A MODEL FOR DESIGNING NON COOPERATIVE SUPPLY

CHAIN WHERE LOGISTICS SERVICE

PROVIDERS TAKE PART

Ernesto Del R. Santibanez-Gonzalez

Department of Computer Science, Federal University of Ouro Preto (UFOP), Ouro Preto, M.G., Brazil

Geraldo Robson Mateus

Department of Computer Science, Federal University of Minas Gerais (UFMG), Belo Horizonte, M.G., Brazil

Henrique Pacca Luna

Computer Science Institute, Federal University of Alagoas (UFAL), Maceió, A.L., Brazil

Keywords: Logistics service providers, Supply chain design, Non-cooperative supply chain, Optimal network design,

Mathematical programming.

Abstract: This paper presents a mathematical model for the problem of designing not cooperative supply chain where

the logistic service providers take part. In this problem, manufacturers are not collaborating or having any

type of bargaining strategy among them, they compete for supplying products to retailers seeking to

maximize their profit. Logistics service providers also compete among them for providing logistics services

to manufacturers and delivering products to retailers. It is considered that manufacturers, logistics service

providers and retailers collaborate to maximize services. Normally this problem can not be modeled as an

optimization problem and we use a variational inequality approach to formulate it. The model determines

the optimal level of production for each manufacturer, the flows of products between manufacturers and

retailers, the flow of products each logistics service provider is going to move and the price retailers are

willing to pay to manufacturer in a non-cooperative environment. We demonstrate and discuss theory results

regarding existence and uniqueness of the solution for the model. An example is presented to illustrate some

properties of the problem.

1 INTRODUCTION

As mentioned by Frankel, Bolumole, Eltantawy,

Paulraj and Gundlach (2008), Giannakis and Croom

(2004), Gibson, Mentzer and Cook (2005),

Giunipero, Hooker, Joseph-Matthews, Yoon and

Brudvig (2008), Lambert, García-Dastugue, and

Croxton (2005), Larson, Poist and Halldórsson

(2007), Supply chain management (SCM) has

become a fertile field for the application of a wide

variety of disciplines, including finance, logistics,

operations management, operations research, and

information technology among others. For some

authors, the philosophy of SCM is to combine some

or all of these disciplines to produce a

comprehensive strategy for improving the

performance of the company (Giunipero et al.,

2008). The large number of articles published till

today, especially in the last twenty years, reflects the

enormous interest shown in SCM by the academic

and business world. Even when there is an enormous

number of publications, different authors agree that

despite the importance of SCM to gain competitive

advantages and improve the performance of

organizations (Cooper, Lambert & Pagh, 1997;

Croom, Romano & Giannakis, 2000; Elmuti, 2002;

Lambert, Cooper & Pagh, 1998; Gunasekaran, Patel

& Tirtiroglu, 2001; Sanders, 2009), there is still no

consensus on its definition, the limits for practical

application and the relationship between SCM and

409

Santibanez Gonzalez E., Robson Mateus G. and Pacca Luna H..

A MODEL FOR DESIGNING NON COOPERATIVE SUPPLY CHAIN WHERE LOGISTICS SERVICE PROVIDERS TAKE PART.

DOI: 10.5220/0003617904090417

In Proceedings of the 13th International Conference on Enterprise Information Systems (SSSCM-2011), pages 409-417

ISBN: 978-989-8425-54-6

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

other disciplines or concepts (Frankel et al., 2008;

Gibson et al., 2005; Lambert et al., 2005; Larson et

al., 2007). For Wisner and Tan (2000) "The concept

is still evolving. There is no generally accepted

definition of SCM or a general understanding of

how SCM affects the characteristics and

organizational practices". Handfield and Bechtel

(2004) noted that "what we are seeing in the field of

SCM, which is that for years was defined in some

way, has now become larger with different

fragments of theory". Certainly the work developed

after year 2000 to define SCM, has helped to close

the gap of uncertainty and lack of agreement, but

still remain an open question.

