AN OPTIMAL ADMITTANCE REACTIVE FORCE CONTROL FOR

COOPERATIVE ROBOT GRASPING TASKS

A. Rodriguez-Angeles, R. de J. Portillo-Velez and C. A. Cruz-Villar

Center for Research and Advanced Studies, CINVESTAV-IPN

Av. Instituto Politecnico Nacional No. 2508, Col. San Pedro Zacatenco, C.P. 07360, Mexico City, D.F., Mexico

Keywords:

Admittance, Optimization, Interaction, Grasping, Cooperation.

Abstract:

In this article it is proposed an optimal admittance algorithm that controls the position of the end effectors in

cooperative robot systems or fingers, in case of robotic hands, reactively according to on-line force sensory

data. The method is free of in-depth models or sophisticated external sensors. The sensors used are simple and

provide only limited and immediate information, nonetheless they allow to reactively correct the applied force

to guarantee object stable grasp. Force sensory information is used to determine modification of the desired

movement of the robots at a cooperative system, so that ultimately the applied force to guarantee a stable

object grasp is achieved. The proposed optimization algorithm uses force error at each robot as a correction

factor when calculating a modified Cartesian desired trajectory, thus it results on real time reactive motion

planning. The novelty of the proposed algorithm is that the adaptive admittance controller is obtained as the

solution of a dynamic optimization problem which is solved via the standard gradient flow approach. The

proposed methodology considers grasps and fixtures whose contacts react according to force displacement

laws consistent with friction constraints at the contact points. It is only assumed that each robot end effector is

capable of generating its own linear force displacement. Experimental results show that the proposed controller

is robust against environmental stiffness uncertainties and its variations, as well as object position uncertainty,

as far as an initial contact between the robots and the object is guaranteed.

1 INTRODUCTION

Traditionally, robot control uses either position con-

trol or force control (or a combination of both modes).

In contrast, intuitive control also considers the actual

task to be performed (Pratt and Pratt, 1998; Duchaine

and Gosselin, 2009); this leads to a disappearing of

the former strict distinction between planning, reac-

tive planning and reactive control. Combining reac-

tive, stimulus-response control with cognitive, pre-

planned behavior government, results in robust, flexi-

ble, autonomous, real-time robot control (Yigit et al.,

2003).

A reactive algorithm means a simple algorithmic

scheme where robot sensors determine immediately

the actions of the actuators. However, note that the ac-

tuators themselves may interact with the sensors (e.g.

by moving them or occluding them, etc.) to close a

feedback loop and thus cause further goal-driven as

well as corrective actions, (Teichmann and Mishra,

2000). Reactive systems present the features of liv-

ing entities such as real time response, robustness and

ability to exploit the environment. Reactive architec-

tures rely on the stimulus-response principle. It con-

sists in rules defining the actions/behaviors which can

be released following the perceived state of the envi-

ronment (Simonin, 2006). Reactiveness is relevant for

autonomous cooperative tasks such as spatial coordi-

nation and grasping. However, considering industrial

applications, some drawbacks must be reported (Si-

monin, 2006): 1.- strong dependence to perception

(quality and nature of percepts); 2.- sensors perturba-

tions due to environmental conditions (changes); 3.-

internal parameters such as weights for actions selec-

tion may be difficult to define (can need a learning

process).

Dexterous manipulation and grasping commonly

assume an accurate model of the object to be grasped

and, from such a model, an off-line geometric algo-

rithm determines a set of grip points, where the end

effectors or fingers are then placed. Over the last

years, several approaches have been proposed to the

problem of grasp determination, many of them based

on predefined models of objects or requiring expen-

sive computation, e.g. (Sanz et al., 1999; Roa and

Suarez, 2009).

50

Portillo-Velez R., Rodriguez-Angeles A. and A. Cruz-villar C..

AN OPTIMAL ADMITTANCE REACTIVE FORCE CONTROL FOR COOPERATIVE ROBOT GRASPING TASKS.

DOI: 10.5220/0003536600500058

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 50-58

ISBN: 978-989-8425-75-1

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

The pre-planned grasp analyses the object to be

grasped and decides where the contacts should be

placed before any action is carried out. The grasp

selection (or grasp planning) task can be broadly de-

fined as follows: given an object to be acquired us-

ing a grasping system, find a combination of posture

and position relative to the object that results in a sta-

ble grasp that is likely to resist expected perturbations

(Shapiro et al., 2010).

Typically, once the grip points have been deter-

mined, the geometry of the object is deemed irrele-

vant and the grasp is determined and maintained by

only controlling the magnitudes of the forces at the

grip points. This approach has provided a clear and

deep understanding of stable grasp, how their exis-

tence depends on the nature of contact and the physi-

cal complexity of grasping, and so on. Nevertheless,

this approach has proved to be less useful in practice,

as obtaining an accurate model of the object might not

be feasible, the exact location of the object might not

be available, poor robot repeatability, or imprecise in-

verse kinematics, see (Teichmann and Mishra, 2000;

Vahrenkamp et al., 2008).

Here the proposed approach is motivated by ordi-

nary human−human interactions. As the awareness

of a person of the motion of another person allows

for a mental prediction of the future motion and pre-

ventive action, including such an ability in the con-

trol strategy of an interactive robot can significantly

improve its effectiveness toward cooperative and col-

laborative tasks. Our results show that in cooperative

robot grasping, reactive force control can correct for a

fair amount of uncertainty on the object position and

its stiffness, which results on real time motion plan-

ning. Based on the measured robot-object interaction

force, our algorithm locally modifies a nominal path

so to achieve the desired contact force, in more so-

phisticated strictly cooperating tasks, to reach the cor-

rect rendezvous between the robot end-effector and,

say, the object, to guarantee a stable grasp.

Several reactive motion planning approaches ex-

ist in this context, mostly based on artificial poten-

tial fields and their algorithmic or heuristic (Khatib,

1986; Brock and Khatib, 2002; Santis et al., 2008).

