SIMULATORS FOR CONTROL ENGINEERS

ADVANCED LEARNING

L. F. Acebes

1

, A. Merino

1

, L. Gómez

1

, R. Alves

2

, R. Mazaeda

1

and J. Acedo

3

1

Department of Systems Engineering and Automatic Control, University of Valladolid

Higher Tech. College of Industrial Engineering, c/Real de Burgos s/n 47011, Valladolid, Spain

2

Department of Informatics and Automatic Control, University of Salamanca

Faculty of Sciences, P/ de Fray Luis de León, 1-8, 37008, Salamanca, Spain

3

Centro Superior de Formación de Repsol (CSFR), Madrid, Spain

Keywords: Dynamic simulators, Continuous process control, Learning, OPC, Object oriented modelling languages.

Abstract: The paper purpose is to show a Windows© NT/XP/7 application oriented to learn control skills to process

engineers and it is used successfully in an industrial master of instrumentation and process control.This tool

contains two sets of process control problems that are very diverse ones, both in the type of process as well

as control techniques (twenty three modules are available). It is possible to study cascade, ratio, selective,

override and feedforward control techniques and the tuning, configuration and operation of PID controllers.

It also allows analyzing complex systems control installed in boilers, furnaces, distillation columns or

reactors and some special control techniques to ensure the process safety. When a module is selected a

dynamic simulation and its graphical user interface are started. So, as example, one of the simplest modules

is shown. Finally, an overview of the methodology and software used to develop this tool is also outlined. In

particular, an object oriented modeling tool is used to develop the simulation models, a SCADA is used as

graphical user interface and the simulation-SCADA communications are supported by the OPC standard.

1 INTRODUCTION

In nuclear, power, thermal, oil, gas, petrochemical,

pulp and paper plants, as well as in other sectors, the

use of process simulators is widespread, both for

operators training and for production process

improvement. Some examples of training simulators

are APROS (VTT, 2011), Industrial System 800xA

simulator (ABB, 2011), SimSCI-Esscor (Invensys,

2011), Team_Aides (Tecnatom, 2011) or UniSim

(Honeywell, 2011). These simulators are oriented to

the operators training in particular industries and

they are so much complex and high cost ones.

There are simulators oriented to the study of

certain control subjects such as Loop-pro

(Controlstation, 2011) or Topas (ACT, 2011). They

are good tools to learn process control, but many

advanced aspects of the industrial implementations

are not considered. However, one advantage is that

are not so expensive.

Other simulation packages, the so called design

simulators, are oriented to build the process and

control structure model and experiment with it. One

example in the field of engineering process is Hysys

(Aspentech, 2011). Other examples of general

purpose modelling and simulation tools are Dymola

(Dynasim, 2011) or EcosimPro (EA, 2011). These

modelling and simulation packages require that the

user has a deep knowledge about them. Modelling

and simulation skills are necessaries, especially in

some cases in which he should develop their own

model libraries. Besides, for training purposes, the

experimental frame is not the more suitable one and

also its price is high.

These tools pursue different objectives ranging

from PID controllers tuning, process identification,

design of process and control structures, study of

advanced control strategies, operation of process

unit and, even, complete industrial processes. Some

of them are reduced to a single industrial field and

other ones cover a reduced number of processes.

Some aspects of interest in the training of process

control engineers cannot be covered by any of them.

For instance: some special control aspects related to

process safety, as anti surge mechanism in

centrifugal compressors; special processes, as

249

Acebes L., Merino A., Gómez L., Alves R., Mazaeda R. and Acedo J..

SIMULATORS FOR CONTROL ENGINEERS ADVANCED LEARNING.

DOI: 10.5220/0003578302490256

In Proceedings of 1st International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH-2011), pages

249-256

ISBN: 978-989-8425-78-2

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

blending processes; or parameterization procedures,

as the linearization of the static operation curves of

valves. In addition the graphical user interfaces

(GUIs) are different ones, both in appearance and

functionality.

So, to give a complete training to a control

engineer requires the use of different tools that use

dynamic simulation. This implies a high economic

cost to the institution that provides training, both for

the licenses purchase as for maintaining and

updating them. For the students, it means an effort to

adapt and learn different tools, some of which have

many features that are not used by the students and

they are being paid by the institution offering the

training.

