ENHANCING DATA EXCHANGE AND MANAGEMENT

SUPERVISION IN A COMPLEX MESH OF SUBCONTRACTORS

A Theoretic Approach to Counter Interface Issues in Micro-, Small-

and Medium-sized Enterprises

Peter Burnickl and Josef Basl

Department of Industrial Engineering and Management, University of West Bohemia

Univerzitní 8, 30614 Pilsen, Czech Republic

Keywords: Enterprise information system, Business process management, Subcontractor, Interface, Information

exchange, Data management.

Abstract: Modern companies face quickly changing demands of customers, selling conditions, and a high fluctuation

of employees because of global competition. Frequently, firms recruit subcontractors and freelancers to

handle short-term bottlenecks and to acquire know-how. Because of various interfaces and internal

structures and a complex mesh of responsibilities between all participating teams, the exchange of

information and data is highly sophisticated. This paper describes the current situation of most small and

medium enterprises that co-operate with subcontractors and, hence, face empirical problems. Key features

and demands for a possible approach are shown to solve these issues with a minimum effort on existing

systems and processes.

1 INTRODUCTION

Modern companies need differentiation against

competitors. Customization of products and

increased flexibility is essential in order to survive

on the market. Because of quickly changing

situations, firms have to act and react expeditiously.

Because of short-term commitments, bottlenecks

in in-house capacities are generated. It is often

necessary to access external expertise and

knowledge or a geographical area with growth

prospects. Additionally the overall process is slowed

down by financial issues (e.g. cost-cutting strategies)

or the need of specialized equipmend and skills to

manufacture either finished products or unique

components (Berry, 1997).

Companies frequently adress these issues by

recruiting subcontractors. These sucontractors are

mostly freelancers, micro-, small- or medium-sized

enterprises, which are directly connected to the

companies’ processes and interact with various

departments simultaneously.

That causes a lot of problems according to the

overwhelming amount of information and digitally

stored data that has to be managed within those

alliances.

This paper describes the current situation of most

SMEs (Small and Medium Enterprises) that co-

operate with subcontractors to adress empirical

problems. A possible approach is presented to solve

these issues with a minimum effort on existing

systems and processes.

2 INFORMATION DEPLOYMENT

Currently, modern SMEs mostly spread information

via proprietary EIS (Enterprise Information

Systems). They spend a huge amount of money and

time for customization of the processes that are

tailored to the overall management tool. The

problem is that the subcontractors usually do not

have an EIS from the same vendor, which means

that they have to customize an interface between the

different systems. Because the bottlenecks and

commitments are short-term, it usually makes no

sense to work on this problem; they simply transfer

the needed data and information via FTP-Servers

(File Transfer Protocol) or regular e-mails.

Generally, even if an EIS is used, data is stored

on local computers or on centralized servers as these

modern tools are not always strictly used. Often, no

95

Burnickl P. and Basl J..

ENHANCING DATA EXCHANGE AND MANAGEMENT SUPERVISION IN A COMPLEX MESH OF SUBCONTRACTORS - A Theoretic Approach to

Counter Interface Issues in Micro-, Small- and Medium-sized Enterprises.

DOI: 10.5220/0003508000950099

In Proceedings of the 6th International Conference on Software and Database Technologies (ICSOFT-2011), pages 95-99

ISBN: 978-989-8425-76-8

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

data management software is used at all and

users spend a significant amount of their working

hours to search and share information.

Of course, if the mesh of participating team

members becomes more complex, this problem

becomes more significant to the overall processes

and the end results.

The possibility of saving time and money by

developing an adequate solution is generally ignored

because the current way of data and information

exchange does—surprisingly—work. The managers

often only realize the tremendous impact of this

problem when it is too late.

The fear of managers to implement a

sophisticated EIS is grounded in the idea that the

outcome of the entire process may not be worth it.

Their fears are justified as 44% of projects are late,

over budget, or partially successful. Sometimes the

results are any combination of these three elements,

but data shows that 24% of all implementations fail

(Standish, 2009).

2.1 Mesh of Subcontractors

OEMs (Original Equipment Manufacturers) often

involve their subcontractors into their supply chain

by creating a subcontracting chain as part of the

overall manufacturing process on a long-term basis

(Lehtinen, 2001). In this case, the subcontractor is

highly involved in the contractors’ processes. If the

subcontractor fulfils a vital part of the supply chain

in production, then the EIS for both the

subcontractor and the contractor is usually the same.

Hence, there are generally no interface issues.