Another method considers the on−line generation of

the Cartesian path of multiple control points on the

manipulator. Alternatively, the so called admittance

control has been also used for reactive planning, such

that it modifies the robot trajectory in order to achieve

some desired force at some direction (Santis et al.,

2006). Despite of the success and simplicity of the

admittance approach, most of the proposed solutions

require a priori knowledge of robot and/or the object

dynamics, which limits their potential applications

(Teichmann and Mishra, 2000; Hsiao et al., 2010).

Furthermore, some factors as geometric uncer-

tainty may lead to excessive forces (Chiaverini et al.,

1999), which possibly overcome safety by causing

damage to the robot structure or the object. Thus,

adaptation schemes are chosen as an alternative so-

lution to deal with uncertainty and to guarantee safe

robot-object interaction. Nevertheless, when adapta-

tion approaches are considered most of the times di-

rect force measurement is needed. These schemes are

referred as direct or explicit methods (Colbaugh and

Glass, 1997; Seraji and Colbaugh, 1997). Other meth-

ods use estimates of the parameters of the robot and/or

the object. Such methods are denominated indirect

or implicit methods (Seraji, 1998; Jung et al., 2001).

The methods described above have been proved to

be effective, nonetheless they require a considerable

amount of computations.

In this paper, an optimal admittance controller is

proposed to ensure the desired pre-planned applied

force to guarantee a stable object grasp by a coopera-

tive robot system. The novelty of the proposed algo-

rithm is that the admittance controller is obtained as

the solution of a dynamic optimization problem which

is solved via the standard gradient flow. The optimiza-

tion problem considers the force error tracking and its

time derivative. It is important to highlight the simple

structure of the proposed admittance controller. The

reference trajectory of each robot at the cooperative

system is computed very fast, yielding on-line reac-

tive motion planning of the robots end-effector tra-

jectory to uncertain forces, which may arise during

object interaction. This fast adaptation results in safe

robot-object interaction by guaranteeing application

of the desired pre-planned grasping interaction force.

On the other side, it is well known that it is not advis-

able to use the force error time derivative, because it

is a highly noisy signal. However, the proposed ap-

proach allows to manage signals with noise, thanks to

the filtering properties of the time integration, which

is used because of the gradient flow approach.

2 COOPERATIVE ROBOT

SYSTEM

The problem faced in this papers reads as follows: to

design an optimal admittance controller to perform

stable robot-object grasping by a cooperative robot

system in a reactive framework.

It is important to highlight that the compliance ap-

proach to robot force control is used, which can be

viewed as unconstrained motion control. Thus, all

control methods for unconstrained motion, such as

AN OPTIMAL ADMITTANCE REACTIVE FORCE CONTROL FOR COOPERATIVE ROBOT GRASPING TASKS

51

PID control, sliding mode control and model based

control, can be used.

First the robots and object models related to the

proposed approach are introduced. It is assumed fully

actuated robots whose working space cover the re-

quirements for the Cartesian task (grasping).

2.1 Kinematic Model

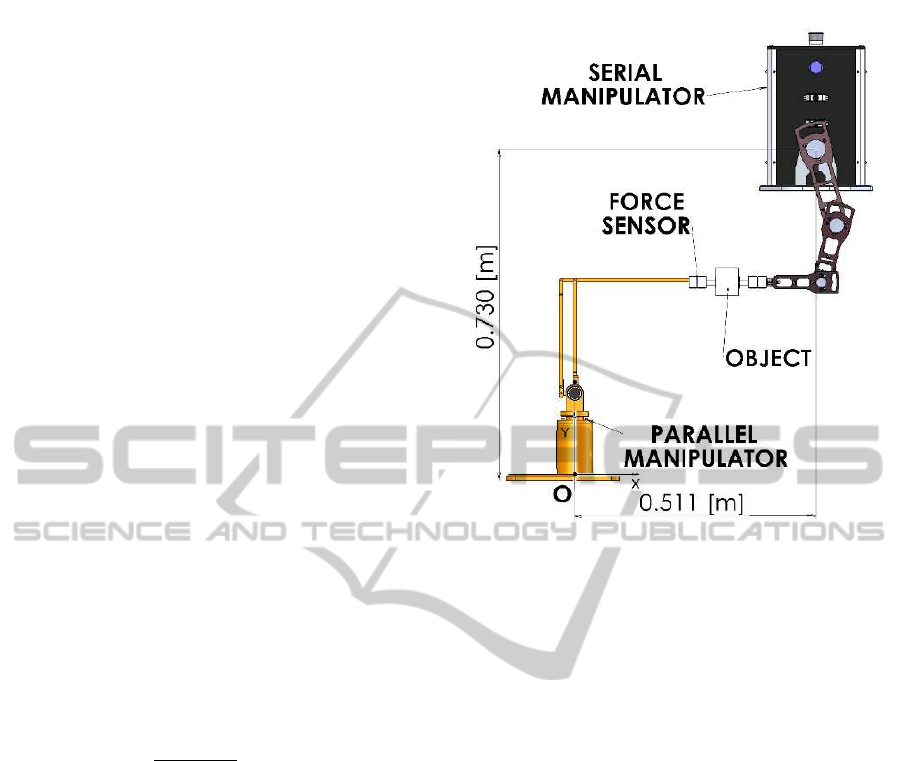

Consider n

i

-joint fully actuated rigid robots, non nec-

essarily identical, where i = 1,.., p identifies the p

robots which conform the cooperative system, see

Figure 1. The robot joint variables are denoted by

q

i

∈ ℜ

n

i

. In general terms, the direct kinematics re-

lates the joint variables, q

i

, and the i− th robot end-

effector Cartesian variables, X

i

∈ ℜ

m

i

, all of them

with respect to a general Coordinate system. It is con-

sidered that the Cartesian working space dimension

m

i

of each robot is at least equal to the task working

space T

s

, i.e. T

s

≤ m

i

∀i = 1,..., p, such that it guaran-

tees that all robots might execute the Cartesian task.

