ASSEMBLY SIMULATION THROUGH A DIGITAL MOCK-UP

APPLICATION

Giampaolo Pascali, Angelo Corallo, Mariangela Lazoi and Alessandro Margherita

EuroMediterranean Incubator, University of Salento, Via Monteroni s.n., Lecce, Italy

Keywords: Design for assembly, Digital mock-up, Naval sector.

Abstract: “Design for X” includes a set of techniques to realize the best product yet during the design avoiding re-

works and loose of time and money. Among these, the design for assembly covers an important role and

aims to design a product “thinking” to the physical assembling moment. Digital Mock-Up (DMU) is a

process to enhance assembly feasibility and efficiency through specific design analysis and allow re-

producing a product virtual assembling. Based on an action research based on a collaboration among

company and university researchers, the paper aims to describe the development of a DMU application in a

naval Italian aerospace company to improve a ship fuel system assembling. Technical features of the

application are described.

1 INTRODUCTION

Different authors face the topics of the new product

development phases (Clark, Wheelright, 1995;

Crawford, Di Benedetto, 2003; Ulrich, Eppinger,

2007; Ribbens, 2000; Rosenau et al., 1996),

everyone specify such phase that goes from the

conceptualization until the production trough the

engineering. Ulrich and Eppinger (2007) suggest

five phases: 0. Planning, 1. Concept Development,

2. System Level Design, 3. Detail Design, 4. Test, 5.

Production. Specially, the Design Phase defines the

new product and prepares the work on which the

manufacturing units will impact (Ulrich and

Eppinger, 2007). The main objective in the product

design is to create a product architecture directly

linked with his functionalities. The creativity in the

first phase of conceptualization has to be translated

in a set of wished functions and blended in the

product architecture through the design in order to

facilitate and optimize the manufacturing and the

following maintenance operations providing an

optimized product. (Ribbens, 2000).

In the ‘design for x’ family, design for assembly

(DFA) is a particularly relevant process/approach by

which product assembly issues (mostly number of

parts, their insertion and orientation) are addressed

in the early design phase, with the goal to reduce

overall assembly cost, time and complexity. Among

company processes, the activities for assembling

individual parts to obtain the final product are

crucial as they use over 50% of total production

time, with costs varying from 20% to 40% for a

single unit. The use of DFA can improve

significantly such performance and several methods

have been developed at this purpose (Miyakawa and

Ohashi, 1986; Boothroyd and Dewhurst, 1986;

Holbrook and Sackett, 1988). The research on DFA

is based on the premise that the lowest assembly cost

can be achieved by designing a product in such a

way that it can be economically assembled by the

most appropriate assembly system. (Boothroyd and

Dewhurst, 1986).

Digital Mock-up is used to support design for

assembly providing assembly simulations that can

be used to address changes in product design and

support the physical assembly phase.

The naval industry is an interesting context of

research. Particular dynamics and routine are

peculiarities of this sector and cannot be found in

other industry. The products are very complex and

require high-technological knowledge and skills.

Design for Assembly and Digital Mock-Up

application can support the development of naval

system improving the company performance.

Based on an action research carried by

Università del Salento and Avio S.p.A., the

commercial application Teamcenter Visualization

Mock Up (VISMOCKUP) has been integrated in the

492

Pascali G., Corallo A., Lazoi M. and Margherita A..

ASSEMBLY SIMULATION THROUGH A DIGITAL MOCK-UP APPLICATION.

DOI: 10.5220/0003650304920497

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (MSIE-2011), pages 492-497

ISBN: 978-989-8425-75-1

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

company CAD system (NX). The paper aims to

answer the question “How is characterized a Digital

Mock-Up application in a naval company?”. The

paper shows criticalities and benefits from the

integration of Digital Mock-Up and CAD

environment in a unique Product Lifecycle

Management System.

In the next section of the paper the Digital Mock-

Up process is described, further insights from the

research design are highlighted and the method used

and application context are described. Another

section is dedicated to the mock-up application

description and finally, conclusions are provided

underling the technological limits of the developed

solution.

2 DIGITAL MOCK-UP

In the last years, there has been a great development

of digital technologies to verify product lifecycle

processes and reduce the need (and thus the costs)

for physical prototypes. Information technologies

can contribute not only to efficiency improvements

but also to improved hypothesis creation capabilities

in engineers and organizations through technical

features such as full visualization, digital pre-

assembly and simulation (Baba and Nobeoka, 1998).

