THE RESEARCH ON STABILITY OF SUPPLY CHAIN UNDER

HIGH ORDER DELAY

Jia Su-ling, Wang Lin, Luo Chang and Wang Qiang

School of Economics & Management, Beihang University, XueYuan Road No.37, HaiDian District, Beijing, China

Keywords: Supply chain, Stability, High order delay, Simulation, System dynamics.

Abstract: Based on system dynamics (SD), a high order delay inventory control model of supply chain is proposed. The

high order delay in SD is regarded as transition between first order lag and pure time delay (PTD), it describes

the more general delay mode in real systems. With simulation, the stable boundaries of inventory control

model under high order delay are confirmed, and the effect of variations in delay mode on stability of

inventory control system is analyzed. It is concluded that the reduction of delay order and delay time can

improve the stability of inventory control model under high order delay; the sensibility of decision parameters

to the change of system order is nonlinear.

1 INTRODUCTION

Bullwhip effect have triggered a series of problems

including the increase of the operational risk of

enterprise and the decline in supply chain

management efficiency (Lee et al., 1997).In recent

years, the dynamic characteristic of supply chain

represented by bullwhip effect had received

considerable attention. The research on stability of

supply chain is helpful to reduce the bullwhip effect

and improve the operation benefit of supply chain.

In the research of stability of supply chain, the

delay structure is a key influencing factor of system

stability. The researches based on the hypothesis of

first order lag focused on revealing the influence of

management practices to the fluctuant phenomenon

in supply chain and proposed several management

strategies to eliminate the bullwhip effect

(Balakrishnan et al., 2004; Disney et al., 2004;

ChengHu et al., 2005; Zhang et al., 2006). Riddalls et

al. (2000) first pointed out that there was difference

between first order models and actual systems.

Henceforth, the studies based on pure time delay

(PTD) emphasized that supply chain structure

determined the convergence of inventory and order

(Riddalls and Bennett, 2002; Warburton, 2004;

Huixin and Hongwei, 2004). Under the influence of

many factors, the delay mode of the actual inventory

control system may be the high order delay which is

the mixed form of first order lag and pure time delay.

As system dynamics (SD) has provided the

scientific basis for describing high order delay

structure, it avoids the obstacle of analytic modeling

in this area. In this paper, we adopt high order delay as

the transition between first-order delay and pure time

delay and built the supply chain SD model. Through

simulation, the dynamic characteristics and stability

of the system are analyzed.

2 HIGH ORDER DELAY

INVENTORY CONTROL

SYSTEM MODEL

2.1 The Implication of High Order

Delay

In a stable production or transportation system, there

exists an average delay time and the distribution of

output with delay is stable. In system dynamics, the

distribution is described by high order delay.

First order delay and pure time delay are the

particular cases of high order delay. System

dynamics suggests that the structure of first order

delay is equivalent to the structure of negative

feedback with linear first-order, and the structure of

high order delay is equivalent to several first-order

delaying links connected in series. When the order of

high order delay approaches to infinity, high order

361

Su-ling J., Lin W., Chang L. and Qiang W..

THE RESEARCH ON STABILITY OF SUPPLY CHAIN UNDER HIGH ORDER DELAY.

DOI: 10.5220/0003583103610367

In Proceedings of the 13th International Conference on Enterprise Information Systems (SSSCM-2011), pages 361-367

ISBN: 978-989-8425-54-6

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

delay is equivalent to pure time delay (Riddalls and

Bennett , 2002).

The structure of linear first-order system with

negative feedback is shown as follows:

