KNOWLEDGE BASED SERVICES FOR DEVICES

IN AUTOMATION

Muhammad Baqar Raza, Robert Harrison and Thomas Kirkham*

Loughborough University, Loughborough, LE11 3TU, Leicestershire, U.K.

*The University of Nottingham, NG7 2RD, Nottingham, U.K.

Keywords: Ontology, SOA, Semantic web service (SWS), Knowledge based system.

Abstract: The integration of manufacturing design and production processes around aggregated shared knowledge

improves production efficiency. In this paper, planning level faults on the assembly lines or conflicts in

product design are identified and picked up in real time via the use of integrated knowledge based services.

Issues with the supply chain can also be fed into the model by linking the services to Enterprise Resource

Planning (ERP) systems. In the production process, errors and/or faults are fed back into the knowledge

base system to aid confident future planning. This approach allows more targeted alerts and reports of

failures, empowering the production operative and allowing more problems to be solved at the source of

origination.

1 INTRODUCTION

Service Oriented Architecture (SOA) has emerged

as a reliable distributed computing method. Web

services are considered the best implementation

method of SOA as they are loosely coupled and

platform independent. Nevertheless to construct

machine processable ‘XML‘ in a complex product

manufacturing enterprise, a higher level of semantics

is required which is provided by ontology. An

ontology is commonly defined as:

a formal, explicit

specification of a shared conceptualization (Gruber,

1993). More specifically, an ontology is an

engineering artifact composed (i) of a vocabulary

specific to a domain of discourse, and (ii) of a set of

explicit assumptions regarding the intended meaning

of the terms in the vocabulary for that domain.

In the manufacturing domain, the relationship

between the design phase of a product and its

creation on a production line is vital for

manufacturing efficiency. Errors in the design or

failure to create an assembly line that suits the

product design can create delays in the process as re-

design or re-configuration occurs. These revisions

have impacts on both the supply chain and overall

manufacturing/assembly output.

The Loughborough University in collaboration

with Ford UK have been investigating how

ontologies and SWSs could be used to improve Ford

production output. These investigations lead to the

development of a software framework, which will

facilitate the integration of product design and

production line configuration. This framework

builds on existing web services developed during

projects such as SOCRADES (Kirkham, 2008).

2 RELATED WORK

The research work on ontologies and the semantic

web has started intruding into real industrial

problems from pure academia work. SOA and its

implementation using Web Services (WS) have

raised significant interest as a technology facilitator

for encapsulating industrial devices as loosely

coupled and interoperable units (Jammes, 2005).

Semantic web is based upon ontology which

provides semantics and reasoning support for

intelligent retrieval and discovery of manufacturing

resources (Ming, 2003).

The use of ontologies in the manufacturing

domain to form intelligent semantic web services to

improve productivity are emerging (Lukibanov,

2005); (Ajit et al, 2004). These ontologies are

applied to a variety of points in the manufacturing

lifecycle ranging from design and production phases.

133

Baqar Raza M., Harrison R. and Kirkham T..

KNOWLEDGE BASED SERVICES FOR DEVICES IN AUTOMATION.

DOI: 10.5220/0003422901330138

In Proceedings of the International Conference on Knowledge Engineering and Ontology Development (KEOD-2011), pages 133-138

ISBN: 978-989-8425-80-5

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

These innovations are significant for companies like

the Ford Motor Company which is currently facing

challenges in maintaining competitive advantage

when faced with competitors who can produce

products on a large scale and lower cost from less

developed economies. To counter this, western

manufacturing has looked towards innovation in

manufacturing process embracing movements such

as agile manufacturing (Yusuf et al., 1999). The

enablement of high quality and customized

production through agile manufacturing requires

changes in production process. Central to the

production line is the ability for it to support change

and reconfiguration (Harrison et al., 2006). Time

saved during this process has a direct impact on the

efficiency of an organization and is a key focus of

research.

To date re-configuration and assembly line

flexibility has been managed in a variety of ways.

Ford’s Powertrain manufacturing/assembly follows

this pattern with assembly lines consisting of a

variety of vendor specific machinery and control

software. Thus integration of machines and lines is a

challenge and integration with enterprise

management such as ERP software is rarely

achieved.