In particular, digital mock-up (DMU) allows

designers to investigate the assembly feasibility of a

product and the constraints imposed by

manufacturing processes. DMU allows the user to

represent the structure of a product and the accurate

position of its geometry, and enables a

multidisciplinary presentation of assembly processes

and analysis (design ‘in context’) such as insertion,

view and collision.

Through DMU, it is possible to obtain a virtual

representation of a product and simulate the shape

and spatial positioning of its components or

subsystems, as well as of the necessary production

tools. By providing the basic representation of a

product, DMU permits to share the core product data

that the different company areas and disciplines use

to collaborate.

DMU has been extensively applied in different

industries such as automotive (Rooks, 1998) and

aerospace. Ford Motor Company is today strongly

involved in the adoption of virtual manufacturing

tools and processes designed to catch possible

manufacture concerns by simulating automotive

performance. An optimized product development

process based on the use of DMU and rapid

prototyping has been defined in the automotive with

the aim to fulfil goals of time and cost reduction, and

quality improvement (Döllner, Kellner and Tegel,

2000).

Shipbuilding is another interesting field for

applying virtual assembly features as it requires a

sophisticated product information model to achieve

the seamless flow of product information. A DMU

system that builds a prototype in a computer has

been proposed for consistent quality control. The

system can simulate models and assemblies on-the-

fly as well as project real-world manufacturability

without the expense and time required to make a

physical mock-up (Won Don, Jong-Ho and Ju Yong,

2007).

3 RESEARCH DESIGN

3.1 Research Method

The study is carried out through an action research

based on an inductive approach in which problems

and solutions have been deducted from observation

of the organizational practices (Bryman, Bell, 2007;

Thomas, 2006; O’Brien, 2001) and working together

to develop the final application. Working with Avio

in several research projects, the researchers of

Università del Salento are very confident with the

company problems and ICT used. The DMU project

has been launched from Avio to improve its

products design through the integration of

VISMOCKUP and the NX CAD system in a way to

work in the direction of a product lifecycle

management system for the company. To develop

the DMU system, three phases have been

accomplished. In the first phase, an analysis has

been done to evaluate how realizes the integration

and its potentialities. A second phase has been of

development and the two software tools have been

integrated in order to guarantee the best performance

for the company. In a last phase, the DMU/CAD

integration has been tested. This phase has been

concluded with a positive results and the application

is widely used inside the company. This action

research is carried out by a team of engineers of

Avio S.p.A and researchers of University of Salento

and the results are presented in the paper in the form

of case study (Yin, 1994) to address the research

question: “How is characterized a Digital Mock-Up

application in a naval company?”. It is a single case

study that wants to express the experiences matured

from the collaboration beetwenn Avio and

Università del Salento in the context of DMU

highlighting the importance and high relevance of

ASSEMBLY SIMULATION THROUGH A DIGITAL MOCK-UP APPLICATION

493

this kind of system for the naval company. To

answer to the research question has been developed

a software solution and the related findings have

described highlighting technological aspects and

managerial implications.

3.2 Company Context

AVIO is a world leader in the design, production

and maintenance of aerospace propulsion

subsystems and components. A smaller part of the

company business is also dedicated to the naval

sector for which produces turbine modules and

automation systems to support the integrated control

of the platform. A central activity is related to

FREMM (Fregata Europea Multi-Missione), a

military ship designed by Fincantieri and DCN to

operate in anti-submarine, anti-air, and anti-ship

settings. In such activity, the company looks for

improving assembly feasibility and optimization of

the (transducer plate of the) fuel system, with the

aim to minimize overall assembly time and costs

while enhancing compliance and operators’ safety.

4 A DMU APPLICATION

Teamcenter Visualization Mockup (from now on

VisMockUp) is a real-time digital prototyping

solution that includes interactive 3D viewing and

robust advanced analysis of large product

assemblies.

Three-dimensional solid models of the

components of the FREMM fuel system transducer

plate were created in UGS NX 2.0. However,

VisMockUp cannot access directly the solid model

data saved in the NX file format. For this reason, the

solid models were exported in JT file format using

the translator provided by NX. We made

modifications on the configuration of the NX

translator (called PVTRANS) in order to increase

reliability in assembly and clearance simulation. We

have used a PER_PART structure option to obtain a

JT file for the assembly and a directory containing

the JT parts.