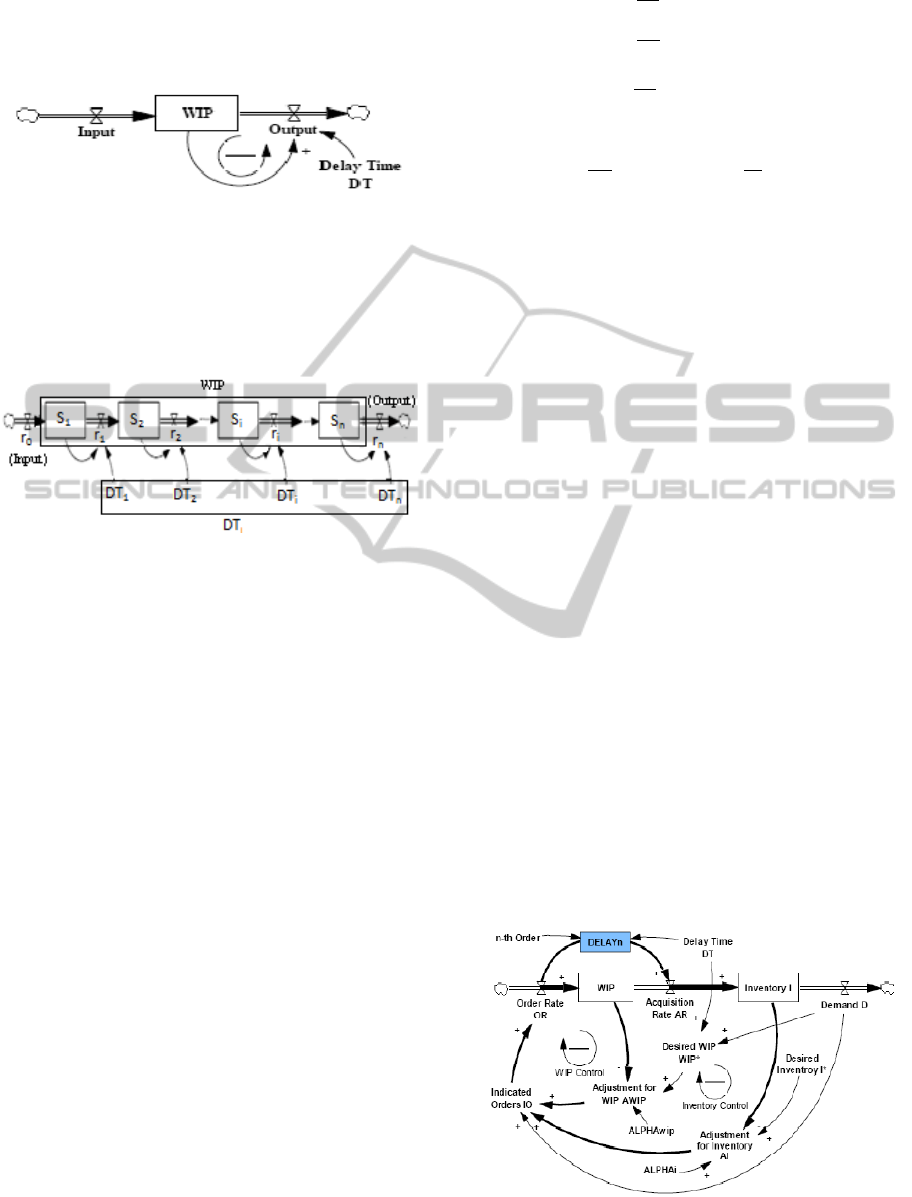

Figure 1: Structure of linear first-order system with

negative feedback.

Output is described as:

Output (t) = WIP/DT (1)

Connecting n first-order delaying links in series,

we can obtain the n orders delay:

Figure 2: Structure of high order delay.

The notation for the model presented in figure 2 is as

follows:

r

i

: input (output) flow at the middle levels. r

0

and r

n

are the input and output of the

model. i = 0,1,…, n

S

i

: the delayed flow at the middle levels, i =

1,2,…, n

WIP:the total flow

DT

i

: the delay time at the middle levels, i =

1,2,…, n

DT:the total delay time

The relationship between the total flow and the

delayed flow at the middle levels is:

WIP=

∑

S

(2)

The total delay time and the delay time at the

middle levels can be simplified (Sterman J. D, 2000):

DT=

∑

DT

DT

=DT

=⋯=DT

=DT/n

(3)

Refer to the structure of first order delay, the

relationship between the input and output at the

middle levels can be represented by differential

equations:

r

=

n

DT

(r

−r

)

r

=

n

DT

(r

−r

)

…

r

=

n

DT

(r

−r

)

(4)

That is:

r

−DTr

′

+

r

′′

+⋯+

(

−1

)

(

)

r

()

=r

(5)

Eq. (5) indicates that it is very difficult to

calculate the output flow r

n

and the delayed flow at

the middle levels may be not differentiable in real

system. Through the analysis of the structure of high

order delay shown in figure 2, we can find that the

greater the order n, the smaller the delay time at the

middle levels DT

i

will be. When the order n

approaches infinity, DT/n is equal to DT

i

and both

are close to zero. That is:

r

0

≈r

1

≈r

2

≈…≈r

i

≈…≈r

n

(6)

r

n

≈r

0

(t - DT) (7)

Therefore, pure time delay can be approximated

by limited high order delay, and the smaller the DT

i

,

the higher the degree of approximation is. It also

indicates that high order delay is the smooth

transition between first order delay and pure time

delay.

