STEP-BASED MODELING & SIMULATION FOR VIRTUAL

PRODUCT DEVELOPMENT

Li Li, Tianyuan Xiao, Wenhui Fan, Hongbo Sun and Cheng Ma

National CIMS ERC, Tsinghua University, Beijing 100084, China

Keywords: Virtual Product Development, HLA, STEP.

Abstract: A novel STEP-based modeling and simulation method is proposed to improve the data consistency and the

model reusability in Virtual Product Development (VPD). Based on the proposed method, a STEP-based

product model is automatically generated from STEP files and CAD/CAE models. In the method, besides

product shape data other effective data can be extracted from STEP files and CAD/CAE models for HLA-

based simulation. An applicable prototype system is designed to support this method. A case study is

performed to demonstrate the feasibility of the method.

1 INTRODUCTION

Virtual Product Development (VPD) is the process

of designing, analyzing product and developing

Virtual Prototype in digital environment. Nowadays,

product simulations within a single discipline cannot

satisfy requirements of VPD. High Level

Architecture (HLA) is a well-known standard for

distributed simulation (IEEE Computer Society,

2001). Adopting HLA, simulation systems in VPD

could reuse existing simulation models, and

integrate different kinds of multi-disciplinary

product simulation models in one simulation task.

However, HLA-based simulations cannot

completely meet requirements of VPD. Simulation

models in HLA-based simulation are usually

independently developed without using the upstream

product information. This cannot satisfy the demand

of data consistency in VPD, and reduces the

credibility of simulation results.

As an ISO standard (ISO 10303) which is widely

used in CAD/CAE/CAM/CAPP, STEP standard

(Technical Committee 184 Sub-Committee 4, 2002)

supports data exchange in many product

development domains. Adopting STEP standard into

VPD would facilitate the reuse of CAD model

information in HLA-based simulation, and enhance

data consistency in the whole process of VPD.

Nowadays, the most representative projects

which use STEP standard to build product models

for data exchange are the Model Based Definition

(MBD) project which is proposed by Boeing (Chen

et al., 2009) and the Share-A-Share project designed

by Eurostep (Shaw, 2009). But in these projects,

STEP-based product model is mainly addressed to

resolve the problem of CAD/PDM data exchange of

complex product, and do not contain the simulation

data that are useful for multi-disciplinary

simulations. Hunten (1997) describes an approach of

CAD/FEA integration with AP209. Thurman and

Benda (2009) built a model-based enterprise

environment with AP210. The above two researches

mainly focus on information integration with single

AP, and it makes these approaches hard to extend to

other simulation domains. Li et al. (2008) define a

STEP AP203-based logical structure of a

mechatronic system using HLA, but the method of

converting STEP files to domain simulation models

is not described in details. Si et al. (2009) proposes

an application framework of Product Collaborative

Design. In this framework, STEP files are converted

into domain simulation models by specific software

interfaces. Using specific software interfaces limits

the framework for further use.

Based on the above reviews, this paper argues

that general STEP-based approach is not convenient

to be used in VPD, especially for HLA-based

simulations. A single application protocol can only

exchange data in single domain, and is lack of the

definitions of assembly constraints which are

indispensable for some specific simulation domains.

Furthermore, most researches mainly focus on the

information of product shape. Actually, there are

more useful information than product shape data

224

Li L., Xiao T., Fan W., Sun H. and Ma C..

STEP-BASED MODELING & SIMULATION FOR VIRTUAL PRODUCT DEVELOPMENT.

DOI: 10.5220/0003596302240227

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

224-227

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

could be reused in STEP files for VPD.

In this paper, a novel STEP-based modeling and

simulation method is proposed to improve the data

consistency and the reusability of models in VPD.

By this method, a STEP-based product model which

is suitable for HLA-based simulation would be

automatically constructed from STEP files and

domain models.

