e

1

4Track

0 2 4 6 8 10 12 14 16 18 20

−0.2

0

0.2

Time (s)

Error (rad)

e

1

5Track

0 2 4 6 8 10 12 14 16 18 20

−0.2

0

0.2

Time (s)

Error (rad)

e

1

6Track

0 2 4 6 8 10 12 14 16 18 20

−0.2

0

0.2

Time (s)

Error (rad)

e

1

7Track

Figure 11: Tracking errors for joints 1 to 7.

ACKNOWLEDGEMENTS

The first author thanks to Universidad Autonoma

del Carmen (UNACAR) and the Programa de Mejo-

ramiento del Profesorado (PROMEP-MEXICO) for

supporting this research.

REFERENCES

Alanis, A. Y., Sanchez, E. N., and Loukianov, A. G. (2007).

Discrete-time adaptive backstepping nonlinear control

via high-order neural networks. IEEE Transactions on

Neural Networks, 18(4):1185–1195.

Ge, S. S., Zhang, J., and Lee, T. H. (2004). Adaptive

neural network control for a class of MIMO nonlin-

ear systems with disturbances in discrete-time. IEEE

Transactions on Systems, Man, and Cybernetics Part

B, 34(4):1630–1645.

Higuchi, M., Kawamura, T., Kaikogi, T., Murata, T., and

NCTA 2011 - International Conference on Neural Computation Theory and Applications

88

Kawaguchi, M. (2003). Mitsubihi clean room robot.

Tecnical review, Mitsubishi Heavy Industries, Ltd.

Huang, S., Tan, K. K., and Lee, T. H. (2003). Decentralized

control design for large-scale systems with strong in-

terconnections using neural networks. IEEE Transac-

tions on Automatic Control, 48(5):805–810.

Jamisola, R. S., Maciejewski, A. A., and Roberts, R. G.

(2004). Failure-tolerant path planning for the PA-10

robot operating amongst obstacles. In Proceedings of

IEEE International Conference on Robotics and Au-

tomation, pages 4995–5000, New Orleans, LA, USA.

Karakasoglu, A., Sudharsanan, S. I., and Sundareshan,

M. K. (1993). Identification and decentralized adap-

tive control using dynamical neural networks with ap-

plication to robotic manipulators. IEEE Transactions

on Neural Networks, 4(6):919–930.

Kennedy, C. W. and Desai, J. P. (2003). Force feedback us-

ing vision. In Proceedings of IEEE International Con-

ference on Advanced Robotics, Co´ımbra, Portugal.

Krstic, M., Kanellakopoulos, I., and Kokotovic, P. (1995).

Nonlinear and Adaptive Control Design. John Wiley

& Sons, Inc, New York, USA.

Liu, M. (1999). Decentralized control of robot manipula-

tors: nonlinear and adaptive approaches. IEEE Trans-

actions on Automatic Control, 44(2):357–363.

Ni, M. L. and Er, M. J. (2000). Decentralized control of

robot manipulators with coupling and uncertainties.

In Proceedings of the American Control Conference,

pages 3326–3330, Chicago, Illinois, USA.

Ramirez, C. (2008). Dynamic modeling and torque-mode

control of the Mitsubishi PA10-7CE robot. Master

dissertation (in spanish), Instituto Tecnol´ogico de la

Laguna, Torre´on, Coahuila, Mexico.

Rovithakis, G. A. and Christodoulou, M. A. (2000). Adap-

tive Control with Recurrent High-Order Neural Net-

works. Springer, London, U.K.

Safaric, R. and Rodic, J. (2000). Decentralized neural-

network sliding-mode robot controller. In Proceed-

ings of 26th Annual Conference on the IEEE Indus-

trial Electronics Society, pages 906–911, Nagoya,

Aichi, Japan.

Sanchez, E. N. and Ricalde, L. J. (2003). Trajectory track-

ing via adaptive recurrent neural control with input

saturation. In Proceedings of International Joint Con-

ference on Neural Networks, pages 359–364, Port-

land, Oregon, USA.

Santiba˜nez, V., Kelly, R., and Llama, M. A. (2005). A

novel global asymptotic stable set-point fuzzy con-

troller with bounded torques for robot manipulators.

IEEE Transactions on Fuzzy Systems, 13(3):362–372.

Song, Y. and Grizzle, J. W. (1995). The extended Kalman

filter as local asymptotic observer for discrete-time

nonlinear systems. Journal of Mathematical Systems,

Estimation and Control, 5(1):59–78.

DECENTRALIZED NEURAL BACKSTEPPING CONTROL FOR AN INDUSTRIAL PA10-7CE ROBOT ARM

89