System dynamics simulation software, Vensim

PLE, has provided the function of high order delay:

DELAY

n

(Input, Delay Time, n)

Where n is the order of high order delay.

2.2 Model Structure

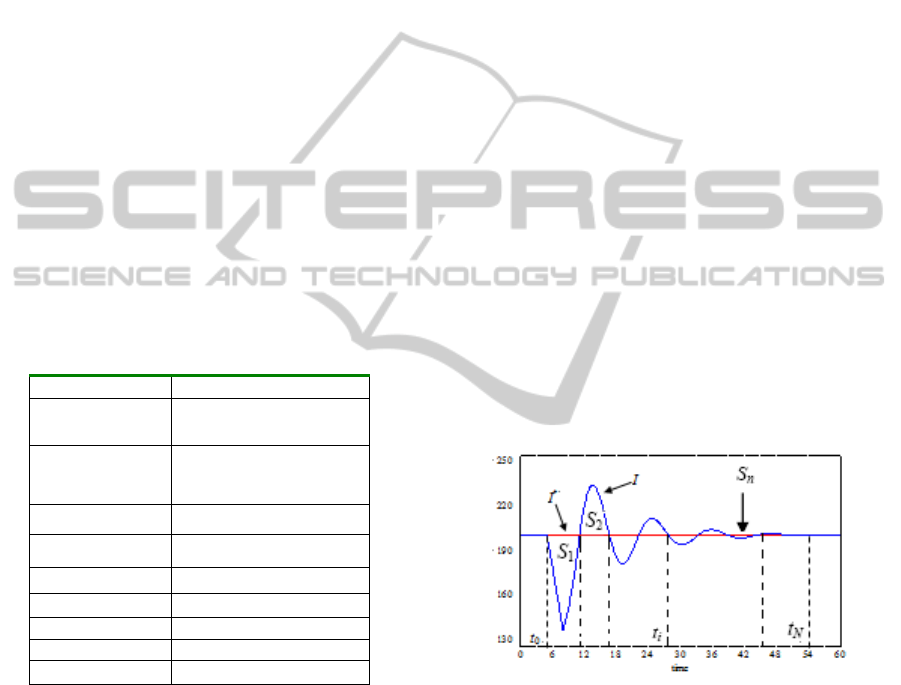

Figure 3 shows the high order delay inventory control

model of supply chain that is built on the basis of the

generic stock-management model proposed by

Sterman (1989).

Considering that the validity of demand forecasting

will influence the system stability, we

Figure 3: High order delay inventory control model.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

362

do not make prediction on market demand. The

adjustments include two aspects:

DELAY

n

: the limited high order delay mode of

WIP;

n-th Order: delay parameter, the order of high

order delay.

In the model, the decision maker first

determines the desired WIP based on demand and

delay time, and then determines the actual

adjustment for WIP. Finally, the order to upstream

will be made according to demand and adjustment

for inventory and WIP.

The expression of the relationship between

order rate and acquisition rate is as follows:

AR = DELAY

n

(OR, DT, n-th Order)

Table 1 shows the variable settings (Sterman,

1989).

Where α

i

is the rate at which the discrepancy

between actual and desired inventory levels is

eliminated, and α

WIP

is the rate at which the

discrepancy between actual and desired WIP levels is

eliminated, 0≤α

i

, α

WIP

≤1. The values of α

i

and α

WIP

represent the sensitivity of decision-maker to the gaps,

that is, (I*-I) and (WIP*-WIP).

Table 1: Variable settings.

Variable Expression

WIP

I

AR DELAY(OR, DT)

AI α

i

(I

*

- I)

AWIP α

WIP

(WIP

*

- WIP)

IO D + AI + AWIP

OR Max(0, IO)

ALPHAi 0≤α

i

≤1

ALPHAwip 0≤α

WIP

≤1

3 STABILITY ANALYSIS AND

CRITERIA OF SUPPLY CHAIN

3.1 The Definition of Stability

There are different definitions of stability of supply

chain. The traditional ideas of system dynamics state

that only the behavior of smooth convergence is

stable while the other fluctuate behaviors are unstable

(Forrester, 1958). The main reason is that system

dynamics methods focus on systems under first order

lag. Scholars based on control theory stress the

importance of pure time delay, it is commonly

accepted that fluctuant convergence is a gradual

process of system to be stable and oscillation with

equi-amplitude is a critical state of stable system.