2 STEP-BASED PRODUCT

MODELING

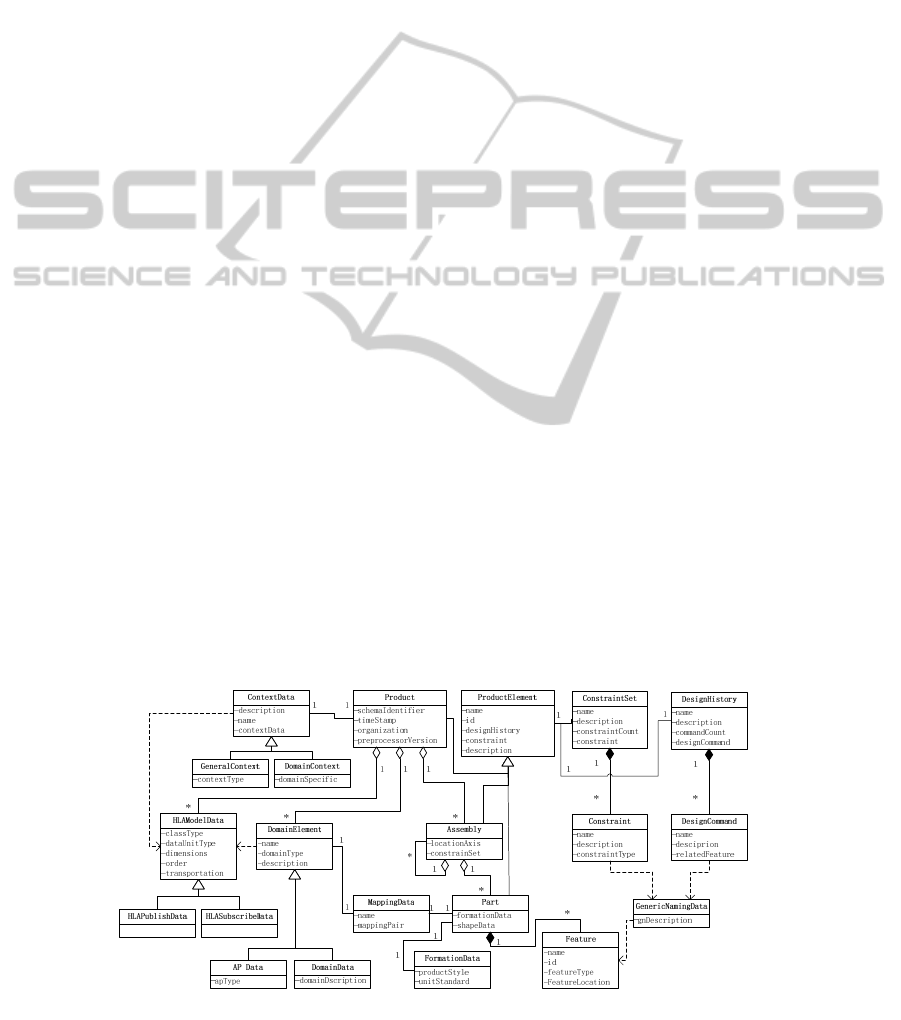

In order to organize the data which is useful in VPD,

this paper gives a metamodel of STEP-based product

as Figure 1 shows. The metamodel specifies the

model data which must be recorded in a unified form,

and indicated basic elements of the model and their

associations. Every product model should contain

one instance of class Product, and an instance of

class Product should contain one or more instances

of class Assembly. The main information contained

in class Part is product shape data which is specified

in AP203 or AP214. An instance of class Part could

contain one or more instances of class Feature.

Class ContextData contains various application

environment and context information.

Class ProductElement which describes the

general information of product elements is

associated with class ConstrainSet and class

DesignHistory, which are used to specify the data

not represented in STEP files but useful in HLA-

based simulation. Class DesignHistory records the

data of product design processes. Including design

history in the STEP-based product model would

bring product designer’s intentions to the model.

Class DomainElement is an abstract class which

could be instantiated with domain-specific

information. In order to store the mappings between

domain elements and product part, class

MappingData is associated with both class Part and

class DomainElement. Based on class

HLAModelData, users could define which data

should be published and which data are needed in

the HLA-based simulation. Several attribute data of

the class HLAModelData, such as dataUnitType, are

dependent on class ContextData, which improves

the data consistency in HLA-based simulations.

Because of the complexity of EXPRESS

language, STEP files may not contain an explicit

data structure. Therefore, analyzing a STEP file to

get explicit data structure is still a difficult job.

