MECHATRONIC SYSTEM MODELING

A Consistent Preliminary Design Process

Jean-Yves Choley, Régis Plateaux, Olivia Penas

SUPMECA (LISMMA Laboratory), 3 Rue F. Hainaut, 93407 Saint Ouen Cedex, France

Christophe Combastel

ENSEA (ECS laboratory), 6 Avenue du Ponceau, 95014 Cergy-Pontoise Cedex, France

Hubert Kadima

EISTI (LARIS laboratory), Avenue du Parc, 95011 Cergy-Pontoise Cedex, France

Keywords: Preliminary design, Mechatronic system, Modelling, Topology, Interval analysis.

Abstract: In order to describe a consistent and collaborative preliminary design process for mechatronic systems, this

study deals with an automotive power lift gate scenario. First, a functional analysis is carried out with

SysML from user requirements. This allows one to define suitable architectures and associated test cases.

Each of them has to be analysed and optimized separately in order to select the best architecture and the best

set of key parameters. The next step of the preliminary design is a modelling of its structure and its

behaviour. In order to merge multi-physical and geometrical parameters, our generic method relies on a

topological analysis of the system and generates a set of equations with physical and topological constraints

previously defined. Finally, an interval analysis is implemented, allowing one to explore exhaustively the

search space resulting from a declarative statement of constraints, in order to optimize the parameters under

the constraint of the relevant test cases.

1 INTRODUCTION

Nowadays, system engineering problems are solved

using a wide range of domain-specific modelling

languages and tools. Standards such as ISO 15288

detail the large number of system aspects and

various components of multi-domain systems

(ISO/IEC 2001) (Turki, 2008). It is also not realistic

to create an all-encompassing systems engineering

language capable of modelling and simulating every

aspect of a system. However, for multi-domain

systems, a global approach is necessary. Indeed,

each domain has its own methodologies and

languages, thus impeding the consistency of the

different modelling. Hence, a global optimization is

difficult during the preliminary design process of

these systems.

Mechatronic systems development involve

considering the modelling of their components

together with their interactions. Models can be used

to formally represent all aspects of a systems

engineering problem, including requirements,

functional, structural, and behavioural modelling.

Additionally, simulations can be performed on these

models in order to verify and validate the

effectiveness of design decisions.

This study covers the preliminary design phase

of a mechatronic system, in order to verify that the

chosen design is in accordance with the system

requirements and to verify that this chosen design

minimizes risks in further design phases. Following

the recent advances in Model Based System

Engineering (Estefan, 2008), the preliminary design

can be viewed as a model transformation process

(Hartman and Kreische, 2005).

Based on the example of a power lift gate, our

goal is to show how the engineering knowledge can

be formalized and used all along the three following

phases of the preliminary design process:

requirements definition and functional analysis,

geometrical and physical modelling, optimization.

Once the early design phases have been

performed with SysML models, the physical

modelling of the overall system has to be built,

based on the topology of the system, in order to

generate the equations required for the optimization

57

Choley J., Plateaux R., Penas O., Combastel C. and Kadima H..

MECHATRONIC SYSTEM MODELING - A Consistent Preliminary Design Process.

DOI: 10.5220/0003598800570064

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

57-64

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

phase. This being done, the Design Space

Exploration can be executed in order to discover the

optimal design solution from all functional and

architectural specifications and constraints. Indeed,

the most efficient way to explore this design space is

to reason about previous SysML models, thus

proving in a mathematically rigorous way that all

required properties and constraints are met.

