GAIN-SCHEDULED PID FOR IMBALANCE COMPENSATION OF A

MAGNETIC BEARING

Laleh Hosseini-Ravanbod and Dominikus Noll

Universit´e Paul Sabatier, Institut de Math´ematiques, Toulouse, France

Keywords:

Scheduled controller for magnetic bearing, H

∞

Optimal decentralized PID controller, Robust control, Distance

to instability, Switching, Hysteresis, Interpolation.

Abstract:

Control of a magnetic bearing device is addressed by parameter varying control. Within the structure of decen-

tralized PID controllers we compare linear interpolation and switching strategies with and without hysteresis.

Piecewise LPV decentralized PID controllers are found to be an interesting alternative. Our method exploits

the possibility to pre-compute for every parameter value an H

∞

optimal decentralized PID controller, and to

use this ideal model to construct practical scheduled controllers with an acceptable H

∞

performance.

1 INTRODUCTION

Magnetic bearings (MB) increasingly become the

choice for high-speed, high-performancerotating ma-

chinery because of their frictionless characteristics.

They utilize a magnetic field generated by radially or

axially placed electromagnets to generate the forces

necessary to suspend and support a shaft without any

contact with its environment. Thus, magnetic bear-

ings are particularly useful in very high or very low

temperature conditions where a lubrication-free en-

vironment is necessary. The advantages of magnetic

bearings are primarily their very low power consump-

tion and their very long maintenance-free life. Some

applications where magnetic bearings offer distinct

advantages are high speed turbo machinery, precision

milling spindles, and combined attitude control and

energy storage for spacecraft and satellites. A dis-

advantage of magnetic bearings is that they require

continuous power input and active control to hold the

load stable.

Active magnetic bearings (AMB) can support ro-

tors without friction but require a sophisticated con-

trol system because specific performance require-

ments such as automatic balancing of the shaft, re-

jection of unwanted disturbances and vibration isola-

tion are required. Many of the controllers proposed

assume a linear time-invariant model, an assumption

which is no longer accurate when the rotational speed

varies.

Control techniques from linear robust control

(Mohamed and Busch-Vishniac, 1995), H

∞

loop

shaping and µ synthesis (Lanzon and Tsiotras, 2005)

as well as adaptive control methods have been used

to attack this problem. Robust control is often overly

conservative as it fails to account for the actual time

variation of the rotor speed, which in addition is mea-

surable.

Another approach is gain-scheduled H

∞

con-

trollers for linear parameter varying (LPV) systems

based on LMI techniques (Tsiotras and Mason, 1996;

Packard, 1994; Apkarian and Gahinet, 1996; Apkar-

ian et al., 1995). Here the idea is to solve a series

of standard H

∞

problems at a pre-specified number of

operating speeds. Using a single Lyapunov function

to show stability and finite L

2

-gain at these selected

points, one guarantees that these properties will also

hold for all operating speeds which are linear combi-

nations of the selected speeds (interpolation). Unfor-

tunately, this strategy is only valid if the controller is

of the same order as the plant. Moreover, due to the

choice of a single Lyapunov functions this also tends

to be conservative. In AMB systems there is strong

interest to use small order controllers or other simple

structures like PID.

High rotor speeds are gaining importance, and

the fast sampling rate necessary for these MB sys-

tems makes the application of digital control a diffi-

cult task. Fast sampling rates call for simplification of

feedback matrices in control design. In order to com-

ply with the demand for simplicity, our present study

uses PID controllers.

330

Hosseini-Ravanbod L. and Noll D..

GAIN-SCHEDULED PID FOR IMBALANCE COMPENSATION OF A MAGNETIC BEARING.

DOI: 10.5220/0003513503300337

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 330-337

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

2 DECENTRALIZED PID DESIGN

PID are still the controllers of choice due to consol-

idated hardware and software tools for design and

hardware embedding, and the implication that more

complex controllers may have. The drawbackof PIDs

in scheduling may be a significant loss of perfor-

mance, and sometimes even worse, loss of internal

stability. Here we present a new method to design

scheduled decentralized PIDs for a parameter vary-

ing MB system, which allows to avoid these fallacies.

The central idea of our approach is to precompute the

H

∞

-optimal decentralized PID controller K

∗

(p) for

every parameter value p, and to use this ideal infor-

mation to construct a parameter dependent decentral-

ized PID K(p), which allows practical hardware em-

bedding, and at the same time does not fall behind the

ideal K

∗

(p) in closed-loop performance for more than

an allowed level of α%.

The paper is organized as follows. Section 3 rep-

resents the open-loop MB system. In section 4 the H

∞

performance channel is discussed, and section 5 gives

the state-space form of the decentralized PID. Section

6 explains the role of the reference curve K

∗

(p) and

explains the rationale of the robustification method.

Re-centralizing plant and controller models of MB are

explained in sections 6.1 and 6.2 and are needed to

apply the LPV procedure in sections 7 and 8. This

is carried out in section 8 by solving a mixed H

∞

/H

∞

program (11) based on the semi-structured stability

radius (see (Hinrichsen and Pritchard, 1986a; Hin-

richsen and Pritchard, 1986b; Karow et al., 2010;

Lawrence et al., 2000)). Experimental results are pre-

sented in section 9.