This article argues that a SC is a set of

interacting organizations (among themselves) under

a common goal and are involved in the flow of

goods, services, resources and information. This is

characterized by the following basic elements:

a. Organizations and / or individuals can be

grouped under a common goal. The common goal

does not necessarily mean that all the organizations

share the same goal or objective.

b. The interactions between the organizations

can take many forms, such as exchange of raw

materials, exchange of goods, services, sale or

purchase of various resources, information

exchange, etc.;

c. The limit - or range- defining which

organizations are part of the supply chain, i.e. the

boundaries (scope) of the SC, is determined by the

type of problem that will be addressed and the

capabilities of the tools of analysis that are used.

For the purposes of this article, it is used the

concept of root manufacturer (provider) to describe a

provider that has no other provider, i.e. for which

there is no organization that provides to it products,

services or resources.

In this paper it is addressed the problem of

designing a supply chain involving the operation of

logistics service

providers (LSP) under a non-

cooperative environment. In particular it is worked

with triad structures for the supply chain which is

composed by manufacturers, retailers and LSP´

layers. In each layer, members of the supply chain

compete with other similar agents and work in a

non-cooperative scenario. Firms belonging to a

different layer of the supply chain work in a

collaborative environment. There are no firms with a

dominant position able to influence in the decisions

of the other members of the supply chain. Each

manufacturer wants to maximize its profitability and

the same is valid for retailers and LSP as well.

Manufacturers are located at the top layer of the

supply chain and are concerned with the production

of products and shipments to the retailers. The

manufacturers compete among them for delivering

products of equivalent quality to retailers through

LSP, whom also compete to attract the

manufacturers and deliver the products to retailers.

In this supply chain, the LSPs are located in the

middle layer. Each LSP is faced with handling and

delivering the products sold by manufacturers to

retailers, conducting transactions with both types of

agents - whom purchase the LSP services- and

retailers -whom purchase products from the

manufacturers-. Retailers are located at the bottom

layer of the supply chain. They demand a certain

quantity of products (single commodity) and agree

to purchase them from any manufacturer at a finite

price. Also transactions and prices per transaction

between manufacturers and LSP must be

determined. Till now authors are not aware of any

other paper working in this problem.

Supply chain design has been extensively

studied so far. For a discussion about the design

problem underlying it is recommended the book by

Simchi-Levi, Kaminsky and Simchi-Levi (2003)

besides the concept of supply chain assumed in this

paper is a bit different from the one discussed in the

book. For a detailed review of supply chain network

design problems and modeling approaches it is

recommended the work by Melo, Nickel and

Saldanha-Da-Gama (2009). Melo et al. (2009)

conducted a detailed literature review of facility

location models in the context of supply chain

management and particularly their applications to

supply chain network design. All the literature

reviewed in these works follows the traditional

supply chain network design models where there is

no competition among the agents and the models

and solution methods are focused on facility

location. For concepts and applications related to

network design in a broader context it is recommend

the book by Ahuja, Magnanti and Orlin (1999). For

additional background on supply chain, see also the

books by Bramel and Simchi-Levi (1997), Pardalos

and Tsitsiringos (2002), and the volume edited by

Simchi-Levi, Wu and Shen (2004).

This paper follows the work by Beckmann,

McGuire and Winsten (1956) who first identified the

applications of networks to conceptualize decision-

making of an organization and particularly in

manufacturing processes and product flows linking

also to the theory of firm. Related to this work is

also the work by Nash (1950, 1951) on game theory.

Nagurney Dong and Zhang (2002) addressed the

problem of a three tier supply chain network design

modeling where firms are located at the nodes of the

network, each firm have their individual profit-

maximization objective functions, and they seek to

determine the optimal flows between tiers of nodes

and also the prices of the product at the various tiers.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

410

In the same line, Dong Zhang and Nagurney (2004)

developed a supply chain network model where a

finite-dimensional variational inequality was

formulated for the behavior of various decision

makers. Chiou (2008) considered a multi-tiered

supply chain network which contains manufacturers,

distributors and consumers and involving two-level

of decision makers. He proposed a new solution

scheme for the supply chain network design problem

formulated as a (non-convex and non-differentiable)

mathematical program with equilibrium constraints.

