ON LOW-CARBON SUPPLY CHAIN MANAGEMENT

Jian Li

1

, Fang Xu

1

and Guowei Hua

2

1

School of Economics and Management, Beijing University of Chemical Technology, Beijing 100029, China

2

School of Economics and Management, Beijing Jiaotong University, Beijing 100044, China

Keywords:

Low-carbon supply chain.

Abstract:

The concept of the low-carbon supply chain management is addressed in this paper. The benefits, the difficul-

ties, and the key issues of low-carbon supply chain management are investigated based on the supply chain

management theory. Finally, some public policies are proposed to support the implementation of low-carbon

supply chain management.

1 INTRODUCTION

Global warming has already become a fact. Cli-

mate catastrophe caused by global warming, such as

flood disaster, food production reduction, eco-system

damage, etc, has seriously threatened human survival

and development. According to IPCC report, human

activities especially large burning of fossil fuel that

produces excessive greenhouse gases is the principal

cause of climate warming and consequently, the es-

sential thing in slowing down global warming is re-

ducing emission of greenhouse gases such as carbon

dioxide. Developing low-carbon economy is an in-

evitable choice to fight against climate change, en-

sure global energy security and achieve sustainable

social development. Developing low-carbon econ-

omy needs joint efforts of governments, enterprises,

individuals and various social organizations around

the world. A report titled The carbonemissions gener-

ated in all that we consume published by The Carbon

Trust shows that ”Consumer purchasing decisions are

the ultimate driver of carbon emissions in an econ-

omy. All carbon emissions can be attributed to the

delivery of products and services to meet the needs of

the consumer ” (CarbonTrust, 2006), so enterprises,

the providers of products and services play a quite

special role in the development of low-carbon econ-

omy.

Low-carbon is the only way for enterprises to de-

velop in the future. There are several issues that drive

enterprises to take actions to reduce carbon emis-

sions, including increase in energy cost, existing and

planned legislations which punish high energy con-

sumption and reward emissions reductions and chang-

ing consumer attitudes to climate change. A report

2008 by the World Resources Institute(WRI) and A.T.

Kearney, Inc. indicates that reduction of 13 to 31 per-

cent in earnings before interest and taxes (EBIT) was

projected by 2013, and 19 to 47 percent by 2018 for

fast-moving consumer goods companies that do not

develop strategies to mitigate the risk posed by envi-

ronmental pressures (WRI and A.T.Kearney, 2008).

At present, more and more enterprises have real-

ized the limits of enterprise’ inward-focused reduc-

tion strategies and are exploring to minimize the car-

bon emissions across the supply chain. As the exten-

sion of enterprise, supply chain management has been

successfully used in practice for years and its benefits

shownin weakening risk, reducing uncertainty, timely

response, increasing efficiency, lowering cost and im-

proving financial performance have greatly enhanced

competitive advantages. Reducing carbon emissions

across the entire supply chain and lunching ”carbon

reduce race” between enterprises in the chain can in-

crease reduction opportunities, lower capital invest-

ment and make more cost savings.

2 THE CONNOTATION OF

LOW-CARBON SUPPLY CHAIN

MANAGEMENT

2.1 The Definition of Low-carbon

Supply Chain Management

Carbon footprint of a product is greenhouse gases

497

Li J., Xu F. and Hua G..

ON LOW-CARBON SUPPLY CHAIN MANAGEMENT.

DOI: 10.5220/0003578204970501

In Proceedings of the 13th International Conference on Enterprise Information Systems (DMLSC-2011), pages 497-501

ISBN: 978-989-8425-55-3

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

emissions over the whole life of a product or service,

from the extraction of raw materials and manufactur-

ing right through to its use and final reuse, recycling

or disposal. It can be seen that the carbon footprint

of a product is throughout its entire supply chain.

Therefore, Low-carbon Supply Chain Management

(LCSCM) can be defined as: consider carbon emis-

sions over the product lifecycle involving raw ma-

terial suppliers, product manufacturers, distributors

and retailers, users and recyclers and make the sup-

ply chain achieve economic benefits while reducing

carbon footprint. Low-carbon supply chain manage-

ment extends the ”carbon management” pattern that

only for a single enterprise or a single plant, inte-

grates multiple enterprises as a joined-up process and

emphasizes the cooperation between upstream and

downstream and the output of low-carbon products.

