FEASIBLE DYNAMIC RECONFIGURATIONS OF PETRI NETS

Application to a Production System

Mohamed Khalgui

1,2

, Olfa Mosbahi

1,2

1

ICTICA, Ariana, Tunisia

Jiafeng Zhang

2

, Zhiwu Li

2

2

Xidian University, Xi’an, Shaanxi, China

Atef Gharbi

University of Carthage, Tunis, Tunisia

Keywords:

Petri Net, Control System, Reconfiguration, Model Checking, Computation Tree Logic.

Abstract:

The paper deals with dynamic automatic reconfigurations of Control Systems to be classically modelled by

Petri nets. Three different forms can be applied at run-time to reconfigure such systems: Addition/Removal of

places, Addition/Removal/Update of transitions or finally the simple change of the initial marking. We define

three formal modules allowing reconfigurations of the system’s Petri nets: changer places to dynamically

change places of the model, changer transitions to dynamically reconfigure transitions, and changer marking

to modify the initial markings of places. To guarantee a correct behavior of this architecture according to

user requirements, we apply a model checking by using the useful tool SESA for the verification of CTL-

based properties of the proposed modules and also of the system. The paper is applied to a Real Benchmark

Production System.

1 INTRODUCTION

The new generation of control systems is addressing

new criteria as flexibility and agility. To reduce their

cost, these systems should be changed and adapted to

their environment without disturbances. Several in-

teresting academic and industrial research works have

been made in recent years to develop reconfigurable

control systems (Gehin and Staroswiecki, 2008). We

distinguish in these works two reconfiguration poli-

cies: static and dynamic reconfigurations such that

static reconfigurations are applied off-line to apply

changes before the system’s cold start (Angelov et al.,

2005), whereas dynamic reconfigurations are dynam-

ically applied at run-time. Two cases exist in the

last policy: manual reconfigurations applied by users

(Rooker et al., 2007) and automatic reconfigurations

applied by Intelligent Agents (Al-Safi and Vyatkin,

2007). We are interested in this paper in automatic

reconfigurations of control systems that we model by

the formal formalism Net Condition/Event Systems

(NCES) which is an extension of Petri nets (Rausch

and Hanisch, 1995). In NCES, places classically cor-

respond to control actions to be done by the control

system. To move from a place to another, a transi-

tion should be fired. There are several conditions to

be fulfilled to enable a transition to fire. First of all,

all pre-places have to be marked with at least one to-

ken. In addition, it may have incoming condition arcs

from places and event arcs from other transitions. A

transition is enabled by condition signals if all source

places of the condition signals are marked by at least

one token. The other type of influence on the firing

can be described by event signals which come to the

transition from some other transitions. We mean in

this research paper by an automatic reconfiguration

any addition-removal of places, transitions, condition

signals or event signals to/from the NCES specify-

ing the control system, and any change in the ini-

tial marking. To handle automatic reconfigurations,

we define three NCES-based modules such that the

first allows the addition-removal of places in/from the

system’s NCES, the second allows addition-removal

of transitions, event signals, condition signals in/from

the system, and finally the third allows modifications

of the initial marking. To guarantee a correct be-

105

Khalgui M., Mosbahi O., Zhang J., Li Z. and Gharbi A..

FEASIBLE DYNAMIC RECONFIGURATIONS OF PETRI NETS - Application to a Production System.

DOI: 10.5220/0003448901050110

In Proceedings of the 6th International Conference on Software and Database Technologies (ICSOFT-2011), pages 105-110

ISBN: 978-989-8425-77-5

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

havior of the whole system after any reconfigura-

tion scenario, we apply a model checking by using

the tool SESA that allows verifications of properties

of system’s NCES and also of the proposed mod-

ules (Rausch and Hanisch, 1995). We use the tem-

poral logic ”‘Computation Tree Logic” (denoted by

CTL) to specify these properties (Roch, 2000a; Roch,

2000b). The paper is applied to a Benchmark Pro-

duction System EnAS available in the Research Lab-

oratory of Prof.Dr. Hans-Michael Hanisch at Martin

Luther University in Germany. We describe this sys-

tem in (Mohamed Khalgui, 2008).