The direct kinematic model of the i−th robot ma-

nipulator can be expressed as

X

i

= F

DK,i

(q

i

) (1)

To fully relate the joint and Cartesian spaces of

the i− th robot manipulator, it is required to establish

a relation among robot joint velocities,

˙

q

i

∈ ℜ

n

i

, and

the i−th end-effector Cartesian velocities,

˙

X

i

∈ ℜ

m

i

.

For this, it is considered the robot Jacobian as follows

J

i

(q

i

) =

∂F

DK,i

(q

i

)

∂q

i

∈ ℜ

m

i

×n

i

(2)

2.2 Dynamic Model

Applying the Euler-Lagrange formalism, the joint

space dynamic model of the i − th robot manipulator

is given by

M

i

(q

i

)

¨

q

i

+C

i

(q

i

,

˙

q

i

)

˙

q

i

+ F

c,i

˙

q

i

+ G

i

(q

i

) = τ

i

+ J

T

i

(q

i

)F

i

(3)

where M

i

(q

i

) ∈ ℜ

n

i

×n

i

is the symmetric, positive-

definite inertia matrix, G

i

(q

i

) ∈ ℜ

n

i

, denotes the vec-

tor of gravity forces, F

c,i

˙

q

i

∈ ℜ

n

i

, is the viscous fric-

tion effects, with F

c,i

a diagonal matrix containing the

viscous friction coefficients of the i − th robot ma-

nipulator joints. The vector,C

i

(q

i

,

˙

q

i

)

˙

q

i

∈ ℜ

n

i

, repre-

sents the Coriolis and centrifugal forces and the vec-

tor of input torques for the i − th robot manipulator

is τ

i

∈ ℜ

n

i

. The vector F

i

∈ ℜ

m

i

represents the i− th

robot-object interaction force.

Figure 1: Cooperative system.

2.3 Robot-object Interaction Force

Typically, the object reaction force model is repre-

sented as a simple linear spring. Hence the i − th

robot-object interaction force depends on its end ef-

fector Cartesian position related to the object position

at the contact point, and it is given by

F

i

= K

o,i

(X

i

− X

o,i

) if X

i

≥ X

o,i

(4)

where K

o,i

∈ ℜ

m

i

×m

i

represents the stiffness at the

contact point between the i − th robot end effector,

or the force sensor in case it is mounted at the end ef-

fector, and the object. X

o,i

∈ ℜ

m

i

is the position of the

undeformed object at the i−th contact point. Notice

that the dimension of the task space T

s

is adjusted to

the dimension of the i− th robot working space m

i

.

This is to establish a proper relation among the differ-

ent working spaces.

2.4 Contact Point Impedance Model

The objective of the impedance control is to establish

a dynamic relation or constraint between the i − th

end-effector position, X

i

, and the object interaction

force F

i

. This relationship can be imposed by either

impedance or admittance. In the impedance relation-

ship, the i−th robot reacts to deviations from its com-

manded end-effector trajectory by generating forces.

Typically no force sensing is required for this. In the

admittance relationship, the measured end-effector

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

52

force is used to modify the robot end-effector trajec-

tory in order to achieve a desired force. In this pa-

per the admittance approach is considered, (Schutter

et al., 1998). When the i− th robot is in closed loop

with a motion controller, the desired Cartesian i−th

end-effector robot impedance might be modeled as

follows (Seraji and Colbaugh, 1997)

M

i

¨

X

i

+ C

i

˙

X

i

+ K

i

(X

i

− X

r,i

) = E

i

(t) (5)

where M

i

, C

i

and K

i

are, respectively, m

i

× m

i

diag-

onal mass, damping and stiffness matrices of the de-

sired impedance for the i − th robot - object contact

point. The diagonal structure of the matrices ensures

that each Cartesian degree of freedom is independent

from each other. The vector E

i

(t) = F

r,i

− F

i

∈ ℜ

m

i

is the force tracking error, and F

r,i

∈ ℜ

m

i

is the de-

sired force interaction for the i−th robot, which is ob-

tained from a pre-planned grasp determination prob-

lem looking to guarantee safe grasping; X

r,i

∈ ℜ

m

i

is

the reference end-effector position with which the de-

sired impedance relationship, (5), is obtained. The

i− th reference end-effector position X

r,i

will be ob-

tained reactively based on measurement of the i− th

force interaction F

i

by solving an on-line optimization

problem.

From equation (5), it can be shown (Seraji and

Colbaugh, 1997) that if F

r,i

is constant, and if the ref-

erence position X

r,i

is chosen such that X

r,i

= X

o,i

+

K

−1

o,i

F

r,i

it holds that

lim

t→∞

E

i

(t) = 0 (6)

thus, force tracking at the i − th contact point is

achieved. However, in general, we are not able to

know accurately a priori neither the position of the

object, X

o,i

, nor the stiffness, K

o,i

. Then, situa-

tions which involve uncertainty, may lead to exces-

sive forces which may cause damage to the robot or

the object, or insufficient forces to guarantee a stable

grasp.

3 OPTIMAL ADMITANCE

CONTROLLER

As stated above, safety of the i − th robot-object in-

teraction can be violated by excessive or insufficient

interaction forces. Moreover, if the object position is

continuously changing, then uncertainty at the i− th

contact point, X

o,i

, and/or object stiffness, K

o,i

, might

be considered. Thus the challenge is to on-line com-

pute a proper reference trajectory X

r,i

which yields the

desired impedance behavior among the i − th robot

and the object at the contact point (5).

For this, an optimization problem is formulated.

To deal with on-line solutions to optimization prob-

lems, there are few admissible approaches. In this pa-

per, a dynamic optimization problem is on-line solved

by using the gradient flow approach, see (Helmke and

Moore, 1996).