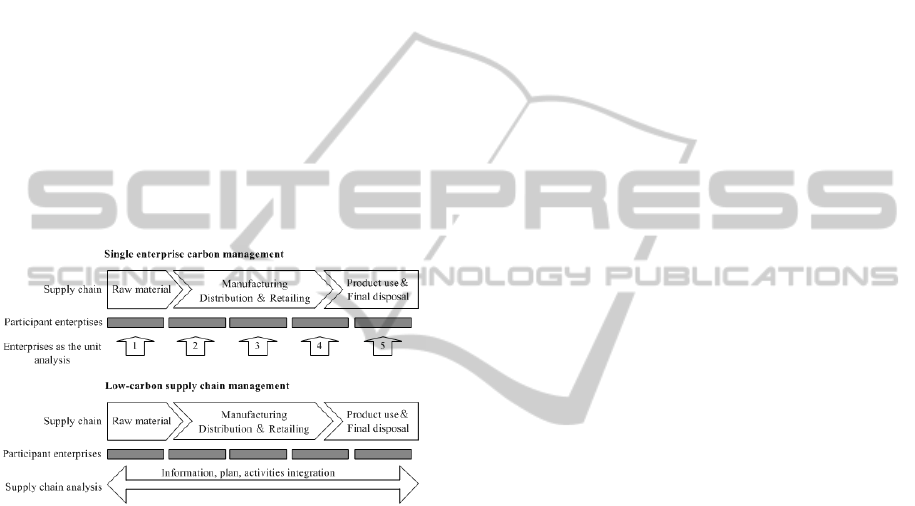

The comparison of ”single enterprise carbon manage-

ment” and ”low-carbon supply chain management” is

shown in figure 1:

Figure 1: Single enterprise carbon management low-carbon

supply chain management.

2.2 The Relationship between

Low-carbon Supply Chain

Management and Green Supply

Chain Management

Low-carbon supply chain management is closely re-

lated to green supply chain management. In 1996, the

Manufacture Research Consortium (MRC) in Michi-

gan State University who had an ”Environmental Re-

sponsible Manufacture” research item then first put

forward the definition of Green Supply Chain Man-

agement (GSCM). As a modern management pattern,

the GSCM, based on the theory of green manufactur-

ing and supply chain management technologies, con-

siders environmental impact and resource efficiency

in the chain, covers suppliers, manufacturers, sellers

and customers and is to minimize the negative impact

on environment and maximize the resource efficiency

in the process of raw material sourcing, manufactur-

ing, packaging, warehousing, transport, use and final

disposal (Dan and Liu, 2000) . GSCM is an impor-

tant means that can improve environmental efficiency

and achieve a coordinated development of economy

and environment. Nevertheless, LCSCM is to address

the greenhouse gases which cause global warming,

to reduce the carbon footprint of products and finally

to mitigate the environmental impact of greenhouse

gases by improving energy efficiency, developing al-

ternative energy sources, new energy and emissions

reduction technology. Low-carbon is a global prob-

lem and is to response to climate change, while the

starting point of green concept is the industrial pollu-

tants bring the damage to people’s health and our liv-

ing conditions, until now, no country except US has

regulated greenhouse gases as pollutants. LCSCM is

not quite consistent with GSCM, although with simi-

larity in energy saving, the former is to reduce green-

house gases emission but the latter is to reduce pollu-

tants emission including solid pollutants, liquid pol-

lutants and gaseous pollutants, so it needs integrating

greenhouse gases emission control into the air pol-

lution prevention. Green supply chain management

research has made a great development and the cor-

responding theories and methods for GSCM have a

reference value to LCSCM.

3 THE IMPLEMENTATION OF

LOW-CARBON SUPPLY CHAIN

MANAGEMENT

Reducing carbon emissions from supply chain per-

spective and integrating ”carbon management” with

supply chain management together can achieve more,

faster, better, cheaper effect. Enterprises that plan

to implement low-carbon supply chain management

need to reintegrate their supply chain.

3.1 The Benefits of Low-carbon Supply

Chain Management

A McKinsey study 2008 shows that about 40 to 60

percent total carbon footprints reside upstream in their

supply chains-from raw materials, transport, packag-

ing to energy consumed in manufacturing processes

for high-tech companies and manufacturing indus-

tries,while reaching 80 percent in retailing (Mckins-

eyCompany, 2008) , therefore, any significant carbon-

abatement activities will require collaboration with

supply chain partners. Considering all stages of sup-

ply chain and implementing low-carbon supply chain

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

498

management can avoid counter-productive trade-offs

between supply chain stages and improve the overall

carbon of the supply chain.