Furthermore, there are many entity instances that do

not contain any useful information in STEP files

which are exported by upstream systems. When

extracting information from STEP files, these

useless instances are usually ignored manually. This

paper proposes a user-friendly method which could

automatically analyze STEP files with the rules

defined by users and convert them into the STEP-

based product model. The process of the method can

be described as follows:

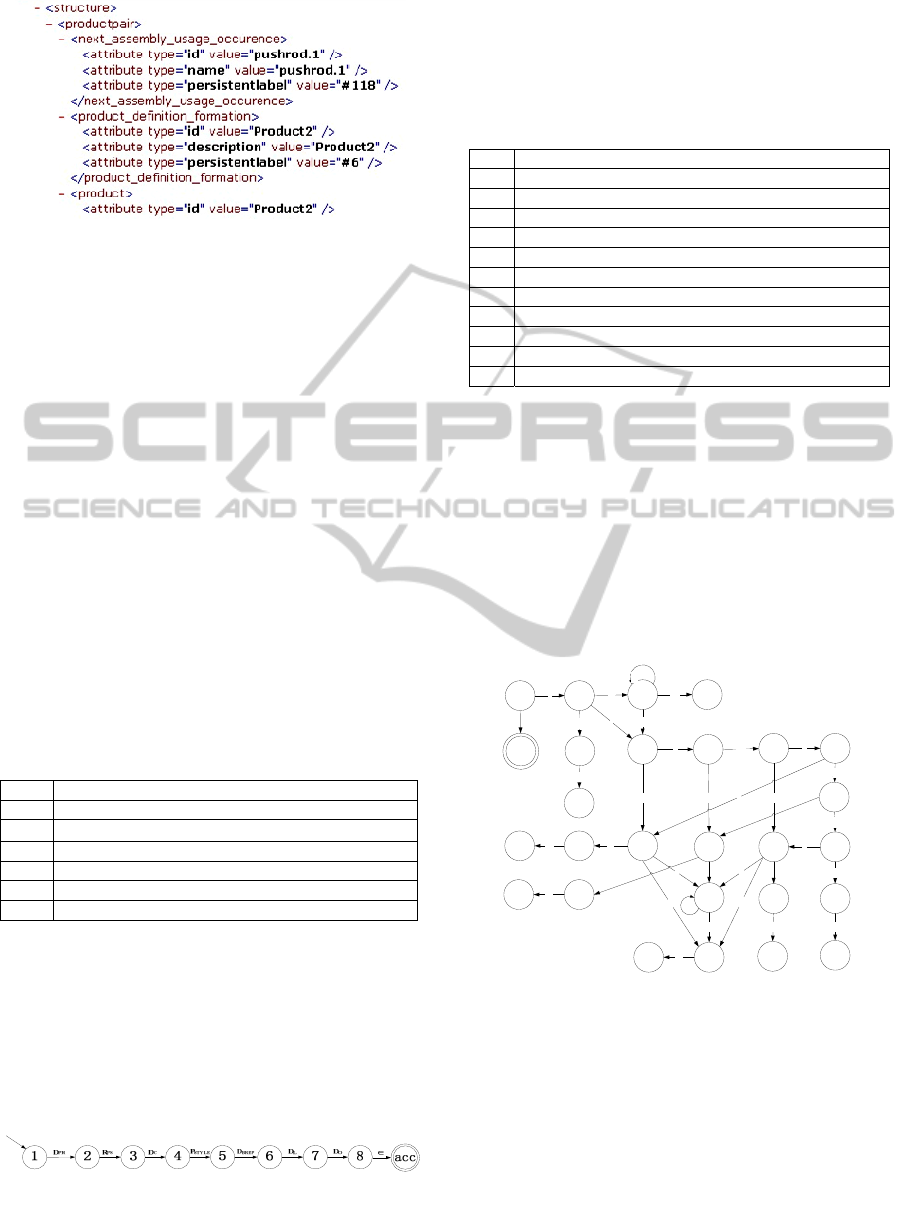

• Construct preliminary STEP file information set.

The method makes search rules first, which

contain an entity as start point and an entity as

end point defined by users. Each search rule

would lead to a file traversal of the STEP file in

the shortest path between the points, and produce

a search result whose data are stored in an

appropriate sequence. The search result can be

generated as Figure 2 shows. This process could

be seen as a data preprocessing which would

facilitate the information analysis of STEP files.