Based on the definition of stability in control theory

and the methods applied by system dynamics, we

propose the following definition of stability of supply

chain system:

Definition 2.1: Suppose the system is stable at

the initial time, when imposing a small step

disturbance on demand, if the inventory (or order rate)

can get stable at a certain equilibrium level after a

period of time, then the system is stable.

3.2 Stability Criterion

Combining with the above definition of stability, this

paper takes inventory as research subject to obtain

the stability criterion. As the underlying cause of the

fluctuation of inventory is the deviation between

actual inventory and desired inventory, we use the

area between the two curves to describe the

fluctuation in supply chain. This practice is similar

to the method in cybernetics that use “noise

bandwidth” to make quantitative description of

bullwhip effect (Dejonckheere , 2003; Wang et al.,

2006).

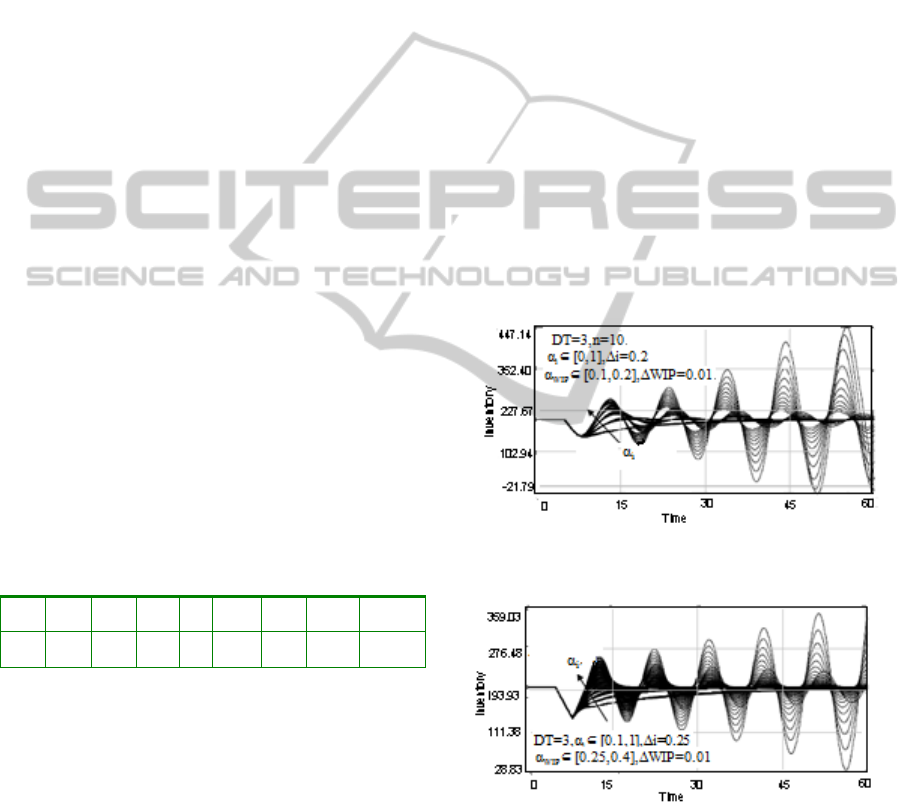

Figure 4 shows the general behavior pattern of

inventory fluctuation.

Figure 4: General behavior pattern of inventory

fluctuation.

As shown in figure 4, assuming that the

inventory curve begins to fluctuate at time t

0

, the

inventory curve and desired inventory level intersect

at time t

1

, t

2

…t

i

…t

n

in succession, and the area

between two curves can be divided into several parts

S

1

,S

2

…S

i

...S

n

. Let the absolute value of the area

between the two curves be s

n

,that is:

S=

∑|

S

|

=

|

I

(

t

)

−I

∗

|

dt

(8)

We can distinguish the behavior of the system

according to the form of curve S, that is, S curve can

0

0

[() ()]

t

t

t

OR t AR t dt WIP

∫

0

0

[() ()]

t

t

t

AR t D t dt I

∫

THE RESEARCH ON STABILITY OF SUPPLY CHAIN UNDER HIGH ORDER DELAY

363

be used as the stability criterion of the system and it

can be obtained by the software, Vensim PLE.