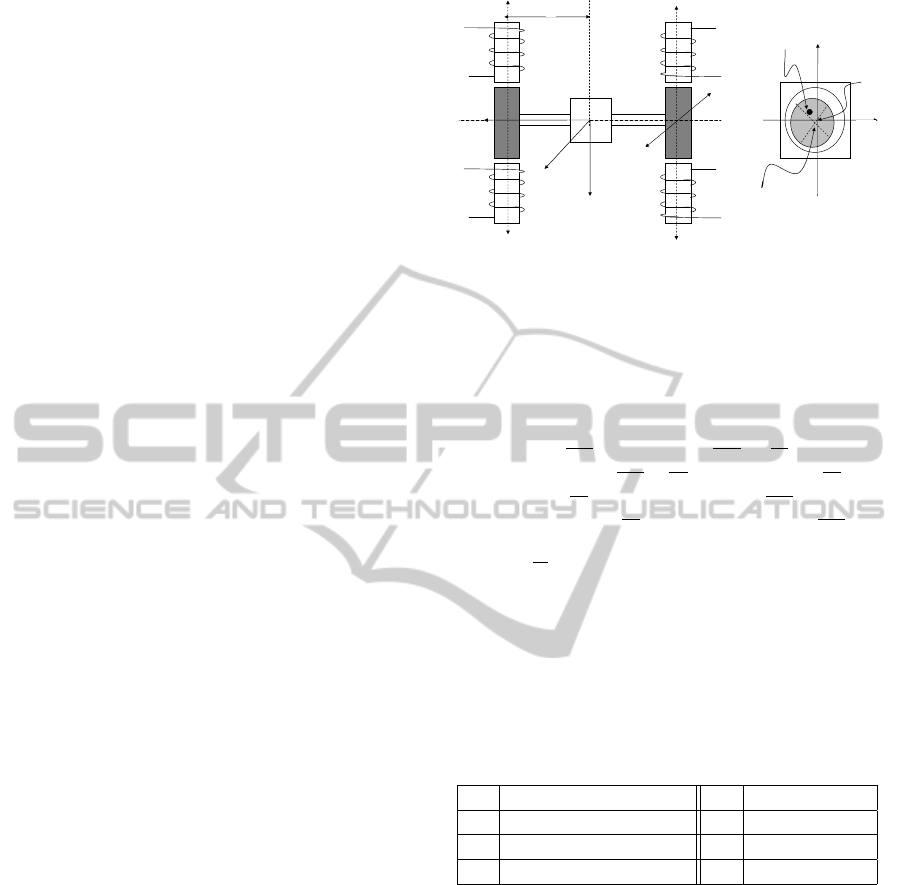

3 OPEN LOOP

In an AMB the axis of rotation does not coincide with

the geometric axis of the rotor. The goal of control

is to effect a rotation about the principal inertial axis

to eliminate the radial centrifugal force, so that the

principal axis of intertia becomes the center of mass

of a cross-section of the rotor. The situation is shown

schematically in Figure 1.

The open-loop magnetic bearing system has the

following parameter dependent form

˙x

mb

= A

mb

(p)x

mb

+ B

mb

u

y = C

mb

x

mb

+ w

(1)

where x

mb

∈ R

6

, while w, u,y ∈ R

2

and the state-space

matrices are given by:

F

r1

F

r4

F

r3

X

Y

Z

F

r2

!

"

e

j

e

j

L

(a) (b)

X

Center of Mass

Center of Geometry

F

l2

F

l1

Y

Center of Rotation

Figure 1: Left image, (a), shows the magnetic bearing con-

figuration with magnetic forces F

r1

,... , F

r4

, F

l1

,... , F

l4

ac-

cording to (Smith and Weldon, 1995). Right image, (b),

shows the rotor unbalance. The purpose of unbalance com-

pensation is to drive the displacements x

1

= Lθ and x

2

= Lψ

to 0.

A

mb

(p) =

0 0 1 0 0 0

0 0 0 −1 0 0

−4c

2

m

0 0

−pJ

α

J

r

2c

1

m

0

0

−4c

2

m

pJ

α

J

r

0 0

2c

1

m

2d

2

N

0 0 0

−2d

1

N

0

0

2d

2

N

0 0 0

−2d

1

N

,

B

mb

=

1

N

0

4×2

I

2

, C

mb

= [I

2

0

2×4

]

with parameters gathered in Table 1. The exoge-

nous input w = [w

1

, w

2

]

T

is a sinusoidal sensor dis-

turbance of the form w

1

=

˜

de

−φt

cos(pt+η) and w

2

=

˜

de

−φt

sin(pt + η), which models the unbalance of the

bearing. Here

˜

d is the magnitude of the unbalance and

η corresponds to un unknown initial phase angle.

Table 1: System constants (Tsiotras and Mason, 1996).

c

1

1.9715e

5

Wb N 400

c

2

325.047Wb

2

/m J

α

0.0136Kg.m

2

d

1

2.1001e

4

Ω.Wb/H.m J

r

0.333Kg.m

2

d

2

7.9804e

3

Ω.Wb/H.m m 19.7041Kg

The varying parameter p represents the rotor veloc-

ity, which is measured on-line and varies in the range

p ∈ Π := [315,1100] rad/s. One can represent the sen-

sor disturbance by the following state space represen-

tation:

˙x

dist

= A

dist

(p)x

dist

+ B

dist

˜

d

w = C

dist

x

dist

(2)

where

A

dist

(p) =

−2φ −p

p 0

, B

dist

=

1

0

, C

dist

= I

2

,

and φ = 0.05. The system is therefore described by

the joint system state x

sys

= [x

mb

, x

dist

]

T

with dynam-

ics

˙x

sys

= A

sys

(p)x

sys

+B

1sys

˜

d + B

2sys

u

y = C

sys

x

sys

(3)

GAIN-SCHEDULED PID FOR IMBALANCE COMPENSATION OF A MAGNETIC BEARING

331

where A

sys

(p) = diag(A

mb

(p),A

dist

(p)) ∈ R

8×8

,

B

1sys

= [0

6×1

, B

dist

]

T

, B

2sys

= [B

mb

, 0

2×2

], C

sys

=

[C

mb

, C

dist

]. For more explication on system mod-

eling see (Lanzon and Tsiotras, 2005), (Tsiotras and

Mason, 1996) and (Smith and Weldon, 1995). In the

latter reference a more complete model is presented,

in which p is one of the states. This means that we

expect p to vary continuously in time.