3 DEVICE LEVEL SERVICES

By encapsulating the functionality of devices as a

service, new systems can be created by composing

simple services into complex applications with a

minimum of programming efforts (Lastra et al.,

2006). Semantic Web is a very strong and flexible

knowledge representation method which can express

entity structure, properties and the causal link

between entities explicitly and concisely (Zhihong,

2002). Semantic web services can foster the

integration of heterogeneous production devices and

of a mix of architectures in systems which would be

chaotic from an ICT perspective (Lastra et al.,

2005).

Embedded web services have developed around

the initial innovation presented by tools such as the

GSOAP toolkit (Engelen and Gallivan, 2002) to a

more detailed and defined toolkit in the form of

DPWS (OASIS, 2009); (Schlimmer, 2010). This

web service toolkit although largely based on

GSOAP, presents support for standards to enable

‘eventing’, subscription and notification of events

enabling a more efficient lower layer of device

based communication. The ability for services to be

present a manufacturing device level allows the use

of semantic web services at real time production

level. This semantic management will impact the

management of the line by injecting the ability to

link the data from the line along with its behaviour

into knowledge based services.

This greater level of management and knowledge

based reasoning on the line will enhance wider

production processes. For example, device level

service behaviour can be factored into ERP and

supply chain management services to help plan

production output.

4 CONFIGURATION

MANAGEMENT

In order to support the execution of services on the

assembly line, supporting services need to be in

place before, during and after device level execution.

In order to make this process dynamic and

transferable, knowledge of service design and

functionality is required. In the BDA project

ontologies were developed to serve this specific

requirement using semantic web services.

Machine, line, component and product data has

been captured into ontologies using Protégé and

OWL (Knublauch et al., 2004); (Martin, 2004).

Ontologies are a key part of a broader range of

semantics based technologies and automated

inference that arose within the Artificial Intelligence

community. Many different representation

formalisms have been explored and reasoning

engines developed. There are different kinds of

ontologies, the ontologies developed for the current

research can be classified as domain ontology as

well as task ontology. Task ontology is developed

for a specific task within a certain domain.

Creating ontology for a domain provides an

opportunity to analyse domain knowledge, make

domain assumptions explicit, separate domain

knowledge from operational knowledge, provide

common understanding of the information structure

and enable reuse of domain knowledge.

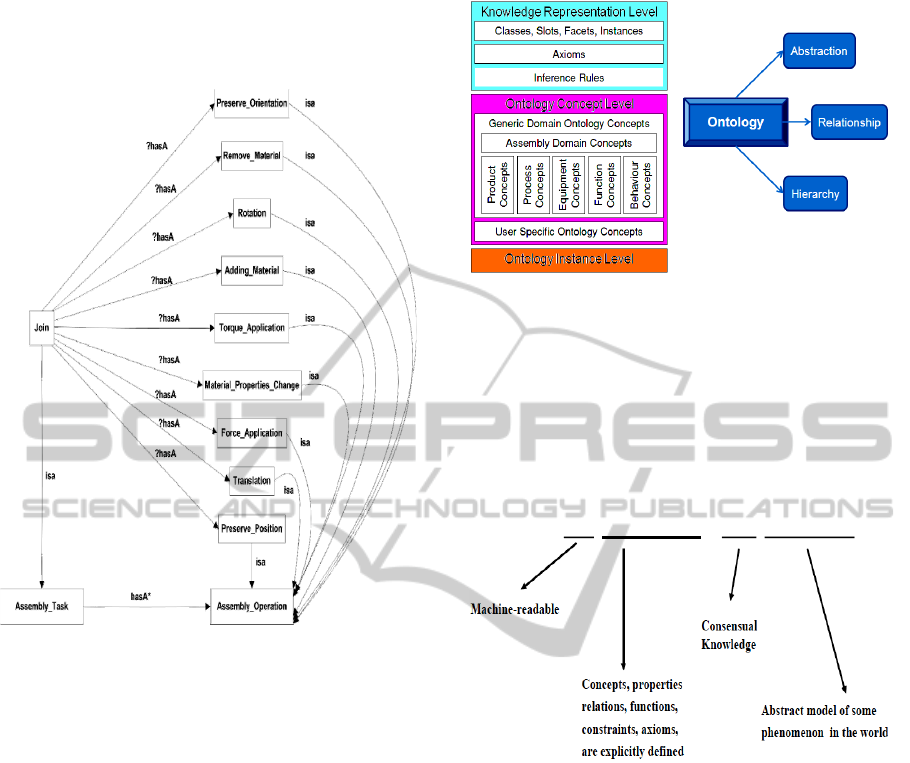

The ontologies in the current research represent

how the Powertrain assembly line is constructed and

example ontology of a production task on an

assembly line can be seen in Figure 1.