We present a quick state of the art on model check-

ers in the next section, before specify reconfigurable

control systems in Section 3, and propose the recon-

figuration modules in Section 4. We apply in Section

5 the model checking of the whole architecture, and

conclude the paper in Section 6.

2 STATE OF THE ART: MODEL

CHECKERS

Finite state machines (abbr. FSM) are widely used for

the modelling of control flow in embedded systems

and are amenable to formal analysis like model check-

ing (Clarke et al., 2000; Clarke and Kurshan, 1996;

Holzmann, 1997; Vardi and Wolper, 1994; Ma and

Tsai, 2008). Two kinds of computational tools have

been developed last years for model checking: tools

like KRONOS (Daws et al., 1996), UPPAAL (Am-

nell et al., 2001), HyTech (Henzinger et al., 1997) and

SESA (SESA, 2008) which compute sets of reachable

states exactly and effectively, whereas emerging tools

like CHECKMATE (Chutinan and Krogh, 1999), d/dt

(Asarin et al., 2000) and level-sets (Mitchell and

Tomlin, 2000) methods approximate sets of reach-

able states. Several research works have been pro-

posed in recent years to control the verification com-

plexity by applying hierarchical model checking for

complex embedded systems. The authors propose in

(Alur and Yannakakis, 1998) an approach for verifica-

tions of hierarchical (i.e. nested) finite state machines

whose states themselves can be other machines. The

straightforward way to analyze a hierarchical machine

is to flatten and apply a model checking tool on the

resulting ordinary FSM, but the authors show in this

interesting research work that this flattening can be

avoided by developing useful algorithms for verifica-

tions of hierarchical machines.

3 SPECIFICATION OF

RECONFIGURABLE CONTROL

SYSTEMS

Reconfiguration means qualitative changes in struc-

tures, functionalities, and algorithms of control sys-

tems as responses to qualitative changes of goals of

controls, of controlled systems, or of environments

the systems behaves within. This could be caused

by (partial) failures, breakdowns, or even by human

interventions. Let us denote by Sys the reconfig-

urable control system to be modelled by Net Con-

dition/Event Systems Σ(Sys) that specify all possi-

ble behaviors of the system to be applied after well-

defined reconfigurations.

Σ(Sys) = {PTN, CN, WCN, I, WI, EN, em}

Where,

PT N = {P

Σ(Sys)

, T

Σ(Sys)

, F

Σ(Sys)

, W

Σ(Sys)

}

We mean by a reconfiguration scenario of Σ(Sys)

(i) any addition/removal of places, (ii) any addi-

tion/removal of transitions, (iii) any addition/removal

of condition-event arcs, (iv) any update of marking.

The system can be specified by different sub-NCES

defining different possible behaviors to be followed

under well-defined conditions. Let ξ(Sys) be a sub-

NCES that models Sys after a well-defined automatic

reconfiguration scenario.

ξ(Sys) = {PT N

ξ(Sys)

, CN

ξ(Sys)

, WCN, I, W I, EN

ξ(Sys)

,

em}

Where,

PT N

ξ(Sys)

= {P

ξ(Sys)

, T

ξ(Sys)

, F

ξ(Sys)

, W

ξ(Sys)

}

Such that,

• P

ξ(Sys)

⊆ P

Σ(Sys)

,

• T

ξ(Sys)

⊆ T

Σ(Sys)

,

• F

ξ(Sys)

⊆ F

Σ(Sys)

.

If ξ(Sys) specifies the system when a particular re-

configuration scenario is applied, the places of P

ξ(Sys)

(resp, transitions of T

ξ(Sys)

and arcs of F

ξ(Sys)

) be-

come the only able places of P

Σ(Sys)

to be activated

(resp, only able transitions of T

Σ(Sys)

and able arcs of

F

Σ(Sys)

). The rest of places, transitions and arcs be-

come disable.