According to the definition of stability, the

sufficient condition of the system to be stable is

presented as following:

lim

→∞

S(t)=C (Constant) (9)

Eq. (9) can be replaced by the following

description:

Assuming t

0

is the starting time of simulation

and t

F

is the end time of simulation, if there exists t

s

(t

0

≤t

s

≤t

F

) to make S(t) = C (Constant), then the system

is stable.

The constant C can be understood as the system

stable level, and the smaller the value of C, the better

stability of the system. In the condition of step

disturbances on demand and no prediction, C is

positive.

4 STABILITY ANALYSIS OF

HIGH ORDER DELAY

INVENTORY CONTROL

SYSTEM

4.1 Simulation Design

The initial values (unit) of variables are presented in

Table 2 (Sterman, 1989; Riddalls and Bennett, 2002).

The model is built using well-known system

dynamics simulation software, Vensim PLE. The run

length for simulation is 60 weeks.

Table 2: Initial Conditions.

I

*

DT α

i

α

WIP

n

MAX

Step

300 200 200 3 1 0 100 50 0.0625

We adopt the small disturbance on demand for

stability examination. This method has been widely

used in the study of system stability based on control

theory and general system theory. The order of delay

gradually increases from 1 to n

MAX

and the demand

function is as follows:

D=D

t0

(1+STEP(h,T

s

)) (10)

Where h is the step signal of amplitude and Ts is

the moment when step change happens. h = 0.2,Ts =

5.

In the presence of small disturbance, the

decision parameter α

i

is changed from 1 to 0 with a

small decrement Δi. At the same time, α

WIP

varies

from 0 to 1 with another small increment ΔWIP, the

smaller the values of Δi and ΔWIP, the higher the

simulation accuracy. Meanwhile, the order of delay

gradually increases from 1 to n

MAX

.

Through simulation, we can observe the

behavior patterns of the high order delay inventory

control model and test the system stability in the

situation of complete rationality (α

i,

α

WIP

∈

[0,1]).

4.2 Dynamics Characteristics

Figure 5 and figure 6 have shown the traverse graphs

of inventory curves of tenth-order delay system and

PTD system. Simulations indicate that the behavior

patterns of inventory shown in figure 5 can represent

the general dynamics characteristics of high order

delay system. It is concluded that high order delay

system can be presence of oscillation with

equi-amplitude and divergent fluctuation, and the

parameters α

WIP

and α

i

show entirely opposite effects

on the dynamics characteristics of high order delay

system. Based on the analysis, we can conclude that

high order delay system has stability boundary

corresponding to PTD system.

Figure 5: The traverse graph of inventory curves of

tenth-order delay system.

Figure 6: The traverse graph of inventory curves of PTD

system.

4.3 Stability Analysis

As high order delay system covers four kinds of

behavior patterns: smooth convergence, fluctuant

convergence, oscillation with equi-amplitude,

divergent fluctuation, it is more appropriate to PTD

0

t

WIP

0

t

I

0

t

D

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

364

system from the visual point of view. The contrast

between figure 5 and figure 6 shows that the range of

decision parameter α

WIP

in ninth-order delay system

is smaller than that in PTD system with the same

delay time and range of decision parameter α

i

. That

is, in high order delay system, the decision maker

can consider more about inventory and consider less

about WIP. Beer game has shown that most

decision-makers think that the actual inventory is

more important than WIP. Therefore, even if the

decision maker has bias against the above conclusion,

the high order delay system may still be stable. In

other words, the decision strategies that lead PTD

system to be unstable may make high order delay

system stable. So, high order delay system is more

stable than PTD system.