A visualization of a simple ontology to represent

a typical assembly task is illustrated in Figure 1. An

ontology in the manufacturing domain is used for

controlled vocabulary, consistency in data quality

and navigation through disparate information

sources through mediation. Ontology is an

KEOD 2011 - International Conference on Knowledge Engineering and Ontology Development

134

intensional formal semantic structure which encodes

the implicit rules constraining the structure of a

piece of reality (Bachimont, 2000).

Figure 1: Ontology for a production line task.

An ontology is seen as a meta-level specification

of a logical theory, in the sense that it specifies the

‘architectural components‘ or ‘primitives‘ used

within a particular domain theory (Wielinga, 1994).

Therefore an ontology is a representation of

components and their allowed interactions, with the

purpose of providing an explicit framework in which

to elaborate the rest of the system. Ontologies

overcome data heterogeneity. Data sources can be

heterogeneous in syntax, schema, or semantics, thus

making data interoperation a difficult task. Syntactic

heterogeneity is caused by the use of different

models or languages. Schematic heterogeneity

results from structural differences. Semantic

heterogeneity is caused by different meanings or

interpretations of data in various contexts. To

achieve data interoperability, the issues posed by

data heterogeneity need to be eliminated. Currently,

the basic ontology model is defined along three

axes: relationships, hierarchy, and abstraction, as

shown in Figure 2.

Figure 2: Ontology structure outline for PPR domains.

On the ontology level all the specific domain

concepts, attributes, constraints, and rules are

defined for the related entities i.e. products,

processes and resources (PPR). Ontologies expose

implicit knowledge that has been previously hidden

in domain assumptions or in the implementation of

an application. Figure 3 describes 04 major

functions of an ontology.

Figure 3: Ontology functions.

To support the decision making, an ontology

model is proposed that include three representation

levels: the underlying knowledge representation

level, the ontology concept level and the

instantiation level. The domain ontologies are

divided into generic and user specific concepts. For

example, a library of physical models may be

represented with the help of an ontology. To each

component in the library, information is attached

that describes the function of the component (for

example, an engine has the function “generate

power”). If this information is represented explicitly,

an engineer may be able to search the library for

component models that fulfill a certain function,

rather then designing a new one. In the ontology-

based approach, domain specific ontologies are

modeled to specify semantics of terminology

systems in a well-defined and unambiguous manner.