JT file format is capable of storing an arbitrary

number of faceted representations with varying

levels of detail (LODs) We have defined two LODs

and set the chordalOption to the ABSOLUTE value

in order to obtain a constant chordal value in the

two LODs defined. In this way, the maximum

absolute distance that a line segment may deviate

from the smooth curve is approximately constant for

each part and independent from the part size. This

distance is expressed in the same unit of measure as

the part. For the two LOD defined we have set a

chordal value of 0.2 and 0.5 millimetres.

Furthermore the second LOD defined has forty

percent less or fewer polygons respect the first

(because its Simplify option has been set to 0.4).

Finally we have used a lossless compression for the

first LOD and a lossy compression in the second

LOD.

VisMockUp alternate hierarchies are generally

used to reorganize product assembly models

according to the specific design needs. We used

alternate hierarchies in order to represent the

assembly steps. In particular, each component of

this alternate hierarchy corresponds to an assembly

step. An assembly step contains the component to

be mounted at this step, the fasteners used and a

reference to the previous assembly step. In Fig. 3, it

is showed a representation of an assembly step in

which the transducer is being installed upon the

plate. The elements highlighted outside the plate are

the transducer to be mounted and the fasteners used

(four screws are visible). This approach was chosen

to take into consideration both the current element

to be mounted and the target assembly on which the

element is mounted. Each step defined is re-mapped

in the VisMockUp animation environment that is

used to implement the path defined by the DFA

procedure.

Figure 1: An assembly step.

The animation system within VisMockUp is

organized by events which are generally organized

in a sequence, unless there are changes in the

interdependencies among the events. Each event

contains a set of actions which are executed in a

concurrent or sequential way according to what has

been specified in the event timeline. In particular,

VisMockUp supports different types of actions

which can be visualized to make an animation. For

instance, the liner path action is used to define a

path that translates and/or rotates the selected parts

along a path that is created in the 3D view. The

camera action is used to rotate, pan, and zoom the

view of the model whereas the snapshot action is

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

494

used to rotate, pan, and zoom the view and also to

set the visibility and transformation of parts. Finally,

the text action is used to add text mark-up to the

view, either anchored to a part or unanchored.

In our application, the assembly simulation at

each event coincides with an assembly step as

defined in the assembly hierarchy. Each event

should thus contain at least linear path actions which

implement a real assembly path and a snapshot

action to establish the initial layout of the assembly

step. In this way, it is possible to execute each

assembly step separately from others. It is important

to remark that the layout of a given step is obtained

from the end of the execution of the previous step.

As an option, an event can contain text and camera

actions to ease up the understanding and

visualization of the assembly simulation.

Another important action for motion simulation

is the action addressed to execute VFM files. These

are files containing a set of discrete positions of the

part to be moved, without interpolation among the

points representing the position of the part. There are

several ways to obtain a VFM file, for instance by

applying transformation on the part and capturing its

position or by using an automated functionality

provided by VisMockUp (called “path planning”).

This functionality identifies extraction paths for

parts or assemblies that need to be removed from

models for maintenance reasons. In particular, this

functionality generates a collision-free extraction

path in the form of a VFM file by specifying the

parts to be extracted and the parts to be avoided, and

a set of “key positions” of extracted parts. The key

positions must be at least two: a “start” position and

an “end” position. Intermediate positions can also be

defined to constrain the path direction. However,

there are several limitations in the use of VFM files.

In particular, they cannot be edited once defined and

it’s not possible to simplify them through

interpolation. We have also used the “path planning”

functionality to discover if a de-assembly path exists

for a particular component and then to establish

manually the related assembly path though the use

of the linear path action.

Once the initial layout of an assembly step has

been defined (snapshot action), it is possible to

define the assembly paths through the use of a linear

path action. A path consists of a series of control

points (nodes) connected by segments. There are

several ways to add a control point to a path: a) by

picking points directly on the 3D model (a feature

called pick mode); b) by using a dedicated node

creation panel; or c) by selecting the component to

be moved along the path and applying directly on

transformations.