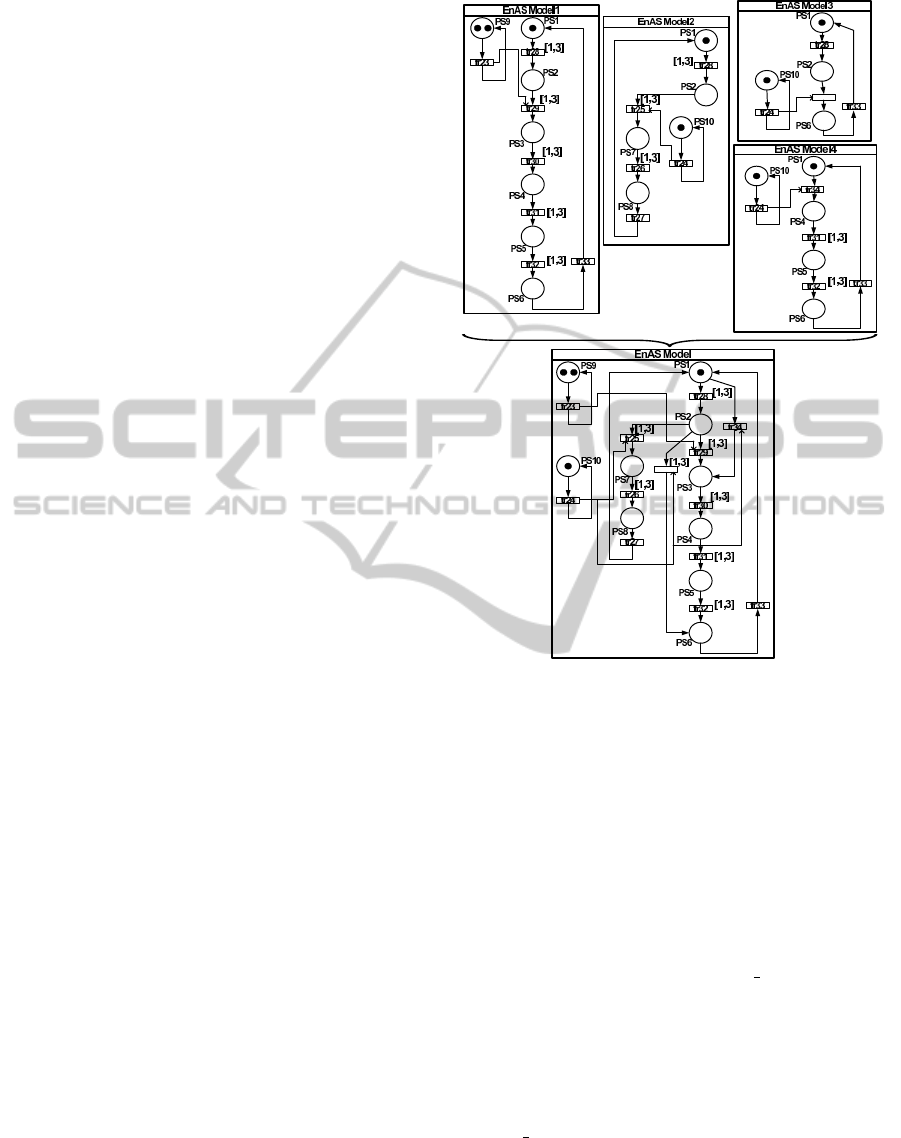

Running Example.

In the Benchmark Production System EnAS, only

four sub-NCES are possible to specify its behavior

when well-defined reconfiguration scenarios are au-

tomatically applied at run-time (Figure 1).

• Let ξ

1

(Sys) be the first sub-NCES that specifies

EnAS when the Second Production Policy is ap-

plied such that (EnAS model1 in Figure 1):

ICSOFT 2011 - 6th International Conference on Software and Data Technologies

106

P

ξ

1

(Sys)

= {PS1, PS2, PS3, PS4, PS5, PS6, PS9}

The place PS1 corresponds to the displacement of

an empty tin on the belt to the first Jack station

where a piece is put (e.g. the place PS2). The

tin is displaced thereafter (e.g. place PS3) to the

second Jack station where a second piece is put

before it is closed with a cup (e.g. place PS4). The

closed tin is displaced thereafter on the belt (e.g.

place PS5) to the second Gripper station G2 for an

evacuation to the second storing station St2. We

note finally that the place PS9 defines the number

of pieces (e.g. two pieces) to be put in the tin

when the Second Production Policy is applied.