In terms of corporate citizenship or corporate so-

cial responsibility (CSR), many world leading busi-

nesses with global operations have been committed to

reduce emissions on their supply chains and achieved

great results. Wal-mart has been dedicating to create

a more transparent supply chain, drive product inno-

vation and ultimately provide his customers with in-

formation they need to assess products’ sustainabil-

ity by developing the sustainability index. The com-

pany’s Sustainable Value Networks helped reduce

carbon emissions through partnerships that extend be-

yond Wal-Mart’s walls to include collaboration from

nonprofits, suppliers, and other environmental stake-

holders spanning from governmental officials to aca-

demics and finally produced up to 30 percent fewer

greenhouse gas (GHG) emissions by 2009 globally

(Wal-mart, 2010) . According to Business for Innova-

tion climate & Energy Policy(BICEP, BICEP Mem-

bers), World famous company Nike has been focused

on reducing its environmental footprint for well over

a decade, in addition to measuring the company’s en-

tire carbondioxide footprint, it also measures its prod-

uct footprint. It estimates the embedded carbon in its

products to be equal to 2.5 times the carbon emitted

by the footwear factories making the products, a con-

clusion which led the company to consider alternative

materials in the design process. Given that the trans-

port operations which move Nike product from the

point of manufacturing to the distribution centers ac-

count for about 25 percent of Nike’s CO2 emissions,

the company has set a target to reduce the inbound lo-

gistics footprint by 30 percent from a 2003 baseline

by 2020.

3.2 The Difficulties of Low-carbon

Supply Chain Management

Implementation

The implementation of low carbon supply chain man-

agement will face significant obstacles:

(1) Awareness side: Now many companies have

not realized the impact of climate change on their fu-

ture development. A Mckinsey survey of more than

2000 global executives finds that while nearly half of

respondents say that climate change is a somewhat

or very important issue to consider in purchasing and

supply chain management, fewer than one-quarter re-

port their companies always or frequently take cli-

mate change into consideration. In addition, some

companies can not afford the upfront investment in

emission reduction. Thus, it is not easy to reach a

consensus on emission reduction issue for enterprises

in supply chain.

(2) Action side: It will take a course to put low-

carbon supply chain management into practice. On

one hand, imperfect market and agent problem can be

significant barriers to embody LCSCM. On the other

hand, LCSCM that need a strategic reintegration on

traditional supply chain will touch on the interests of

some stakeholders. The partner selection and Logis-

tics Network Configuration in the re-design of supply

chain structure will undoubtedly affect the stable op-

eration of current supply chain. Furthermore, it will

become more complex in LCSCM globally optimiza-

tion problem considering both economic and environ-

mental factors. So to speak, it should be a big job

to build low-carbon supply chain for most decision-

makers.

(3) Legislation and policy: In the past two

decades, global commerce has come to depend on an

intricate web of supply chains. On the issue of cli-

mate change, Annex I countries commit themselves

to a reduction of greenhouse gases, while Non-Annex

I countries are not obligated by the limits of emis-

sions in the Kyoto Protocol, moreover, national poli-

cies and standards made by different countries differ-

ing with each other will ultimately pose a challenge to

the concept and objective integrating for global sup-

ply chains.

3.3 The Key Points of Low-carbon

Supply Chain Management

Implementation

By analyzing the difficulties of implementing low-

carbon supply chain above, some proposals are pro-

vided with the theory of supply chain management as

follows:

3.3.1 Playing the Leading Role of Core

Enterprise and Adopting Low-carbon

Concept

Most of the supply chains are built around core enter-

prises and core enterprises play a significant part in

the process of reengineering low-carbon idea. Core

enterprises should have a sight into what LCSCM

could lead in the direction of future competition, es-

tablish low-carbon idea and vigorously promote low-

carbon activities to make other partners understand

the low-carbon connotation, the necessities and possi-

bilities to implement low-carbon and the benefits of-

fered by strengthening ”carbon management” such as

risk avoidance of public policies and cost saving, etc .

ON LOW-CARBON SUPPLY CHAIN MANAGEMENT

499

3.3.2 Emphasizing Cooperation between

Enterprises in the Chain

LCSCM is based on cooperation, not only requiring

all enterprises to take effective measures respectively

such as staff training, energy efficiency and prod-

uct process improvement, etc, but much more impor-

tantly, building on ”carbon management” across the

supply chain. Strengthened cooperation between en-

terprises in the chain can attain greater abatement op-

portunities and create larger profit space.

