MODELING, SIMULATION AND CONTROL OF A WATER

RECOVERY AND IRRIGATION SYSTEM

Mohamed Abdelati

Electrical Engineering Department, IUG, Gaza, Palestine

Felix Felgner, Georg Frey

Chair of Automation, Saarland University, Saarbrücken, Germany

Keywords: System modeling, Water recovery, Automation, Modelica.

Abstract: For the modeling and simulation of large water recovery and irrigation systems, standard component models

as found in simulation tool libraries are too complex. In this work, simple models are derived and applied

for the modeling and simulation of a real system. In this system, water for irrigation will be collected by

recovery wells around the wastewater treatment plant infiltration basins located in northern Gaza. There will

be 27 recovery wells to collect the water in a reservoir before being distributed for irrigation via 10 booster

pumps. During summer time, the system is expected to recover and distribute about 50885 m

3

daily. The

model derived in this paper using Modelica helps better understanding the system dynamics and provides a

tool for evaluating the performance of possible control schemes.

1 INTRODUCTION

Daily amounts of about 15000 m

3

of partially treated

wastewater are infiltrated through allocated basins in

northern Gaza. Once the construction of a new

treatment plant is completed, the infiltrated water

will reach an average of 35000 m

3

per day. This

infiltrated water is not suitable for domestic use and

eventually will contaminate the aquifer of all over

northern Gaza (Werner, 2006). However, this water

is suitable for irrigation and is recommended to be

utilized due to the scarce water recourses of Gaza.

Consequently, the Palestinian Water Authority

(PWA) with technical assistance from specialists

proposed the construction of 27 recovery wells

around the infiltration basins. Pumps of 56 kW will

be used in these wells and recovered water will be

collected in a 8000 m

3

reservoir before being

distributed for irrigation via 10 booster pumps, each

with a rating of 350 kW (Ziara, 2010). Recovery

pumps have an expected head of 90 m and a pumping

capacity of 170 m

3

/hr at that head, while booster

pumps have an expected head of 115 m and a

pumping capacity of 750 m

3

/hr at that operating

point. Figure 1 illustrates the layout of the waste

water treatment plant in northern Gaza.

Figure 1: The recovery wells and collection pipes.

The presented work is part of a project which

aims to design a control system for the infiltrated

wastewater recovery. To this end, first a simulation

model is designed based on the physical properties of

the process. This model, using the component-

pipe

reservoir

recovery

well

infiltration

basins

Scale 1:22000

323

Abdelati M., Felgner F. and Frey G..

MODELING, SIMULATION AND CONTROL OF A WATER RECOVERY AND IRRIGATION SYSTEM.

DOI: 10.5220/0003457303230329

In Proceedings of the 8th International Conference on Informatics in Control, Automation and Robotics (ICINCO-2011), pages 323-329

ISBN: 978-989-8425-74-4

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

oriented modeling language Modelica (Tiller, 2004),

is then used to design and validate proposed

automation strategies.

The paper is organized as follows: Section 2

describes the recovery process and the irrigation

scheme. In Section 3, the modeling is described and

in Section 4, some simulation results of the proposed

control scheme are presented. Finally, Section 5

concludes with summary and outlook on future work.

2 RECOVERY PROCESS AND

IRRIGATION SCHEME

Hydrology specialists have studied the aquifer

characteristics and the process of water infiltration

and decided on the number, capacity, and location of

wells so as to siege the pollution plume within

standard limits. The whole amount of infiltrated

water within one year will be recovered along the

year depending on the demand patterns of the crops.

At least 10% extra should be abstracted to ensure

capturing of all infiltrated quantity. Due to security

conditions at northern Gaza, pumping is only

allowed during day time and should be adjusted

monthly with a maximum of 12 hrs in summer and 8

hrs in winter. The expected quantity of recovered

water, the number of running wells, and the duration

of daily operation are summarized in Table 1. The

beneficiary agricultural area is about 15 km

2

. It has

been split into six zones of approximately equal

sizes. Each zone will be served for one day every

week and receive the same amount of extracted

water. This irrigation pattern is recommended by

agriculture specialists after studying the soil and

types of crops.

Table1: Recovery process data.

Month

Recovered

(m

3

/day)

Number

of wells

Duration

(hrs/day)

Jan. 33081 19 8

Feb. 35816 21 8

Mar. 34995 21 8

Apr. 34204 20 10

May 46622 23 11

June 50885 25 12

July 50136 25 12

Aug. 49073 24 12

Sept. 40290 20 11

Oct. 30187 18 9

Nov. 31484 19 8

Dec. 33146 20 8

Average 39160 21 10

3 MODEL DERIVATION

Modelica is an object-oriented language developed

by the Modelica Association. Its standard library

contains a fluid package which provides components

for 1-dimensional thermo-fluid flow in networks of

pipes. All components are implemented such that

they can be used for an incompressible or

compressible medium, a single or a multiple

substance medium with one or more phases

(Elmqvist, 2003). Although it provides a user

friendly way to model water networks, we preferred

to build our own library. The reasons behind our

approach are:

1. The fluid library is a general purpose tool,

associated with an overhead that is manageable

in systems with small number of component

instances (Link, 2009). However, as the

number of instances increases, the resultant

number of equations may lead to problems in

simulation. Simplifying the components to deal

with the basic dynamics of our application

allows generating models with much less

equations.