The proposed admittance optimization controller

results on independent controllers for each robot at

the cooperative system. The interaction among the

robots is due to the resulting force at the object, due

to the interaction force of all the robots. Thus the pro-

posed controller resembles ordinary human−human

interactions in a reactive manner, since the interaction

among the robots results from the robot - object inter-

action force measurement.

3.1 Optimization Problem

The optimization problem considers an objective

function for each contact point, I

i

∈ ℜ, related to the

contact point force error, E

i

(t), and its time derivative,

˙

E

i

(t). The optimization problem reads as follows

min

X

r,i

∈ℜ

m

i

I

i

=

1

2

E

i

+ α

i

˙

E

i

T

E

i

+ α

˙

E

i

(7)

where, α

i

∈ ℜ, is a positive gain which weights the

time derivativeof the i−th force error. Now, consider

the gradient flow

˙

X

r,i

= −γ

i

∂I

i

∂X

r,i

(8)

were, γ

i

∈ ℜ

m

i

×m

i

, is a positive definite diagonal ma-

trix of gains related to the convergence properties of

the gradient flow.

Considering the diagonal structure of

M

i

, C

i

and K

i

in (5), as well as vectors

E

i

(t)+ α

i

˙

E

i

(t)

T

= [(e

i,1

+ α˙e

i,1

) ··· (e

i,m

+ α˙e

i,m

)],

and X

r,i

= [X

r,i

1

··· X

r,i

m

], the gradient

∂I

i

∂X

r,i

is given

by

∂I

i

∂X

r,i

= −K

i

E

i

(t)+ α

˙

E

i

(t)

(9)

Which shows that the Cartesian reference trajectory is

independently generated for each end-effector Carte-

sian degree of freedom of the i−th robot, i.e. position

an orientation reference trajectories are uncoupled for

each robot at the cooperative system, as well as for

their own Cartesian degrees of freedom. From equa-

tions (8) and (9), the i−th Cartesian reference trajec-

tory is computed as follows

X

r,i

= γ

i

K

i

Z

t

0

E

i

(t)+ α

˙

E

i

(t)

dt (10)

Uncertainties at the i−th contact point diagonal stiff-

ness matrix, K

i

, are absorbed by the diagonal gain

AN OPTIMAL ADMITTANCE REACTIVE FORCE CONTROL FOR COOPERATIVE ROBOT GRASPING TASKS

53

matrix, γ

i

, since at the end their product can be seen as

a gain which regulates the gradient flow convergence.

Notice that the proposed optimization index (7)

might include barrier functions for considering per-

formance constraints such as bounded interaction

force, geometric constraints, etc., thus increasing the

potential of the proposed approach. In the uncon-

strained case the proposed approach yields equation

(10), which might be interpreted as a PI control based

on force interaction error E

i

, similar to the controller

proposed in (Chiaverini and Sciavicco, 1993).

3.2 Object Interaction Control Scheme

The idea of the admittance controller is to modify the

desired position of the i−th robot end-effector trajec-

tory, X

d,i

∈ ℜ

m

i

, in order to achieve the desired robot-

object interaction force F

r,i

. The i − th desired robot

end-effector trajectory, X

d,i

, is the ideal robot end-

effector trajectory, which should be commanded to

the motion controller if no uncertainties on object po-

sition or its stiffness are considered. Thus, the imple-

mentation of the admittance controller is performed

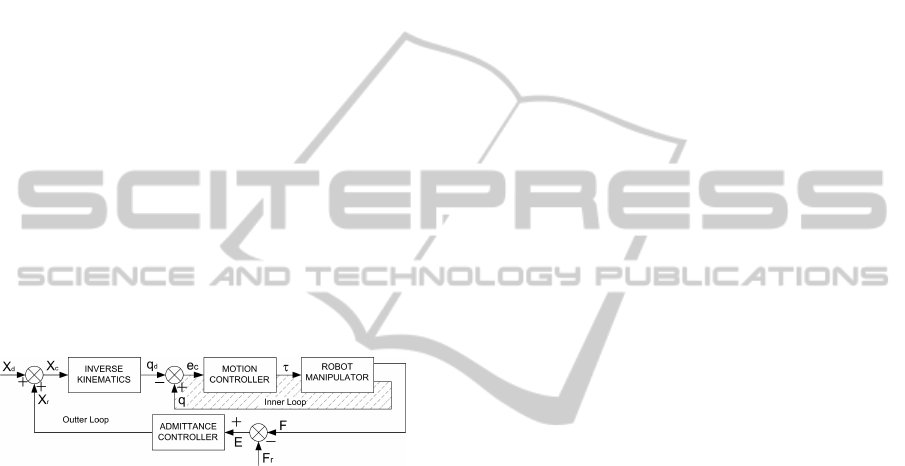

via an inner/outer control loop, see Figure 2.

Figure 2: Implementation of the admittance controller for

the i−th robot.

This is, the measured force error, E

i

(t), is used to

generate a proper reference trajectory, X

r,i

given by

equation (10), which is added to the ideal desired po-

sition X

d,i

. Thus, the commanded position reference

X

c,i

to the motion controller of the i−th robot is given

by

X

c,i

= X

d,i

+ X

r,i

(11)

4 MOTION CONTROLLER

For the proposed impedance controller to be applied

it is required a motion controller, either Cartesian or

joint type. Since the interaction force control prob-

lem is solved by the admittance approach, then one

might consider free motion controllers, rather than

constraint ones. Several controllers have been pro-

posed to achieve regulation and trajectory tracking

of robot manipulators in free motion, (Siciliano and

Khatib, 2008). Nonetheless in this article a simple

joint PID controller at each robot at the cooperative

system is considered, this controller is given by

τ

PID,i

= K

P,i

e

c,i

+ K

D,i

˙e

c,i

+ K

I,i

Z

e

c,i

dt (12)

where K

P,i

,K

D,i

,K

I,i

∈ ℜ

n

i

×n

i

are the proportional,

derivative, and integral diagonal gain matrices, re-

spectively. The i − th joint error is denoted by e

c,i

∈

ℜ

n

i

while ˙e

c,i

∈ ℜ

n

i

represents its time derivative. The

joint tracking error e

c,i

is defined as follows

e

c,i

= q

i

− q

d,i

= q

i

− F

IK

(X

c,i

) (13)

where X

c,i

, represents the i − th commanded robot

end-effector Cartesian position, given by (11), and

F

IK

(X

c,i

) denotes the inverse kinematic model of the

i−th robot.