In some way, the problem addressed in this

paper could be considered as a Strategic Planning

problem involving a long-term planning horizon and

the selection of some mix of manufacturer, LSP and

retailers in order to satisfy customer´s demand.

Eventually could also involve a facility location

problem and capacity planning of

manufacturing/servicing units to supply retailers, as

well as the transportation capacity required among

manufacturers and retailers. Simchi-Levi et al.

(2003) stated that “the strategic level deals with

decisions that have a long-lasting effect on the firm.

These include decisions regarding the number,

location and capacities of warehouses and

manufacturing plants, or the flow of material

through the logistics network”. This statement

establishes a clear link between location models and

strategic SCM. Problems of this type are mostly

modeled as mixed integer linear programming

problems, for example, see the paper by Chauhan

Nagi and Proth (2004) and the annotated

bibliography for a discussion. However, in the

general case, the kind of problem we work on this

paper can not be modeled as an optimization

problem, and then we use a variational inequality

approach to formulate it. One of the central points in

this type of problem is to demonstrate the existence

of the solution and demonstrate its uniqueness.

Normally, the complexity of this problem derives

from considering that the cost functions for members

of the supply chain depend on each other, then the

Jacobian of the cost functions is no longer

symmetric.

The paper by Meixell and Gargeya (2005)

reviewed the literature on models to support the

design of global supply chain and focused on the

logistics aspects of the supply chain, i.e., the

movement of goods from the point of origin to the

point of consumption. Meixell and Gargeya (2005)

studied a supply chain design problem comprising

the decisions regarding the number and location of

production facilities, the amount of capacity at each

facility, the assignment of each market region to one

or more locations, and manufacturer selection for

sub-assemblies, components and materials. Global

supply chain design extends this definition to

include selection of facilities at international

locations, and the special globalization factors this

involves.

We do not make any distinction among global or

domestic supply chain design. Cohen, Fisher and

Jaikumar (1989) “present the main features that

differentiate an international supply chain from a

single-country model” (as cited in Vidal and

Goetschalkx, 1997). In this paper, the selection of

locations for production (manufacturers) and/or

distribution facilities in global supply chains scale is

modeled/considered in implicit way. The model

focuses on solving the problem of how the material

flows from manufacturers to retailers and the

definition of how many products should be

manufactured and delivered when a LSP take part.

This paper is organized as follows. In section 2 is

discussed the formulation of the supply chain design

problem involving the operation of logistics services

providers, whom attend the demand of

manufacturers for delivering products to their

customers. In Section 3 is derived and analyzed the

existence and uniqueness of the solution for the

problem. Finally in Section 4 conclusions are

presented.

2 PROBLEM FORMULATION

We address the problem of producing and delivering

homogeneous products from manufacturers to

retailers through logistics service providers

contracted by the manufacturers. The model consists

of n profit-maximizing manufacturers, with a typical

manufacturer denoted by i; m profit-maximizing

retailers, with retailers denoted by j and with a

typical demand denoted by

, and q profit-

maximizing logistics service providers (LSP), with a

typical LSP denoted by k. The manufacturers are

involved in the production of homogeneous

products, which can be purchased by the retailers,

who, in turn, make the product available to

consumers at the demand markets. The links in the

supply chain network denote

transportation/transaction operations. In every layer,

manufacturers, LSP and retailer compete in the

sense of Nash (1950, 1951). Each firm acts in his

own benefit and will determine his optimal choice

given the optimal choices of the competitors, in such

a way that the whole system gets an equilibrium

state.