For these reasons, a simulation tool oriented to

study typical problems of operation and control in

production units of the process industry has been

developed. The modules have been carried out by

the Department of Systems Engineering and

Automatic Control of the University of Valladolid

and they are based on the expertise of control and

instrumentation engineers of Repsol (a Spanish

company in which one of its main activities is the

production of petroleum derivates). This tool is

being used in the “Master in instrumentation and

process control ISA-REPSOL”) given by the CSFR

(“Superior Training Center Repsol”).

The paper describes the mentioned tool. In

particular, a simulation module will be shown as an

example. Afterwards, the software structure of the

simulation tool is detailed, as well as, the software

used for its development

2 TOOL DESCRIPTION

The mentioned tool is a Windows® NT/XP/7

application that allows selecting a set of simulation

modules organized in two graphical menus: “Control

techniques” and “Process control units”. The tool

provides a help that explain each module in Spanish

language. The great majority of the study cases are

well explained in (Acedo J, 2003) and (Acedo J.,

2006).

The “Process control units” modules are (Figure 1):

• Steam production boiler. Level and pressure

control (ten coupled control loops).

• Boiler Burner Management System (BMS).

• Exothermic chemical reactor. Hydrodesul-

phurization process control.

Figure 1: "Process control units " menu.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

250

• Endothermic chemical reactor. Catalytic re-

forming process control.

• Furnace. Temperature control (eight coupled

control loops) driving two combustibles (fuel

and gas).

• Distillation column. Two control structures and

study of the economic and control aspects

integration.

• Blending. Process control and mixture pres-

cription specification.

• Automatic valves. Characterization of digital

valve positioners.

• Heat exchangers. Cascade and feedforward

compensators.

• Centrifugal compressors. Anti-surge mecha-

nism.

• Alternative compressors. Two control op-tions,

load steps or split-range control.

• Centrifugal pump. Minimum recycling control

of centrifugal pump.

• ON-OFF level controller. Dead band hysteresis

effect and logic controller.

The “Control techniques” modules are:

• Ratio Control. Two options comparative for

products mixture.

• Cascade control. Level tank control using

cascade controllers. Mainly the tuning and the

switching of the manual and automatic mode of

the nested controllers are outlined.

• Selective control. Two cases, case 1 is a

compression station control and case 2 is a

pumping station control. Particular interest in

the anti reset windup mechanism is shown.

• Feed forward control. Temperature control

comparative in a heat exchanger without

feedforward compensator and with a static or

dynamic one.

• Split range control. This technique is applied to

three systems. A pressure control in a

distillation column head, a pressure control in a

blanketing and a simultaneous flow and

temperature control.

When a module is selected, from one of the main

menus, the corresponding dynamic simulator and its

GUI are started. Later, some details about the

simulation are given. Now, the GUI of each module

will be the focus of attention.

The GUI of the selected module corresponds to a

P&ID (ISA, 1992), Piping and Instrumentation

Diagram. These schematics have passive

components that show information as standing or

running equipment indicators, trend and historical

charts, other types of charts (characteristic valve

curves), value displays,... and active components

that allow acting over the system: starting or

stopping pumps, valves or process units; selecting

automatic/manual/cascade mode in controllers;

modifying the boundary condition and the process

and control parameters,...

By default the simulation runs in real time, but

the user can change the simulation run speed using a

time factor that can be greater than 1 to accelerate it,

if the PC allows it, or lower than 1 to decelerate it

(Figure 2).

3 EXAMPLE

In order to show how works the simulation tool, one

of the simplest modules has been selected (minimum

recycling control of centrifugal pump). First, a

physical system description and the GUI will be

outlined. Second, an experiment is run.

Figure 2: Time factor.

