THE BUSINESS PROCESS REENGINEERING STUDY

OF STEEL INDUSTRY BASED ON ERP

Xiaogang Shi and Bing Zhu

School of Economics and Management, Beijing Jiaotong University, Beijing, China

Keywords: Steel Industry, ERP, BPR.

Abstract: The steel industry is the one of the most important industry related with the national economy and the

people's livelihood. Today, the informatization of the steel industry in China is still not advanced, which is

not able to be compatible with the development of the steel production and the steel trade.

This paper analyzed the current situation of the informatization development of the steel industry in china

firstly. Then it analyzed the current situation of information management of the steel company (hereinafter

referred to as “S company”) base on the theory of ERP and BPR, and gave the existent problems. Lastly, the

paper presented the solution and the optimum proposal to the inventory module of the S company. The

solution attained the objective of integration of production information system and the financial information

system, optimized the business process and the management mode of the S company.

1 INTRODUCTION

The production and management process of the steel

enterprise, which contains the supply of the

materials, the production and sales of the steel

product, the recovery and the recycle of the waste, is

a supply chain integrated by business flow,

information flow, capital flow, material flow. The

steel enterprise, which is resource intensive, energy

intensive, technology intensive and capital intensive,

find it more and more difficult to extend

development and profit space in the production area

in nowadays. However, the information management

is becoming a new way to get the competitive

advantage.

Today, the informatization of the steel industry

in China is developing quickly. However, it is still in

its infancy compared with the foreign levels.

Overall, the level of modernization and the

efficiency of the informatization of the steel industry

in china are relatively lower, which is not able to be

compatible with the development of the steel

production and the steel trade. Optimizing the

information management mode is the urgent affairs

to promote the competitive advantage in the steel

industry in china.

2 THE FUNDAMENTAL

PRINCIPLE OF ERP AND BPR

2.1 The Definition of the ERP

Enterprise resource planning (ERP) integrates

internal and external management information

across an entire organization, embracing finance,

manufacturing, sales and service, etc. ERP, which is

driven by the demand of the market and the client,

optimizes the internal and the external resource

configuration of the enterprise, eliminates all the

useless resource. It aims to integrate the information

flow, the material flow, capital flow and improve the

satisfaction of the client. (Yuning and Wenyu, 2004)

2.2 The Management thoughts of the

ERP

Zhou Yuqing considered that the essence of the

ERP, which is reflected in 3 main aspects, is to

manage the whole supply chain effectively. (Yuning

et al., 2000)

1. To Manage the Whole Supply Chain

Effectively

The modern enterprise can’t get the competitive

edge by its own resource only if the suppliers,

producers, distribute network, clients etc are brought

591

Shi X. and Zhu B..

THE BUSINESS PROCESS REENGINEERING STUDY OF STEEL INDUSTRY BASED ON ERP.

DOI: 10.5220/0003595305910594

In Proceedings of the 13th International Conference on Enterprise Information Systems (PMSS-2011), pages 591-594

ISBN: 978-989-8425-56-0

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

into its own supply chain. The supply chains has

become the key point of the competition between the

modern enterprises. The ERP satisfy the demand of

the market and manage the supply chain of the

enterprise effectively.

2. Lean Production

LP (lean production) is to bring the clients, sales

agents, suppliers, cooperation into the supply chain

of the enterprise and share the profit with them.

3. Agile Manufacturing

Agile manufacturing means when there are changes

in the market and the cooperators of the enterprise

can’t satisfy the demand of the development and the

production of the new products, the enterprise

immediately organize a temporary supply chain

which is constituted by the specific suppliers, start

the production and launch the new products into the

market in the shortest time.

Overall, the management thoughts of the ERP are

quite extensive and profound. The ERP system can

transform many modern management thoughts into

the software system that we can use in the work with

the application of the modern information

technology.

2.3 Business Process Reengineering

BPR (Business Process Reengineering) theory is the

hot spot in the field of the enterprise and the

management in nowadays. The BPR, which is

proposed by Michael Hammer who is the famous

master of enterprise management and the professor

of MIT, popularized immediately in the field of the

management of Europe and America.

