LOGISTICS OPERATION SIMULATION IN BEIJING

OLYMPIC GAMES STADIUM

Xiaochun Lu and Zheng Ni

School of Economics and Management, Beijing Jiaotong University, Beijing, China

Financial Department, Ministry of Railways, Beijing, China

Keywords: The 29th Olympic Games, Sports stadium, Logistics optimization, Simulation.

Abstract: In 2008, the 29th Olympic Games was held successfully in Beijing. It was the largest scale games in the

history, and achieved amazing results. The experience of the Olympic Games is worth to summary. Statics

and analyse of logistics operation volumes in an Olympic Games stadium are made in this paper. A

simulation model about stadium logistics system based on discrete event is developed by using Anylogic

software. With the simulation model, the logistics resource dispatching is discussed. We find logistics

coefficient that 3.2 order sheets for a fork truck and 1.6 orders sheets for a worker are proper burden. These

coefficient could help us to plan logistics resources readily. The paper is useful for us to improve logistics

system in a stadium.

1 INTRODUCTION

In 2008, the 29th Olympic Games were held in

Beijing. High level logistics service of the Olympic

Games was required. The sports equipments,

grocery and other things for competition were

delivered by logistics system. The well done

logistics system ensured the sports games carried on

smoothly. It proves that the logistics system of

Beijing Olympic Games could run smoothly.

As the uncertainty of the transportation in

Beijing, it was difficult for logistics system to be run

accurately, effectively and quickly. It is very useful

to study logistics system operation in Beijing. In this

paper, the simulation model is developed to

investigate the logistics operation in a stadium. It

can help us to understand how to make logistics run

better in sports games.

2 REVIEW ON OLYMPIC GAMES

LOGISTICS SYSTEM

STUDYING

The issues of communication and information

system on Olympic Games were discussed in many

theses. But fewer people have studied Olympic

Games logistics thoroughly. Some papers have

reviewed logistics of Atlanta Olympic Games and

Sydney Olympic Games logistics.

John Mascaritolo (1996) introduced the function

of logistics department of Atlanta Organizing

Committee for the Olympic Games. The challenge

and problems occurred in Atlanta Olympic Games

were illustrated in his paper as well.

Trunick (2004) summarized the Olympic Games

logistics organization of Sydney. In his report the

various logistics problems, such as the problems of

international logistics, the information technology

application, and the cargo transportation during the

Olympic Games held were put forward.

Ioannis (2006)

wrote a paper focused on the

design of the organization, processes, and systems of

Olympic logistics. In his paper, a systematic

methodology has been developed to design the

strategy and tactics of logistics operations for the

Athens 2004 Olympic Games. It is the first time that

a systematic view of Olympic logistics is dealt with,

as opposed to experiential knowledge with local

applicability that has been used in the past to plan

similar operations.

In China, the studying on Olympic logistics

became hotter after Beijing was elected host city for

the 2008 Olympic Games. Most researching

concentrated on such aspects: the logistics market

development, the company’s strategy around

404

Lu X. and Ni Z..

LOGISTICS OPERATION SIMULATION IN BEIJING OLYMPIC GAMES STADIUM.

DOI: 10.5220/0003550404040409

In Proceedings of the 13th International Conference on Enterprise Information Systems (ICEIS-2011), pages 404-409

ISBN: 978-989-8425-55-3

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Olympic, the operation of Olympic logistics and the

Olympic logistics system planning.

Xianliang Shi, Keming Zhang (2003) forecasted

the quantities of delivery, the transportation, the

storage, and the distribution for the Beijing Olympic

Games logistics.

Olympic logistics system will be studied on the

actual operation data in this paper.

3 THE LOGISTICS OPERATION

ANALYSIS OF A BEIJING

OLYMPIC GAMES STADIUM

We have studied the logistics operation in an

Olympic Games stadium. This stadium is divided

into five regions: goods unload area, VOC (Venue

Operation Centre), FOP (Field Of Player), TC

(Temporary Construction), media area, shown as in

Fig.1. The logistics department responded for

service in these regions, and also provided fork

trucks lending for other departments as well. We

have taken statistical analysis of the logistics

operation and have used it in model.