2. Implementing the fluid components provides

more insight on the physical process and

allows better capabilities in resolving possible

programming and simulating problems.

3. It is not intended to end up with a complex

model for detailed hydraulic investigations

rather than to conclude with a manageable

working model which is well suited to test

control methodologies in large scale water

networks. It is analogues to the load flow

analysis on power systems where simple

models are used for electrical equipment and

loads.

The system under study contains instances of key

components which are tank, source/sink, pipe, fixed

speed pump, variable speed booster pump, valve,

end users, and some instruments. Developing a

model in Modelica starts by defining the connectors

(ports), then building the components, and finally

creating necessary instances of these components

and interconnecting them properly.

Water network components are interconnected

through a water connector where conservation of

mass flow is assumed. The water connector (c) is

defined as:

connector c

Modelica.SIunits.Pressure p;

flowModelica.SIunits.MassFlowRate q;

end c;

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

324

where is the mass flow rate of water into the

connector and is the water pressure at that

connector. The pressure is measured relative to the

atmospheric pressure, which is assumed to be

constant in our work. Finishing the definition of the

water port, the system components are then

addressed in the following subsections.

3.1 Water Tank

The tank has two water connectors; one is positioned

at the top for filling while the other is located at the

bottom for draining as illustrated in Figure 2. A third

connector of type real output is added to deliver the

water level information () to the controller.

Figure 2: Water tank icon.

The pressure at the outlet port is given by:

=

(1)

where is the water density, is the acceleration

due to gravity, and is the water level in the tank.

At the inlet port, a velocity head pressure is

assumed according to:

=

(2)

where is a constant that may be determined

experimentally. In simulations, is set to 0.07

Pa·s

2

/kg

2

so as to allow about one bar pressure at full

capacity.

The water level is related to the mass flow rate in

the ports as follows:

=

+

(3)

where is the cross sectional area of the tank.

Finally, the signal at the “level” port is assigned the

value of.

3.2 Boundary Source/sink

The model for source and sink has one water port as

shown in Figure 3. It is assumed that the absolute

pressure at the water source/sink is the same as the

nominal ambient pressure. Hence, a source/sink is

simply modeled by the equation=0.

Figure 3: Water source/sink icon.

3.3 Pipes

A pipe has two water ports as illustrated in Figure 4.

All pipes have circular cross section and each one is

characterized by its diameter and length.

Figure 4: Water pipe icon.

Pipes are modeled according to the Hazen–

Williams equation:

=0.849

.

.

(4)

where is the water velocity, is the roughness

coefficient, is the hydraulic radius, and is the

head loss per length of the pipe (Brater, 1996). The

value of can vary from around 100 to 150. For

PVC pipes used in our network, a value of 140 is

adopted.

Substituting

=∆/(), =/((/2)

), and

=/4 in the Hazen-Williams equation and

manipulating gives the dynamic pressure drop as:

Δ=

10.67

.

.

.

.

(5)

Let the static head of the pipe equal “”

then the pressure deference between the pipe ports is

given by:

−

=

10.67

.

.

.

.

+

(6)

3.4 Recovery Pumps

A recovery pump is a fixed-speed pump which has

two water ports and one Boolean input port () for

on/off control as illustrated in Figure 5.

Figure 5: Water recovery pump.