2 A POWER LIFT GATE

SCENARIO

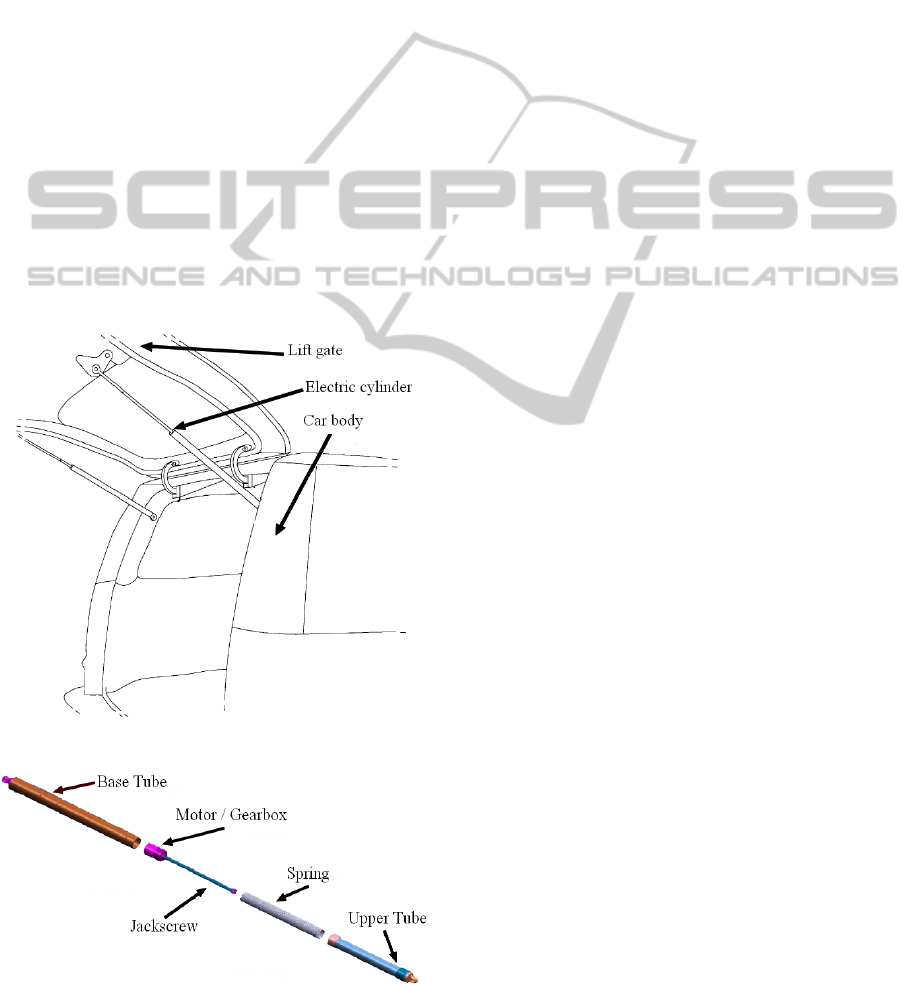

An automotive power lift gate (Figure 1) includes a

lift gate door hinged to a car body. This system

moves the lift gate between its open and closed

positions, thanks to electric cylinders (Figure 2) that

replace the usual gas struts in a classic manual lift

gate. It includes a motor and a gearbox that are fixed

to the base tube and a jackscrew that drives the

upper tube, helped by a spring, in order to sustain

static forces. Both electric cylinders are identical and

are fixed to the car body and the lift gate.

Figure 1: The Power Lift Gate Location on a Car Body.

Figure 2: The Electric Cylinder Architecture.

In order to ensure that the main requirements are

fulfilled, such as the opening duration and the power

consumption, the electric cylinder has to be

preliminarily designed, whatever its internal

structure is, meaning that the fixing points on the

car-body and the lift gate, the force needed to open

and maintain the lift gate and its full length and rest

length have to be determined.

3 THE PRELIMINARY DESIGN

PROCESS

The proposed preliminary design process relies on a

methodology that deals with different modelling,

(SysML model, topological model) in order to

provide consistent equations for an optimisation of

the mechatronic system with interval analysis.