• Let ξ

2

(Sys) be the second sub-NCES that speci-

fies EnAS when the First Production Policy is ap-

plied such that (EnAS model2 in Figure 1):

P

ξ

2

(Sys)

= {PS1, PS2, PS7, PS8, PS10}

The place PS7 corresponds to the displacement

of a tin containing a piece and closed with a cup

from the first Jack station to the first Gripper sta-

tion (e.g. place PS8). We note finally that the

place PS10 defines the number of pieces (e.g. one

piece) to be put in the tin when the First Produc-

tion Policy is applied.

• Let ξ

3

(Sys) be the third sub-NCES that specifies

EnAS when the second Jack station is broken such

that (EnAS model3 in Figure 1):

P

ξ

3

(Sys)

= {PS1, PS2, PS6, PS10}

The place PS2 corresponds to the placement of a

piece in a tin to be closed with a cup in the first

Jack station. The place PS 6 corresponds to the re-

moval from the belt to the second Storing Station

St2.

• Let ξ

4

(Sys) be the fourth sub-NCES that specifies

EnAS when the first Jack station is broken such

that (EnAS model4 in Figure 1):

P

ξ

4

(Sys)

= {PS1, PS3, PS4, PS5, PS6, PS10}

The places PS1 and PS3 correspond to the dis-

placement of an empty tin on the belt to the sec-

ond Jack station where a piece and a cup are put

(e.g. the place PS4). The closed tin is displaced

thereafter on the belt (e.g. place PS5) to the sec-

ond Gripper station G2 for an evacuation to the

second storing station St2 (e.g. PS6). We note

finally that the place PS10 defines the number of

pieces (e.g. only one piece) to be put in the tin

when the first Jack station is broken.

Figure 1: Specification of the Reconfigurable EnAS with

NCES.

4 RECONFIGURATION OF NET

CONDITION/EVENT SYSTEMS

To dynamically reconfigure the NCES Σ(Sys), we de-

fine nested state machines where states correspond

to other state machines. Each state machine forms

a module allowing reconfigurations of the system.

Three types of modules are distinguished in this pa-

per: the first module called changer places is mod-

elled by a NECS to be denoted by CP in which each

place p = recon f igure(ξ(Sys)) corresponds to a sub-

set P

ξ(Sys)

⊆ P

Σ(Sys)

. Therefore each transition in this

state machine corresponds to the addition-removal of

places in/from the system’s specification. For each

place p of CP, we define a particular module called

changer transitions and modelled by NCES to be de-

noted by CT (CT = transition(p)) in which each place

corresponds to a particular composition of places in

the system’s specification ξ(Sys). Each transition

corresponds therefore to the addition or removal of

transitions, event or condition arcs in ξ(Sys) (p =

FEASIBLE DYNAMIC RECONFIGURATIONS OF PETRI NETS - Application to a Production System

107

recon f igure(ξ(Sys))). We define finally a third par-

ticular type of modules called changer marking mod-

elled by a NCES to be denoted by CM in which each

place corresponds to a particular marking of Σ(Sys).

A place of CM corresponds to one or more places of

a module changer transitions or the whole module

changer places.

CP =

{PT N

CP

, CN

CP

, WCN

CP

, I

CP

, W I

CP

, EN

CP

, em

CP

}

PT N

CP

= {P

CP

, T

CP

, F

CP

, W

CP

}

CT =

{PT N

CT

, CN

CT

, WCN

CT

, I

CT

, W I

CT

, EN

CT

, em

CT

}

PT N

CT

= {P

CT

, T

CT

, F

CT

, W

CT

}

CM =

{PT N

CM

, CN

CM

, WCN

CM

, I

CM

, W I

CM

, EN

CM

, em

CM

}

PT N

CM

= {P

CM

, T

CM

, F

CM

, W

CM

}

We denote by ∆(CT ) (resp. ∆(CM)) the set of C T

(resp. CM) modules. The whole control system is

characterized by different behaviors such that each

one should be executed after a well-defined recon-

figuration scenario. Each scenario to be denoted by

(p, q, k) (p ∈ P

CP

, q ∈ P

CT

= transition(p) such that

CT ∈ ∆(CT ), and k ∈ P

CM

such that CM ∈ ∆(CM))

is executed when the corresponding place p is ac-

tive in CP, the place q is active in CT and finally

the place k is active in the module CM. We denote

by Behavior

p,q,k

(Sys) the sub-NCES of Σ(Sys) that

can implement Sys when the reconfiguration scenario

(p, q, k) should be automatically applied. We syn-

chronize the modules CP, CT and CM by event sig-

nals as follows: For each scenario (p, q, k),

• ∀t1 ∈

•

p and t2 ∈

•

q, ∃ev1 ∈ (t1, t2),

• ∀t2 ∈

•

q and t3 ∈

•

k, ∃ev2 ∈ (t2, t3).