FOP

(Field Of Player)

Warehouse

VOC

(Venue Operation Center)

Unload Area

Media

Area

TC

(Temporary Construction)

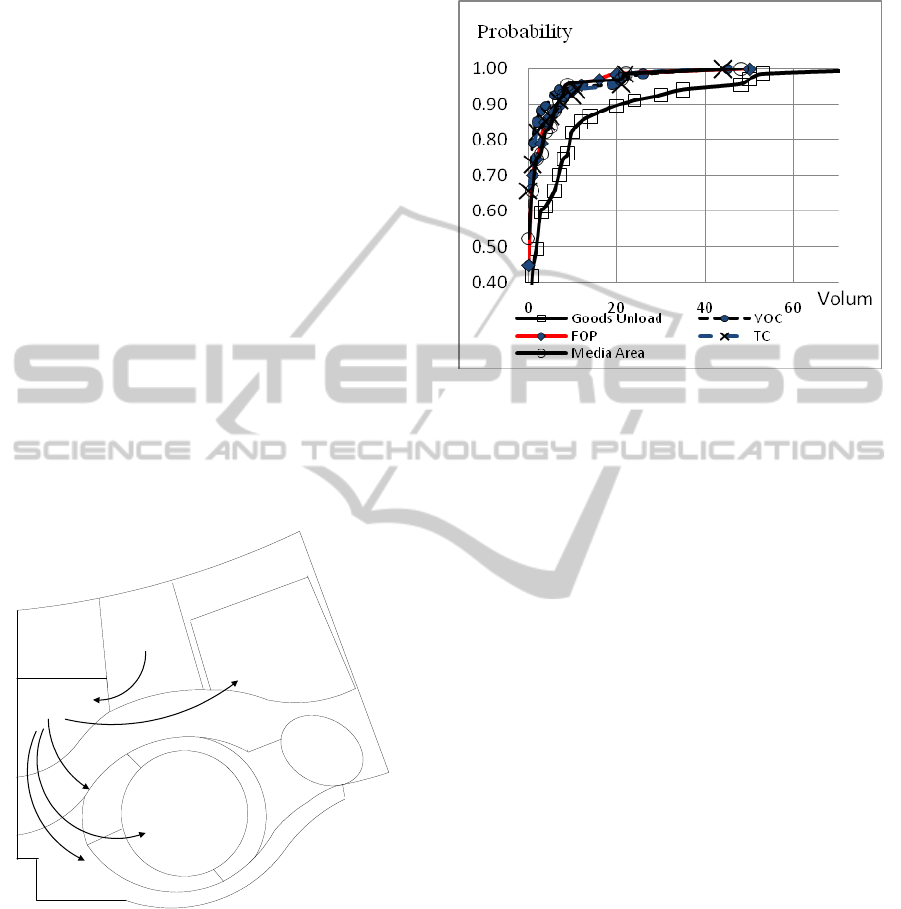

Figure 1: Regions of a Beijing Olympic Games Stadium.

3.1 Operation Volume of Goods

Unload

During the Olympic Games in August 2008, the

goods arriving schedule was changing from time to

time due to the influence of traffic.

According to the operational standards of the

United Parcel Service (UPS), which provided

Olympic Games logistics sevice, we got handling

volumes statistics in each area. It is shown in Fig.2.

It is found that the burden in each region normally is

no more than 10 pieces.

Figure 2: the Probability of the Operating Volume in Each

Region.

3.2 Logistics Operation Time

By analyzing this stadium, we got the operation time

of manual fork trucks, and found that the average

operation time for a fork truck is half an hour. The

variance is about 0.16 hour, meaning operation time

is 0.5 ± 0.16 hour.

In this stadium, the logistics service is mainly

provided to BOCOG (Beijing Organizing

Committee for the Games of the 29th Olympiad) and

sponsors for materials handling. But other

department’s workers often borrowed tools from

logistics department. According to the stipulated

process, other department’s workers should put

forward an application in 24 hours in advance. The

tools borrowed were non-power devices, such as

trolleys, manual fork trucks, etc. When tools were

occupied by other departments, it might cause urgent

task postpone. So it is important to study tools

lending time and frequency. Because fork trucks are

key devices, so we studied fork trucks lending

regular.