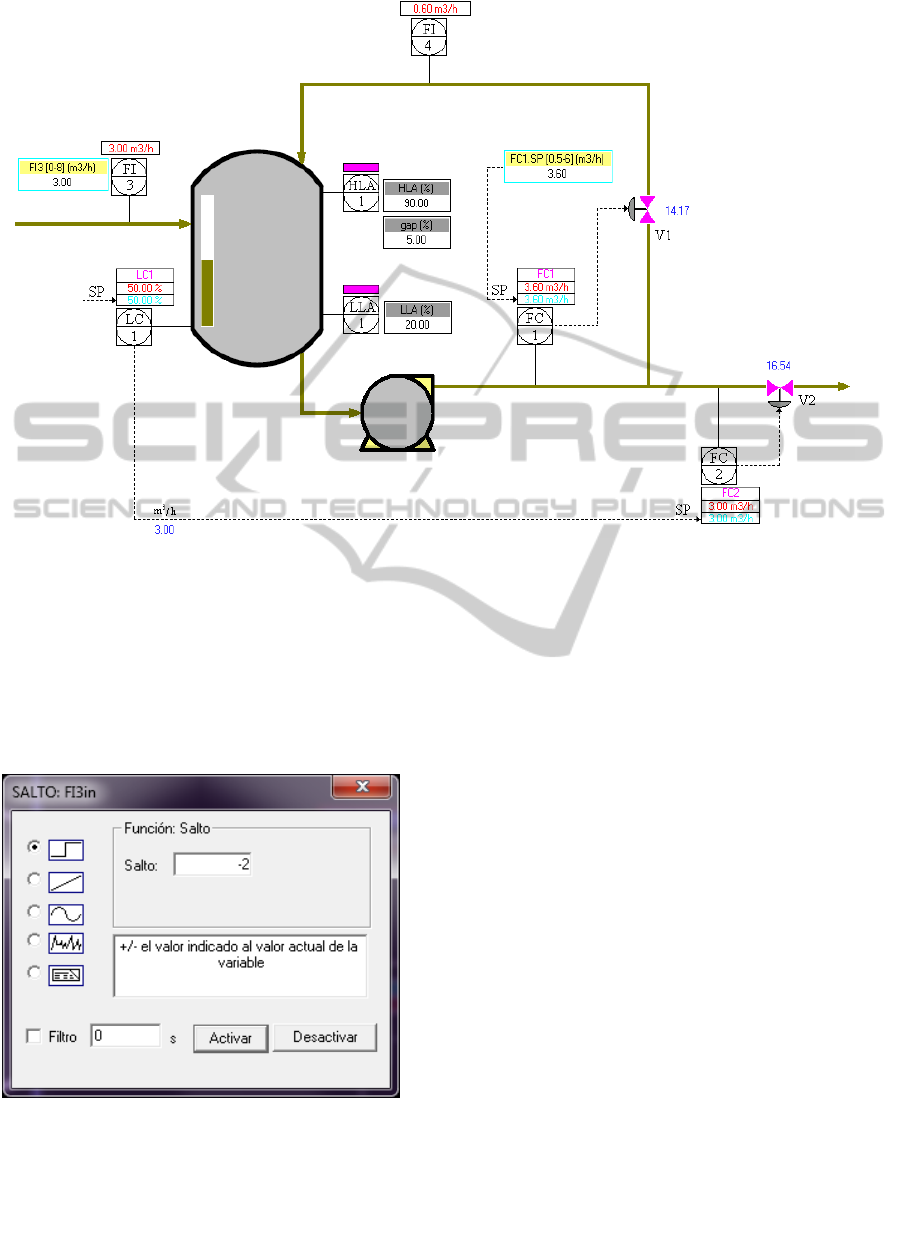

The system (Figure 3) is composed by a tank that

receives a flow of water, a centrifugal pump

connected to the tank outlet, a recirculation valve

(V1) and an outlet valve (V2). The level controller

(LC1) output is connected, in cascade, with the flow

controller (FC2). The FC2 output drives V2. At the

pump outlet, there are two pipes; one is connected to

V2 and the other one to V1. The recirculated flow

(FI4) is governed by the flow controller (FC1) that

drives V1.

The aim of the control structure is ensure that,

regardless of the LC1 actions, the pumped flow

(FC1) must be always greater that a minimum value

in order to avoid both thermal, mechanical or

electrical problems and the pump cavitation. So, the

Set Point (SP) of FC1 is the minimum pumped flow,

which is a manufacturer specification. All

controllers are implemented by PIDs (Proportional,

Integral and Derivative). The process disturbance is

the external flow to the tank (FI3). Besides, there are

two alarm indicators to high and low level in the

tank. The module allows modifying the PIDs

parameters and observing the control structure

performance when the feed flow changes, in

SIMULATORS FOR CONTROL ENGINEERS ADVANCED LEARNING

251

Figure 3: Minimum recycling control of centrifugal pump.

particular when it is less than the minimum pumped

flow.