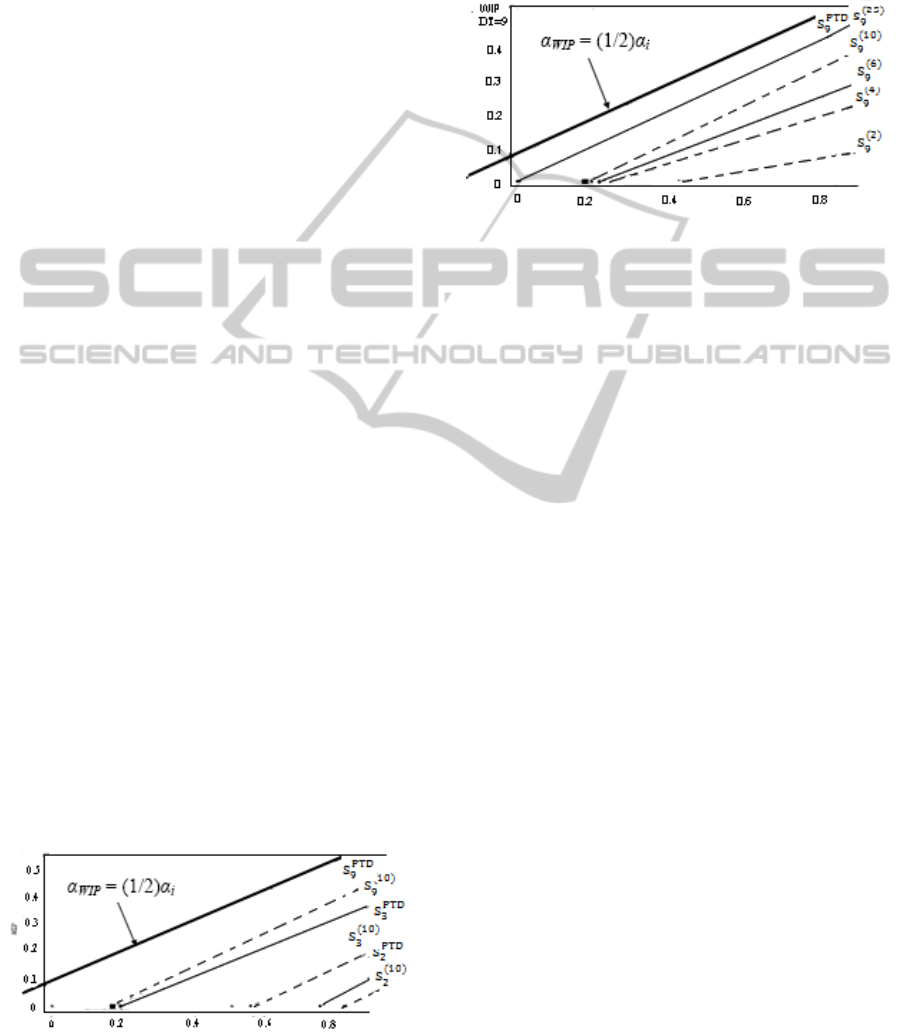

Through simulations, we can find the critical

stable state of n-th order delay system with a given

DT and obtain the critical stable points (α

,

, α

,

).

Therefore, the critical stable condition of inventory

control system under n-th order delay is defined as

following:

Definition: Suppose the n-th order delay

inventory control system is stable at the initial time.

With a given DT, when imposing a small step

disturbance on demand, if there exists the decision

parameters (α

,

, α

,

) that can keep the inventory

curve oscillate with equi-amplitude, then the state is

called critical stable state, (α

,

, α

,

) is the critical

stable point of the system under the given DT.

As high order delay system considers the order of

delay, its critical stable points are determined by four

dimensional vectors, (DT, α

i

, α

WIP

, n). Through the

traversal simulation of α

i

and α

WIP

under certain DT,

several critical stable points are found. After

connecting these points in the plane that takes α

i

as

horizontal axis and α

WIP

as vertical axis, we obtain

the stability boundary of the tenth-order delay

system named s curve. Figure 7 shows some s curves

under different DT and the index of s represents the

value of DT. For comparison, the corresponding

stability boundaries of PTD system are also given.

Figure 7: Comparison between the stability boundaries of

tenth-order delay system and PTD system.

Furthermore, s curve of high order delay system is

approximate to linear property and the lower right of

s curve is the unstable region. For comparison, figure

8 shows the stability boundaries of five high order

delay systems with different delay orders

(n=2,4,6,10,25) under certain DT (DT=9).

Figure 8: The effect of delay order on system stability

(DT=9).

After running simulations for the high order

delay inventory control model under different DT

and comparing with PTD system, we can draw the

following conclusions:

First, the stable region of high order delay

system is larger than that of PTD system. With the

same delay time, the larger order of delay, the closer

the stability behavior of high order delay system to

PTD system, and the oblique line (α

WIP

=α

i

/2) is the

upper bound when s curve moves up to top left.