3.1 Modelling of the Power Lift Gate

System with SysML

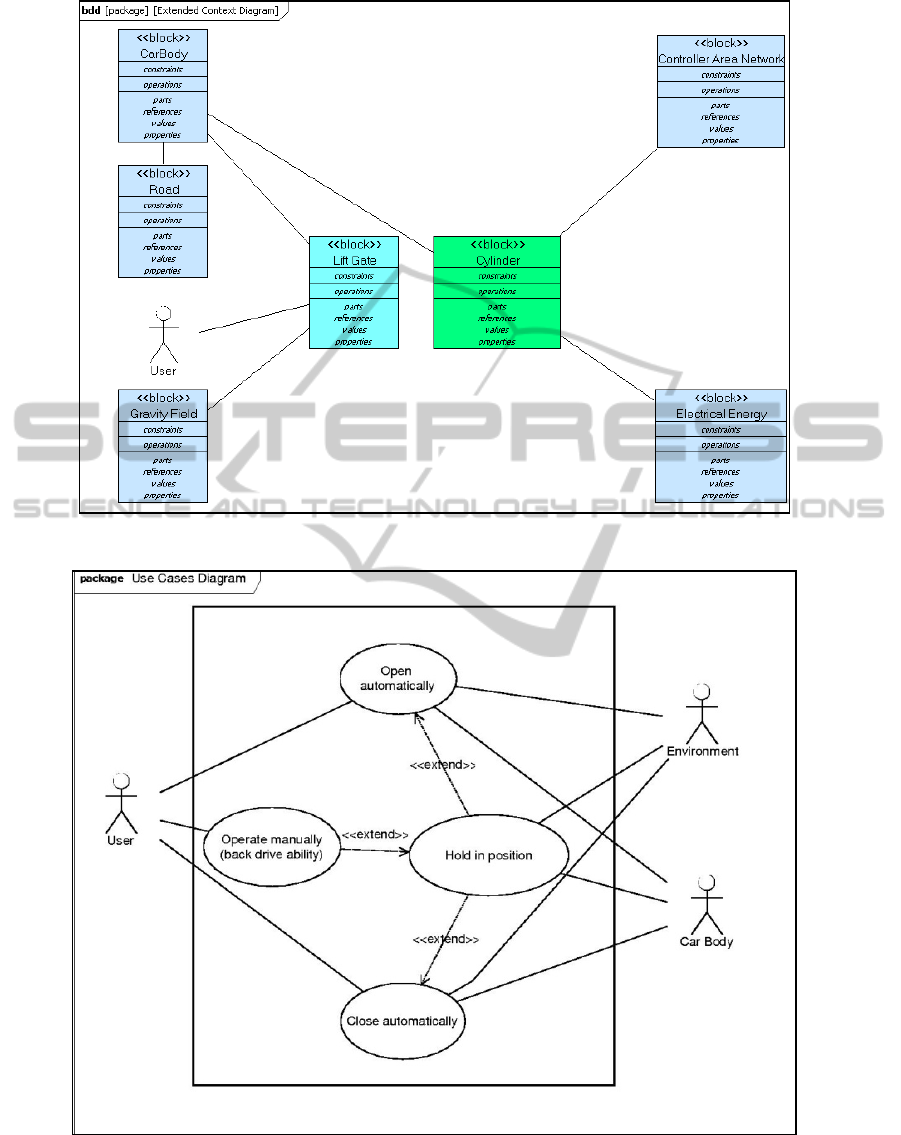

We propose a modelling of a power lift gate system

by means of appropriate SysML models at the early

stages of the technical engineering process. The

different SysML diagrams make it possible for

engineers from various disciplinary fields to share a

common view about the system. First, we create an

extended context diagram, in order to present the

different interactions between the extended system

(Lift gate + Electric cylinder) and its environment

(Figure 3).

Then a Use Case Diagram is defined to describe

the system services (Figure 4).