Pumps have head-versus-flow characteristics

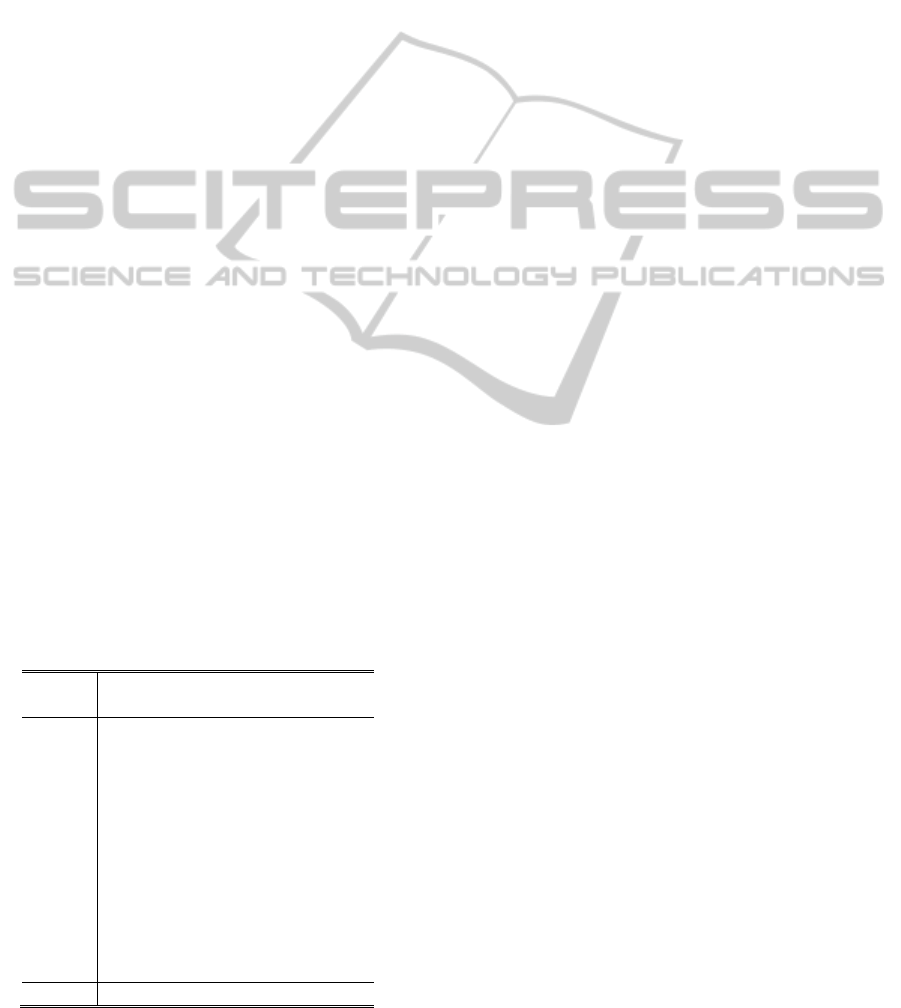

similar to the curve illustrated in Figure 6.

Por t

Por t 1 Por t 2

Por t1

Por t2

c

1

(p

1

,q

1

)

c

2

(p

2

,q

2

)

L

c(p,q)

c

1

(p

1

,q

1

)

c

2

(p

2

,q

2

)

c

1

(p

1

,q

1

)

c

2

(p

2

,q

2

)

u

MODELING, SIMULATION AND CONTROL OF A WATER RECOVERY AND IRRIGATION SYSTEM

325

Figure 6: Typical pump flow characteristic.

It may be linearized around its nominal operating

point (ℎ

,

) at which the slope of the curve is

(−). This implies that the water flow rate near the

nominal operating point is approximately given by:

=

−(ℎ−ℎ

)

(7)

If simulation is expected to encounter operating

points which are too far away from the nominal one,

then the curve may be approximated by a

polynomial equation. A check valve is installed at

each pump preventing reverse flow when a pump is

shutdown (=false). Substitutingℎ=

and

=

results in

=

−

−

−ℎ

∶=true

0 ∶=false

(8)

At the nominal operating point (90 m, 47 kg/s),

the value of for the currently selected pump is

found to be 1.04 kg/s/m.

In order to simplify modeling the recovery

network, a recovery well module consisting of a

boundary source, a vertical pipe, and a recovery

pump is encapsulated. This module is graphically

represented as illustrated in Figure 7.

Figure 7: Recovery well icon.

3.5 Booster Pumps

A booster pump is similar to a recovery pump but it

has a real signal input () for speed control as

illustrated in Figure 8.

Figure 8: Booster pump.

Currently investigated boosters are of model type

NK 150-315 from Grundfos (Grundfos, online). This

type has a flow-head slope of -2.78 kg/s/m at our

nominal operating point (115 m, 208 kg/s). As

booster pumps have a rated speed (

) of 2900 rpm,

the flow at a certain speed () is given by:

=

[

−

−

−ℎ

]

(9)

3.6 Valve

The valve model is used here to facilitate the total

user demand of water flow. Therefore, it has a linear

relation between flow and pressure drop. The model

valve has two water ports and one real input port for

opening control as illustrated in Figure 9. The

control signal is named “” and its value

ranges from 0 at full closure to 1 at full opening.

Figure 9: Water valve.