A MODEL FOR DESIGNING NON COOPERATIVE SUPPLY CHAIN WHERE LOGISTICS SERVICE PROVIDERS

TAKE PART

411

2.1 The Manufacturers Optimization

Problem

Each manufacturer i seeks to maximize its profit by

setting the total quantity

that he must produce

and determining for each retailer j, the sales price p

and the quantity of product x

to deliver to retailer j.

In this problem all the delivery services from the n

producers (i=1,…n) to the m retailers are contracted

to logistics service providers (LSP) k (k=1,…q) at a

price p

. A manufacturer i can contract one or more

LSP k to deliver the products purchased by the

retailer j. Manufacturer i have a service cost function

(

) to make available the products to the

retailer j through LSP k. Consider that

=

∑

x

∀=1…,

. There are not production costs

at this stage of the problem:

=

−

−

(

)

(1)

s.t.

≥0∀,

,

(2)

Notice that the total production of manufacturer i

must satisfy that.

=

∀=1,…, (3)

That is, all the products sold by manufacturer i to

all the retailers j, j=1,…,m is equal to all the

products delivered by manufacturer i to all the

retailers j through LSP k, k=1,…,q.

In this problem, the service costs functions

(

) for each manufacturer i are continuously

differentiable and convex. Assuming that the

manufacturers compete in a non-cooperative

fashion in the sense of Nash (1950, 1951), which

states, in this context, that each manufacturer will

determine his optimal production quantity and

shipments, given the optimal ones of the

competitors, the optimality conditions for all

manufacturers i simultaneously are as follow:

Determine

∗

∗

є R satisfying:

(

∗

+

(

∗

)

)

∗

−

∗

−

∗

∗

−

∗

≥0,

(4)

≥0,∀,

,

(4a)

Where

∗

∗

are the optimal values

for the corresponding variables.

2.2 The Logistics Service Providers

Profit Maximizing Problem

The LSPs are also profit-maximizing agents. They

seek to maximize the profit resulting from selling

their services to manufacturers and the costs of

servicing the retailers - the costumers of the

manufacturers-. Remember that all the LSPs

compete in the sense of Nash. For each LSP k, the

problem is the following:

=

−

(

)

(5)

s.t.

=

∀=1,…,

(6)

≥0,∀,

,

(6a)

LSPs incur in operating costs

(.) to take

products from manufacturer i and deliver to retailer

j. The cost function

(.) is continuous

differentiable and convex. The profit for LSP k in

(5) is given by the prices

charged to

manufacturer i to deliver the products to retailer j

minus the corresponding costs

(.). It is

reasonable consider that the LSP deliver all the

products arrived from the manufacturers, what is

modeled by (6).

As in the manufacturer case, the LSPs act in a

non-cooperative way and there are not bargaining or

any type of collaboration between them. The

optimality conditions for all LSPs simultaneously

are as follows, determine

∗

є R such that:

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

412

(

(

)

−

∗

)

∗

−

∗

≥0,

(7)

≥0,∀,

,

(7a)

Where

∗

is the optimal flow of products

coming from manufacturer i that LSP k will deliver

to retailer j.

2.3 The Retailers Problem

The retailers j purchase products to manufacturer i at

sale price

∗

, but they also consider in their

decision the unit cost

(

) of making the

transaction with this manufacturer i. These costs are

continuous and depend on the quantity of products

purchased by others retailers, then could be

interpreted as the procurement cost incurred by the

retailer in a non-cooperative scenario. The retailers

are willing to pay a demand price

∗

for the

products. Then the equilibrium conditions for all

retailers j=1,…,m are the following:

∗

+

=

∗

≥0

≥

∗

=0

(8)

=

∀

=1,…,

(9)

In the same way as the other agents in the supply

chain, considering that (8) must hold for all market

in equilibrium, the variational inequality problem

can be expressed as follows:

∗

+

∗

−

∗

≥0

(10)

∗

≥0∀,

(10a)