Each search result is deemed as a data block, then

they form a preliminary STEP file information set

which contains all the information needed in

VPD.

Figure 1: STEP-based product metamodel.

STEP-BASED MODELING & SIMULATION FOR VIRTUAL PRODUCT DEVELOPMENT

225

Figure 2: The search result of STEP files.

• Analyze the information set and construct the

STEP-based product model. In this process, the

instances of class Product, class Assembly and

class Part in the model would be generated first,

as well as their relationships. Then instances of

other classes defined in the metamodel are added

to the STEP-based product model. After the

process, useless entity instances are removed

according to the requirements of users.

• Use specific interfaces to access domain specific

information from domain product models, such as

product assembly constrains and design history

data, and attach them to the STEP-based product

model based on the architecture of the metamodel.

This process would be varied in different specific

domains.

For the purpose of describing and completing the

processes in detail, this paper develops a grammar to

describe the information set.

Table 1: Grammar of information set.

No. Grammar rules

1

S→P

2

P

→D

R

D

P

D

D

D

ϵ

……

76

ϵ→/

77

ϵ→/δ

78

δ →an

y

string does not contain ternimal

ϵ and δ are deem as terminals, and this paper

denotes “<product>” as θ, “<attribute type =δ δ>” as

α and so on. Handles such as D

and R

represent

data blocks in the information set. Users could

define new handles if they want to introduce new

data blocks into the set. Based on rule 2, a gross

deterministic finite state automata (Figure 3) could

be built to describe the grammar.

Figure 3: Gross deterministic finite state automata.

Rule 3 to 12 represent the grammar of the data

block shows in Figure 2. This paper takes this data

block as an example to demonstrate the process of

information transformation. The augmented

grammar of the data block is listed as follows:

Table 2: Augmented Grammar of the data block.

No. Augmented Grammar rules

1

S′ →S

2

S→P

ϵ

3

P

→P

P

4

P

→P

5

P

→ P

PNP

Pϵ

6

P→θA

ϵ

7

P

→ ηA

ϵ

8

N→γA

ϵ

9

A

→AA

10

A

→A

11

A → δ δ ϵ

Using the rules mentioned above, the reachable

item sets and the transitions between them can be

found. A state machine can be represented as Figure

4. For brevity, the parsing table and attached actions

for generating the STEP-based product model are

not represented. Because of the serial structure of the

gross finite state automata, users could easily add or

remove data blocks in the information set, and

modify the states in the finite state automata as well

as the attach actions in order to analyze the STEP

files in their own rules.

2

0

2

3

2

2

2

5

2

1

S

β

P

RS

P

R

ζ

P

R

2

7

P

RS

2

4

∈

2

6

ζ

2

8

N

2

9

γ

2

15

2

16

A

S

∈

2

11

A

2

13

2

14

2

10

2

17

2

18

∈

∈

η

α

α

2

19

P

DF

2

23

2

24

2

25

2

26

2

27

P

N

P

DF

P

∈

2

20

A

θ

2

21

2

22

∈

γ

θ

α

A

S

A

A

η

A

S

Figure 4: State machine of search result data.