In the

《

The Essence of Business Re-

engineering

》

, Joe Peppard, Philip Rowland

considered that the BPR means the business process

of the enterprise had to be rethought and rebuilt

fundamentally by using the modern information

technology and the management tools. It aims to

optimize the cost, quality, efficiency and service etc

and make the enterprise to adapt to the market

environment that changing rapidly. It helps the

enterprise automate and simplify the business

process and the management. (Peppard and

Rowland, 2003)

2.4 The Necessity of Integrating ERP

and BPR

The application of the ERP demand the enterprise to

introduce modern management software, what’s

more important is that the traditional business

processes have to be changed fundamentally. To

optimize the whole process, the enterprise have to

redesign each operation activity properly and

reasonably, establish the new management

organization that client oriented and response to the

change of market quickly.

a) The background of ERP needs the enterprise to

reengineer the business process.

The ERP is an enterprise information

management system to help the enterprises to

adapt to the operational mode and the

management requirement of market economy in

western countries. In nowadays China is still in

the stage of transforming from the traditional

planned economy to the market economy. The

management levels of Chinese enterprise are

relatively low. The current situation of China

demand the enterprises to reengineer the business

process before the application of the ERP.

b) The function of the ERP needs the enterprise to

reengineer the business process

The realization of function of ERP demands

the enterprise to rearrange the organization and

the business process.

c) The aim of application of the ERP needs the

enterprise to reengineer the business process.

The aim of application of ERP is to improve

the management and the economic benefit of

enterprise. That requires the enterprise to

optimize the business process with the

application of ERP in order to make the whole

operation more properly and reasonably.

d) The continual improvement of enterprise

management needs the enterprise to reengineer

the business process.

The BPR require the business process of the

enterprise has to be rethought and rebuilt

fundamentally. Enterprises have to improve the

satisfaction of client, reduce the cost of the

operation, strengthens the core competence

continually. Therefore, in the process of

optimization the each operation activities also

have to be eliminated, simplified, integrated and

automated continually.

3 CASE STUDY

3.1 The Current Situation of

Informatization in S Company

S company is a Subsidiary Company of a large-scale

steel corporation in china. S company not only

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

592

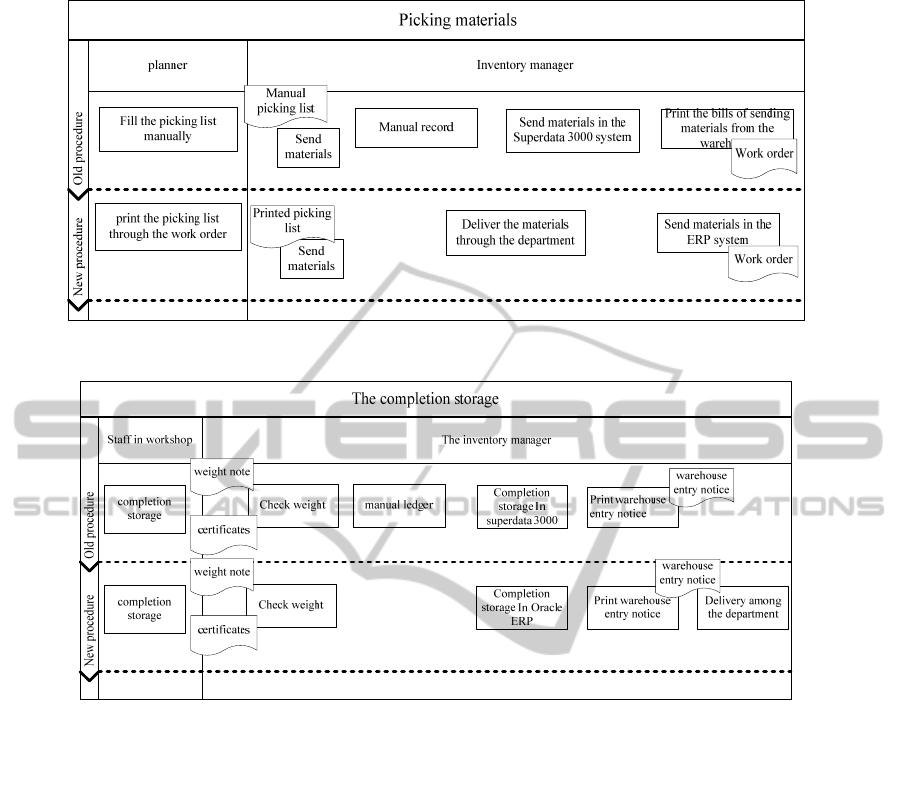

Figure 1: The BPR optimizations of picking materials.