2.4 Supply Chain Management

Perspective

In a non-cooperative scenario with manufacturer,

retailers and logistics service providers seeking to

maximize their profit hold equilibrium conditions

for the supply chain in which the total quantity of

products that manufacturer produces and ships to

retailers through logistics service providers must be

equal to the amount of product purchased by a

retailer, as well as the quantity of products the

logistics service provider receive from the

manufacturer to be delivered to retailers, must be

equal to the shipment of the logistics service

providers to the retailers. Finally the shipments and

price pattern must satisfy the sum of inequalities (4),

(7) and (10) described previously. Formally this is

stated as follows:

2.4.1 Definition 1

The equilibrium state of the given supply chain

design problem in the presence of logistics service

providers is one where the flows of products

between manufacturers, logistics service providers

and retailers coincide and the product shipments and

prices satisfy the sum of the optimality conditions

(4), (7), and the conditions (10).

2.4.2 Theorem 1

A product shipment(

∗

,

∗

) is an equilibrium

pattern of the supply chain design model according

to Definition 1 if and only if it satisfies the

variational inequality problem:

(

+

∗

)∗(

−

∗

)

+

∗(

−

∗

)≥0

(11)

,

≥0∀,

,

(11a)

Proof

Consider the definition 1. Sum up the

inequalities (4), (7) and (10). After algebraic

operations it gets the inequality (11).

Now, consider the inequality (11). To the first

term in bracket of inequality (11) adds

−

,

then follows:

(

+

∗

+

−

)∗(

−

∗

)

(12)

To the second term in bracket of inequality (11)

add

−

then

A MODEL FOR DESIGNING NON COOPERATIVE SUPPLY CHAIN WHERE LOGISTICS SERVICE PROVIDERS

TAKE PART

413

(

)+

−

∗(

−

∗

)

(13)

After the above additions (12) and (13),

inequality (11) can be rewritten as follows:

(

(

∗

)

+

)∗(

−

∗

)−

∗

∗

−

∗

+(

(

)

−

∗

)

∗

−

∗

+

∗

+

∗

−

∗

≥0

(14)

In the above inequality (14), the first two terms

of (14) are the same of (4), the third term is equal to

(7) and the last term is identical to (10). Hence

inequality (11) is the sum of conditions (4), (7) and

(10) according to Definition 1. So the proof is

complete.

3 THEORY RESULTS

In this Section, it is presented some qualitative

properties regarding inequalities (11). In particular it

derived the existence and uniqueness of the solution

to (11).

3.1 Theorem 2: Existence of the

Solution

Assuming that the feasible set is nonempty, then

variational inequality (11) admits a solution.

Proof

Since there is a finite demand for the products in

the market, i.e., d ≤ u for some μεR

. Then each

retailer j =1,…,m also demands a finite amount

≤

of product from the manufacturers, for some

μ

εR

.

By the side of manufacturers, each of them, i

=1,…,n, has a finite capacity of production

. Then

for each pair i, j, there is a finite capacity of

shipments

εR

for the retailers. That is

≤

.

Since

≤

, then there is

εR

such that

≤

for each i, j and k=1,…,q . This is, by the

side of LSP, they deliver a finite amount of products

to retailers already sold by manufacturers and

demanded in a finite amount by the retailers.

Suppose we define

as the quantity of

products retailer j is receiving from LSP k. Since

≤

, and

≤

for each i, j and k, then

≤

for some j,k.

So it can be said that the set

=

,

,

≥0

≤

,

≤

,

(15)

≤

,∀,

,

is bounded, closed and convex, then X is a

compact subset .

Now, let H be a real Hilbert space, whose inner

product is denoted by <,>. Let X be a nonempty

closed convex subset of H and A:X→ H a nonlinear

map. Then (11) can be written as the problem of

finding x

∗

in standard variational inequality format

such as,

∗

|

−

∗

≥0,∀

(16)

Where mapping A has a correspondence with the

terms in (11).

Assuming the mapping A is continuous, from

(15) and (16) there is a solution for (11).