Notice that the joint tracking error e

c,i

as de-

fined by (13) depends on the inverse kinematic model,

which might present uncertainty or imprecisions as

pointed by (Teichmann and Mishra, 2000; Hsiao

et al., 2010), nonetheless it is expected that the pro-

posed reactive controller would compensate for all

uncertainties that are present at the grasping task.

5 TESTBED

In the following the experimental testbed is described,

then, experimental results are shown. The proposed

optimization admittance controller was tested for uni-

dimensional robot-object interaction forces, consider-

ing an object grasping task executed by a two robots

cooperative system.

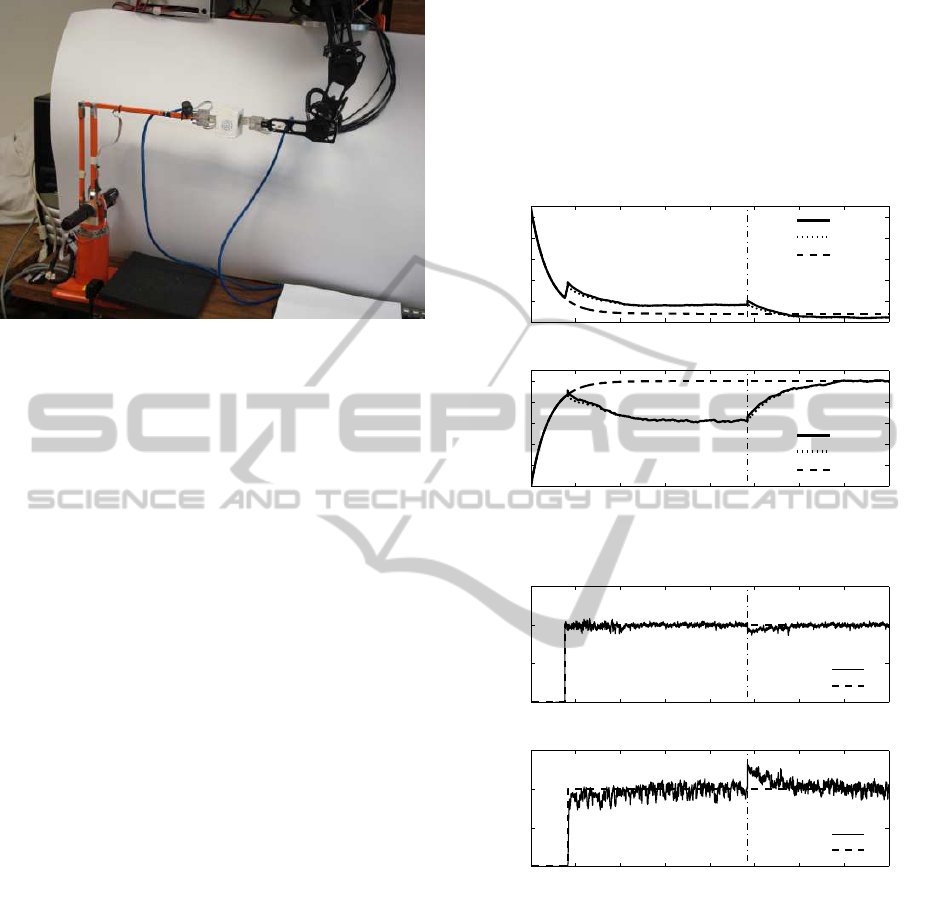

5.1 Robot Manipulators

One of the robot manipulators used to perform the ex-

periments is a three degree of freedom planar manip-

ulator, see Figure 3. Its joints are driven by three DC

brushless servomotors of the brand Micromo

c

Elec-

tronics Inc. The complete design of the robot manip-

ulator is presented in (Muro-Maldonado, 2006).

The second robot is a closed chain five bar parallel

robot, shown in Figure 4. The robot is a spatial three

degree of freedom closed chain manipulator. Its joints

are actuated by Maxon

c

motors coupled to optical

encoders of 1000 ppr. The complete design of the

robot is presented in (Cortes-Martinez, 2007).

Both robots are built on aluminum (alloy 6063 T-

5) of 9.525 mm thickness. They are equipped with

low-cost force sensors of the branch Tekskan

c

at the

end effector.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

54

Figure 3: Planar robot manipulator.

Figure 4: Parallel robot manipulator.

5.2 Force Sensor

Most of commercial force sensors are expensive and

have large dimensions, which limit their applications.

On the other hand, low cost force sensors have re-

ceived attention from robotics community because

they are tiny and their applications are wider as ex-

plained in (Lebosse et al., 2008). In this paper

the low cost one axis force sensor from Tekskan

c

Flexiforce

c

is considered. The Flexiforce

c

A201

force sensor is made of two layers of polyester film.

On each layer, a conductive material (silver) is ap-

plied. Between the two layers a layer of pressure-

sensitive ink is applied. The active sensing area is

defined by the silver circle on top of the pressure-

sensitive ink. The force sensors are terminated with

male square pins, allowing them to be easily incorpo-

rated into a circuit. The force range of measurement

is 0− 100 N. The signal conditioning circuit for the

force sensor consists of an operational amplifier and

analog filter as proposed at the data sheet provided by

the fabricant.