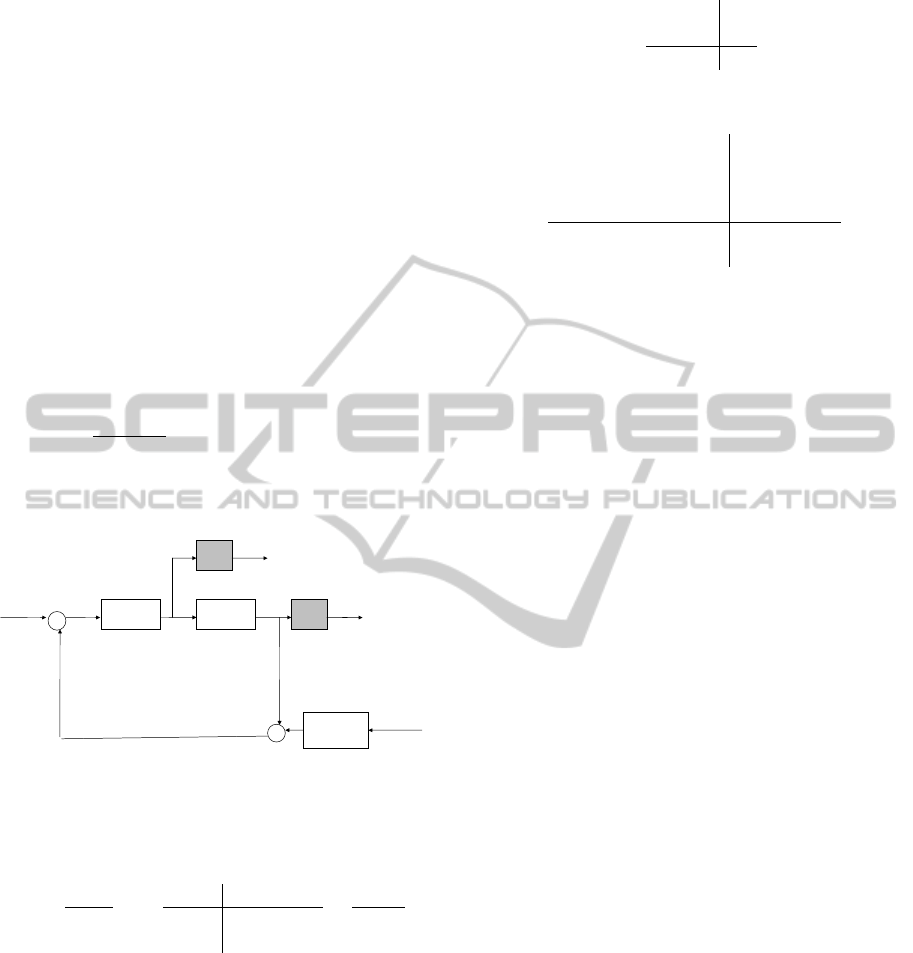

4 PERFORMANCE INDEX

In our next step we have to define controlled outputs

z ∈ R

4

to assess the system performance. We use

the control configuration shown in Figure 2. Follow-

ing (Tsiotras and Mason, 1996), the controlled out-

put z regroups u and y with appropriate frequency

weighing filters: W

u

= diag(W

u1

,W

u2

) with W

u1

=

W

u2

= 0.01

(s+1500)

2

(s+10000)

2

and W

y

= diag(0.5, 0.5) which

up to a factor 10

−4

are as in (Tsiotras and Mason,

1996). Altogether this adds 4 states to the 8 states

of the open loop system. We add a reference signal

G(p)

w

1

+

-

dw

~

2

=

W

y

W

u

z

1

z

2

+

K

y

per

u

per

Dynamics of

disturbances

+

Figure 2: Block diagram of H

∞

system.

r ∈ R

2

for y to the exogenous inputs, which leads to

w = (r

1

,r

2

,

e

d) ∈ R

3

. Altogether we obtain a parame-

ter varying linear fractional transform (LFT)

P(p) :

˙x

z

per

y

=

A(p) B

1

B

2

C

1

D

11

D

12

C

2

D

21

0

x

w

per

u

with dimensions x ∈ R

12

, z

per

∈ R

4

, y ∈ R

2

, w

per

∈

R

3

and u ∈ R

2

. We shall refer to w

per

→ z

per

as the

performance channel.

5 CONTROLLER

PARAMETRIZATION

In this study we design a decentralized PID controller

which depends on the scheduling parameter p. Re-

call that a SISO PID controller K

pid

(s) = d + r

i

/s +

r

d

/(s+ τ) has the state space representation

K

pid

:

0 0 r

i

0 −τ r

d

1 1 d

.