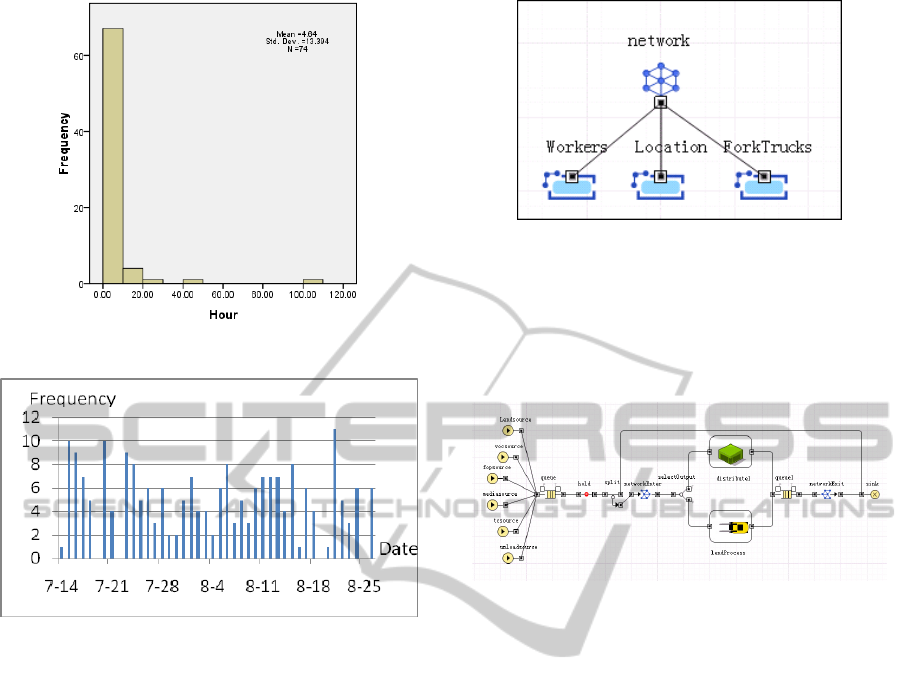

The fork trucks lending time is shown in Fig. 3.

We found that the lending time is about 4.6 hours,

and its standard deviation is 13.4.

We analyzed the frequency of the forklift

lending. It is shown in Fig. 4.

By using the software SPSS, We carried One-

Sample Kolmogorov-Smirnov Test. The frequency

of the forklifts lending obey the

Poisson distribution

(mean λ =5.023), and asymptotic significant (2-

tailed) is 0.784

LOGISTICS OPERATION SIMULATION IN BEIJING OLYMPIC GAMES STADIUM

405

Figure 3: the Lending Time of Forklifts.

Figure 4: the Frequency of Forklifts Lending.

4 THE SIMULATION MODEL

OF LOGISTICS OPERATION

4.1 The Simulation Model

In this paper, we take Anylogic (a simulation

software of XJ technology Company) to establish

the simulation model of logistics operation in the

stadium. The model includes two parts of module:

the resources network module and the logistics

operation module.

In the resources network module, the application

of resources is defined. The process of logistics

service is simulated in the logistics operation

module.

Network objects in Anylogic mainly are used for

maintaining the topological structure and resources

management. There are three kinds resources are

defined in the paper: workers, fork trucks, and the

location. The resources network structure of the

model is shown in Fig. 5.

Figure 5: The Model of Resources Network.

The logistics operation in the stadium is

simulated in this module. The operation process

includes 2 sections: materials receiving and

distribution, the forklifts lending .This model is

shown in Fig. 6.

Figure 6: the Module of Logistics Operation.