We synchronize in addition the reconfiguration

modules and the specification Σ(Sys) of the system

Sys by event signals as follows: For each scenario

(p, q, k) such that Behavior

p,q,k

(Sys) = ξ(Sys),

• ∀t1 ∈

•

q, ∃t2 ∈ T

ξ(Sys)

such that ∃ev1 = (t1, t2),

• ∀t3 ∈

•

k, ∃t4 ∈ T

ξ(Sys)

such that ∃ev2 = (t3, t4).

The events ev1 and ev2 allow applications of re-

configuration scenarios to activate places and/or tran-

sitions and/or arcs and/or to change marking in the

NCES ξ(Sys) ∈ Σ(Sys).

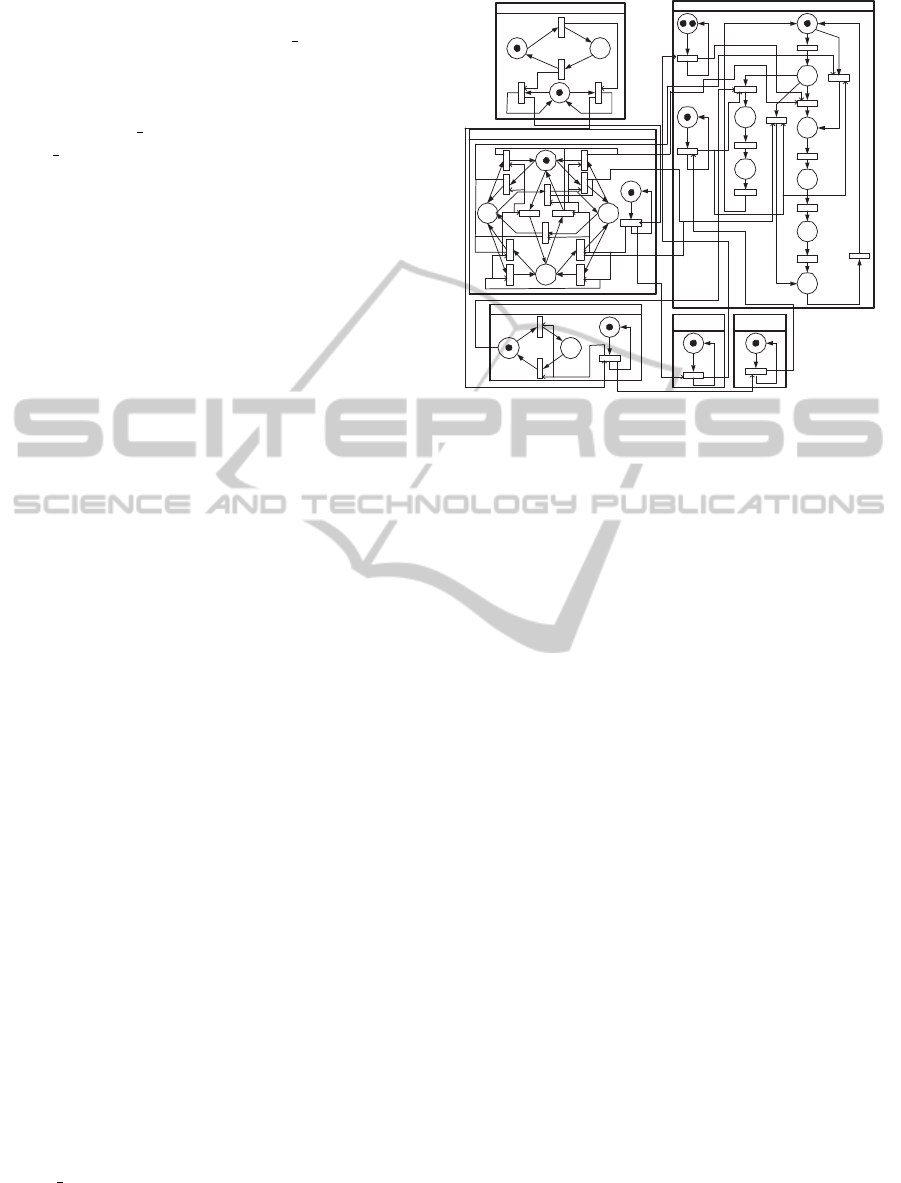

Running Example.