Second, as the oblique line (α

WIP

=α

i

/2) is the

upper bound when s curve of n-th order delay

inventory control system moves up to top left with

certain DT, it can be concluded that the upper left

area of oblique line (α

WIP

=α

i

/2) is the stable region

which is independent of delay (IoD), and the oblique

line (α

WIP

=α

i

/2) can be defined as IoD stability

boundary which is only determined by systemic

structure.

Third, under the same delay condition, the

smaller delay time, the larger the stable region of

high order delay time; and under the same delay time,

the smaller the order of delay, the larger the stable

region. Therefore, the stability of high order delay

system with short delay time and small order of

delay is closer to first-order system.

Further analysis on figure 8 reveals that when

the order of delay is small, the s curves tend to be

relative dispersive, and when the order of delay is

large, the s curves are comparatively concentrated.

This shows that the sensibility of decision

parameters to the change of system order is

nonlinear.

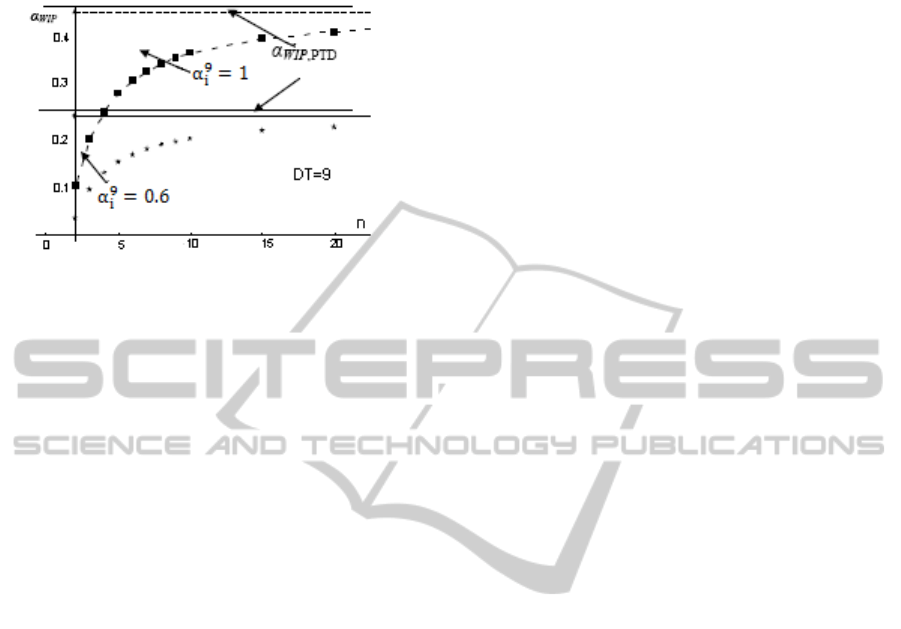

Based on figure 8, when the decision parameter

α

i

takes a certain value, figure 9 shows the relation

THE RESEARCH ON STABILITY OF SUPPLY CHAIN UNDER HIGH ORDER DELAY

365

curves between the decision parameter α

WIP

and the

order of delay (

α

i

=0.6; α

i

=1).

Figure 9: The delay order's sensitivity curve.

Figure 9 indicates that under the given delay time

and decision parameter α

i

, the value of α

WIP

increases

as the order of delay increases and it finally tends to

that of PTD system in the same condition, but the

increase margin of α

WIP

drops when the order of

delay increases. In other words, when the order of

delay is large, the decision parameter α

WIP

has a low

sensitivity to the change of it. After simulations of

delay systems under different DT, the above

nonlinear characteristics still exist in the system.

The analysis above shows that in order to

maintain system stability, decision maker should

make clear the delay mode of WIP when focusing on

the change of inventory and WIP. Overestimating

the order of delay will artificially limit the stable

region and restrict the implementation of certain

ordering strategies. At the same time,

underestimating the order of delay may enlarge the

stable region and result in accidental fluctuations in

the system.

4.4 Discussion

The structure of high order delay is the transition

between first-order delay and pure time delay and it

describes the more general delay mode in real

systems. Therefore, it is more accurate to assume the

delay mode in real systems to be high order delay.

Researchers have shown that the delay mode of WIP

is determined by the service rules of system and the

order of delay is an important parameter to describe

the delay mode. The order of delay can be

approximately evaluated based on system data and

then be used for simulation.