A parameter dependent state-space representation of

the decentralized PID is therefore obtained as

K(p) =

0 0 0 0 r

i

(p) 0

0 −τ(p) 0 0 r

d

(p) 0

0 0 0 0 0 r

′

i

(p)

0 0 0 −τ

′

(p) 0 r

′

d

(p)

1 1 0 0 d(p) 0

0 0 1 1 0 d

′

(p)

(4)

with 8 scheduling functions r

i

(p),... ,r

′

d

(p) to be de-

termined. If we assume an affine parametrization,

then we have 16 free parameters to determine.

6 RATIONALE

For every parameter value p we consider the H

∞

-

synthesis problem

minimize kT

w

per

→z

per

(P(p),K)k

∞

subject to K has decentralized

PID structure (4)

K stabilizes P(p) internally

(5)

Let K

∗

(p) be the solution of (5), which we compute

by the Matlab function

hinfstruct

. This furnishes 8

optimal parameter values r

∗

i

(p),... ,d

′∗

(p). The curve

p 7→ kT

w

per

→z

per

(P(p),K

∗

(p))k

∞

=: P

∗

(p) gives the

best possible H

∞

performance plotted over the inter-

val p ∈ Π = [315,1100]. Clearly the parametrization

p 7→ K

∗

(p) is not practical, and we need approxima-

tions of the mapping K

∗

(·) which can be stored conve-

niently. This leads to a trade-off between the quantity

to be stored and the unavoidable loss of performance.

In order to control the loss of performance we adopt

the following convention. Fixing α > 0, we call a

parametrization p 7→ K(p) acceptable, if

(i) K(p) has structure (4),

(ii) K(p) stabilizes P(p) internally for every p, and

(iii) kT

w

per

→z

per

(P(p),K(p))k

∞

≤

(1+ α)kT

w

per

→z

per

(P(p),K

∗

(p))k

∞

for every p.

To get a scheduling function K(·) which needs as

few elements to store (to embed) as possible, we dis-

cuss two approaches, which use either interpolation,

or switching. For switching we identify subintervals

I = [p

1

, p

2

] ⊂ Π as large as possible on which we can

represent K(p) as an affine function without violat-

ing criteria (i) - (iii). Then we cover Π with as few

as possible of these subintervals I

1

,... ,I

N

. The rule

to control P(p) is then by switching between these I

i

.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

332

The way to construct I together with an affine repre-

sentation K(p) valid on I is given in the next section.

A variation which uses interpolation is given in sec-

tion 9.

Remark. We recall that condition (ii) is only neces-

sary but not sufficient for stability of the switched or

interpolated closed loop system. In general it is dif-

ficult to prove stability over the parameter domain if

nothing is known about the parameter trajectory p(t).

Sufficient conditions based on prior bounds | ˙p(t)| ≤ ν

can be stated, but are generally hard to establish due

to the inherent conservatism. In the same vein, con-

dition (iii) should be understood as a worst case point

of view. Namely, unlike in chess where it would be

enough to know the best move K

∗

(p) in any given

position p, the situation here is more complicated, be-

cause the payoff may be different in different param-

eter regions, and the seemingly ”best” move K

∗

(p) at

p might lead to an unfortunate parameter trajectory in

the future. (A similar situation would arise in chess as

soon as e.g. winning with more material on the board

would count more than winning with few pieces left.

The notion of a ”best” move would then have to be

re-defined).

6.1 LPV Model of Magnetic Bearing

For fixed p

0

∈ Π we wish to find an interval I (p

0

)

containing p

0

as large as possible such that we have

a simple controller parametrization K(p) valid in the

sense of (i) – (iii) on I (p

0

). In order to construct these

intervals, it is helpful to change the parametrization

and write p = p

0

(1+ δ). The new parameter δ is now

centered at 0 and more symmetric, |δ| ≤ r, and we

wish to have a range of validity r as large as possible.

We re-write the open-loop system accordingly. For

example, for the third state in (3) we have

˙x

3

=

−4c

2

m

x

1

−

pJ

α

J

r

x

4

+

2c

1

m

x

5

=

−4c

2

m

x

1

−

(p

0

(1+δ))J

α

J

r

x

4

+

2c

1

m

x

5

.

Introducing an auxiliary input w

rob,1

and output z

rob,1

via w

rob,1

= −

J

α

J

r

p

0

x

4

and z

rob,1

= δ·w

rob,1

, we obtain

˙x

3

=

−4c

2

m

x

1

−

p

0

J

α

J

r

x

4

+

2c

1

m

x

5

+ z

rob,1

.

Repeating the same thing for all states leads to a stan-

dard representation of P(p), p = p

0

(1+ δ), as an un-

certain system:

"

˙x

z

rob

1

y

#

= (6)

"

A

sys

(p

0

) B B

1,sys

B

2,sys

C 0 0 0

C

2,sys

0 0 0

#

x

w

rob

1

˜

d

u

where z

rob

1

∈ R

4

, w

rob

1

∈ R

4

, w

rob

1

= ∆

1

z

rob

1

with

∆

1

= δI

4

and:

B =

0 0 0 0

0 0 0 0

1 0 0 0

0 1 0 0

0 0 0 0

0 0 0 0

0 0 1 0

0 0 0 1

,

C =

0 0 0

−J

α

J

r

0 0 0 0

0 0

J

α

J

r

0 0 0 0 0

0 0 0 0 0 0 0 −1

0 0 0 0 0 0 1 0

× p

0

.