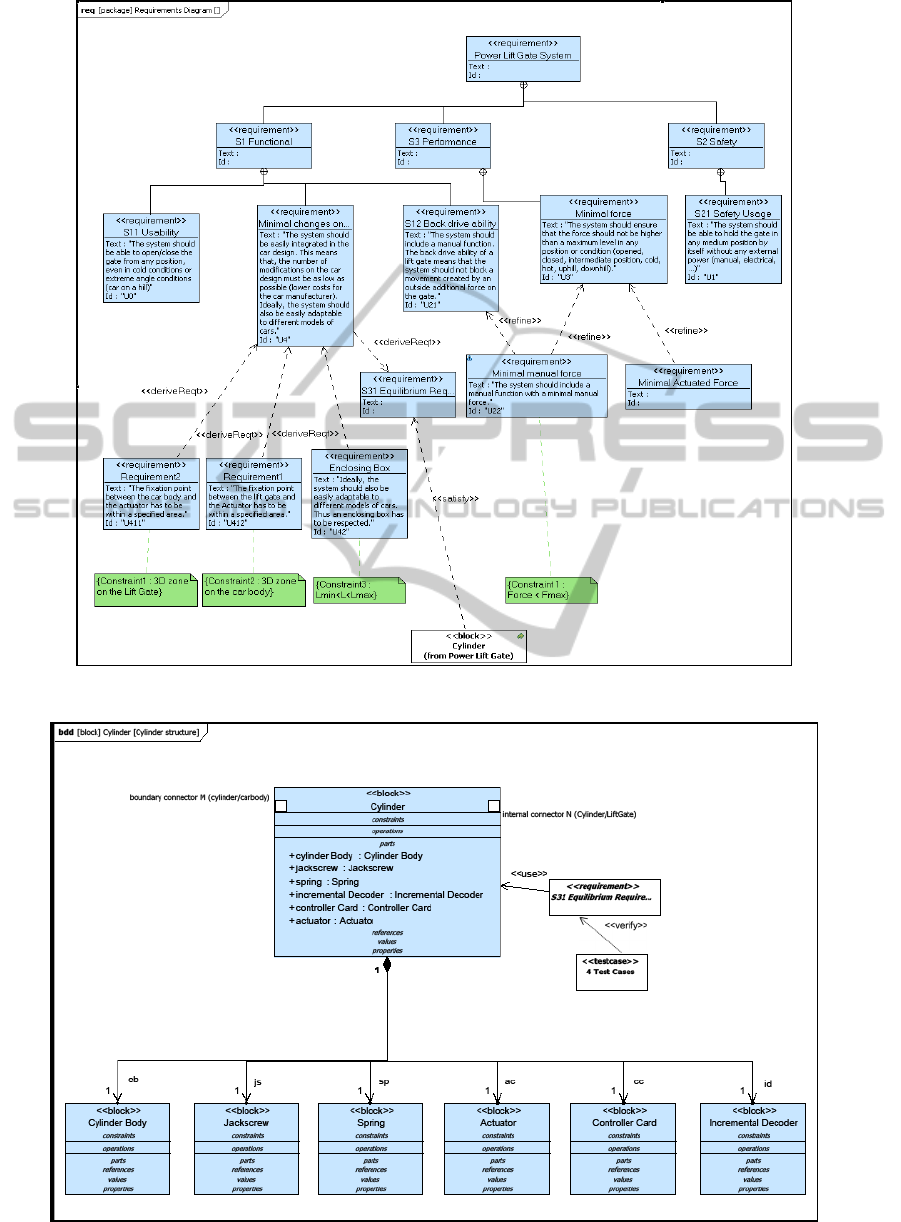

SysML Requirement Diagram can be used to

clearly organize user and derived system

requirements (Figure 5). By using a hierarchical

representation of the requirements, clear gains can

be made in the elaboration of requirements, in

tradeoffs, as well as in the validation and the

verification of requirements. Indeed, during design

activities, verification activities need to be defined to

satisfy system constraints and properties. Links

between the Requirements Diagram and other

models allow engineers to connect test criteria to test

cases used throughout the development process.