According to Figure 2, the module

Changer places CP1 is composed of two places

P1 and P2 that respectively define the Second and

the First Production Policy. The transitions tr1 and

tr2 define in this case the addition and removal

Controller of Transitions: CT1

Controller of Places: CP1

Controller of Transitions: CT2

Controller of

Marking: CM1

Controller of

Marking: CM2

EnAS Model

P4

P1 P2

P3

P5

P6

P7

P8

P9 P10

P11

P12 P13

PS1

PS2

PS3

PS4

PS5

PS6

PS7

PS8

PS9

PS10

tr1tr2

tr3

tr4

tr5tr6

tr7tr8

tr9

tr10

tr11

tr12

tr13

tr14

tr15tr16

tr17

tr18tr19

tr20

tr21

tr22

tr23

tr24

tr25

tr26

tr27

tr28

tr29

tr30

tr31

tr32

tr33

tr34

[1,3]

[1,3]

[1,3]

[1,3]

[1,3]

[1,3]

[1,3]

[1,3]

Figure 2: NCES-based Modules for Automatic Reconfigu-

rations of EnAS.

of places in the system’s specification. When the

transition tr1 is fired, we disable the places PS3,

PS4, PS5, PS6 and PS9, and we activate the places

PS7, PS8 and PS10. We associate for the place P1

the NCES CT 1 and for the place P2 the NCES C T 2.

The place P4 of the module CT 1 corresponds to

the execution of the second production policy when

PS1, PS2, PS3, PS 4, PS5, PS6, PS9 are specifying

EnAS. The place P5 specifies the system when

the second Jack station is broken. The place P6

corresponds to any problem in the first Jack station.

The place P7 is reached when the first and the second

Jack stations are broken. The place P9 of the module

CT 2 defines an execution scenario of EnAS when the

first Jack and Gripper stations are used to produce

pieces. We note in addition that the places P12 is

active from the module CT 1 when we put two pieces

in the tin, whereas the place P13 is active when only

one piece is put in the tin (e.g. it is activated by CT 2).