6.2 LPV model of Decentralized PID

Controller

We repeat the same procedure for the controller

parametrization (4). We write each of the 8 schedul-

ing functions as r

i

(p) = r

i0

+ δ · r

i1

, and so on until

d

′

(p) = d

′

0

+ δ · d

′

1

, with 16 parameters r

i0

,..., d

′

1

to

be determined for each I (p

0

). Notice that r

i0

= r

i

(p

0

)

depends on the choice of p

0

, and similarly for the

other scheduling functions. It is helpful to denote

this controller as K(p

0

,δ) = K(p

0

)+ δ· dK(p

0

), even

though it still has the form (4).

Having symmetrized the parameter, we get a simi-

lar uncertain block ∆

2

= δ·I

8

with δ repeated 8 times,

4 times for each PID. Altogether this leads to the

scheduled controller structure shown in Figure 3.

˙

ξ

1

˙

ξ

2

z

k

1

z

k

2

z

k

3

z

k

4

u

=

0 0 1 0 0 0 r

i0

0 −τ

0

0 1 1 0 r

d0

0 0 0 0 0 0 r

i1

0 −τ

1

0 0 0 0 0

0 0 0 0 0 0 r

d1

0 0 0 0 0 0 d

1

1 1 0 0 0 1 d

0

ξ

1

ξ

2

w

k

1

w

k

2

w

k

3

w

k

4

y

, (7)

where ∆

21

= δ· I

4

. We get a similar block for the sec-

ond PID with primed parameters in (4). This leads to

w

rob

2

= ∆

2

z

rob

2

where ∆

2

= diag(∆

21

,∆

22

) = δI

8

for

K. We then apply a standard procedure to the whole

LFT which gives us what is on the right of figure 3.

The controller is nowindependentof δ and gathersthe

16 unknown coefficients of the scheduling functions,

or rather, the free parameters in (4). The uncertain

block is of size ∆ = diag(∆

1

,∆

2

) = δ· I

12

.

7 ROBUSTNESS INDEX

The constellation on the right of Figure 3 corresponds

to the LFT

GAIN-SCHEDULED PID FOR IMBALANCE COMPENSATION OF A MAGNETIC BEARING

333

P

rob

(p

0

) : (8)

"

˙x

z

rob

y

#

=

"

A(p

0

) B

0

B

2

C

0

D

00

D

02

C

2

D

20

0

#"

x

w

rob

u

#

,

w

rob

= ∆z

rob

, u =

e

K(p

0

)y. (9)

The matrix dimensions are

e

K(p

0

) ∈ R

14×14

, A(p

0

) ∈

R

12×12

, ∆ ∈ R

12×12

, etc. Notice that

e

K(p

0

) carries the

same information as K(p

0

,δ) = K(p

0

) + δ · dK(p

0

),

that is, it regroups the 16 unknown coefficients of

K(p

0

) and dK(p

0

) which we want to compute. This

Plant 1

K

1

∆

2

∆

u

y

Plant 2

1

∆

2

∆

K

d

~

y

u

w

rob1

z

rob1

w

rob2

z

rob2

d

~

w

rob2

z

rob2

z

rob2

w

rob2

w

rob1

z

rob1

Figure 3: LFT scheme.

is now a known situation in robust respectively LPV

control. If K in (7) was not structured, we could for

instance use mu-tools to design full-order parametric

robust controller of size 14× 14 which makes the in-

terval of robustness |δ| ≤ r as large as possible. Sim-

ilarly, the LPV procedure of Scherer (Scherer, 2003)

would lead to a full order solution, (see also the mono-

graph (Chesi et al., 2009) for the robustness approach

to uncertain systems). The necessity to satisfy the

structural constraint (7) complicates matters, and we

have to take recourse to a heuristic method.

We concentrate on stabilizing K(p,δ) respectively

e

K(p) on as large an interval I (p) as possible, so

we consider (8) without performance channel. The

closed-loop system matrix is then

A(

e

K, δ) = A + B

2

e

KC

2

+ (B

0

+ B

2

e

KD

20

)∆× .. .

×(I − D

00

∆− D

02

e

KD

20

∆)

−1

(C

0

+ D

02

e

KC

2

) (10)

which we re-write as

A(

e

K, δ) =

˜

A+

˜

B∆(I −

˜

D∆)

−1

˜

C

with

˜

A = A + B

2

e

KC

2

, etc. Our goal is to guarantee

stability of this matrix for as large a range |δ| ≤ r as

possible. We interprete (10) as the semi-structured

complex stability radius r

C

(A+ B

2

e

KC

2

) of the nom-

inal closed-loop matrix

˜

A = A + B

2

e

KC

2

. It is well-

known that

r

−1

C

(

˜

A) =

˜

C(sI −

˜

A)

−1

˜

B+

˜

D

∞

,

so that computing the stability radius of A + B

2

e

KC

2

amounts to computing an H

∞

-norm. Altogether, we

have

r

−1

C

(

˜

A) = kT

w

rob

→z

rob

(P

rob

(p

0

),

e

K)k

∞

,

where P

rob

(p

0

) is the plant in (8).