During the architecture analysis, system synthesis by

assigning functions to identified physical

architecture elements (subsystems, components) is

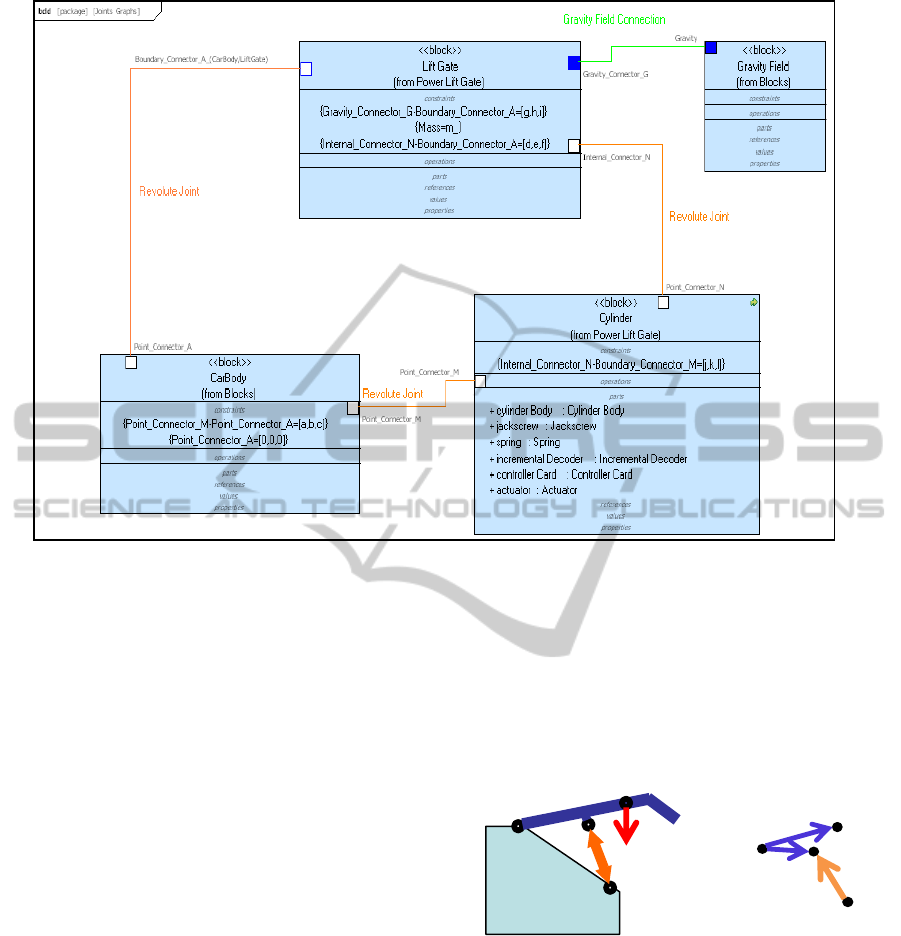

carried out (Figure 6). Finally we create a kinematic

joint diagram (Figure 7) with connectors regarding

to application points and with links representing the

field or the type of joints between two elements.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

58

Figure 3: Extended Context Diagram of the Power Lift Gate System.

Figure 4: Use Cases Diagram of the Power Lift Gate System.

MECHATRONIC SYSTEM MODELING - A Consistent Preliminary Design Process

59

Figure 5: Requirements Diagram.

Figure 6: Architecture, Test Cases and System Requirements Attachment.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

60

Figure 7: Kinematic Joints Relations Diagram in SysML.

3.2 Vector-based Mechanical

Modelling Derived from System

Topology

The previous SysML diagrams bring to light the key

parameters and the topology of the power lift gate

system. In order to optimize these key parameters,

this mechanical problem has to be translated into

equations. We propose to use a highly suitable

method (Plateaux et al, 2008) for multi-domain

systems such as automotive mechatronic

components. Based on a topological analysis of the

system, this generic method delivers equations that

can be processed by a solver. It relies on the works

of Kron (Kron, 1959), Branin (Branin, 1966) and

Björke (Björke, 1995). Here, our method is

restrained to the mechanical study of the static

equilibrium of the lift gate but it may also be used to

express the internal structure of the electric cylinder

(screw and nut system, tubes, gearbox, spring,

sensors, electrical engine and electronic

components...).

The isolated system includes the lift gate with the

electric cylinder between the points M and N, the car

body being an external system. Let us assume that:

the mechanical joints are perfect; points A, M and G

belong to the system boundary; there is neither

external mechanical force nor torque on internal

point N; P is the external force on the gravity centre

G; F

C

is the force created by the electrical cylinder,

which corresponds to the internal force R

MN

.

In order to model the architecture of the system,

a topological graph has first to be defined from

geometrical and mechanical definitions of the

problem (figure 8).

M

A

G

N

P=mg

M

A

N

G

Figure 8: Power Lift Gate Topological Graph.

We use the kinematic joints diagram and the

vectorial constraints between characteristic points of

previous SysML diagrams to describe the

topological structure. Indeed, each connector in the

kinematic joints relations diagram represent a

particular point, named “node” in the topological

structure, and each link between two connectors give

the nature of the kinematic screw, dual of its static

screw. The automation of this process between

SysML diagrams and our topological representation

is made through the analysis of a xml/xmi generated

MECHATRONIC SYSTEM MODELING - A Consistent Preliminary Design Process

61

file from the SysML Kinematic Joints Relations

Diagram (Figure 7). So, the boundary of the system

is expressed by means of labels attached to each

node (boundary) named (A, G, ...), like the SysML

connectors, and to each branch (internal), all of them

inherited from SysML diagrams.

Then, the topology has to be mathematically

expressed (equation 1) using a connexion (or

incidence) matrix named C and an algebraic graph

that allows one to connect nodes and branches. The

topological structure (graph) is overlaid with an

algebraic structure. This global structure connects

nodes and branches of the graph, and may include

physical parameters which govern the behaviour of

the system. This method has been thoroughly

described in previous papers (Plateaux et al, 2007)

(Plateaux et al, 2008).