3.2 Theorem 3: Uniqueness of the

Solution

Assume the conditions in Theorem 2 and that the

map A(X) is strictly monotone on X, that is:

−

−>0,∀,

(17)

Then the solution x* to variational inequality

(16) is unique.

Proof

Given that inequality (11) can be re-written as

inequality (16), follows from standard theory of

inequality the Theorem 3.

4 SOME NUMERICAL

EXAMPLES

In this section we provide a numerical example of

the model presented in previous section and also

discuss the results and some interesting issues. The

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

414

example was figure out in order to illustrate the

problem and be simple to solve it. We use some data

from the literature (Braess, Nagurney and

Wakolbinger, 2005) and adapt them to our problem.

The example was solved analytically, and algorithms

for solving general cases could be discussed in a

future paper.

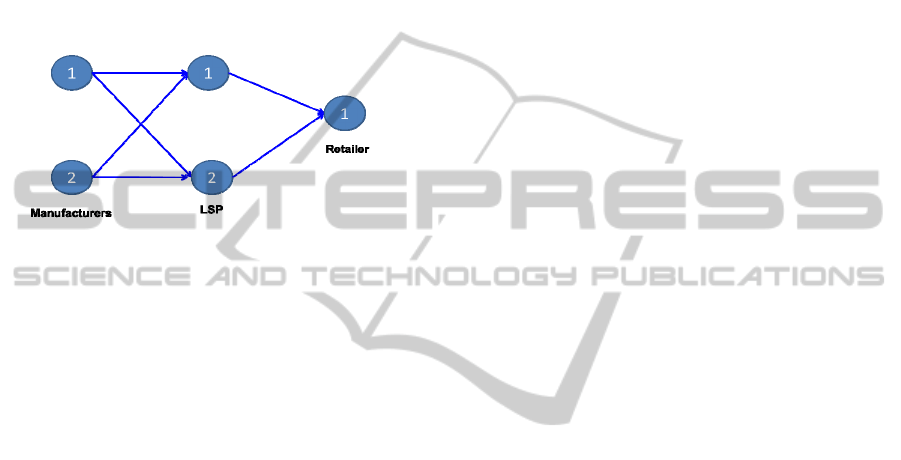

Consider a problem as represented by the graph

depicted in Figure 1, with two manufacturers (m=2),

two logistics service providers (q=2) and one retailer

(n=1),

Figure 1: Example supply chain.

The transaction cost functions

faced by

manufacturers i and LSP k to meet demand of

customer j are given by:

=0,5

+50

;

=5

=0,5

+100

;

=10

The operating cost functions

of LSP k, to

deliver products from the manufacturer i to the

customer j are the following:

=5

;

=0,5

+50

=10

;

=0,5

+100

The transaction cost functions

associated

with the customer j in obtaining products from

manufacturer i are given by:

=5

;

=10

The demand is set to D=6 units.

Analyzing the data and after some algebraic

operations it is obtained the following values for the

variables

and

:

=

=3

=

=0

The demand price customer is willing to pay is

113 for the products sold by manufacturer 1. There

are no products purchased to manufacturer 2. Using

(8) we can obtain the price charged by manufacturer

1, that is equal to 83.

From this example and regarding the model, we

can observe the following issues:

i.- The demand price retailer(s) are willing to pay

to manufacturers make no difference whether the

retailer is serviced by LSP 1 or LSP 2. But in

practice, if LSP (anyone) has a value-added service

offering to customers, and the customers perceive

this difference among the LSPs then, they could be

willing to pay more for the same product but making

the difference by the service they receive. So this

fact, proved in practice, it is considered in the model

by the operating cost functions c

of LSP k, and

also by the price ρ

charged to manufacturer i by

LSP k to service customer j. Nevertheless, could be

also interested to include in the model a service cost

perceived by the customers depending of the LSP.

ii.- The demand price retailer(s) are willing to

pay is exactly the sum of the “operating costs” of

manufacturers and LSPs plus the cost of obtaining

the products. This last cost in fact, could include the

benefits perceived by retailers in making the

purchasing, and a kind of procurement costs,

including all the internal costs incurred by the

retailer in making the purchasing to manufacturers.