FI3 and FC1 SP can be modified using a step,

ramp, oscillatory or random signal. The user must

click on the corresponding indicator of the P&ID.

So, an experiment is made in which a step from 5 to

3 m

3

/h in FI3 signal is activated (Figure 4).

Figure 4: Change boundary condition.

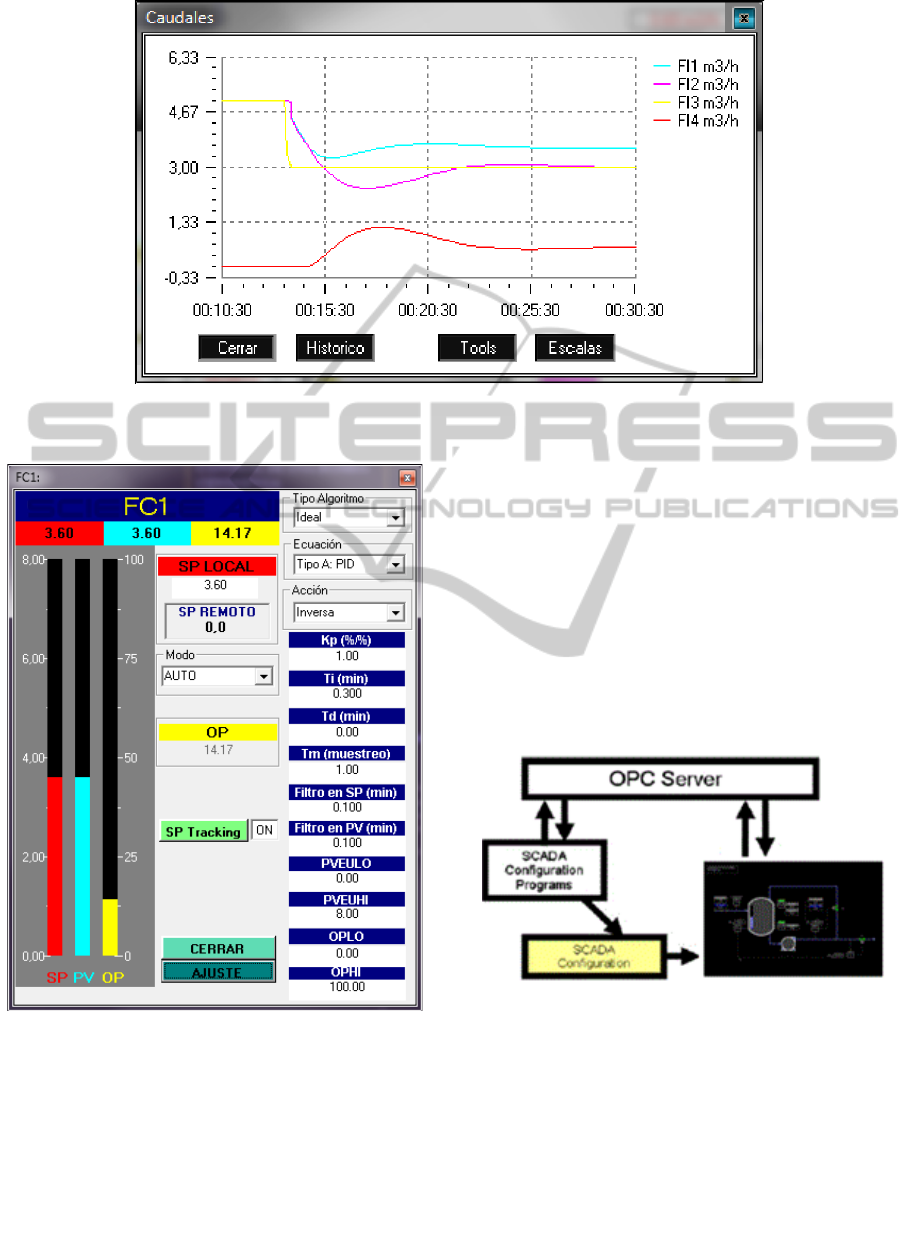

Initially, the outlet and pumped flow are equals and

greater than the minimum pumped flow (3.6 m

3

/h) and

therefore V1 is closed and FI4 is zero. As FI3 step result,

FC2 and FC1 will be under the minimum pumped flow

and the controller of minimum flow must act. First,

FI3 decreases from 5 to 3 m

3

/h. The tank level

decreased and LC1 acts decreasing FC2 SP. Conse-

quently, the outlet and pumped flows (in figure 5

FI1 and FI2) decrease simulteneously. When the

pumped flow (FI1) is under the minimum pumped

flow, FC1 acts opening

V1 and, as result, FI4, the

tank level and FI1 are increased and the pumped

flow rises the minimum pumped flow value.