A

M

N

G

⎛⎞

⎜⎟

⎜⎟

⎜⎟

⎜⎟

⎝⎠

AN

MN

AG

⎛⎞

⎜⎟

⎜⎟

⎜⎟

⎝⎠

1010

C=(-1) 0 1 1 0

1001

−

⎡⎤

⎢⎥

−

⎢⎥

⎢⎥

−

⎣⎦

Branches

(internal)

Nodes

(external)

(1)

Thus, the transposed matrix C

T

can be used to

express (equation 2) the connection between internal

and external mechanical forces and moments,

defined with their associated static screws, with T

A

standing for “screw of external mechanical action on

point A” and T

AN

standing for “screw of internal

mechanical action on AN structure”:

AN

MN

AG

T

T

T

⎛⎞

⎜⎟

⎜⎟

⎜⎟

⎝⎠

AANAG

MMN

NANMN

GAG

TTT

TT

TTT

TT

+

⎛⎞⎛

⎞

⎜⎟⎜

⎟

⎜⎟⎜

⎟

=

⎜⎟⎜

⎟

−−

⎜⎟⎜

⎟

−

⎝⎠⎝

⎠

T

10 1

010

C=(-1)

110

001

−−

⎡⎤

⎢⎥

−

⎢⎥

⎢⎥

⎢⎥

⎣⎦

(2)

As a result, an equations system (3) is obtained, with

the decomposition of screws in 4 force equations

and in 4 moment equations expressed in the

arbitrarily chosen point A:

A

A

A

AN

AN

MN

MN

AG

AG

R

M

R

M

R

M

⎛⎞

⎧⎫

⎜⎟

⎨⎬

⎩⎭

⎜⎟

⎜⎟

⎧⎫

⎜⎟

⎨⎬

⎜⎟

⎩⎭

⎜⎟

⎧⎫

⎜⎟

⎨⎬

⎜⎟

⎩⎭

⎝⎠

A

AANAG

MMN

NANMN

GAG

AANAG

MMN

NANMN

GAG

R=R R

R=R

R=R R

R=R

M=M M

M=M

M=M M

M=M

+

⎧⎫

⎪⎪

⎪⎪

⎪⎪

−−

⎪⎪

−

⎪⎪

⎨⎬

+

⎪⎪

⎪⎪

⎪⎪

−−

⎪⎪

⎪⎪

−

⎩⎭

T

10 1

010

C=(-1)

110

001

−−

⎡⎤

⎢⎥

−

⎢⎥

⎢⎥

⎢⎥

⎣⎦

(3)

The equations system is solved and the static

equilibrium of the lift gate system is expressed.

3.3 Computational Support for the

Exploration of the Solution Space

based on Constraint Programming

and Interval Analysis

Special emphasis is also placed on interval-based

computational methods (Jaulin et al, 2001) allowing

one to explore exhaustively the search space

resulting from a declarative statement of constraints

(Yannou et al, 2003). Given the previous high level

vector model linked to a given topology, formal

calculus and causal ordering based on bipartite

graphs theory (Duff, 1981) (Pothen and Chin-Ju,

1990) can be used to avoid part of the tedious work

consisting in giving the mathematical expressions of

some constraints as required to run dedicated

solvers. The use of interval computations within a

constraint programming paradigm (Blick et al, 2001)

also provides a computational support to quantify

uncertainties and to detect inconsistencies. From a

methodological point of view, the refinement

inherent to the design process is underlined.

A Constraint Satisfaction Problem (CSP) is

usually defined by (X, D, C) where X = {x

1

, x

2

, …,

x

n

} is a set of variables, D = {d

1

, d

2

, …, d

n

} is a set of

domains such that

∀

i

∈

{1,…, n}, xi

∈

di, and C =

{C1, …, Cm} is a set of constraints depending on the

variables in X. Each constraint includes information

related to constraining the values for one or more

variables. When continuous variables are

considered, the use of interval analysis techniques

naturally arises in order to represent the domains.

Those methods make it possible to explicitly take

uncertainties (in the sense of deterministic

imprecision rather than probabilistic variability) into

account in the preliminary design process. The use

of an interval CSP solver (here, RealPaver)

(Granvilliers, 2003) allows an exhaustive search

within the search space D which is partitioned into

three sets, D = D

0

∪

D

1

∪

D

?

, the latter two being

described by a box paving: D

0

is a sub-domains of D

where the constraints are never satisfied; D

1

is a sub-

domains of D where the constraints are always

satisfied; D

?

is a sub-domains of D where the

satisfiability of the constraints has not been decided

yet according to some stopping criterion (precision,

for instance).

From an engineering design point of view, the

variables in X can be a set of design parameters, the

domains in D can be used to define the range of the

search space of interest, and the constraints in C can

be concurrently stated by several engineers in any

order. Such a declarative modelling is a significant

advantage of the CSP paradigm throughout the life

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

62

cycle of a Computer Aided Engineering (CAE)

application (Raphael and Smith, 2003).