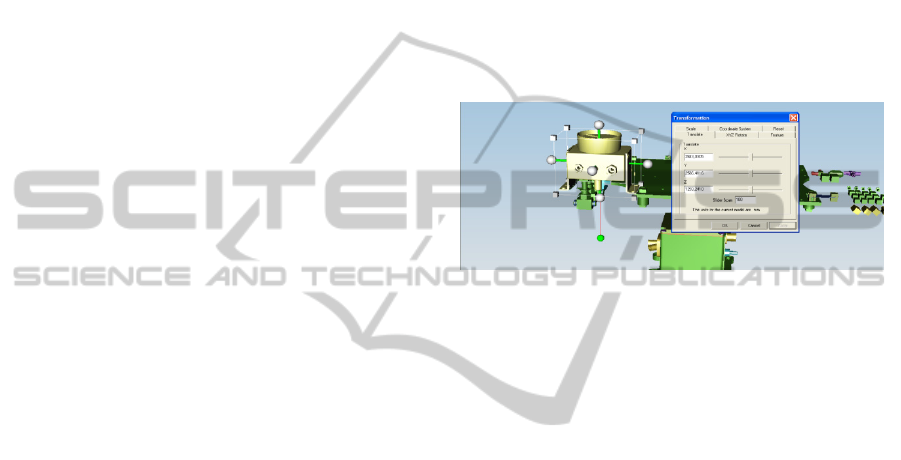

The control of one point’s coordinates is

obtained through the use of a manipulator or

transformation window (figure 4) in which it is

possible to precisely characterize the current

manipulator‘s position and orientation. Since the

manipulator and the part coincide, this also

determines the part’s position (x, y, z) and its spin

angles (θ

x

, θ

y

, θ

z

) which refer to a reference

coordinates’ system defined in the NX CAD

environment. VisMockUp doesn’t allow to estimate

the path duration time, which has been therefore

deducted based on the results of the DFA analysis.

Figure 2: Manipulator and transformation window.

Once an assembly path for the components is

established, they undergo a test for clearance

analysis. Clearance analysis identifies points of

contact and/or penetration among parts or groups of

parts. We can define clearance as the distance

between a pair of items in which there is no physical

interference. VisMockUp allows to specify a

clearance distance. All the items below this distance

(including contacts and penetrating items) are

identified and signalled to the user. VisMockUp

allows both static and dynamic clearance detection.

By setting the dynamic clearance analysis option,

when components are selected and the path

associated with them is executed, all the parts that

are within a predefined range from active parts are

analyzed. For the clearance analysis, we have

imposed to the calculator to use NURBS for the

calculation of the points of contact in order to obtain

a better approximation respect to the JT tessellated

data.

If a collision occurs, the colliding path has to be

modified in order to make it collision-free. There are

some collisions which are acceptable and that the

engineers should be capable to identify (e.g. a screw

that collides with its screwed hole).

To make the assembly simulation more reliable,

we also developed the tools used in the assembly

process. In particular, the tools have been modelled

in NX CAD environment, according to the Italian

UNI standard and using NX parts families. For each

ASSEMBLY SIMULATION THROUGH A DIGITAL MOCK-UP APPLICATION

495

type of tool, a part family was developed to allow

the user to obtain the necessary tool by varying some

typical parameters. Naturally, parameters are

selected by the user in a way to obtain tools

available on the market. Figure 5 shows the sketch

of part families realized in NX and which represents

single open end wrench. The process of importing

from NX to VisMockUp has been described in

paragraph 3.1.

Figure 3: Single open end wrench used in assembly

simulation.

Once an assembly step has been verified, it is

possible to add the assembly instructions that the

operator must follow in order to execute that step.

We keep separated assembly path verification from

assembly text instruction. In fact, assembly

instructions are contained in a separated event

executed in parallel with its associated assembly

event. An assembly instruction contains the part

number of components to be mounted, the fasteners’

part number, and the assembly tool to be used. It is

also possible to specify the tightening torque for

fasteners such as a nuts or bolts and any other

technical information. The complete assembly

simulation, along with assembly instructions, can be

exported in a standard video file format (e.g. avi,

mpeg, etc.) and used for company training purposes.