The nominal hydraulic conductance of a valve, ,

is defined as the ratio of nominal flow to nominal

pressure drop at full opening. Assuming linear

pressure drop, then the flow is governed by the

following equation:

=··(

−

)

(10)

3.7 Users’ Demand

There are variations in irrigation demand during the

year as well as during the day. In what follows,

modeling users’ demand during the peak month of

June is explained as an example. The irrigation plan,

which is already illustrated in Table 1, specifies

daily recovery and distribution of 50885 m

3

of water

during June. The variation in distribution during the

day has been determined based on the number and

size of farms as well as the irrigation preference by

farmers. The number and sizes of farms in each of

the six irrigation zones has been determined. In

addition, a questionnaire to farmers has shown that

farmers prefer to irrigate in the morning hours.

Therefore, it is assumed that all farmers start

irrigation once the pumping process starts in the

morning (7 am) and end at various times depending

on the farm size. The minimum irrigation period for

the smallest farm size of less than 1500 m

2

is 4

hours. This is achieved by allocating proper

subscription capacity for each farm. The irrigation

period increases by one hour for each 1500 m

2

increase in the farm size until reaching the

maximum of 12 hours for farms larger than 12000

q

h

Head

Flow

n

n

Slope=-m

c

Port1 Port 2

Port 1 Port2

c(p,q)

u

c

1

(p

1

,q

1

)

c

2

(p

2

,q

2

)

s

c

1

(p

1

,q

1

)

c

2

(p

2

,q

2

)

opening

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

326

m

2

where irrigation ends at 7 pm. Table 2 illustrates

demand calculations carried for one of the irrigation

zones.

Table 2: Irrigation demand calculations for zone F.

farm class

No. of

Farms

Period

(hr)

Area

(m

2

)

Demand

(m

3

/day)

Demand

(m

3

/hr)

< 1.5 5 4.0 7300 152.7 38.2

1.5 - 3.0 35 5.0 95000 1987.7 397.5

3.0 - 4.5 65 6.0 289400 6055.1 1009.2

4.5-6.0 34 7.0 213500 4467.1 638.2

6.0-7.5 19 8.0 153400 3209.6 401.2

7.5-9.0 17 9.0 165800 3469.1 385.5

9.0-10.5 13 10.0 150100 3140.6 314.1

10.5-12 11 11.0 147000 3075.7 279.6

>12 49 12.0 1210500 25327.4 2110.6

total 2432000 50885.0 5574.0

During the first 4 working hours (from 7 to 11

am), the demand has a peak of 5574 m

3

/hr (1548.3

kg/s). During the next hour (form 11 to 12 am),

demand will be reduced by 38.2 m

3

/hr and in the

consecutive hour, it will be reduced by 397.5 m

3

/hr

and so on. Using this approach, the demand values

along the day are computed for each irrigation zone

and the results are normalized to their maximum

value (1548.3 kg/s) as listed in Table 3.

Table 3: Relative demand values for irrigation zones.

Time A B C D E F

07:00 - 11:00 0.8152 0.8831 0.8489 0.8830 0.9237 1.0000

11:00 - 12:00 0.8137 0.8826 0.8479 0.8780 0.9232 0.9970

12:00 - 13:00 0.8063 0.8709 0.8353 0.8637 0.9156 0.9579

13:00 - 14:00 0.7987 0.8326 0.8110 0.8392 0.8632 0.8389

14:00 - 15:00 0.7777 0.8008 0.7791 0.8082 0.8049 0.7512

15:00 - 16:00 0.7570 0.7255 0.7489 0.7336 0.7189 0.6881

16:00 - 17:00 0.7427 0.6678 0.7272 0.6949 0.6506 0.6199

17:00 - 18:00 0.7216 0.6226 0.6827 0.6384 0.5414 0.5582

18:00 - 19:00 0.6883 0.5804 0.6785 0.5978 0.4915 0.4977

Sharp transitions are smoothed by a first-order

low pass filter whose time constant is 3 minutes to

generate more realistic transitions in the demand

function. This function is used to specify the

opening of the users’ valve. Designers of the

irrigation network specified the nominal head at

farmers tab to be 2.5 bar. Therefore, in simulations it

is assumed that the valve has a nominal flow of

1548.3 kg/s and a nominal pressure drop of 2.5 bar.

This implies that the hydraulic conductance of the

valve is 0.061932 kg/s/Pa.

3.8 Instruments

The flow and pressure meters are modeled as ideal

devices. They just tap the required physical

quantities and provide them through connectors of

type real.