Figure 2: The BPR optimizations of the completion storage.

produces many kinds of steel products and also does

quite a lot of researches and applications about steel

wire rope and steel materials.

In the earlier stage, the financial module and the

human resource module of the Oracle ERP has been

implemented in S company. And the supply and

sales department of S company uses the Superdata

3000 system to manage the purchasing, sales and the

inventory.

The production system of Oracle ERP has not

been implemented. The convergence between the

production and the financial is realized by the

manual documents.

In conclusion, each information system in S

company is running separately. The financial

information system and the business information

system in S company have not been integrated.

3.2 The Problems of the Inventory

Module in S Company

1. The basic data in S company is managed by

each business department but not by a specific

data department. The encoding rules of basic

data made by each department are not identical

so that the basic data can’t be generally used.

2. The sales system, procurement system and the

work in process system, which have no

information system, are managed manually.

3. The financial information system and the

business information system in S company

have not been integrated.

4. The information of the purchasing, the sales

and the inventory are managed by the

Superdata 3000 system. The financial module

of Oracle ERP is responsible for managing the

financial information.

5. The link between the two systems relies on the

printed receipts which can’t make sure the

THE BUSINESS PROCESS REENGINEERING STUDY OF STEEL INDUSTRY BASED ON ERP

593

accuracy and the instantaneity of the data.

6. There are no specifications about the disposing

of the rejected products from the workshop and

the client.

3.3 The BPR Solution of Inventory

Module

The BPR optimizations have been done to the two

procedures of inventory module: picking materials

and the completion storage. The accuracy and the

efficiency of the inventory management have been

improved. What’s more, the integration of the

business module and the financial module has been

realized.

3.3.1 The Procedure of Picking Materials

In the figure 1, the points have been improved in the

procedure of picking materials:

a) The quantity of the raw material can be

reflected in the ERP system.

b) The picking lists are generated by the ERP

system so that the operation of sending materials

relies on the work bills only and the efficiency and

the accuracy can be improved greatly.

c) It is more convenient to calculate the cost of

the workshop when the sending materials and the

missions in workshop are linked through the work

bills.

d) The financial entry can be generated instantly

when picking the materials so that he inventory

management is more accurate.

The improvement of the management:

a) The efficiency of management in workshop is

improved.

b) The accuracy of the cost calculation of the

product is more precise.

c) The operation of picking materials and the

financial module are highly integrated.

3.3.2 The Completion Storage

In the figure 2, the points have been improved in the

procedure of completion storage:

a) The reduction of manual ledger which is due

to warehouse entry based on work orders increases

the accuracy and effectiveness of operation.

b) The financial entries are generated instantly

through the delivery among the departments so that

the business data and the financial data can be

consistent.

The improvement of the management:

a) Increase the management effectiveness of the

end products.

b) The accuracy of the cost calculation of the

product is more precise.

4 CONCLUSIONS

The current situation of information management

based on the theory of ERP and BPR of the S

company has been analyzed and the existent

problems have been indicated in this paper. Then the

solution and the optimum proposal to the inventory

module of the S company have been presented. The

solution attained the objective of integration of

production information system and the financial

information system, optimized the business process

and the management mode of the S company.

There are still many other points to be

optimized. I hope the applications of BPR based on

ERP can be more and more widespread.

REFERENCES

Li Yuning, Jia Wenyu. The Junior Stage of Enterprise

Informatization, Beijing, Eectronic Industry Press,

2004. 4.

Zhou Yuqing, Liu Boying, Yang Baogang. The Principles

and Applications of ERP, Machine Press, 2000.

Joe Peppard, Philip Rowland, The Essence of Business Re-

engineering, CITIC Publishing House, 2003.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

594