5 CONCLUSIONS

Supply chain management sometimes confounded

with logistics, is a multidisciplinary approach for

effective and efficient management of the supply

chain.. In turn, supply chain is a set of interacting

organizations (among themselves) under a common

goal and they are involved in the flow of goods,

services, resources and / or information. In this

paper is used this approach to model a non-

cooperative problem in a supply chain composed of

manufacturers and retailers and where there are

logistics service providers servicing the demand of

retailers. The model considers that manufacturers,

retailers as well as LSP act on their own advantage,

seeking to maximize their profit individually. Also,

the model considers that the agents located in

different layers -manufacturer, retailers and LSP-

collaborate to get the best available service level. In

the optimal solution, the model determines the flow

of products going from the manufacturers to retailers

and passing across the LSP. Hence the model

permits to handle the amount of products shipped

from each manufacturer to each retailer and

specifying the LSP servicing both the manufacturer

A MODEL FOR DESIGNING NON COOPERATIVE SUPPLY CHAIN WHERE LOGISTICS SERVICE PROVIDERS

TAKE PART

415

and the retailer. The model also determines the price

the retailer agrees to pay for the products sold by

manufacturers. Some theory results are also

analyzed in term of existence and uniqueness of the

solution to the problem. An example is discussed to

illustrate the model.

ACKNOWLEDGEMENTS

This research was partially supported by the

Fundação de Amparo á Pesquisa do Estado de Minas

Gerais – FAPEMIG, CNPq e Capes - Brazil.

REFERENCES

Ahuja, R.K., Magnanti, T.L., & Orlin, J.B. (1993).

Network Flows: Theory, Algorithms, and Applications.

Englewood Cliffs, N.J.: Prentice Hall.

Beckmann, M.J., Mcguire, C.B., & Winsten, C. B. (1956).

Studies in the Economics of Transportation, New

Haven, Connecticut:Yale University Press.

Braess, D., Nagurney, A., & Wakolbinger, T. (2005). On a

Paradox of Traffic Planning. Transportation Science,

39(4), 446–450.

Bramel, J., & Simchi-Levi, D. (1997). The Logic of

Logistics: Theory, Algorithms, and Applications for

Logistics Management. New York: Springer-Verlag.

Chauhan, S.S., Nagi, R., & Proth, J.M. (2004). Strategic

capacity planning in supply chain design for a new

market opportunity. Int. Journal of Production

Research, 42(11), 2197–2206.

Chiou, S-W. (2008). Optimization of multi-tiered Supply

Chain Networks with Equilibrium Flows. In V. Kordic

(Ed.), Supply Chain,Theory and Applications (pp. 231-

246). Vienna, Austria: I-Tech Education and

Publishing.

Cohen, M.A, Fisher,, M. & Jaikumar, R. (1989).

International manufacturing and distribution networks:

a normative framework. In K. Ferdows (Ed.),

Managing international manufacturing (pp. 67–93).

Amsterdam: North-Holland,

Cooper, M.C., Lambert, D.M., & Pagh, J.D. (1997).

Supply Chain Management: More Than a New Name

for Logistics. The International Journal of Logistics

Management, 8(1), 1-13.

Croom, S., Romano, P., & Giannakis, M. (2000). Supply

Chain Management: An Analytical Framework for

Critical Literature Review. European Journal of

Purchasing and Supply Management, 6(1), 67-83.

Dong, J., Zhang, D., & Nagurney, A. (2004). A supply

chain network equilibrium model with random

demands. European Journal of Operational Research,

156, 194–212.

Elmuti, D. (2002). The Perceived Impact of Supply Chain

Management on Organizational Effectiveness. Journal

of Supply Chain Management, 38(3), 49-57.