8 OPTIMIZATION PROGRAM

For every fixed p

0

we now compute the solution

K

rob

(p

0

) of the following mixed H

∞

/H

∞

optimization

program:

minimize R (K) = kT

w

rob

→z

rob

(P

rob

(p

0

),

e

K)k

∞

subject to P (K) = kT

w

per

→z

per

(P(p

0

),K)k

∞

≤ (1+ β)P

∗

(p

0

)

K has structure (4)

K stabilizes internally

(11)

where P

∗

(p

0

) is the nominal performance at p

0

, that

is, P

∗

(p

0

) = kT

w

per

→z

per

(P(p

0

),K

∗

(p

0

))k

∞

. This pro-

gram presents a trade-off between performance and

robustness in the sense of r

C

. Namely, as we know,

the best possible performance at p

0

is obtained by

K

∗

(p

0

), which corresponds to choosing r

i0

= r

∗

i

(p

0

),

etc. and δ = 0. In (11) we accept a loss of 100 · β%

performance over the nominal value P

∗

(p

0

) and use

this freedom to buy some additional robustness in

the sense of r

C

, hoping that this will lead to a con-

troller K

rob

(p

0

) with as large an interval of validity

I (p

0

) as possible. Clearly, in order to respect rule

(iii), be have to choose β < α, and in our experi-

ments we use β = α/2. For more information on this

type of trade-off between performance and robust-

ness see (Hosseini-Ravanbod et al., 2011b; Hosseini-

Ravanbod et al., 2011a).

Algorithm 1: Algorithm to compute parametrized PID with

switching.

Parameters: α > 0, 0 < β < α.

1: Pre-compute approximation of optimal curve K

∗

(p)

using

hinfstruct

.

2: For a sufficient number of parameters p solve mixed

H

∞

/H

∞

program (11). The solution curve is K

rob

(p).

3: For every p find interval of validity I (p) of K

rob

(p)

using conditions (i) – (iii).

4: Remove a small portion on each side of I (p) and

call the shrunk interval I

♯

(p).

5: Select minimum number of I

♯

(p

ν

), ν = 1, . .., N,

covering Π. This means the intervals I (p

ν

) cover

Π with some slight overlap.

The gain scheduling function is now as follows.

Let ν(p) be such that p ∈ I (p

ν

) and define the con-

trol law as K(p) = K

rob

(p

ν(p)

). If there are several

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

334

ν with p ∈ I (p

ν

), then use the hysteresis rule. That

is, stay on the interval in which the trajectory moves,

and only jump on a new interval when the boundary

of the first is reached. This means that for a value p in

the intersection I (p

ν

) ∩ I (p

µ

) the actual control law

changes depending whether one arrives from the right

or from the left.

9 EXPERIMENTAL RESULTS

The measured parameter p varies in Π =

[315, 1100] rad/sec. We use hinfstruct at 51

equidistant points in Π to compute the optimal

decentralized PID controller curve K

∗

(p).

For each of the 51 values p

0

we use program (11)

with β = α/2 to compute 51 controllers K

rob

(p), sat-

isfying (i) – (iii) in tandem with their intervals of va-

lidity I (p).

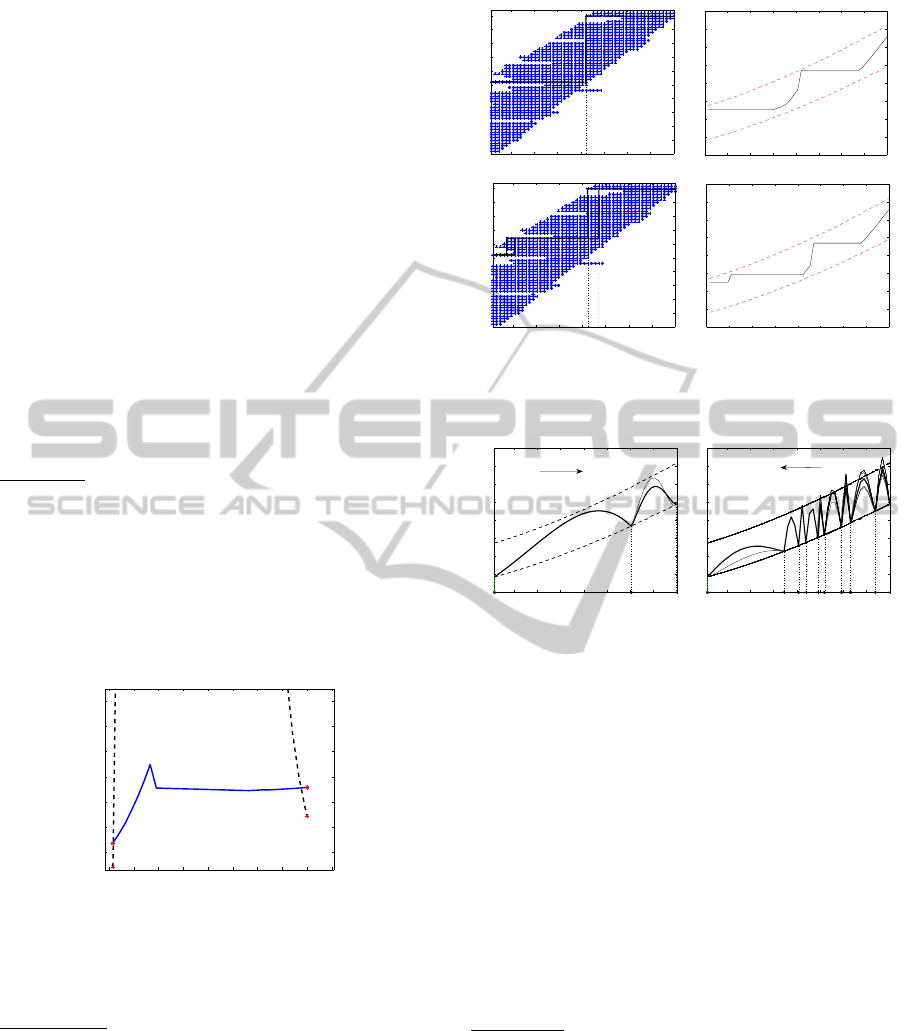

First study:

Our first test uses α = 0.38 which allows to cover Π

with only two intervals I (315) and I (1100). As one

can see in Figure 4, the switched controller (contin-

uous line) maintains stability over the entire Π, but

interpolating K

∗

(315) and K

∗

(1100)leads to a loss of

stability (broken line). This indicates that interpola-

tion of controllers is more delicate to arrange for than

switching.