From a methodological point of view, the

refinement inherent to the design process can be

supported as follows: the poor initial knowledge

results in a small number of constraints with few

variables belonging to rather large intervals; then,

the sequence of assumptions, trials and evaluations

constituting the heart of an iteration within the

design refinement loop allows the engineers to

acquire knowledge, to organize it, and to gradually

converge toward what will become the detailed

solution (Aughenbaugh and Paredis, 2006).

In this paper, our case study is restricted to a few

design parameters and focuses on the equilibrium

requirement for the power lift gate. The design

parameters are X = [x

MB

, y

MB

, x

NL

, y

NL

] i.e. the 2D

coordinates of the electric cylinder fixation points M

(on the car body) and N (on the lift gate). The

equilibrium requirement is related to four constraints

previously identified in the analysis based on

SysML:

C

Δ

F

: “The additional force value

Δ

F required to

maintain the lift gate static equilibrium is inferior to

some threshold level (

Δ

F

max

)”.

Δ

F refers here to the

force

Δ

F defined as F

cyl

= F

spring

+

Δ

F, where F

cyl

is

the cylinder force required to maintain the static

equilibrium and where F

spring

is the force of the

spring within the power cylinder used to reduce the

power of the electrical motor;

C

L

: “The electric cylinder length L is within the

interval [L

min

, L

max

] related to the aperture angle of

the lift gate”;

C

M

: “The car body fixation point M is within a

specified area”;

C

N

: “The lift gate fixation point N is within a

specified area”.

Following formal computations guided using causal

ordering techniques, all the constraints are expressed

as functions of the design parameters, and the text

file required as input of the interval CSP solver is so

obtained. The preliminary design of the power lift

gate then consists in using the interval solver outputs

to understand the influence of the opening angle on

the position of fixation points and to perform a

(possibly iterative) refinement by selecting an area

in the solution space.

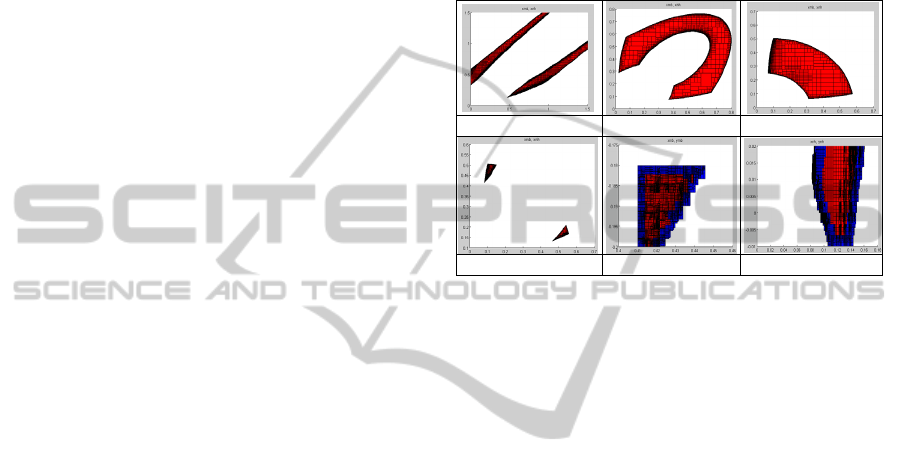

Table 1 (a-d) illustrates the influence of the

opening angle on the solution set. This corresponds

to a preliminary study before an exhaustive search

for all the opening angles. Focusing on an area in the

search space corresponds to the refinement related to

the preliminary design process. The reduced search

area allows a more precise exploration while

preserving a reasonable computation time. The

proposed refinement iteration aims at being

reproduced all along the preliminary design process

in order to converge toward the solution set, table 1

(e,f), that will be kept to initiate the detailed design

of the power lift gate.

Table 1: Interval CSP Outputs.

(a)

θ

=0° (b)

θ

=0° (c)

θ

=0°

(d) = (a)

∩

(b)

∩

(c)

(e) M in (x

MB

,y

MB

) (f) N in (x

NL

,y

NL

)

4 CONCLUSIONS

We have presented a proven solution for a global

multi-domain constraints-based preliminary design

supported by a robust design methodology in

conformance with System Engineering Standards.

Based on three interactive design environments and

illustrated by a mechatronic example, it

demonstrates the power of collaborative engineering

in model-based design. As a result, Model-Based

System Engineering simplifies the development of

mechatronic and other multi-domain systems by

providing a common approach for design and

communication across different engineering

disciplines.