Clicking on the control signals or variables

displays, trend charts showing the performance of

the control structure are shown. These charts can be

configured by the user. Figure 5 shows the flows

performance.

PID controllers implement the main aspects of

the industrial controllers. Pressing the left mouse

button placed on each PID controllers, the GUI for

managing the corresponding PID is shown (Figure

6). The bar graph lets you see (graphically and

numerically) the value of the process variable (PV in

blue), set point (SP in red) and control (OP in

yellow). The user can select the controller mode

(Automatic, Manual or Cascade). In AUTO mode,

he can specify the SP value and, in MAN mode, the

OP value. In manual mode, the user can activate the

SP tracking mechanism to avoid the well-known

“bumpless” of the auto/man controller commutations.

Pressing the “AJUSTE” button the user accesses.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

252

Figure 5: Process and control structure response.

Figure 6: PID interface.

to the tuning parameters (proportional gain, reset

time, derivative time, sampling period, SP and PV

time constant filters, PV and OP span values in

Engineering Units). Additionally, there are three

menus to select the type of algorithm (Ideal or

Interactive), the PID equation (PID, PI-D, I-PD, I)

and the action controller (direct or reverse). The PID

equations use normalized SP, PV and OP values.

4 SOFTWARE STRUCTURE AND

DEVELOPMENT TOOLS

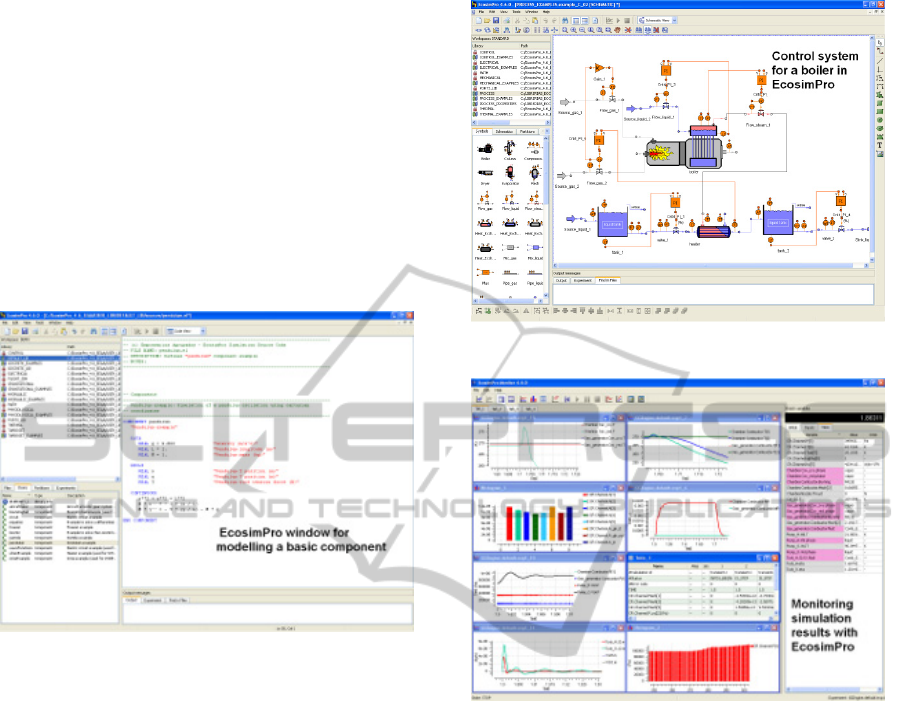

When selecting a particular module a SCADA

system is started. This SCADA is called EDUSCA

(Alves R. et al, 2006) and it is the simulation module

GUI. EDUSCA starts the simulation program linked

to the selected module. The development of each

module GUI involves the EDUSCA setting, which is

done by a drag & drop strategy through a setting tool

(Figure 7).

Figure 7: GUI setting.