5.3 Force Sensor Mounting

In order to ensure that the force is always applied on

the force sensing area, a mechanical cover was de-

signed and build. A finger-type silicon cover was

placed at the end-effector to consider a soft finger

contact type. The sensor was then mounted on the

end-effector of each robot manipulator, as shown in

Figure 5.

Figure 5: Force sensor mounting.

6 RESULTS

The goal is that the robots at the cooperative sys-

tem grasp and move a prismatic shaped object, which

is a high density Styrofoam block (6 × 6 × 5[cm],

mass = 0.03[Kg]). The block is affected by gravity

forces, as shown in Figure 6. The ideal desired po-

sition is such that perpendicular contact between the

object and the end effectors is obtained. This guar-

antees that the interaction forces are aligned to the

force sensor axis. Two cases are tested, external force

perturbation on a grasped object, and transporting a

grasped object by the cooperative system.

A grasping analysis was carried out to select the

best grasping positions on the object, while consider-

ing its inertial properties, (Murray and Sastry, 1994).

Therefore, the selected grasping points are located

at the centroid of the opposite squared faces of the

block, and assuming a static friction coefficient µ =

AN OPTIMAL ADMITTANCE REACTIVE FORCE CONTROL FOR COOPERATIVE ROBOT GRASPING TASKS

55

Figure 6: Cooperative grasping task.

0.5 (plastic-styrofoam), the desired force which guar-

antees stable grasp is F

r,i

= 0.265[N]. However, due

to uncertainty on the friction coefficient and the un-

known stiffness coefficient K

o,i

we set F

r,i

= 1[N].

6.1 Experiment Setup

To perform cooperative transport, both manipulator

workspaces must intersect in the area where the object

is transported. This fact imposes some restrictions to

the experimental set-up. First, a reference frame must

be selected to provide an absolute value of the object

position, as shown in Figure 1. On the other hand, the

parallel manipulator is spatial and the serial manipu-

lator is planar. Then, we are limited to perform coop-

erative tasks in the 2D serial robot workspace. This

is accomplished by fixing the first degree of freedom

of the parallel manipulator that is in charge of waist

rotation. The final configuration for the experiments

is shown in Figure 6.

The experiments were performed as follows. First

the manipulators are commanded to a home position

with its end-effectors near the object, i.e. the object

position is not exactly known. Once the manipulators

are at home, they are commanded to pinch or squeeze

the object by two contact points applying the desired

force, previously selected via the grasp analysis. The

pinch command is performed by setting the end effec-

tor trajectories such that the difference between the

end effectors is smaller than the width of the block,

W = 0.05[m]. The gains of the admittance controller

were set to γ

1

= 0.00022 and α

1

= 0.1, for the parallel

robot and γ

2

= 0.001 and α

2

= 0.1 for the serial robot.

6.2 Test of Stable Grasp

At the first case a fixed object position is commanded,

and after the setting forces have reached the steady

state, the object is perturbed by an unknown external

force. The goal is that the controller compensates the

external force ensuring stable object grasp. The prob-

lem arises in the pinch command. Due to the uncer-

tainty on the object position, unexpected forces may

appear, which are not desirable for the grasp because

they can cause unstable behavior or contact break-

age/slippage.

0 5 10 15 20 25 30 35 40

0.352

0.353

0.354

0.355

0.356

0.357

Time [s]

X [m]

Cartesian trajectories of serial robot

X

X

c

=X

d

+X

r

X

d

0 5 10 15 20 25 30 35 40

0.3

0.301

0.302

0.303

0.304

0.305

Time [s]

X [m]

Cartesian trajectories of parallel robot

X

X

c

=X

d

+X

r

X

d

Figure 7: Cartesian trajectories.

0 5 10 15 20 25 30 35 40

0

0.5

1

1.5

Time [s]

F [N]

Force tracking of serial robot

F

F

d

0 5 10 15 20 25 30 35 40

0

0.5

1

1.5

Time [s]

F [N]

Force tracking of parallel robot

F

F

d

Figure 8: Force regulation.