300 400 500 600 700 800 900 1000 1100 1200

200

220

240

260

280

300

320

Performance

p

PID+sch (dashed), PID−LPV (solid)

Figure 4: Interpolating linearly between the two controllers

K

∗

(315) and K

∗

(1100) (dashed line) fails due to a loss of

stability, while switching using K

rob

(315) and K

rob

(1100)

holds the stability (solid line).

Second study:

Our second test uses α = 0.1, which leads to more

realistic results. We seek a switching controller and

compute intervals I (p) according to algorithm 1 for

51 equidistant values p ∈ Π.

Figure 5 (a) shows the validity region for each of

the 51 controllers K

rob

(p), that is, the values p

′

for

which controller K(p) satisfies (i) – (iii). For each

of the 51 controllers K

rob

(p) the zone where (i) –

(iii) hold corresponds to a horizontal array marked

by ∗. As can be seen, by following the thick line,

400 500 600 700 800 900 1000 1100

0

5

10

15

20

25

30

35

40

45

50

Selection the minimum number of controllers, switch

p [rad/s]

(a)

300 400 500 600 700 800 900 1000 1100

180

190

200

210

220

230

240

250

260

Performance obtained by 2 controllers

p [rad/s]

(b)

1.1 nominal performance

nominal performance

400 500 600 700 800 900 1000 1100

0

5

10

15

20

25

30

35

40

45

50

Selection the minimum number of controllers, switch + hysteresis

p [rad/s]

(c)

300 400 500 600 700 800 900 1000 1100

180

190

200

210

220

230

240

250

260

Performance obtained by 3 controllers

p [rad/s]

(d)

1.1 nominal performance

nominal performance

Figure 5: (a) and (c): Validity regions I (p) plotted against

p. This allows to read off the intervals needed to cover Π.

(b) and (d) the final performance obtained for each case.

400 500 600 700 800 900 1000 1100

180

190

200

210

220

230

240

250

260

Selection the minimum number of controllers, upwards interpolation

p [rad/s]

1.1 nominal performance

nominal performance

(a)

400 500 600 700 800 900 1000 1100

180

190

200

210

220

230

240

250

260

Selection the minimum number of controllers, downwards interpolation

p [rad/s]

1.1 nominal performance

nominal performance

(b)

Figure 6: By upwards interpolation, (a), we need 3 con-

trollers to cover Π and by downwards interpolation, (b), we

need 10. Thin lines shows bisection procedure and thick

line the final performance.

we can find a way covering all the variation of p.

This requires only two controllers K

rob

(707.5) and

K

rob

(1084.3) with switching at p = 723.2rad/s (con-

trollers number 26 and 50).

If we insist on a non-negligible overlap between

the intervals I (p), using the I

♯

(p) as in the algorithm,

then Figure 5 (c) shows that we need three controllers

K

rob

(707.5), K

rob

(801.7) and K

rob

(1084.3), to cover

Π (controllers number 26, 32 and 50). The same Fig-

ures 5 (b) and (d) show the performance obtained in

each case.

Third study:

Our third test still uses α = 0.1, but now we interpo-

late optimal controllers K

∗

(p). Start at the left end

p

1

= 315. Having found p

k

, we examine for p > p

k

the closed-loop performance curve obtained by the

controller K

int

(p

k

, p) interpolating between K

∗

(p

k

)

and K

∗

(p). As p increases, this curve eventually hits

the upper limit curve (1+α)P (K

∗

(p

′

)) at some p

′

be-

tween p

k

and p. We put p

k+1

= p and continue until

the right end point is reached. A similar procedure

starts at the right end point and moves downward.

GAIN-SCHEDULED PID FOR IMBALANCE COMPENSATION OF A MAGNETIC BEARING

335

Figure 6 gives the results of this algorithm in

our study. Upwards interpolation needs 3 con-

trollers K

∗

(p) at p = 315, 903.75, 1100, while down-

wards interpolation requires more, namely K

∗

(p)

at p = 1100,1037.7,931.7,892.2,817.9, 790.9, 707.5,

644.65,315.

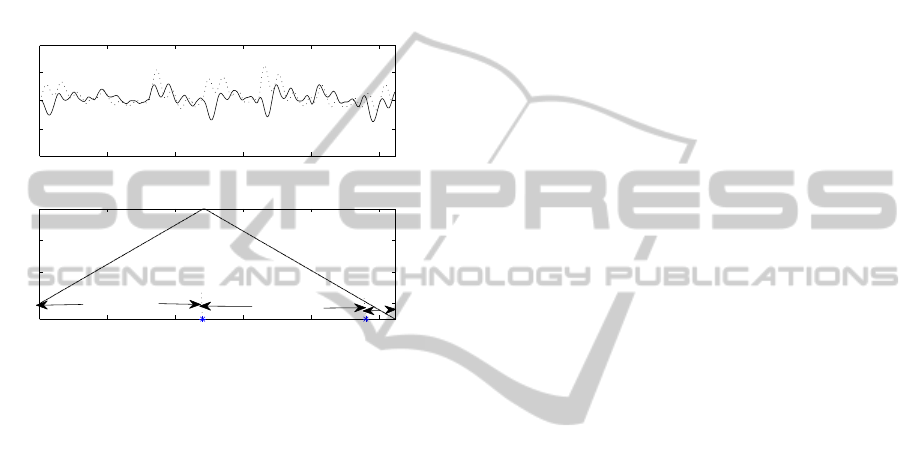

Figure 7 shows a simulation in closed-loop where

the scheduling function K(p) uses three robust con-

trollers K

rob

(p), and where p(t) increases within 1.2

sec from 720 to 780 and then decreases back to 710.