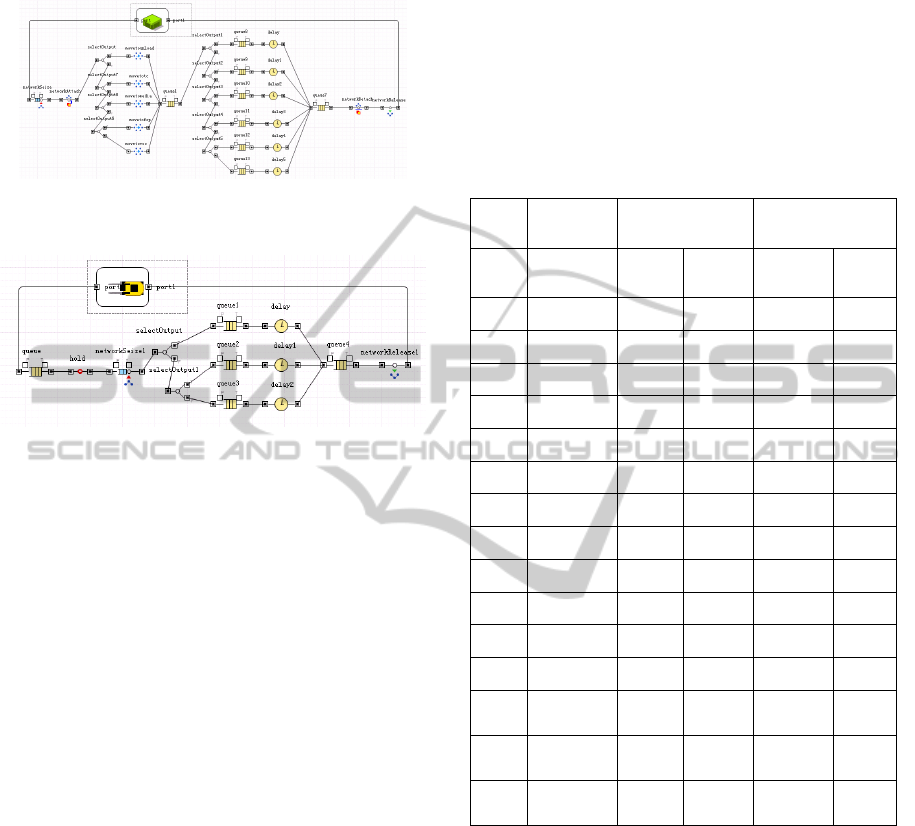

(1)The Module of Material Receiving and

Distribution

In this venue, a work group (fork truck and

worker) could start material handle working when

they got a working-sheet from logistics department.

In our model, the network resources are used to

simulate the materials receiving and distribution.

The module is shown in Fig. 7.

In this model, the waiting tasks in 5 regions and

application of forklifts lending are presented by

queues. But the tasks in 5 regions priority are higher

than the task of forklifts lending.

(2)The Module of Fork Trucks Lending

The amount of fork trucks in this venue is 6. But

these trucks couldn’t be all lend out. If a fork truck

was ideal, the other departments could borrow it.

But if all fork trucks were busy, the other

departments must fill an application form and wait

till a fork truck was ideal.

The fork trucks lending must be treated specially.

So we build a sub-model to deal with the fork trucks

lending. This model is shown in Fig. 8.

When a lending application appears, firstly it

waits in queue to size the resources (shown as the

object of ‘Network Seize1’ in Fig.8). The action is

that a fork truck can be lent only if staffs register it.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

406

So the lending process can be carried when there is a

fork truck is ideal.

Figure 7: the Module of Material Receiving and

Distribution.

Figure 8: the Module of Fork Trucks Lending.

4.2 The Model Parameters

With the consideration of the actual situation in the

stadium, the model parameters are set as follow:

(1) The working-sheets priority. According to the

actual logistics operation in the stadium, the

working-sheets of materials delivered in should be

given the highest priority. The working-sheets of

materials distribution were given a normal priority.

The working-sheets of lending forklifts were given

the lowest priority. When the staffs were busy in

working with receiving goods or distributing goods,

the forklifts must be provided for them and forklifts

couldn’t be lent out.

(2) The resources occupancy. In accordance with the

logistics service standards, when a forklift was in

operating state, an operation occupies three workers

and a truck.

(3) The simulation length. In this model, the

simulation time is set as minute. A working day is 8

hours. The simulation length is set as 120 working

days.

(4) The number of workers. In this stadium, 11

workers were working for logistics department and

the number of forklifts was 6.

5 SIMULATION RESULT

ANALYSIS

In this paper, the model has been simulated for ten

times. The forklift lending, material receiving and

distribution results has been analyzed. It is shown in

table 1. The simulation result shows data in the

range of 95% confidence.

Table 1: the Simulation Result.

Exp.

Forklifts

Lending

Material Receiving

and Distribution

Resource Utilization

No.

Waiting Time

(hour)

Over-time

Freq.

Operation

(hour)

Workers’

Load Rt.

Forklifts’

Util.

1 0.49 11.7% 3.5 35.3% 30.9%

2 0.46 11.6% 3.0 35.0% 30.3%

3 0.45 11.9% 3.1 32.8% 30.7%

4 0.55 11.4% 3.4 33.6% 31.9%

5 0.52 11.2% 3.2 32.4% 29.7%

6 0.46 11.8% 3.3 33.6% 32.8%

7 0.48 11.8% 3.3 34.1% 29.5%

8 0.54 11.1% 3.8 34.5% 30.6%

9 0.51 11.1% 3.3 31.1% 29.8%

10 0.47 11.4% 3.6 33.3% 30.3%

Mean 0.51 11.5% 3.3 33.0% 30.2%

Variance 0.04 0.3% 0.2 1.3% 1.0%

95%

Conf.