5 MODEL CHECKING OF

RECONFIGURABLE

PETRI-NETS

Once the reconfigurable Petri nets are well-modelled,

the next step to be addressed is their verification in or-

der to guarantee a correct behavior of the system after

any reconfiguration scenario. We use in this research

work the model checker SESA to verify CTL-based

properties defined in user requirements. This tool al-

lows the verification of any reactions of reconfigura-

tion modules as well as their synchronization with the

ICSOFT 2011 - 6th International Conference on Software and Data Technologies

108

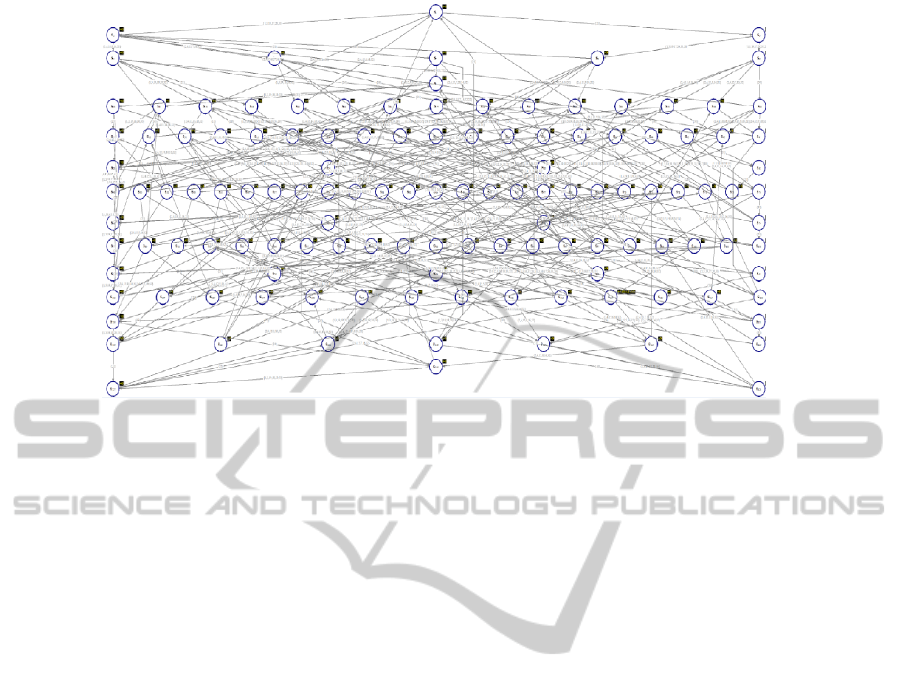

Figure 3: Reachability Graph of the Reconfigurable Architecture.

system’s NCES that should be checked too. We show

in Figure 3 a reachability graph generated by SESA

for the verification of NCES depicted in Figure 2.

Running Example.

In the system EnAS, we check functional proper-

ties of the state machines that encode the agent and

the system’s NCES. We have to check in particular

that whenever the transition tr1 is fired, then the place

PS7 should be reached:

AGAtr1XPS 7

This formula is proven to be True by applying this

tool. Indeed, when conditions are satisfied to apply

the Second Production Policy, the state PS7 should

be reached. We have also to check that whenever the

transition tr5 is fired to apply the second policy, the

place PS5 should be applied to bring the tin from the

first and second Jack stations to the second Gripper

station:

AGAtr5XPS 5

This formula is proven to be True. We check also

the correct behavior of the system EnAS when the

Second Production Policy is applied by verifying the

following formula:

AGAtr29XAFEtr30X AFEtr31X AFEtr32XT RUE

Indeed, whenever the belt is activated to transport

a piece to the first Jack station, it is activated again to

transport the piece to the second Jack station before

reaching the second Gripper station. This formula is

proven to be True by SESA. When the Second Pro-

duction Policy is applied, we check also if the evac-

uation of a closed tin from the belt can be done in

4 time units. The following formula is proven to be

False by SESA:

EF[3, 4]PS 6

The following formula is proven to be True:

AF[5, 6]PS6

Indeed the state PS6 (e.g. evacuation from the

belt) should be reached 5 time units at least after the

activation of the place PS1.

6 CONCLUSIONS

The paper deals with automatic reconfigurations to

dynamically change the behaviors of control systems:

it is a New Challenge in Industry. We specify this

behavior by Net Condition/Event Systems which is

an extension of Petri nets. A reconfiguration scenario

is any addition-removal-update of places, transitions,

event signals, condition signals, or just the modifica-

tion of the initial marking. We define formal modules

allowing reconfigurations of NCES, where the first

module deals with places, the second with transitions

and the third with the marking. We apply a model

checking for the verification of CTL-based properties

in order to guarantee a safe bevahior of this recon-

figurable architecture. In future works, we plan the

NCES-based modelling and CTL-based verification

of communication protocols that allow safe coordi-

nations inside distributed control systems.

ACKNOWLEDGEMENTS

This work was supported in part by the Natural Sci-

ence Foundation of China under Grant 60773001, the

FEASIBLE DYNAMIC RECONFIGURATIONS OF PETRI NETS - Application to a Production System

109

Fundamental Research Funds for the Central Uni-

versities under Grant No. 72103326, the National

Research Foundation for the Doctoral Program of

Higher Education, the Ministry of Education, P. R.

China, under Grant No. 20090203110009, ”863”

High-tech Research and Development Program of

China under Grant No 2008AA04Z109, the Research

Fellowship for International Young Scientists, Na-

tional Natural Science Foundation of China, and

Alexander von Humboldt Foundation.

REFERENCES

Al-Safi, Y. and Vyatkin, V. (2007). An ontology-based

reconfiguration agent for intelligent mechatronic sys-

tems. In Third International Conference on Indus-

trial Applications of Holonic and Multi-Agent Sys-

tems. Springer-Verlag.