A model is a simplified representation of a system

KNOWLEDGE BASED SERVICES FOR DEVICES IN AUTOMATION

135

intended to enhance our ability to understand,

predict and control the behavior of a system. Based

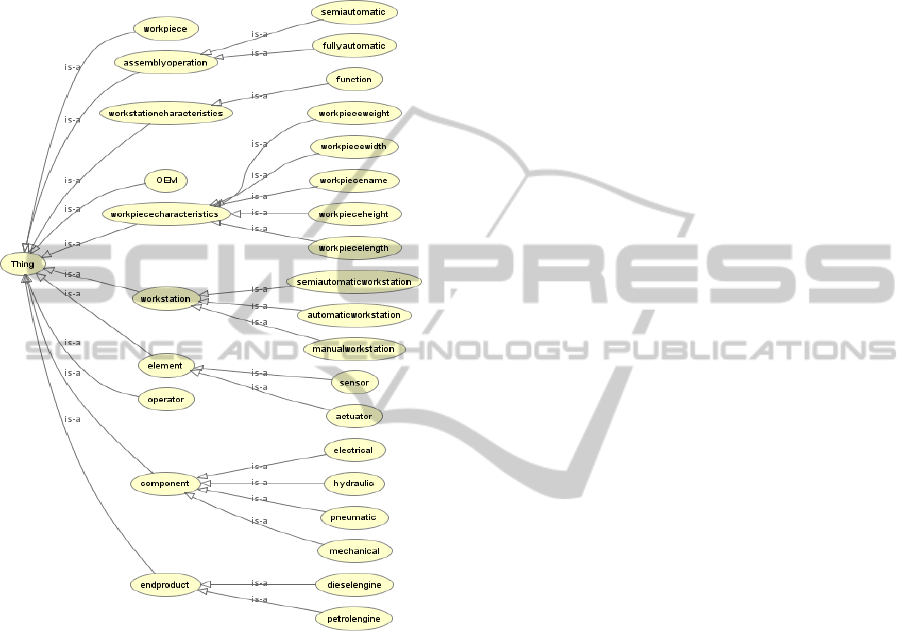

upon the presented categorisation, ontology of the

complete assembly line was modeled and an

example of the abstract concepts is shown below in

Figure 4.

Figure 4: Ontology for a production line - snapshot of line

in Protégé 4.0.

Key concepts introduced into the ontology are

work piece, work piece characteristics, workstation,

workstation characteristics, assembly operation,

operator and end product. Based upon these

concepts, relations among products, processes and

resources are established into the ontology which

constitutes manufacturing backbone. The current

assembly line reconfiguration approach is largely

based on the skill and knowledge of engineers rather

than the actual process involved. Whenever there is

any change in the product it is then essentially

engineer’s responsibility to examine the needs of the

reconfigured system to support the new product

(Raza et al., 2011).

Current automation systems fail to meet business

requirements (Raza and Harrison, 2011). The

assembly lines, such as powertrain assembly line for

automotive engine, have a limited capacity to

produce variety of products (engines). The built in

capability to deal with variety has to be limited to

justify investment and is a trade-off between the

inevitable but unpredictable changes and the

increased cost of flexibility (Raza and Harrison,

2011). One of the main reasons for automation

systems and especially the assembly automation

systems in automotive sector not fulfilling the

business requirements is that the relational

knowledge base among products, processes and

resources is either non-existent or not properly

designed / used. There is a genuine industrial

requirement to establish relationships among PPR

domains to readily assimilate the requisite

information for any change in product at any time

(Raza and Harrison, 2011).

Therefore it is imperative to create a knowledge

base among PPR domains to fully utilise the

available knowledge. Ontologies are not only useful

for helping solving the information overload

problem, but can be used for a variety of different

applications, such as sharing explicit knowledge,

increase communication, and help in natural

language understanding. With the help of practical

knowledge in ontology, a quick evaluation of many

potential resource configurations is possible as well

as the best suited one for a changed product (Raza

and Harrison, 2011). There are no platform

independent application tools available for

modelling the PPR information explicitly neither

does any tool exist to link PPR relational

information unequivocally (Raza and Harrison,

2011).