0.03 0.2% 0.2 0.9% 0.7%

Upper

Bound

0.54 11.7% 3.5 33.9% 30.9%

Lower

Bound

0.48 11.3% 3.2 32.1% 29.5%

5.1 Submodel Simulation Results

(1) The model of material receiving and distribution

simulation result.In the case of 11 workers, the

simulation result shows that the time spending on

material receiving and distribution is 3.3 hours. It

means that to carry the material handling usually

needs a half working day. The probability of over-

time work is 11.3%~11.7%(the mean is 11.5%).It

indicates that, when the quantity of material

handling work is quite large, there will be 11.5%

tasks beyond the normal working hours.

By the simulation result, we find that it can meet

the need of work with 11 workers. Actually, due to

the large amount of unexpected tasks before the

LOGISTICS OPERATION SIMULATION IN BEIJING OLYMPIC GAMES STADIUM

407

Olympic Games helding, the staffs of logistics

department often has to work overtime.

(2) Forklifts lending simulation result. Under the

circumstances of 6 forklifts, the simulation result

shows that average waiting probability of trucks

lending is 3.2%. The waiting time of forklifts

lending is about 0.51 hours. It indicates that the

process of trucks lending is relatively smooth. Other

departments can borrow forklifts nearly without

waiting. It can meet the needs of other departments

very well.

5.2 Resources Utilization Optimization

From the simulation results, it is found that there is

room for improvement in the logistics resources

planning in this stadium. There is lot of work to do

on optimizing resources so as to improve resource

utilization rates.

From the simulation result, we find that the load

rate of workers and forklifts utilization are lower.

The load rate of workers is only 33%, their work rate

could be improved.

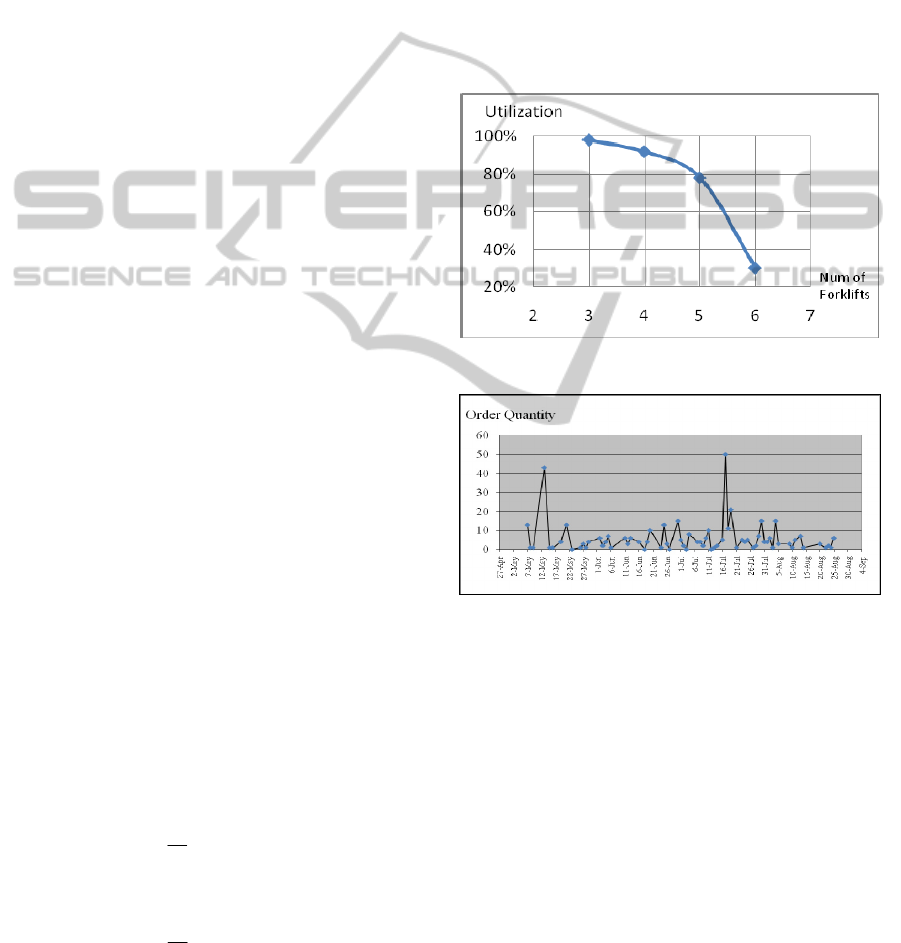

The number of forklifts is 6. In this situation, it

may be considered to streamlining appropriately.