REFERENCES

Aughenbaugh, J. M., Paredis, C. J. J., 2006. “Why are

intervals and imprecision important in engineering

design ?” NSF Workshop on Modelling Errors and

Uncertainty in Engineering Computations, REC’2006,

hosted by Georgia Tech Savannah, February 22-24.

Bjørke, Ø., 1995. "Manufacturing systems theory – a

geometric approach to connection ", Tapir publisher,

ISBN 82-519-1413-2.

Bliek, C., Spellucci, P., Vicente, L. N., Neumaier, A.,

Granvilliers, L., Monfroy, E., Benhamou, F., Huens,

E., Van Hentenryck, P., Sam-Haroud, D., Faltings, B.,

2001. “Algorithms for solving non linear constrained

MECHATRONIC SYSTEM MODELING - A Consistent Preliminary Design Process

63

and optimization problems: the state of the art”, The

Coconut Project, Deliverable D1, June 8.

Branin Jr., F. H., 1966."The algebraic-topological basis

for network analogies and the vector calculus ", in

Proceedings of the Symposium on Generalized

Networks, Polytechnic Institute of Brooklyn.

Duff, I. S., 1981. “On algorithms for obtaining a

maximum transversal”. ACM Association for

Computing Machinery, Transactions on Mathematical

Software, Vol. 7, No. 3, pp. 315-330, September.

Duff, I. S., 1981. “Algorithm 575, Permutations for a

zero-free diagonal”. ACM Association for Computing

Machinery, Transactions on Mathematical Software,

Vol. 7, No. 3, pp. 387-390, September.

Estefan, J., 2008. “Survey of Candidate Model-Based

Systems Engineering (MBSE) Methodologies”,

www.omgsysml.org/MBSE_Methodology_Survey_Re

vB.pdf. Rev. B, May 23.

Granvilliers, L., 2003. “RealPaver user’s manual: solving

nonlinear constraints by interval computations”,

Edition 0.3, for RealPaver Version 0.3, Institut de

Recherche en Informatique de Nantes (IRIN), July.

Hartman, A, Kreische, D., 2005. (Eds) "Model Driven

Architecture - Foundations and Applications", First

European Conference, ECMDA-FA 2005 Nuremberg,

Germany, November 2005 Proceedings Springer.

ISO/IEC 2001. ISO 15288, Systems lifecycle Processes,

International Electro-technical commission. Brussels.

Jaulin, L., Kieffer, M., Didrit, O., Walter, E., 2001.

“Applied interval analysis, with examples in

parameter and state estimation, robust control and

robotics”. Springer.

Kron, G., 1959. "A short course in tensor analysis for

electrical engineers ". Tensor Analysis of Networks

(New York: John Wiley & Sons, Inc., 1939), Wiley,

New York; Chapman & Hall, London, 1942.

Republished as Tensors for Circuits. With a new

Introduction and List of Publications of Gabriel Kron.

Dover, New York.

Plateaux, R., Choley, J-Y., Pénas, O., Rivière, A., Cardon,

F., Clément, A., 2008. “A piezoelectric mechatronic

systems modelling based on a topological analysis”,

7th France-Japan congress, Mechatronics 2008, Le

Grand Bornand, France, May 21-23.

Plateaux, R., Penas, O., Rivière, A., Choley, J-Y., 2007.

“Need for the definition of a topological structure for

the complex systems modelling”, CPI 2007, Rabat,

Morocco, October 22-24.

Pothen, A., Chin-Ju, F., 1990. “Computing the Block

Triangular Form of a Sparse Matrix”, ACM

Transactions on Mathematical Software, Vol. 16, No.

4, pp. 303-324.

Raphael, B., Smith, I. F. C., 2003. “Fundamentals of

Computer-Aided Engineering”, John Wiley & Sons

Ltd.

Turki, S., 2008. «Ingénierie système guidée par les

modèles: Application du standard IEEE 15288, de

l'architecture MDA et du langage SysML à la

conception des systèmes mécatroniques», Thesis of

University of South Toulon. France.

Yannou, B., Simpson, T. W., Barton R. R., 2003.

“Towards a computational design explorer using

meta-modelling approaches and constraint

programming”. In DETC/DAC: ASME Design

Engineering Technical Conferences / Design

Automation Conference, Chicago, Illinois, USA,

September 2-6.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

64