4 SIMULATION RESULTS

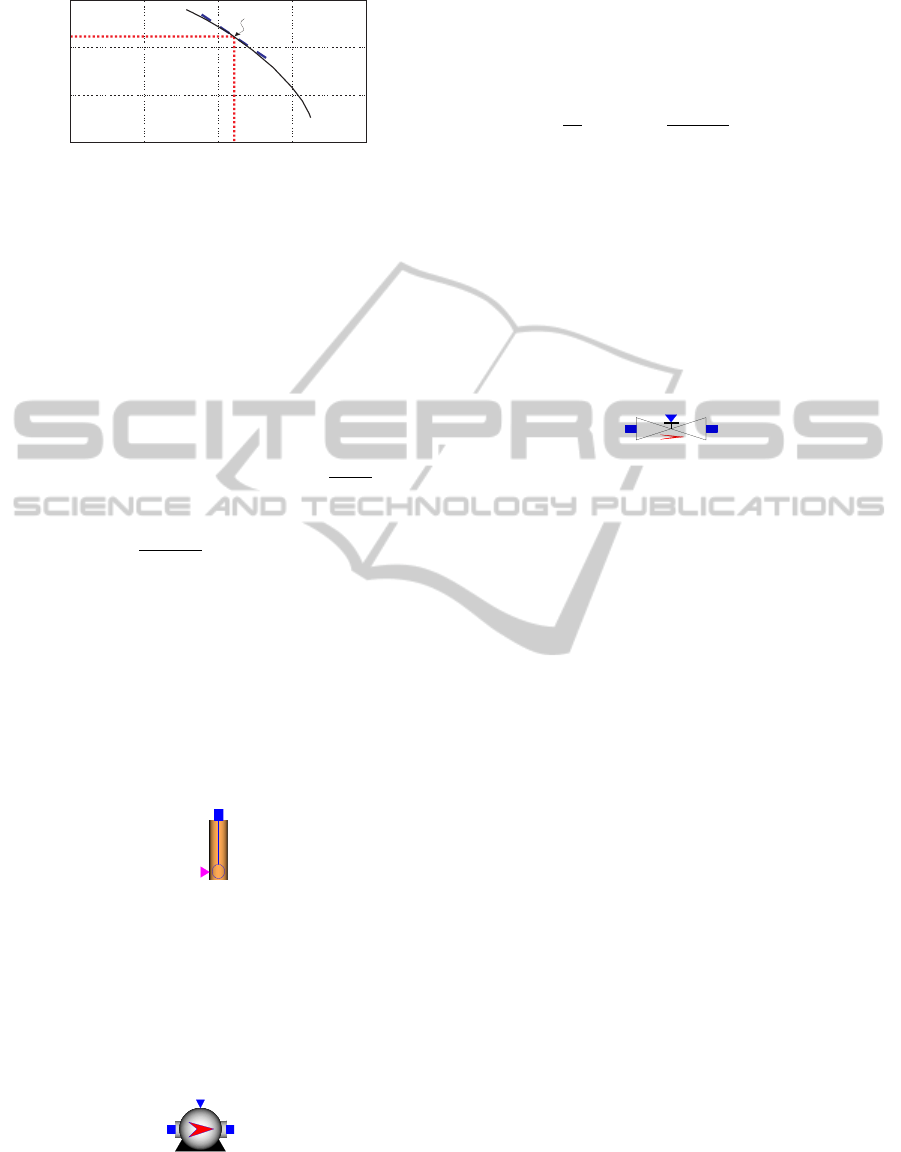

The system is built in Dymola and fed by wells’

depths and pipes’ data as illustrated in Figure 10.

Different control schemes and various running

scenarios are examined to validate the model.

Selected results are presented in this section to

provide an overview of the system dynamics.

Figure 10: Top level model of the system.

The control variables are the water level of the

tank (L) and the water flow rate at the distribution

pipe (Q). The tank has a capacity of 8000 m

3

and has

a height of 5m. The reference value of L is set to 4.9

m. This tolerates possible overshoots up to 2% of the

height before occurrence of overflow. Meanwhile, it

utilizes about 98% of storage capacity to handle

possible daily demand variations. The reference

value of the flow is the expected water demand. In

regular conditions, the controller will be able to

manage water distribution as planned. However, in

certain circumstances, the behavior of farmers may

not be as scheduled. This has a direct impact on the

pressure at the distribution network. The controller

should use the pressure signal (P) at the output of the

booster pumps as an interlock variable. The

controller should protect the distribution network

from over-pressure conditions by keeping the signal

P less than the threshold value specified by the

hydraulic system designers (11 bar in our case). On

the other hand, if farmers require more water than

scheduled while having some idle pumping

resources, resultant decrease in the pressure may be

Users

ON/OFF vector

Speed vector

W1 W2 W3 W4 W5

W6 W7 W8 W9 W10 W11

W12 W13 W14 W15 W16

W17 W18 W19 W20 W21

W22 W23 W24 W25 W26 W27

Demand

Rela t iv e

Controller

s

L

P

Q

u

LPF

MODELING, SIMULATION AND CONTROL OF A WATER RECOVERY AND IRRIGATION SYSTEM

327

used by the controller to increase the pumping rate.

However, this has an impact on the aggregated

amount of extracted water. Due to this consequence,

it has been decided to ignore low pressure events so

as to encourage farmers to obey the planned

irrigation schedule.