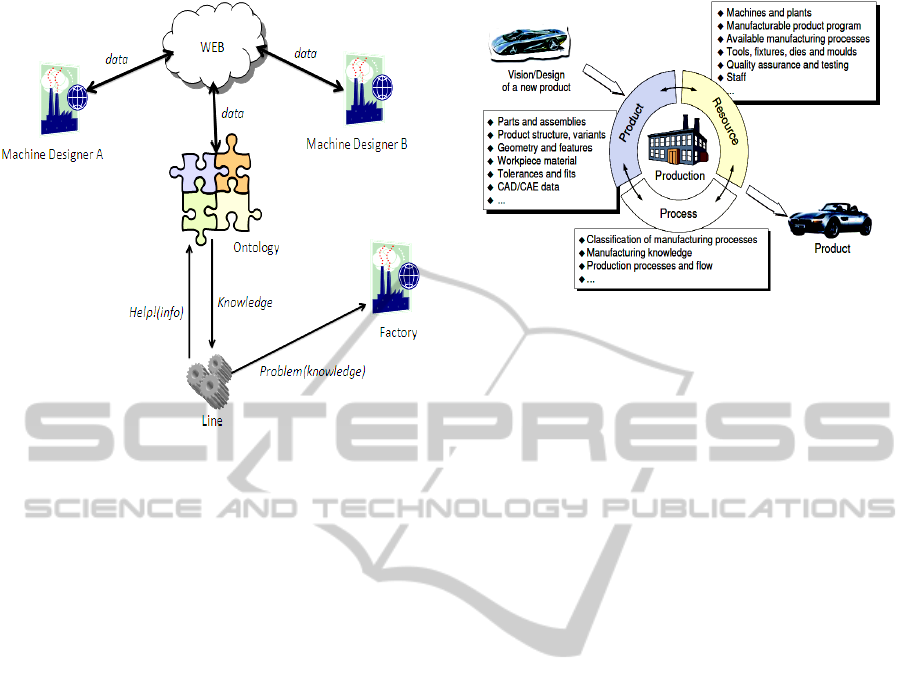

Ontology assists the mapping of data from a

variety of vendors and sources that constitute a

production line. This enables a layer of knowledge

to exist over the distributed data sources that are

needed to help configure, support and run the

production process / assembly line. For example a

breakdown on the line can be followed up by a

detailed report on faulty components based on line

data and distributed component design records from

various vendors. This information could aid the

recovery and repair time for the line as shown

below:

KEOD 2011 - International Conference on Knowledge Engineering and Ontology Development

136

Figure 5: Knowledge based service use in assembly line

management.

Thus a layer of distributed knowledge is wrapped

and exposed as semantic web services as shown in

Figure 5. These services abridge knowledge to data

to be represented in web service processes thus

aiding re-configurations of lines. Another example is

the integration of new product specifications in

existing line designs. Here the new specification can

be accessed using web service calls and compared

using an OWL ontology against the existing line. To

automate (fairly) the task of assembly line

configuration / reconfiguration, product and resource

(line) link points need to be defined at early stages

of design and made available easily to be searched,

analysed and implemented on ‘when and where

required’ basis (Raza et al, 2011). This will enable

automated comparison of new products against

existing line data also expressed as ontologies. This

method will ensure conflicts in the product design

with the line can be found and picked up at earlier

program stages. It provides a broad encompassing

structure of the domains that is handy and practical,

a knowledge based support on every engineer’s desk

for making intrigue calculations and quick relational

constraints. As a result, a PPR domains can be

modelled realistically and constitute a complete

knowledge management cycle of the automotive

domain for the assembly line design activity, as

depicted in Figure 6.

Figure 6: Product, Process and Resource integration

constitute manufacturing knowledge backbone.

5 CONCLUSIONS AND FUTURE

WORK

In this paper we explored a methodology that

incorporates and improves distributed intelligence at

the shop floor level. Currently the ontologies are

used to aid the re-configuration of the assembly lines

for new products. Live use of the ontologies has

been

limited to a few basic error conditions. As the

development and use of the knowledge based

services evolve they will be used as support in the

entire production lifecycle. However, to make it a

reality the data has to be captured or represented into

ontologies from a wide variety of proprietary and

legacy data sources throughout Ford, UK.

Using knowledge based services a new layer of

manufacturing management can be envisaged that

will help the entire production lifecycle. This layer is

enhanced by the use of device level web services

which will enable the live use of knowledge in

automated decision making on assembly lines. To

date, the use of knowledge based services has been

limited to the design phase of machines. By using

the technology in SOCRADES and BDA projects

this approach can be widened out to encompass the

whole process. This will standardise production

management and responses to errors that will reduce

cost and improve manufacturing efficiency.

The recently started AESOP (ArchitEcture for

Service Oriented Process Monitoring and Control)

project EU FP7 (AESOP, 2011) is now extending

the application of the approach in the process control

domain. AESOP deals with several key challenges

that arise such as real-time web services,

interoperability, plug and play, self-adaptation,

reliability, cost-effectiveness, energy-awareness,

KNOWLEDGE BASED SERVICES FOR DEVICES IN AUTOMATION

137

high-level cross-layer integration and cooperation,

event propagation, aggregation and management.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the support of

UK EPSRC and Loughborough University’s

IMCRC through Business Driven Automation

(BDA) project, the EU SCORADES FP6 and the

ongoing EU AESOP FP7 project. We would like to

thank all the project participants and engineers who

have contributed in this research from

Loughborough University and participant companies

especially Ford Motor Company and Schneider

Electric.