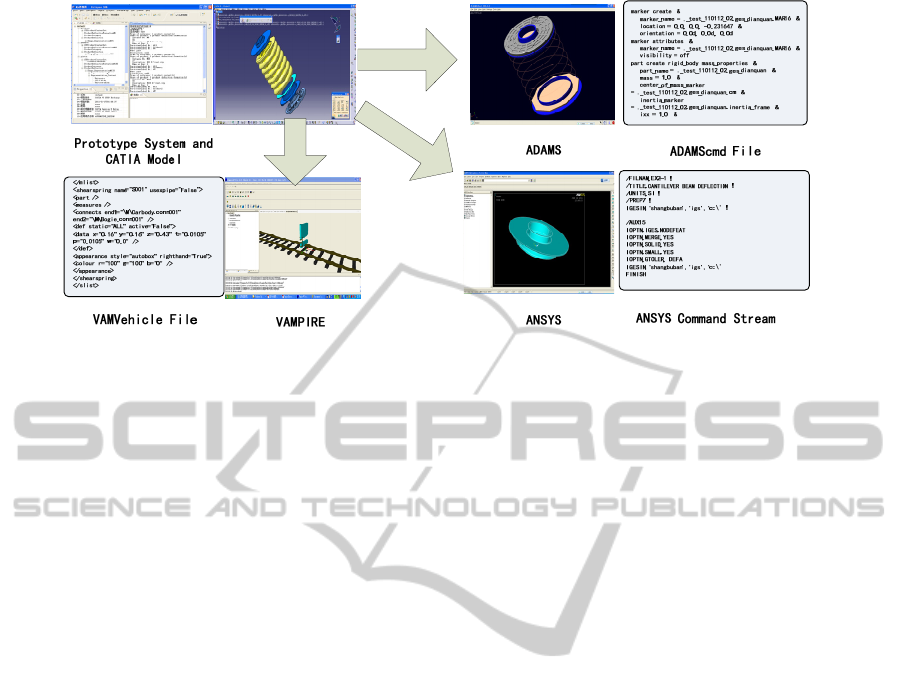

3 CASE STUDY

This case is part of the research project of the

National High Technology Research Development

Program of China (863 Program). A prototype

system is developed based on the proposed method.

The prototype system could convert the information

in STEP files and domain models into the STEP-

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

226

Figure 5: Part of the codes of simulation models and the prototype system.

based product models, and transform the model to

several kinds of simulation domain models for HLA-

based simulations. This paper mainly focus on the

information extracting, so we do not describe the

method of converting the STEP-based product

model into several kinds of domain simulation

models (such as ADAMS model, VAMPIRE

model). The prototype system and part of the codes

of these models are shown in Figure 5.

Compared to other approaches, the proposed

method could integrate more useful information in

STEP files than product shape data for simulation,

and the information of domain models are also

integrated. So the STEP-based product model could

provide all the necessary information for design and

multi-disciplinary simulations in VPD. Moreover,

the method of extracting information from STEP

files are more flexible and user friendly, this could

facilitate simulation modeling for VPD in a more

effective way.

REFERENCES

Chen, T. C. and McGowan, T. (2009). MBD Data

Exchange. In PDE2009, the 11th NASA-ESA

Workshop on Product Data Exchange, Kent,

Washington.

Hunten, K. A. (1997). CAD/FEA Integration with STEP

AP209 Technology and Implementation. Retrieved

from http://www.mscsoftware.com/ support/library/

conf/auc97/p01297.pdf

IEEE Computer Society. (2001). IEEE standard for

modeling and simulation (M&S) high level

architecture (HLA)- object model template (OMT)

specification (IEEE Std 1516.2- 2000). NewYork: The

Institute of Electrical and Engineers.

Li, X., Li, X. and Chen, L. (2008). Research on

collaboration simulation of complex mechatronic

system based on HLA. In ICMA'08, Mechatronics and

Automation, 2008, Takamatsu, Japan.

Park, J., Moraga, R., Rabelo, L., Dawson, J., Marin, M. N.

and Sepulveda, J. (2005). Addressing complexity

using distributed simulation: a case study in spaceport

modelling. In SWC’05, Simulation Conference,

Proceedings of the 2005 Winter Simulation

Conference, Orlando, USA.

Shaw, N. (2009). Experience with a standards based

product data collaboration hub. In PDE2009, the 11th

NASA-ESA Workshop on Product Data Exchange,

Kent, Washington.

Si, N., Zhang, L., Laili, Y., Zhang H. and Cong, K. (2009).

Study on Semantic SOA Based Product Collaborative

Design. In ICICTA'09, Intelligent Computation

Technology and Automation, 2009, Zhangjiajie, China.

Technical Committee 184, Sub-Committee 4. (2002).

Industrial automation systems and integration -

Product data representation and exchange - Part 21:

Implementation methods: Clear text encoding of the

exchange structure. International Organization for

Standardization.

Thurman, T. and Benda, M. (2009). From Paper Based

Analysis to Model Based Analysis: Applications of

AP 210 at Rockwell Collins. In PDE2009, the 11th

NASA-ESA Workshop on Product Data Exchange,

Kent, Washington.

STEP-BASED MODELING & SIMULATION FOR VIRTUAL PRODUCT DEVELOPMENT

227