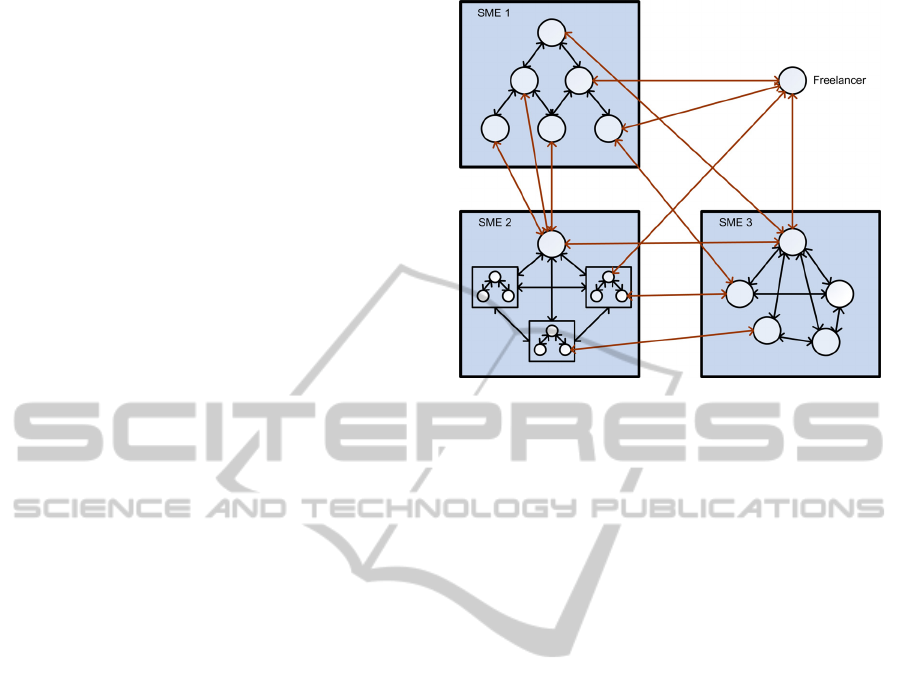

A Mesh of Subcontractors is created when

various companies are involved in the same project

or alliance, as shown in Figure 1. In this case, every

company is involved in one overall process but

utilizing a different EIS. The small arrows show the

connections between the different users. The users’

responsibilities can vary during the on-going

process. For example, a project leader of the

contracting company can be a subordinate team

member of the subcontractor’s firm for a certain part

of a process. As those alliances are usually based on

short-term commitments, no expensive interfaces

and customizations can be designed.

The subcontractors’ position is hard to define as

they can be involved in various processes and

projects simultaneously. They can act as go-

betweens for users and SMEs. One subcontractor

can be responsible for a certain task which is bonded

to another subcontractor’s and user’s task at the

same time.

Figure 1: Mesh of Subcontractors.

Every user in Figure 1 can be a contractor and

subcontractor simultaneously. Hence, a mesh of

subcontracting parties is created. Often, this

situation has to be addressed by complex processes

were a continuous exchange of data and information

is required.

Mesh of Subcontractors will be used as a new

definition for this work. Previous studies defined the

relationship between one company and another

company as subcontracting. For this approach, each

single connection between one user and another is

considered subcontracting.

The definition of the connections can vary

during the on-going processes and steps of the

product lifecycle. For example, frequently the

subcontractors’ positions cannot be rigidly defined.

Therefore a flexible process is created.

2.2 Current Problems in SMEs

The following subchapters show current problems

within subcontracting alliances as a basis for a new

approach which were analysed based on previous

surveys and interviews with SMEs that address the

mentioned issues.

2.2.1 No Data-management

Currently, required data is often pushed from one to

another via e-mail or FTP-Servers. There is often no

encryption used as the users have neither the

understanding of the risk to data security nor the

specific knowledge to implement protection.

ICSOFT 2011 - 6th International Conference on Software and Data Technologies

96

2.2.2 Missing Responsibilities

Every involved company has its own hierarchy. The

diverse responsibilities of integrated subcontractors

are often not obvious and can lead to several

problems. Often, employees without a leading

position can be in charge for a subtask of a certain

area within the process. Hence, non-leading

employees can be contractors in this specific case.

2.2.3 Sophisticated Task-allocation

Because of various niche areas of complex

processes, tasks need to be shifted to subcontractors

in order to obtain solutions and results.

Single subtasks can get lost due to short-term

employment relationships and a mismanagement of

subcontractors. The missing data-management

hampers the task-allocation to the needed experts.

2.2.4 Slow Management Interaction

Due to a lack of time and overview of the on-going

processes, managers often do not have the needed

insight to determine the current state of the project.

Another reason for the lack of management

interaction is the increasing amount of involved

people and data.

For this reason, the supervision of processes is

getting ever more complicated. Subordinate staff

have to deal with situations were improvisation can

lead to a loss of quality.

2.2.5 Data Safety

Large enterprises make extensive efforts to ensure

data safety. These companies purchase expensive

and complex tools with effective encryption

capabilities to protect sensitive data. Employees then

participate in mandatory training on how to use and

apply these tools.