Alur, R. and Yannakakis, M. (1998). Model checking of

hierarchical state machines. In Sixth ACM Symposium

on the Foundations of Software Engineering, pp. 175-

188.

Amnell, T., Behrmann, G., Bengtsson, J., D’Argenio, P. R.,

David, A., Fehnker, A., Hune, T., Jeannet, B., Larsen,

K. G., Mller, M. O., Pettersson, P., Weise, C., and

Yi, W. (2001). Uppaal - Now, Next, and Future. In

Proceedings of Modelling and Verification of Paral-

lel Processes (MOVEP’2k), France. LNCS Tutorial

2067, pages 100-125, F. Cassez, C. Jard, B. Rozoy,

and M. Ryan (Eds.).

Angelov, C., Sierszecki, K., and Marian, N. (2005). De-

sign models for reusable and reconfigurable state ma-

chines. In L.T. Yang and All (Eds): EUC 2005, LNCS

3824, pp:152-163. International Federation for Infor-

mation Processing.

Asarin, E., Bournez, O., Dang, T., and Maler, O. (2000).

Approximate reachability analysis of piecewise-linear

dynamical systems. In Hybrid Systems: Computation

and Control, Third International Workshop, LNCS.

Chutinan, A. and Krogh, B. K. (1999). Verification of

polyhedral-invariant hybrid automata using polygonal

flow pipe approximations. In Hybrid Systems: Com-

putation and Control, Second International Work-

shop, LNCS.

Clarke, E., Grumberg, O., and Peled, D. (2000). Model

checking. In MIT Press.

Clarke, E. and Kurshan, R. (1996). Computer-aided verifi-

cation. In IEEE Spectrum, 33(6).

Daws, C., Olivero, A., Tripakis, S., and Yovine, S. (1996).

The tool kronos. In Hybrid Systems III, Verification

and Control, LNCS 1066, Springer-Verlag.

Gehin, A.-L. and Staroswiecki, M. (2008). Reconfiguration

analysis using generic component models. In IEEE

Transactions on Systems, Machine and Cybernetics,

Vol.38, N.3.

Henzinger, T. A., Ho, P., and Womg-Toi, H. (1997). Hytech:

the next generation. In TACAS95: Tools and Algo-

rithms for the Construction and Analysis of Systems,

LNCS.

Holzmann, G. (1997). The model checker spin. In IEEE

Transactions on Software Engineering, 23(5).

Ma, L. and Tsai, J. (2008). Formal modeling and analysis of

a secure mobile-agent system. In IEEE Transactions

on Systems, Machine and Cybernetics, Vol.38, N.1.

Mitchell, I. and Tomlin, C. (2000). Level set methods for

computation in hybrid systems. In Hybrid Systems:

Computation and Control, Third International Work-

shop, LNCS.

Mohamed Khalgui, Martin Hirsch, D. M. H.-M. H. (2008).

Reconfiguration of embedded systems. In Interna-

tional Conference on Informatics in Control, Automa-

tion and Robotics ICINCO-ICSO, pages: 157-162.

Rausch, M. and Hanisch, H.-M. (1995). Net condition/event

systems with multiple condition outputs. In Sympo-

sium on Emerging Technologies and Factory Automa-

tion. Vol.1, pp.592-600.

Roch, S. (2000a). Extended computation tree logic. In Pro-

ceedings of the CESP2000 Workshop, number 140in

Informatik Berichte, pages225-234, Germany.

Roch, S. (2000b). Extended computation tree logic: Im-

plementation and application. In Proceedings of the

AWPN2000 Workshop, Germany.

Rooker, M. N., Sunder, C., Strasser, T., Zoitl, A., Hum-

mer, O., and Ebenhofer, G. (2007). Zero downtime re-

configuration of distributed automation systems : The

εcedac approach. In Third International Conference

on Industrial Applications of Holonic and Multi-Agent

Systems. Springer-Verlag.

SESA (2008). Signal/net system analyzer.

In http://www.ece.auckland.ac.nz/ vy-

atkin/tools/modelchekers.html.

Vardi, M. and Wolper, P. (1994). Reasoning about infi-

nite computations. In Information and Computation,

115(1).

ICSOFT 2011 - 6th International Conference on Software and Data Technologies

110