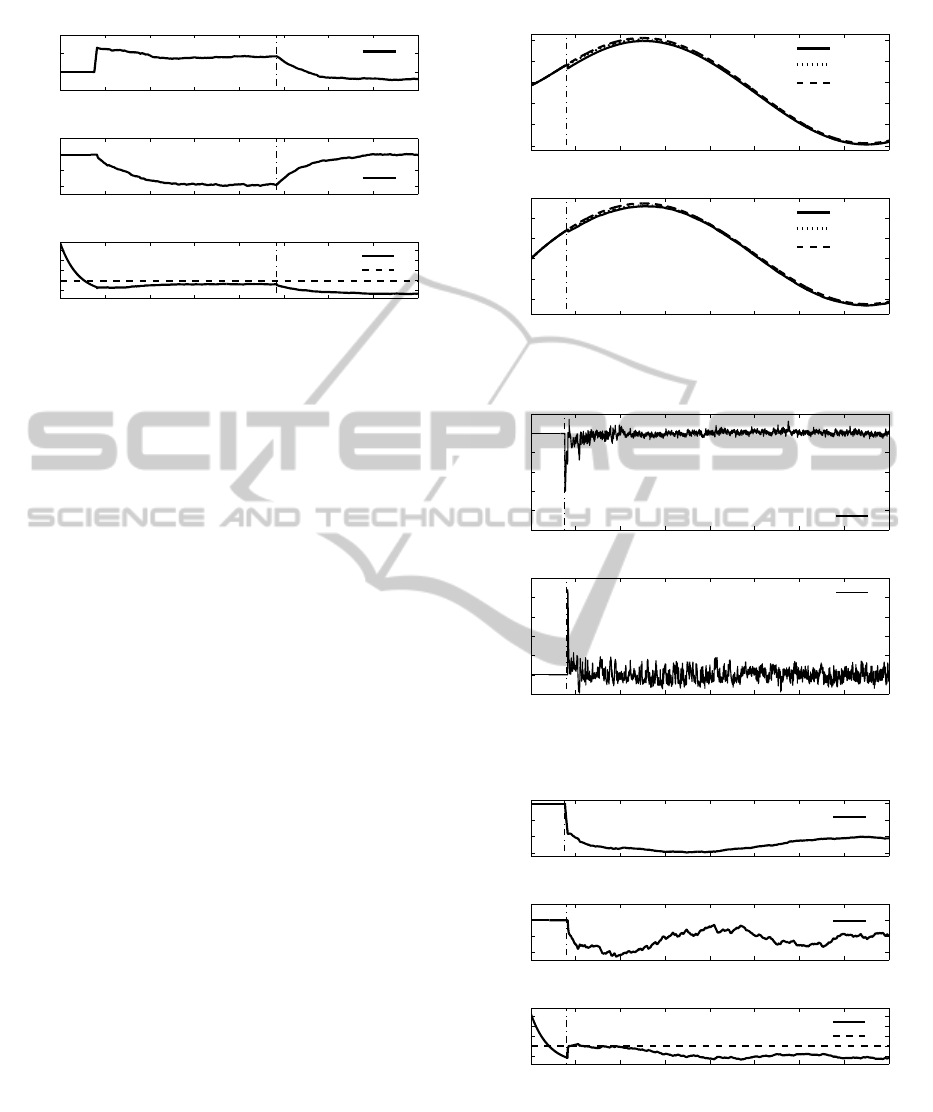

The desired X

d,i

, commanded X

c,i

and robot carte-

sian X

i

trajectories are shown in Figure 7. The dashed

line represents the desired trajectory X

d

, which is de-

signed to perform the pinch command and to grasp the

object. Thus, the optimal admittance controller gener-

ates proper trajectories in order to achieve the desired

force F

r,i

= 1[N], which are shown in Figure 8. Then,

around time t = 24[s], an external force is applied on

the object in the negative direction with respect to the

global reference frame O (see figure 1), this effect is

depicted in Figures 7 and 8.

Figure 9 shows the optimal reference trajectories

X

r

, generated to keep the stable grasp, despite the un-

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

56

0 5 10 15 20 25 30 35 40

−5

0

5

10

x 10

−4

Time [s]

X

r

[m]

Optimal trajectory generation for the serial robot

X

r

0 5 10 15 20 25 30 35 40

−2

−1

0

1

x 10

−3

Time [s]

X

r

[m]

Optimal trajectory generation for the parallel robot

X

r

0 5 10 15 20 25 30 35 40

0.048

0.05

0.052

0.054

0.056

Time [s]

H [m]

Distance between manipulator‘s end effector (H), and object Width (W)

H

W

Figure 9: Optimal trajectories.

certainty in object position, friction coefficient, stiff-

ness and external perturbations. The bottom plot of

Figure 9 shows that the generated trajectories makes

the robot to grasp the object by squeezing it, thus

the distance between the end effectors, H is such that

H < W.

6.3 Object Position by Grasping

For the second experiment the robots are commanded

to follow a desired trajectory in cartesian space while

stable grasping is guaranteed.

The first step is to grasp the object stably, while

the manipulators are commanded to follow a syn-

chronized sinusoidal trajectory along the x axis of the

global coordinate frame, located at the base of the

parallel manipulator. The cartesian trajectories are

shown in Figure 10.

Before the object contact time t ≈ 4[s], the robots

follow their trajectories accurately, however after t ≈

4[s], the admittance controller modifies the com-

manded trajectories by generating reference trajecto-

ries X

r

, which yields the force set point, the force

tracking errors are shown in Figure 11. Again, the

bottom plot of Figure 12 shows that the generated

trajectories makes the robot to grasp the object by

squeezing it, thus the distance between the end effec-

tors, H is such that H < W.

7 CONCLUSIONS AND FUTURE

WORK

In this paper an optimal reactive admittance approach

for safe robot-object interactions in cooperative robot

grasping task is proposed. The optimal admittance

controller is free of robot dynamic model, however it

0 5 10 15 20 25 30 35 40

0.3

0.32

0.34

0.36

0.38

0.4

Time [s]

X [m]

Cartesian trajectories of serial robot

X

X

c

=X

d

+X

r

X

d

0 5 10 15 20 25 30 35 40

0.26

0.28

0.3

0.32

0.34

0.36

Time [s]

X [m]

Cartesian trajectories of parallel robot

X

X

c

=X

d

+X

r

X

d

Figure 10: Cartesian trajectories.

0 5 10 15 20 25 30 35 40

−1

−0.8

−0.6

−0.4

−0.2

0

0.2

Time [s]

E [N]

Force tracking of serial robot

E

0 5 10 15 20 25 30 35 40

−0.2

0

0.2

0.4

0.6

0.8

Time [s]

E [N]

Force tracking of parallel robot

E

Figure 11: Force tracking errors.

0 5 10 15 20 25 30 35 40

−15

−10

−5

0

x 10

−4

Time [s]

X

r

[m]

Optimal trajectory generation for the serial robot

X

r

0 5 10 15 20 25 30 35 40

−2

−1

0

1

x 10

−3

Time [s]

X

r

[m]

Optimal trajectory generation for the parallel robot

X

r

0 5 10 15 20 25 30 35 40

0.048

0.05

0.052

0.054

0.056

Time [s]

H [m]

Distance between manipulator‘s end effector (H), and object Width (W)

H

W

Figure 12: Optimal trajectories.

has been shown by experimental results that our ap-

proach is effective, yielding stable object grasp. This

is achieved due to the fast on-line generation of the

reference trajectory, which modifies the commanded

trajectory to the motion controller. It is important

AN OPTIMAL ADMITTANCE REACTIVE FORCE CONTROL FOR COOPERATIVE ROBOT GRASPING TASKS

57

to highlight that the success of the implementation

of the admittance controller is dependent on the per-

formance of the motion controller. As future appli-

cations, this approach might be extended to consider

on-line repositioning of the contact points to increase

flexibility and robustness of cooperative robot sys-

tems.