Unfortunately, SMEs frequently disregard this

issue because of extra costs to the company and a

general lack of knowledge about the consequences

of compromised data.

2.2.6 Costs of Tools

The direct comparison of license proposals is

challenging because the models are so different that

it is difficult to distinguish common aspects between

the tools to assist in making an effective comparison

(Adelsberger, 1995); (Zarnekow, 2006).

That frequently leads to license-sharing.

2.2.7 Overall Time Schedule, Management

Time schedules involve a high risk potential. If

milestones in roadmaps are not met, a sub-process

can emerge to a tremendous issue of the overall

process. Subcontractors frequently get short-term

delivery dates, several days in advance of the

milestone to avoid time issues.

The lack of time leads to careless mistakes often

due to poor time management. The worst case

scenario, for example, may be when a one-week

milestone is a one-day job for the last subcontractor,

as the superordinate levels need several steps within

the process to edit the results.

2.2.8 Proprietary Tools and Interfaces

Communication and data exchange via a variety of

proprietary tools is still not easy to handle. Adjusted

solutions, which are often based on out-dated

operating systems and databases, are not designed

for easy communication and interaction with other

software.

As the customization of EIS interfaces seems to

be insuperable for short-term alliances, widespread

files are used to exchange information and to work

on corporate processes associated with the

aforementioned problems.

3 EMPIRICAL METHODOLOGY

The analysis is based on previous surveys from

Bramorski (2008), and Al-Hammad (2000), and

publications within the EIS industry about the

corresponding problems on realized projects.

As the focus of previous research was on the

overall EIS and general interfaces among the

companies rather than the single connections on the

spanning mesh, the obtained conclusions had to be

expanded and interpreted from a new perspective,

combined with personal experience adding support

to the interpretation.

The mentioned problems in a Mesh of

Subcontractors were discussed and analysed in a

variety of companies that try to handle those issues

without a big investment on complex EIS.

4 RESULTS

The key results of the research were analysed to

determine if a deviation would allow for the needed

interfaces to be created for the Mesh of

ENHANCING DATA EXCHANGE AND MANAGEMENT SUPERVISION IN A COMPLEX MESH OF

SUBCONTRACTORS - A Theoretic Approach to Counter Interface Issues in Micro-, Small- and Medium-sized

Enterprises

97

Subcontractors. In order for such a new tool to serve

the function for which it was created, it must meet

the following criteria to enhance the management of

data exchange and security:

simple and secure,

affordable,

implementable,

non-complex communication,

clear responsibilities,

unsophisticated task-allocation, and

quick interaction of management.

4.1 Simple and Secure

Not every employee is an enthusiastic software user.

Because of frequently changing hardware, software,

updates, etc., many users are overwhelmed with the

technical aspects of their job. Data security must be

automated without special software or extra steps.

4.2 Affordable

Because of the overpriced costs of the majority of

EIS, firms frequently use only a single license for

the entire team or company involved in order to save

money. As responsibilities are bonded to various

tasks and datasets, this approach is not possible in a

Mesh of Subcontractors.

4.3 Implementable

Hardware and software compatibility may become a

major issue within a Mesh of Subcontractors. Short-

term relationships often need to be established very

quickly when expert knowledge is urgently required.

However, arranging these relationships is difficult as

implementation of EIS and other data management

and exchange tools slows down the overall process.

4.4 Non-complex Communication

No matter which tool is in use, digital firms

generally use quasi-standard e-mail software for any

kind of communicating and exchanging information.

Even the state-of-the-art chat-tools used in some

modern companies cannot replace verbal

communication (Vintean, 2008).

4.5 Clear Responsibilities

Hierarchies within the overall process are not

generally obvious. The development of complex

relationships can change an individual’s

responsibilities in the overall process. Often,

organizational charts are not updated as roles change

frequently.

To complicate the issue, every involved

company has its own hierarchy as shown in Figure

1. Subcontractors integrated into the company may

have diverse responsibilities that make their role in

the process opaque. Also, it is not unusual for an

employee without a leading position in a company to

spearhead a subtask of a specific area.

4.6 Unsophisticated Task-allocation

Involved team members shift tasks back and forth in

a not-so fluid process to accomplish the overall

goals. Complex processes and products need the

input of various experts in niche areas. Frequently,

the need for a specialist’s advice arises suddenly.

New employees and subcontractors need to be

incorporated quickly when the need for this

specialized knowledge or skill is short-dated.

4.7 Quick Interaction of Management

Frequently, managers and top managers are

smothered with paperwork and obligations so that

their time schedule has no gaps. There is little time

available to troubleshoot big issues and to interact

with project leaders.

Due to a lack of time and understanding of the

on-going processes, managers often do not have the

needed insight on the sub-processes.

Subordinate staff members have to perform in

these situations. At times the pressure to perform

causes users to improvise solutions to the problems

of managing and exchanging data and information.