4.1 Technological Limitations

There are some limitations in the version of

VisMockUp used for the application in AVIO. For

example, in the linear path creation it is not possible

to obtain a feature-based alignment for the path

nodes definition and it is not possible to realize a

simple screw hole alignment using a linear path pick

mode option. Indeed, it’s not possible to select the

hole and the screw centres as inferred points. A

possible workaround is to include in CAD models

some datum points in correspondence of the inferred

points of interest, so that they are present and

selectable in the relative JT files. Datum points

insertion, however, would involve extra work time

for designers who own CAD models. Another

limitation is the fact that flexible components are not

supported since all the components are treated as

rigid bodies. To address this problem, it could be

supposed that if a path exists for a flexible

component treated as a rigid body then it also exists

the path for the flexible component itself. However,

this is not always true and in particular for complex

wiring systems that need different assembly

procedures respect to rigid components. For those

limits the activity of DMU development has been

frozen. However, Avio actually uses the DMU

application knowing its limits. The limits above

described can be overcome by the subsequent

versions of the DMU tool that should provide

improved and ease of use functionalities.

Furthermore, immersive virtual reality technology

integration can be an interesting evolution of this

research that could be thus channelled towards the

integration, within the DMU environment. .

DMU allows the user to make some geometric

verification on product or its sub-system. Therefore,

purpose of a Digital Mock-up is all kind of

simulations concerning the geometric shape,

kinematics or design studies. Instead simulations

regarding product intrinsic functionalities (e.g.

performances) not related to geometric envelopes or

product components spatial position are excluded

form the DMU verifications. In this case other

simulation tools are needed.

5 CONCLUSIONS

Starting from the relevance of design for new

product development, the paper highlights the

importance of the Digital Mock-Up to provide

assembly simulation to improve the result of the

design phase of a new product.

The paper is a technical one and describes the

development of a Digital Mock-Up application in a

naval company. Limits of the application are related

to the technology used.

Future research will apply process based

performance measurement methods to assess how

the new technology impacted assembly processes.

REFERENCES

Baba, Y. and Nobeoka, K. (1998). Towards knowledge-

based product development: the 3-D CAD model of

knowledge creation. Research Policy, 26 (6), 643-659,

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

496

Boothroyd, G. and Dewhurst, P. (1986). Product design

for assembly. Boothroyd Dewhurst, Wakefield, RI.

Bryman A., Bell E., (2007), Business Research Methods,

Oxford University Press, Oxford.

Clark, K. B., Wheelright S. C., (1995), The Product

Development Challenge: Competing Through Speed,

Quality, and Creativity, Harvard Business School

Press

Crawford, C. M., Di Benedetto, C. A., (2003), New

Product Management, McGraw Hill Higher Education

Döllner, G., Kellner, P. and Tegel, O. (2000). Digital

mock-up and rapid prototyping in automotive product

development. Journal of Integrated Design and

Process Science, 4 (1), 55-66.

Holbrook, A. E. K. and Sackett, P. J. (1988). Design for

assembly - guidelines for product design. Proceedings

9

th

International Conference on Assembly Automation,

London, UK.

Khan, Z. (2008). Design for assembly. Assembly

Automation, 28 (3), 200-206.

Miyakawa, S. and Ohashi, T. (1986). The Hitachi

assembly evaluation method (AEM). Proceedings of

the International Conference on Product Design for

Assembly, Newport, RI.

O'Brien, R., (2001), An Overview of the Methodological

Approach of Action Research, Roberto Richardson

Pessoa, Universidade Federal da Paraíba, Brazil.

Ribbens, J., (2000), Simultaneous Engineering for new

product development, John Wiley & Sons, Inc.

Rooks, B. (1998). Shorter product development time with

digital mock-up. Assembly automation, 18 (1), 34-38.

Thomas D., (2006), A General Inductive Approach for

Analyzing Qualitative Evaluation Data, American

Journal of Evaluation, Vol. 27, No. 2, pp. 237-246.

Ulrich, K. T., Eppinger, S. D., (2007), Product Design and

Development, McGraw Hill Education Singapore

Won Don, K., Jong-Ho, N. and Ju yong, P. (2007). A

digital mock-up system for construction of product

information model in shipbuilding process. Journal of

Ship Production, 23 (1), 7-16.

Yin, R. K., 1994, Case Study Research: Design and

Methods, Sage Pubblications.

ASSEMBLY SIMULATION THROUGH A DIGITAL MOCK-UP APPLICATION

497