ACKNOWLEDGEMENTS

All authors acknowledgesupport from CONACyT via

projects 133527and 084060. Second author acknowl-

edges support of CONACyT Mexico via scholarship

205757.

REFERENCES

Brock, O. and Khatib, O. (2002). Elastic strips: a

framework for motion generation in human environ-

ments. The International Journal of Robotics Re-

search, 21(12):1031–1052.

Chiaverini, S. and Sciavicco, L. (1993). The parallel ap-

proach to force/position control of robotic manipula-

tors. IEEE Transactions on Robotics and Automation,

9(4):361–373.

Chiaverini, S., Siciliano, B., and Villani, L. (1999). A sur-

vey of robot interaction control schemes with experi-

mental comparison. IEEE Transaction on Mechatron-

ics, 4(3):273–285.

Colbaugh, R. and Glass, K. (1997). Adaptive compliant mo-

tion control of manipulators without velocity mea-

surements. Journal of Robotic Systems, 14(7):513–

527.

Cortes-Martinez, R. (2007). Diseo y construccion de un

sistema de teleoperacion maestro esclavo no similar.

Master Thesis (In Spanish), Center for Research and

Advanced Studies (CINVESTAV-IPN), Mexico.

Duchaine, V. and Gosselin, C. (2009). Safe, stable and intu-

itive control for physical human-robot interaction. In

2009 IEEE International Conference on Robotics and

Automation, pages 3383–3388.

Helmke, U. and Moore, J. (1996). Optimization and Dy-

namical Systems. Springer-Verlag, London.

Hsiao, K., Chitta, S., Ciocarlie, M., and Jones, E. G. (2010).

Contact-reactive grasping of objects with partial shape

information. In IEEE/RSJ International Conference

on Intelligent Robots and Systems, pages 1228–1235.

Jung, S., Hsia, T. C., and Bonitz, R. G. (2001). Force track-

ing impedance control for robot manipulators with an

unknown environment: Theory, simulation and ex-

periment. The International Journal of Robotics Re-

search, 20(9):765–774.

Khatib, O. (1986). Real-time obstacle avoidance for robot

manipulators and mobile robots. The International

Journal of Robotics Research, 5(1):90–98.

Lebosse, C., Bayle, B., de Mathelin, M., and Renaud, P.

(2008). Nonlinear modeling of low cost force sensors.

In IEEE International Conference on Robotics & Au-

tomation, pages 3437–4342.

Muro-Maldonado, D. (2006). Control ptimo de Manip-

uladores Redundantes. Master Thesis (In Span-

ish), Center for Research and Advanced Studies

(CINVESTAV-IPN), Mexico.

Murray, R. M., L. Z. and Sastry, S. (1994). A Mathemati-

cal Introduction to Robotic Manipulation. CRC Press,

United Kingdom, 1st edition.

Pratt, J. and Pratt, G. (1998). Intuitive control of a planar

bipedal walking robot. In 1998 IEEE International

Conference on Robotics and Automation, pages 2014–

2021.

Roa, M. and Suarez, R. (2009). Computation of indepen-

dent contact regions for grasping 3D objects. IEEE

Transactions on Robotics and Automation, 25(4):839–

850.

Santis, A. D., Pierro, P., and Siciliano, B. (2006). The vir-

tual end-effectors approach for human-robot interac-

tion. In 10th International Symposium on Advances in

Robot Kinematics, pages 133–144.

Santis, A. D., Siciliano, B., Luca, A. D., and Bicchi, A.

(2008). An atlas of physical human-robot interaction.

Mechanism and Machine Theory, 43:253–270.

Sanz, P. J., Recatala, G., Traver, V. J., and del Pobil, A. P.

(1999). Towards a reactive grasping system for an in-

dustrial robot arm. In Computational Intelligence in

Robotics and Automation, CIRA 99, pages 1–6.

Schutter, J. D., Bruyninckx, H., Zhu, W., and Spong, M. W.

(1998). Force Control: a bird’s eye view. Lecture

Notes in Control and Information Sciences - Control

Problems in Robotics and Automation, Vol. 230.

Seraji, H. (1998). Nonlinear and adaptive control of force

and compliance in manipulators. The International

Journal of Robotics Research, 17(5):467–484.

Seraji, H. and Colbaugh, R. (1997). Force tracking in

impedance control. The International Journal of

Robotics Research, 16(1):97–117.

Shapiro, A., Rimon, E., and Shoval, S. (2010). On the

passive force closure set of planar grasps and fix-

tures. The International Journal of Robotics Research,

29(11):1435–1454.

Siciliano, B. and Khatib, O. (2008). Springer Handbook of

Robotics - Motion Control. Springer, London.

Simonin, O. (2006). Reactive multi-agent approaches for

the control of autonomous mobile robots. In 1st Na-

tional Workshop on Control Architecture of Robots:

software approaches and issues CAR 06, pages 183–

191.

Teichmann, M. and Mishra, B. (2000). Reactive robotics I:

reactive grasping with a modified gripper and multi-

fingered hands. The International Journal of Robotics

Research, 19(7):697–708.

Vahrenkamp, N., Wieland, S., Azad, P., Gonzalez, D., As-

four, T., and Dillmann, R. (2008). Visual servo-

ing for humanoid grasping and manipulation tasks.

In 8th IEEE-RAS International Conference on Hu-

manoid Robots, pages 406–412.

Yigit, S., Burghart, C., and Woern, H. (2003). Con-

cept of combined control mechanisms for human

robot co-operation. In International Conference on

Computer, Communication and Control Technologies

(CCCT ’03).

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

58