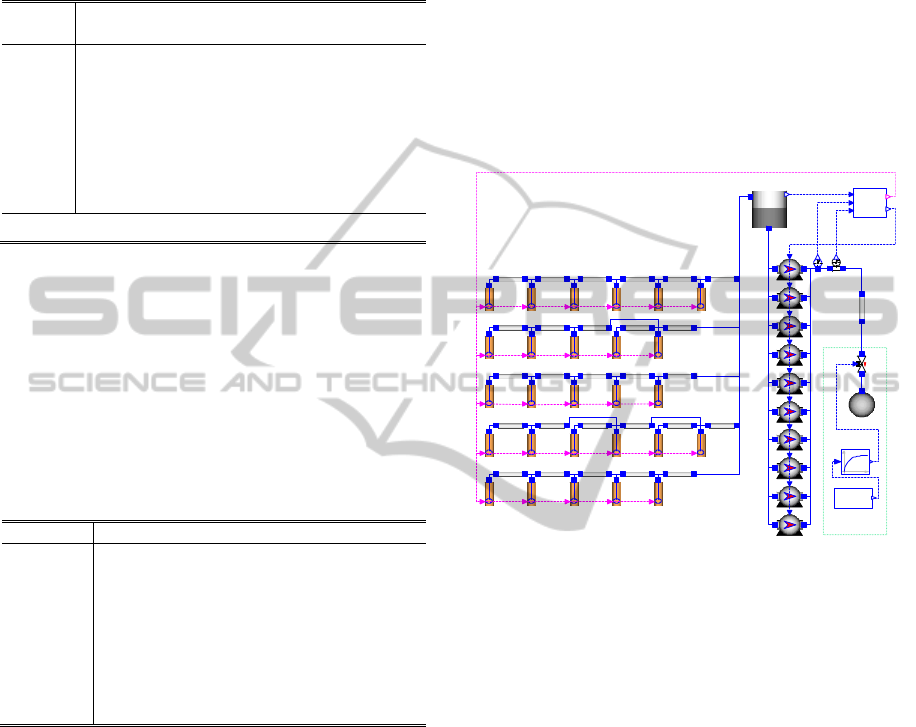

The filling process controller is based on a PID

controller with limited output, anti-windup

compensation and set point weighting as illustrated

in Figure 11 (Astrom, 1995). This PID controller is

available in the Modelica standard library. The

controller is tuned and its output is limited to the

range [0, 25]. The analog output is quantized taking

into account a sufficient hysteresis value (0.4) to

prevent possible oscillations. The resultant number

specifies the required number of running wells. One

should mention that this number is limited to 25 in

order to leave 2 wells as standby.

Figure 11: Filling process controller.

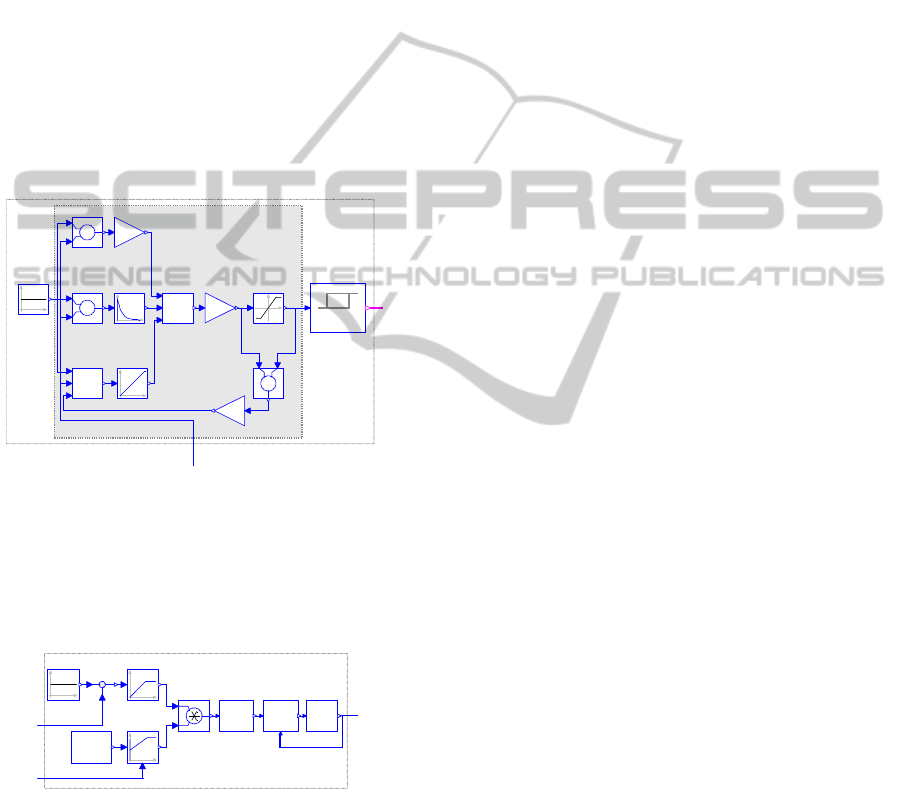

On the other hand, the distribution process has

10 speed-controlled boosters and the maximum

capacity is limited to 8, leaving 2 as standby. The

simulated controller of this process is shown in

Figure 12.