(1) Sharing information and knowledge, devel-

oping strategies together. Enterprises should ex-

pand companies’ borders, incorporate other part-

ners in the chain and make joint efforts to explore

means to minimizing emission by strengthening inter-

communication and exchanging views on environ-

mental issues and actions to be taken. For example,

sharing the information of products carbon footprint

that can be get by measuring carbonemitted by supply

chain stages can help enterprises understand carbon

emission condition of their own and the entire sup-

ply chain, can help identify the main emission source

which can also be interpreted as emission reduction

opportunities and then make carbon reduction strate-

gies by weighing the costs and opportunities, and

can help make a reasonable decision on the questions

of product development, procurement, manufacturing

and distribution.

(2) Developing emission trading between enter-

prises along the supply chains. According to emis-

sion trading, companies that exceed the emission cap

allocated by a central authority can buy credits from

companies who require fewer permits to meet their

increases in emission permits. Due to the good long-

term cooperation relations, emission trading between

enterprises in the supply chain can help to reduce

transaction cost and lower risk.

3.3.3 Considering the Cost of Carbon in Supply

Chain Optimization

Price for carbon has become a reality, or through car-

bon taxes or carbon trading. As an important impact

factor in the total cost of any product, it requires com-

panies to consider the cost of carbon as a key per-

formance indicator. Except for applying theories and

methods of modern supply chain management such

as inventory control, supply contracts, distribution

strategies, the cost of carbon and the risk of volatile

carbon price should be taken into account in supply

chain integration and optimization.

3.3.4 Life Cycle Assessment Method

According to the ISO 14040 and 14044 standards, as

one of the methods being developed, LCA (life cycle

assessment) addresses environmental aspects and po-

tential environmental impacts throughout a product’s

life cycle from raw material acquisition through pro-

duction, use, end-of-life treatment, recycling and final

disposal, i.e. cradle-to-grave. LCA Method can also

be used to analyze carbon emission at various points

in low-carbon supply chain which will help to con-

struct the carbon footprint, identify emission reduc-

tion opportunities and support ongoing implementa-

tion steps.

4 THE EFFECT ON

LOW-CARBON SUPPLY CHAIN

MANAGEMENT OF

GOVERNMENT POLICIES

Strengthening cooperation and making joint efforts

between enterprises across the supply chain will be

important, but government involvement must be more

critical to put LCSCM into effect. Various coun-

tries in the world have already set reduction targets

by participating in controlling emission with a posi-

tive stance and fulfilled it concretely to development

strategies and policies, the EU, for example, who has

set a target that 2020 emission level should be 20to

do still, we make the following recommendations in

order for LCSCM to be effective.

(1) Making carbon emission as one of the crite-

ria in the government and public sector procurement

which will guide companies’ management idea.

(2) Making international worldwide carbon emis-

sion measurement standards to avoid divergence and

emission reduction failure.

(3) Advancing product carbon footprint label and

product carbon levels standards of different industries

at different development stages to motivate compa-

nies to control carbon emission and meanwhile enable

customers to identify low-carbon products.

(4) Providing consistent subsidies for low- or no-

carbon alternatives and penalties for high consump-

tion and high emission to encourage companies in

emission reduction.

(5) Other incentives, for example, investing IT in-

frastructure and transportation networks.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

500

5 CONCLUSIONS

Global warming has seriously threatened to hu-

man survival and development and mitigating global

warming is a matter that admits of no delay for

mankind. Low-carbon choices are the future develop-

ing tendency and enterprises can implement LCSCM

to cost-effectively abate greenhouse gases emission

through cooperation with other partners in the chain.

It is worth noting that, the successful operation of

LCSCM largely depends upon the common efforts of

government sector and enterprises sector, therefore,

in addition to the strategic and operational decisions

enterprises can take with respect to their own sup-

ply chains, engaging in public policy frameworks is

significant for both stabilizing the global climate and

staying credible.

REFERENCES

CarbonTrust (2006). In The carbon emissions generated in

all that we consume.

Dan, B. and Liu, F. (2000). In Research on green supply

chain and its architecture. Chinese Mechanical engi-

neering.

MckinseyCompany (2008). In Climate change and supply

chain management.

Wal-mart (2010). In Wal-mart Global Sustainability Report

2010 Progress Update.

WRI and A.T.Kearney (2008). In Rattling supply chain.

ON LOW-CARBON SUPPLY CHAIN MANAGEMENT

501