Simulation results show that system stability

can be improved through decreasing the order of

delay and shortening the delay time. Decreasing the

order of delay suggests the adjustment on service

rules, that is, the production or transportation system

must be designed reasonablely. So decreasing the

order of delay system can improve both the system

stability and the overall level of service.

Finally, although the stability boundary of

system exists objectively, it is definitely difficult to

obtain the stability boundaries from theory or

simulation. The inaccurate estimate of decision

maker on the delay mode will lead to wrong decision

and even the optimized rules may make the system

instable. Therefore, to strengthen the control to the

system and avoid the subjective error are important

means of increasing system stability.

5 CONCLUSIONS

To conduct quantitative analysis on the stability of

high order delay system, we first give the abstract

analysis on the structure of high order delay and then

built the high order delay inventory control model of

supply chain. By simulation analysis, a

system-dynamics-based criterion for stability

judgment is proposed. With simulation, the criterion

can be used to describe the nonlinearities of supply

chain system and judge the influences exerted on

supply chain stability by decision behavior.

According to the concept of stability and stability

criterion proposed in the paper, stability boundaries of

high order delay inventory control system are

confirmed. It is concluded that the IoD stability

boundary has nothing to do with the delay time and

order of delay and the stability of high order delay

inventory control system is mainly decided by the

features of feedback systems.

As high order delay system considers the order

of delay, this paper further analyzes the effect of

order of delay on system stability and finds that the

sensibility of decision parameters to the change of

system order is nonlinear. Synthetic analysis indicates

that the subjective sensation of decision maker on the

structure and behavioral pattern of system has great

influence on the system stability. The paper finally

points out that system stability and the overall level of

service can be improved by adjusting the service rules

in inventory control system, and further research

needs to be done on how to adjust the service rules.

REFERENCES

Lee H. L., Padmanabhan V., Whang S.(1997). The bullwhip

effect in supply chains. Sloan Management Review,

38(3), 93–102.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

366

Balakrishnan A, Geunes J, Pangburn M.S. (2004).

Coordinating supply chains by controlling upstream

variability propagation. Manufacturing and Service

Operations Management, 6, 163–183.

Disney S. M., Towill D. R., Van De Velde W.

(2004).Variance amplification and the golden ratio in

production and inventory control. International Journal

of Production Economics, 90(3), 295-309.

Chen Hu, Han Yuqi, Wang Bin, (2005). The Study of

Inventory Management Based on System Dynamics.

Journal of Industrial Engineering and Engineering

Management. 19(3), 132-140.

Zhang Libo, Han Yuqi, Chen Jie et al. (2006). System

Dynamics in Plant Capacity Enlargement. Journal of

System Simulation. 18(5), 1327-1330.

Riddalls C. E., Bennett S, Tipi N.S. (2000). Modeling the

dynamics of supply chains. International Journal of

System Science, 31(8), 969-976.

Riddalls C. E., Bennett S. (2002). Production-inventory

system controller design and supply chain dynamics.

International Journal of Systems Science, 33(3),

181-195.

Warburton R. D. H. (2004). An exact analytical solution to

the production inventory control problem. International

Journal of Production Economics.92 (1), 81-96.

Liu Huixin, Wang Hongwei. (2004). Performance analysis

of a supply chain under order-up-to policy. Computer

Integrated Manufacturing Systems, 10(8), 939-944.

Riddalls C. E., Bennett S. (2002).The stability of supply

chains. International Journal of Production Research,

40,459-475.

Sterman J. D. (2000). Business Dynamics: Systems

Thinking and Modeling for a Complex World. New

York: McGraw –Hill /Irwin.

Sterman J D. (1989). Modeling managerial behavior:

misperceptions of feedback in a dynamic

decision-making experiment. Management Science,

35(3):, 321-339.

Forrester J. W. 1958.Industrial dynamics: a major

breakthrough for decision makers. Harvard Business

Review. 36(4): 37–66.

Dejonckheere J., Disney S. M., Lambrecht, M. R. et al.

(2003).Measuring and avoiding the bullwhip effect: A

control theoretic approach. European Journal of

Operational Research, 147(3), 567-590.

Wang Jing, Sun Haiyan, Li Yilan, (2006).Irregular

information distortion and weakening methods in

supply chains. Journal of Beijing University of

Aeronautics and Astronautics.32 (12), 1481-1484.

THE RESEARCH ON STABILITY OF SUPPLY CHAIN UNDER HIGH ORDER DELAY

367