The communication between EDUSCA and the

simulation program is performed by the OPC (OLE

for Process Control) communications standard for

process control applications for Windows environ-

ments (OPC Foundation, 2011). EDUSCA acts as an

OPC client and the simulation program as an OPC

server.

The simulation models have been performed

using EcosimPro. EcosimPro belongs to the so

SIMULATORS FOR CONTROL ENGINEERS ADVANCED LEARNING

253

called object oriented modelling languages

(OOML). Many of the EcosimPro characteristics are

similar to the modeling tools that implement

Modelica (Modelica Foundation, 2011). In the sense

that it supports non-causal models able to be

modified automatically according to the context in

which they are used. Its simulation language, called

EL (Ecosimpro Language), allows the description of

process models, named components, in a natural

way by means of continuous differential algebraic

equations and discrete events variables. Each

component can have a ports based interface to

connect to other components.

Figure 8: Ecosimpro textual modelling view.

These components are grouped in libraries and

an icon can be attached to each one. The user can

built the system model interconnecting components

by ports, using directly the modeling language) or

the GUI that allows the graphical modeling (Figure

9). Then, the resulting mathematical model is

compiled and, after establishing a partition, that is,

describing which variables constitute the known

boundary conditions, EcosimPro generates the

simulation model that is converted to C++

simulation code linked to the numerical solvers.

Finally, the user runs simulation experiments

from another EcosimPro GUI view (Figure 10).

In this project, two basic model libraries have been

developed, one for process units and another one to

design control structures. The mathematical models

of the process units library components are based on

first principles and the detail of the model is required

for the purpose of the simulator. So, distributed or

globalized parameter models can be found; fast

dynamics can be explicitly modeled or simplified

using static equations; empiric equations can be used

to reduce the model complexity.

The EcosimPro simulation models don’t hold

Figure 9: Ecosimpro graphical modelling view.

Figure 10: Ecosimpro experimental view.

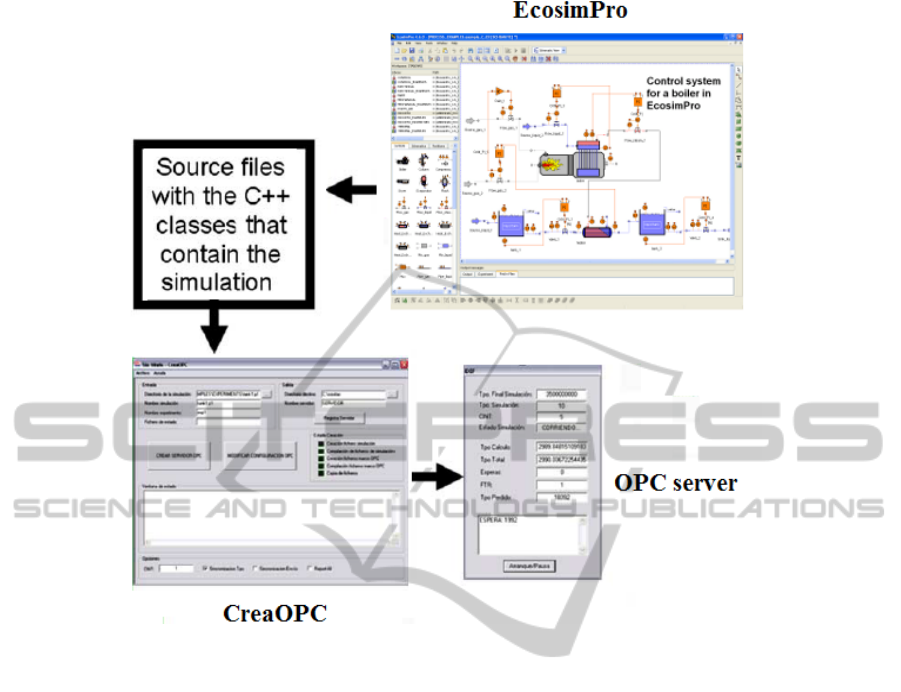

OPC communications. However an OPC server can

be created by adding to the C++ simulation code the

communication routines provided by the OPC

standard. Then, the simulation program is an OPC

server can be accessed from any OPC client. This

process can be automated. In our case, an

application, CreaOPC (Alves R. et al., 2005), creates

OPC servers from the sources files generated by

EcosimPro.

5 CONCLUSIONS

A program with a library of simulation modules of

typical control problems has been briefly exposed.