But the utilization of fork trucks is only about 30.2%.

We set the number of fork trucks from 6 to 5. In this

solution, the utilization could be improved to 78%.

The optimization work on forklifts’ utilization

has been made. When the number of forklifts is 4,the

simulation result shows that the utilization of

forklifts is 92%. When the number of forklifts is 3,

the utilization is 98%. The result is shown as Fig.9.

So we think that 5 forklifts are better for this

stadium. The forklifts could be working in a good

state.

We have got received order quantity of this

stadium, which is shown as Fig.10. To this stadium,

order quantity median value is 4 sheets a day. Its

mean value is 6 sheets and stand deviation is 8.

Considering 90% probability, this stadium received

order quantity is under 16 sheets .

So we can get coefficient to determine numbers

of fork trucks and workers in a stadium.

Fork truck coefficient is:

16

3.2

5

=

Worker coefficent is:

16

1.6

10

=

So we think that in this stadium, 3.2 order sheets

for a fork truck and 1.6 sheets for a worker are

proper durden. By using these logistics cofficent, we

can get numbers of fork trucks and workers in a

stadium easily.

6 CONCLUSIONS

The logistics system of this stadium, there is certain

of balance between fork trucks lending services and

material handling. The logistics department's main

task is to receive and delivery material, in order to

maintain the high efficiency of this service, it is

bound to occupy quite a lot of material resources.

Figure 9: Forklifts’ Utilization Optimization.

Figure 10: Received Order Quantity of this Stadium.

Based on the analysis above, this paper considers

that the proportion of workers and fork trucks could

be adjusted. The number of workers can be cut down

to 10 and the fork trucks can be cut down to 5. In the

Olympic stadiums, the configuration ratio of actual

workers and logistics tools is fixed, which is due to

operational efficiency and safety. If we can

flexibility adjusts the amount of forklifts and

workers based on actual situation, the overall

flexibility of the system can be enhanced, which

makes the system efficiency improve. By studying

simulation results, we think that 3.2 order sheets for

a fork truck and 1.6 orders sheets for a worker are

proper burden coefficient. These coefficient could

help us to plan logistics resources readily.

ICEIS 2011 - 13th International Conference on Enterprise Information Systems

408

REFERENCES

Ioannis Minis, Eric Keys, Theodore Athanasopoulos, 2006.

Contribution to the design of the Athletes Bus

Network during the Athens 2004 Olympic Games.

Transportation Research Part A: Policy and Practice.

2006-11, 40(9): 776-791

Ioannis Minis, Marion Paraschi, Apostolos Tzimourtas,

2006. The design of logistics operations for the

Olympic Games. International Journal of Physical

Distribution & Logistics Management. 2006, 36(8):

621 – 642. Emerald Group Publishing Limited

Jinghai Sun, 2004. The Research on Beijing Olympic

Games Organization Based on P-A-C4ISR Theory.

Conference of Sports Science (Chinese). Beijing:

Sports Science,2004:22

John Mascaritolo, 1996. Logistics at the 1996 Olympic

Games. Annual Conference Proceedings, Council of

Logistics Management.OAK BROOK, ILL: 1996.

263-276

Trunick, Perry A, 2004. Going for Logistics Gold:

Apparel maker Roots prepares for the challenge of

outfitting the 2004 Summer Olympics. Logistics

Today. Penton Media, Inc: 2004. Vol 45; Part 3: 25-26.

Xuejun Tian, 2007. Logistics at Beijing Olympic Games:

The opportunity and Challenge. Logistics Technology

(Chinese), 2007(6):8-13

Xianliang Shi, Keming Zhang, 2003. Forecast of Logistics

of Beijing Olympic Games in 2008. Quantitative and

Technical Economics (Chinese). 2003(10):151-154

Zheng Bai, 2005. The studying on Logistics System

Planning of Beijing Olympic Games. Journal of

Chengdu Sports University (Chinese). 2005, 31(6):

18-21

LOGISTICS OPERATION SIMULATION IN BEIJING OLYMPIC GAMES STADIUM

409