Frankel, R., Bolumole, Y.A., Eltantawy, R.A., Paulraj, A.,

& Gundlach, G. (2008). The domain and scope of

SCM'S foundational disciplines insights and issues to

advance research. Journal of Business Logistics, 29(1),

1-30.

Giannakis, M., & Croom, S.R. (2004). Toward the

development of a supply chain management paradigm:

a conceptual framework. Journal of Supply Chain

Management, 40(2), 27-37.

Gibson, B.J., Mentzer, J.T., & Cook, R.L. (2005). Supply

Chain Management: The pursuit of a concensus

definition. Journal of Business Logistics, 26(2), 17-25.

Giunipero, L.C., Hooker, R.E., Joseph-Matthews, S.,

Yoon, T.E., & Brudvig, S. (2008). A decade of SCM

literature: past, present and future implications.

Journal of Supply Chain Management, 44(4), 66-86.

Gunasekaran, A., Patel, C., & Tirtiroglu, E. (2001).

Performance Measures and Metrics in a Supply Chain

Environment.

International Journal of Operations and

Production Management, 21(1-2), 71-77.

Handfield, R.B., & Bechtel, C. (2004). Trust, Power,

Dependence and Economics: Can SCM Borrow

Paradigms?. International Journal of Integrated

Supply Management, 1(1), 3-32.

Lambert, D.M., Cooper, M.C., & Pagh, J.D. (1998).

Supply Chain Management: Implementation Issues

and Research Opportunities. The International Journal

of Logistics Management, 9(2), 1-19.

Lambert, D.M., García-Dastugue, S.J., & Croxton, K.L.

(2005). An evaluation of process-oriented Supply

Chain Management frameworks. Journal of Business

Logistics, 26(1), 25-51.

Larson, P.D., Poist, R., & Halldórsson, A. (2007).

Perspectives on logistics vs. SCM: A survey of SCM

professionals. Journal of Business Logistics, 28(1), 1-

24.

Meixell, M.J., & Gargeya, V.B. (2005). Global supply

chain design: A literature review and critique.

Transportation Research Part E, 41, 531–550.

Melo, M.T., Nickel, S., & Saldanha-Da-Gama, F. (2009).

Facility location and supply chain management – A

review. European Journal of Operational Research,

196(2), 401-412.

Nagurney, A., Dong, J., & Zhang, D. (2002). A supply

chain network equilibrium model. Transportation

Research Part E, 38, 281-303.

Nash, J. F. (1950). Equilibrium points in n-person games.

In Proceedings of the National Academy of Sciences,

36, 48-49.

Nash, J. F. (1951). Noncooperative games. Annals of

Mathematics, 54, 286-298.

Pardalos, P.M., & Tsitsiringos, V. (Eds.). (2002).

Financial Engineering, E-commerce and Supply

Chain. Dordrecht, The Netherlands: Kluwer Academic

Publishers.

Sanders, N.R. (2009). Bridging the gap between

methodological camps in supply chain management.

Journal of Supply Chain Management, 45(1), 49-51.

Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (2003).

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

416

Designing and Managing the Supply Chain: Concepts,

Strategies, and Case Studies (2nd ed.). New York: The

McGraw-Hill Companies.

Simchi-Levi, D., Wu, S. D., & Shen, Z. J. (Eds.). (2004).

Handbook of Quantitative Supply Chain Analysis:

Modeling in the E-Business Era. Boston: Kluwer

Academic Publishers.

Vidal, C.J,, & Goetschalkx, M. (1997). Strategic

production-distribution models: a critical review with

emphasis on global supply chain models. European

Journal of Operational Research, 98, 1–18.

Wisner, J.D., & Tan, K.C. (2000). Supply Chain

Management and Its Impact on Purchasing. Journal of

Supply Chain Management, 36(4), 33-42.

A MODEL FOR DESIGNING NON COOPERATIVE SUPPLY CHAIN WHERE LOGISTICS SERVICE PROVIDERS

TAKE PART

417