However, this type of improvisation is prone to

human error, which often leads to a loss of quality.

5 CONCLUSIONS AND FUTURE

RESEARCH

In order to enhance data exchange and management

supervision in a complex Mesh of Subcontractors, a

new tool needs to be simple and secure. For

example, it has to be self-explaining in its usage and

should not replace regular quasi-standard e-mail

software. A user-friendly copy of e-mails to a web

address could assure the ability to trace the source of

data, information, and errors within the data-

exchange process. This improves and addresses the

issue of quality assurance without affecting the daily

used standard processes.

ICSOFT 2011 - 6th International Conference on Software and Data Technologies

98

Micro enterprises, small subcontractors, and

freelancers are frequently involved in various

projects by different contractors. The goal is to

include the communication into the new method. If

an extra step, such as to save communications

between users or to disseminate new information to

users, is necessary, then people will soon start to

avoid the tool or use it thriftily. Users need to be

able to use the tool without purposefully using it.

Plug-ins to the standard e-mail software would solve

this issue.

License costs should also be reasonable to

implicitly avoid the sharing of accounts.

To address the compatibility issue stemming

from the various hardware and software in use at the

participating firms, the tool must be independent of

operating systems. Hence, a web-based tool would

be the fastest available solution without any

implementation at all. Interface issues because of

proprietary EIS would become obsolete. The main

contractor could implement the web-based tool into

the used EIS and its databases; the subcontractor

could use the web-based software to manage and

share information and data for a specific project with

the contractor; and files commonly used within a

project could be stored within the web-based

software for easy retrieval by subcontractors who

need access to the information quickly.

Also, overall time schedules need to be

accessible through the new tool without confusing

Graphical User Interfaces (GUIs). Overall, the

responsibility for a task or project needs to be

allocated appropriately and clear at any time. For

example, if a task is created, then it needs to be

assigned to a person, who then is in charge until the

task is complete. In addition, the organizational

chart for each process must always be up-to-date and

clear at any given time.

Tasks, as part of processes always need to be

“owned” by somebody in order to avoid mistakes

(Burnickl, 2010). For this reason, an unsophisticated

task-allocation tool is essential. If a task is processed

by a variety of involved team members, there must

always be the “task-owner” that leads the

management of the single step in the process. This

clarifies a user’s role and responsibility in the

process to all interested parties.

Reports and evaluations are gaining more and

more importance for leading personnel. The current

state of the projects and processes needs to be

present and easy to inspect. Visualized status

reports, such as the traffic light principle or status

bars, can easily indicate the current standing of tasks

and overall projects. This report will support

managers and leaders in their supervisory roles. A

quick intervention is possible when responsibilities

are clear.

As networks are getting more complex and

short-dated through the vicissitude of the market,

this topic provides sufficient reasons for deeper

research. The single connections and interfaces of

team members over an overall Mesh of

Subcontractors need to be considered for future

studies, as many issues arise due to sweeping

approaches.

ACKNOWLEDGEMENTS

We wish to thank Kathryn Fuller for proof-reading

the manuscript.

This paper was supported by Internal Grant

Agency of University of West Bohemia. Project No.

SGS-2010-065 "Multidisciplinary Design Optimi-

zation and Operation of production system in digital

factory environment”.

REFERENCES

Adelsberger, H., Lazansky, J., Marik, V. 1995. A

Comprehensive Guide to State-of-the-Art CIM

Solutions. Springer-Verlag, Band 973, Lecture Notes

in Computer Science.

Al-Hammad, A., 2000. Common Interface Problems

among Various Construction Parties. In Journal of

Performance of Constructed Facilities, Vol. 14, Issue

2.

Berry, A., 1997. SME Competitiveness: The Power of

Networking and Subcontracting. In IFM. Inter-

American Development Bank.

Bramorski, T., 2008. A Case Study of ERP Implemen-

tation, University of Wisconsin.

Burnickl, P., 2010. Enterprise Information Systems – The

Management of Data, Information and

Responsibilities in European SMEs, University of

West Bohemia.

Lehtinen, U., 2001. Changing Subcontracting, Oulu

University Press.

Standish Group, 2009. CHAOS Summary 2009, Standish

Group Boston, Massachusetts.

Vintean, A., 2008. Non Verbal Communication in

Business Life, MPRA Munich Personal RePEc

Archive, Paper Nr. 6732.

Zarnekow, R., Brenner, W., Pilgram, U., 2006. Integrated

Information Management, Springer-Verlag. ISBN 3-

540-32306-6.

ENHANCING DATA EXCHANGE AND MANAGEMENT SUPERVISION IN A COMPLEX MESH OF

SUBCONTRACTORS - A Theoretic Approach to Counter Interface Issues in Micro-, Small- and Medium-sized

Enterprises

99