0 0.5 1 1.5 2 2.5

−1

0

1

x 10

−5

Perturbation rejection: w

2

=[1.3e−5sin(pt),1.3e−5cos(pt)]

0 0.5 1 1.5 2 2.5

720

740

760

780

t [s]

Rotor speed variation

K

rob

(707.5)

K

rob

(801.7)

K

rob

(707.5)

x

2

(a)

(b)

x

1

Figure 7: Simulation in closed loop. The scheduled pa-

rameter increases within 1.2 sec from 720 to 780, and de-

creases back to 710 within another 1.5 sec. Three con-

trollers K

rob

(p(t)) are called for. Upper image shows

unbalance compensation x

1

,x

2

for simulated w

2

(t) =

(1.3e− 5sin p(t), 1.3e− 5cos p(t)). (For x

1

,x

2

,w

2

see sec-

tion 3).

10 CONCLUSIONS

Several methods to compute a parameter varying de-

centralized PID for a magnetic bearing device were

compared. Performance was measured in the H

∞

norm, and the curve K

∗

(p) of optimal H

∞

-controllers

was taken as a reference to assess the performance

of the different parameterizations K(p). If parame-

terizations K(p) with a maximum loss of 10% over

K

∗

(p) were allowed, switching between piecewise

affine controllers on subintervals was found to per-

form best, but needs solving a mixed H

∞

/H

∞

synthe-

sis program. Interpolation based on computing vari-

ous K

∗

(p) was an interesting alternative, even though

it was observed that interpolation seems to have a

stronger tendency to lose stability and important de-

pendence at the beginning point. While the switching

technique carries over to 2D parameter sets, there is

no obvious way to extend interpolation into two di-

mensions.

ACKNOWLEDGEMENTS

This work was supported by research grants Techni-

com from Fondation d’Entreprise EADS, and Survol

from Fondation de Recherche pour l’A´eronautique et

l’Espace (FNRAE).

REFERENCES

Apkarian, P. and Gahinet, P. (1996). A convex characteriza-

tion of gain-scheduled H

∞

controllers. In IEEE Trans-

actions on Control Systems Technology, vol. 40, No. 5,

pp. 835-864.

Apkarian, P., Gahinet, P., and Becker, G. (1995). Self-

scheduled H

∞

control of linear parameter-varying sys-

tems: a design example. In Automatica, vol. 31, No.

9, pp. 1251-1261.

Chesi, G., Garulli, A., Tesi, A., and Vicino, A. (2009). Ho-

mogeneous polynomial forms for robustness analysis

of uncertain systems. In Springer Verlag.

Hinrichsen, D. and Pritchard, A. (1986a). Stability radii of

linear systems. In Systems and Control Letters, vol. 7,

pp. 1-10.

Hinrichsen, D. and Pritchard, A. (1986b). Stability radius

for structured perturbations and the algebraic riccati

equation. In Systems and Control Letters, vol. 8, pp.

105-113.

Hosseini-Ravanbod, L., Noll, D., and Apkarian, P. (2011a).

On a generalization of the LTR procedure. In Chinese

Control and Decision Conference, Mianyang, China.

Hosseini-Ravanbod, L., Noll, D., and Apkarian, P. (2011b).

Robustness via structured H

∞

/H

∞

-synthesis. In Inter-

national Journal of Control. In press.

Karow, M., Kokiopoulou, E., and Kressner, D. (2010).

On the computation of structured singular values and

pseudospectra. In Systems and Control Letters, vol.

59, No. 2, pp. 122-129.

Lanzon, A. and Tsiotras, P. (2005). A combined applica-

tion of H

∞

loop shaping and µ- synthesis to control

high-speed flywheels. In IEEE Transactions on Con-

trol Systems Technology, vol. 13, No. 5.

Lawrence, C., Tits, A. L., and Dooren, P. (2000). A fast

algorithm for the computation of an upper bound on

the µ-norm. In Automatica, vol. 36, pp. 449-456.

Mohamed, A. and Busch-Vishniac, I. (1995). Imbalance

compensation and automation balancing in magnetic

bearing systems using the q-parametrization theory.

In IEEE Transactions on Control Systems Technology,

vol. 3, No. 2.

Packard, A. (1994). Gain scheduling via linear fractional

transformations. In Systems and Control Letters, vol.

22, pp. 79-92.

Scherer, C. (2003). Higher-order relaxations for robust lmi

problems with verification for exactness. In Proceed-

ings of the 42nd IEEE Conference on Decision and

Control, pp. 4652 - 4657.

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

336

Smith, R. and Weldon, W. (1995). Nonlinear control of

a rigid rotor magnetic bearing system: modeling and

simulation with full state feedback. In IEEE Transac-

tions on Magnetics, vol. 31, no. 2, pp. 973 - 980.

Tsiotras, P. and Mason, S. (1996). Self-sheduled H

∞

con-

trollers for magnetic bearings. In Proc. Int. Mechan-

ical Engineering Congr. Exposition, Atlanta, GA, pp.

151-158.

GAIN-SCHEDULED PID FOR IMBALANCE COMPENSATION OF A MAGNETIC BEARING

337