Figure 12: Distribution process controller.

The lower part of the controller has a PID

module with limited output, anti-windup

compensation and set point weighting. Its output

specifies the required pumping capacity which has a

minimum of 0 when all pumps are off and a

maximum of 8·2900 when 8 booster pumps run at

their full speed. The upper part has an integrator

with a limited output [0,1]. In regular cases, the error

signal is positive and the integrator saturates to unity

value. Once the pressure exceeds the specified

threshold (P

th

≈98% of the maximum permissible

pressure), the integrator output starts to decrease and

eventually saturates to 0. This gives a measure for

the persistence of the pressure to exceed the

threshold value. The result of this integrator is

multiplied with the output of the Limited PID

module to generate the recommended pumping

capacity. The distributer module uses this value to

generate the reference speeds for the boosters. In

order to maximize efficiency, only one booster

pump may be assigned a partial load while all others

that share the pumping load must be assigned the

rated speed. The sequencer block regulates the

starting and shutting operations of the boosters. In

order to protect the hydraulic system from water

hummer effects and also to protect the power system

from electrical surges, booster pumps are allowed to

enter or leave operation only one after another.

Having a feedback from the Variable Frequency

Drives (VFD) of the motors, the sequencer is able to

manage that task. The VFD is modeled by a first-

order block with a time constant of 5 s resulting in

an acceleration time of about half a minute to move

forward or backward between zero speed and rated

speed states.