This library deals with normal control problems

(PID tuning; cascade, feedforward and ratio

control)but, additionally, it includes other type of

control problems (selective, override, split-range

control) and special control strategies to guarantee

security and quality process requirements. A variety

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

254

Figure 11: OPC server simulation generation.

of processes are considered, from the simplest ones,

as tanks or heat exchangers, to the more complex

ones, as boilers or distillation columns.

We consider that the program is user-friendly,

few hardware and software resources are required

and the functionality, the level of detail and the GUI

are adapted to the industrial environment and the

learning requirements for control process engineers.

Moreover, it has been validated by experts with

industrial skills. So, it’s used successfully in the

“Master in instrumentation and process control ISA-

REPSOL”.

Finally, to make the simulation based learning

tool for control engineers a diverse set of programs

and EcosimPro libraries have been developed:

• Two complete EcosimPro model libraries of

unit process and control elements. They can be

used to design and test different control

structures to production process.

• EDUSCA: a SCADA and its setting tool.

EDUSCA can be used for different purposes to

the outlined one in this paper. It can access to

any OPC server and, consequently, it can be

used to supervise laboratory plants or any OPC

server simulator.

• CreaOPC, to generate OPC server simulation

programs from the EcosimPro simulation

models. So, the OPC server simulators can be

connected to any OPC client, for instance any

industrial SCADA.

Additionally, as future work, new modules can

be added to the library, for instance a multivariable

predictive control module. Other possible

development and research line is to follow up

EDUSCA to support the web based learning.

ACKNOWLEDGEMENTS

The authors want to express their gratitude to the

ISE (Instituto Superior de la Energía, Fundación

Respsol-YPF) and to the ISA (International Society

of Automation) Spanish Section for the financial and

technical support.

SIMULATORS FOR CONTROL ENGINEERS ADVANCED LEARNING

255

REFERENCES

ABB, 2011. Industrial System 800xA simulator by ABB.

[Online]. Retrieved from http://www.abb.com

Acedo J., 2003. Control avanzado de procesos. Teoría y

Práctica. Ediciones Díaz de Santos. ISBN: 84-7978-

545-4

Acedo J., 2006. Instrumentación y control avanzado de

procesos. Teoría y Práctica. Ediciones Díaz de Santos.

ISBN: 978-84-7978-754-7

ACT, 2011. Topas by ACT. [Online]. Retrieved from

http://www.act-control.com

Alves R. et al., 2005. “OPC based distributed real time

simulation of complex continuous processes”.

Simulation Modelling Practice and Theory. Volume

13, Issue 7, October 2005, Pages 525-549. ISSN:

1569-190X

Alves R. et al., 2006. “EDUSCA (EDUcational SCAda):

Features and applications”. Advances in Control

Education, Volume 7, Part 1. Proceedings of the 7th

IFAC Symposium on Advances in Control Education

Aspentech, 2011. Hysys by Aspentech. [Online]. Retrieved

from http://www.aspentech.com

ControlStation, 2011. LoopPro by ControlStation.

[Online]. Retrieved from http://www.controlstation.

com

Dynasim, 2011. Dymola by Dynasim [Online]. Retrieved

from http://www.dynasim.se

EA, 2011. EcosimPro Dynamic modeling and simulation

tool by EA Internacional. [Online]. Retrieved from

http://www.ecosimpro.com

Honeywell, 2011. UniSim by Honeywell. [Online].

Retrieved from http://hpsweb.honeywell.com

Invensys, 2011. SimSCI-Esscor by Invensys. [Online].

Retrieved from http://iom.invensys.com

ISA-The Instrumentation, Systems, and Automation

Society, 1992. Instrumentation Symbols and

Identification. ISA-5.1-1984 (R1992). Formerly

ANSI/ISA-5.1-1984 (R1992)

Modelica Foundation, 2011. [Online]. Retrieved from

http://www.modelica.org

OPC Foundation, 2011. [Online]. Retrieved from

http://www.opcfoundation.org

Tecnatom, 2011. TEAM_AIDES by Tecnatom. [Online].

Retrieved from http://www.tecnatom.es

VTT, 2011. APROS Process Simulation Software by VTT

Technical Research Centre of Finland. [Online].

Retrieved from http://www.apros.fi.

SIMULTECH 2011 - 1st International Conference on Simulation and Modeling Methodologies, Technologies and

Applications

256