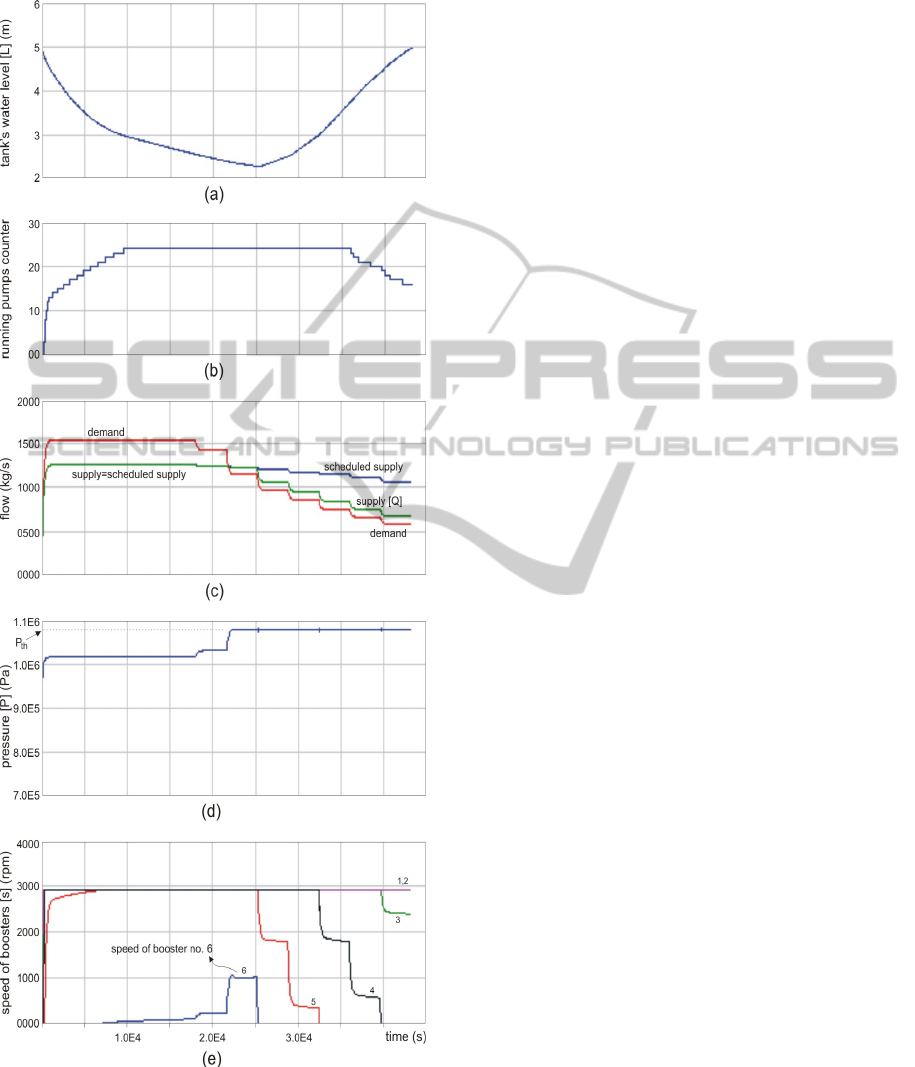

The most important simulation outputs are

shown in Figure 13. The tank’s water level (L) is

depicted in Figure 13a. As intended, the tank starts

at full state in the morning and the controller

returned it back to that state at the end of day. The

number of running pumps, which is shown in Figure

13b, demonstrates how pumps are called for running

when the error signal (deviation from the tank full

state) and its derivative is high in the morning. Later

in the afternoon, supplied water is less than collected

water, and thus the water level in the tank starts to

increase. Consequently, the controller decreases the

number of running pumps. Figure 13c shows the

demanded flow, the scheduled supply flow, and the

supplied flow (Q). The test data is designed to

explore the controller behavior when there is a large

mismatch between demand and scheduled supply.

During the first half of the day, there is excessive

demand and the controller supplies the planned

quantity. In contrast, during the second half of the

day, demand is much less than the scheduled supply.

The controller delivers excess flow to the extent that

pressure (P) at the network does not exceed the safe

limit as illustrated in Figure 13d. Finally, Figure 13e

shows how 6 booster pumps share the pumping load

of that day. At any given time, the controller adjusts

LimPID

L

u

tank's water level

limiter

uMax={25}

limiter

addP

-1

wp

addP

+

wp

-1

addD

-1

wd

addD

+

wd

-1

k={1}

P

I

I

k={16000}

D

k={5000}

k={12}

gainPID

addPID

+1

+1

+1

+

addI

+1

-1

+1

+

addSat

-1

+1

addSat

+

+1

-1

k={0.093}

gainTrack

Quantizer

Setpoint

k={4.9}

P

actual supply flow

speed vector

s

Q

limPID

PID

-

feedback

product

LimIntegrator

I

k={1e-5}

sequenc er

distributer

VFD

Pt h

k={10.8e5}

Supply

Schedualed

ICINCO 2011 - 8th International Conference on Informatics in Control, Automation and Robotics

328

the speed of only one booster pump. Other boosters

are either off or at their rated speed.

Figure 13: Major simulation outputs.

5 SUMMARY AND OUTLOOK

This work presents the design of an easily

manageable model of the water reuse system in

northern Gaza. The resultant model provides a novel

tool for testing the performance of the system under

different operation scenarios and control schemes. It

also helps in understanding the dynamics of the

system and enables designing and tuning a stable

and robust controller for the system. It is our aim in

a future work to elaborate on the control problem

and derive a cost function for running the system. In

other words, we plan to develop a practical criterion

for optimal performance of the system and study the

influence of uncertainties in users’ demand.

ACKNOWLEDGEMENTS

The authors would like to express their gratitude to

Alexander von Humboldt Foundation for supporting

this work. M. Abdelati is also grateful to his

colleagues at The Center for Engineering and

Planning and at the Finnish Consulting Group for

their cooperation.

REFERENCES

Astrom K. and Hagglund T., 1995. PID Controllers:

Theory, Design, and Tuning, North Carolina,

Instrument Society of America, 2nd edition.

Brater E., King H. and Lindell J., 1996. Handbook of

Hydraulics, Mc Graw Hill, New York, 7th Edition.

Elmqvist H., Tummescheit H., and Otter M., 2003.

Object-Oriented Modeling of Thermo-Fluid Systems,

Proceedings of the 3rd International Modelica

Conference, Linköping.

Grundfos, NKG 16 bar End Suction Pumps, pp60: www.

unopomp.com/Resimler/SiteIcerik/NKGendsuctionpu

mps16bar.pdf

Link K., Steuer H., and Butterlin A., 2009. Deficiencies of

Modelica and its simulation environments for

largefluid systems, Proceedings 7th Modelica Confe-

rence, Como, Italy.

Tiller M., 2004. Introduction to Physical Modeling with

Modelica, Kluwer Academic Publishers.

Massachusetts, 2ed printing.

Werner M. et al., 2006. North Gaza Emergency Sewage

Treatment Plant Project - Environmental Assessment

Study, Engineering and Management Consulting

Center.

Ziara M. et al., 2010. Consulting Services for Detailed

Design and Tender Documents of Effluent Recovery

and Irrigation Scheme of NGEST, Joint Venture

Association of the Center for Engineering and

Planning (CEP) and the FCG International Ltd.

MODELING, SIMULATION AND CONTROL OF A WATER RECOVERY AND IRRIGATION SYSTEM

329