REFERENCES

Ajit S., Sleeman D., Fowler D., and Knott D., ConEditor:

Tool to Input and Maintain Constraints, 14th

International Conference on Engineering Knowledge

in the Age of the Semantic Web, Proceedings of EKAW

2004, pp 466-468.

Bachimont B., Engagement sémantique et engagement

ontologique: conception et réalisation d'ontologies en

ingénierie des connaissances, In Charlet, Zacklad,

Kassel, Bourigault, Ingénierie des connaissances

Evolutions récentes et nouveaux défis. Eyrolles, 2000.

Engelen R. A. van and Gallivan K.., “The gSOAP Toolkit

for Web Services and Peer-To-Peer Computing

Networks” in the proceedings of the 2nd IEEE Intl

Symp.on Cluster Computing and the Grid, pages 128-

135, May 21-24, 2002, Berlin, Germany.

Gruber, T., A translation approach to portable ontology

specifications. Knowledge Acquisition 5:199-220;

1993

Harrison, R., A. W. Colombo, A. A. West and S. M. Lee,

Reconfigurable modular automation systems for

automotive power-train manufacture. International

Journal of Flexible Manufacturing Systems, 2006.

18(3): p. 175-190.

Jammes F., Smit H., Service-Oriented Paradigms in

Industrial Automation, IEEE Transactions on

Industrial Informatics, Vol 1(1), pp. 62-70, Feb 2005.

Kirkham T., Savio D., H. Smit, Harrison R., R. P.

Monfared, and P. Phaithoonbuathong, "SOA

Middleware and Automation: Services, Applications

and Architectures" in 6th International Conference on

Industrial Informatics (IEEE, INDIN 2008): IEEE

Comp. Soc., 2008.

Knublauch H., Fergerson R., Noy, N., and M., Musen. The

protégé OWL plugin: An open development

environment for semantic web applications. In Proc.

of ISWC, 2004, number 3298 in LNCS, pages 229–

243.

Lastra J. L. Martinez, "On Future Self-Orchestrating

Manufacturing Systems", Position paper for the FP7

Workshop on The Agile, Wireless Manufacturing

Plant, Brussels, February 10th, 2005.

Lastra J. L. Martinez, I. M. Delamer, "Semantic Web

Services in Factory Automation: Fundamental Insights

and Research Roadmap", to appear in IEEE

Transactions on Industrial Informatics, Feb 2006.

Lukibanov O., Use of Ontologies to Support Design

Activites at DaimlerChrysler, 8th Intl. Protégé

Conference, 2005.

Martin D., Burstein M., Hobbs J., Lassila O., D.

McDemott, S. McIlraith, S. Narayanana, M. Paolucci,

B. Parsia, T. Payne, E. Sirin, N. Srinivasan and K.

Sycara. Ming C., L. Lin, and J. Dong. “Intelligent

Service Matching in Internet-Based Manufacturing.”

CIMS, vol.9, no. 7, pp. 589-594, March 2003.

OASIS DPWS standard page: http://docs.oasis-

open.org/ws-dd/ns/dpws/2009/01

OWL-S: Semantic markup for web services. Member

Submission 22, W3C, November 2004.

Raza M. B., Harrison R., Kirkham T., –Knowledge Based

Flexible and Integrated PLM System at Ford –Journal

of Information & Systems Management, Volume 1,

Number 1, March 2011, pp 8-16

Raza Muhammad Baqar, Robert Harrison, Information

modeling and knowledge management approach to

reconfiguring manufacturing enterprises, International

Journal of Advanced Information Technology (IJAIT)

Vol. 1, No. 3, June 2011.

Raza Muhammad Baqar, Robert Harrison, Ontological

Knowledge Based System for Product, Process and

Resource Relationships in Automotive Industry,

Proceedings of the 1st International Workshop on

Ontology and Semantic Web for Manufacturing

(OSEMA, 2011), co-located with the 8th Extended

Semantic Web Conference, ESWC2011, Heraklion,

Crete, Greece, May 29, 2011.

Schlimmer J., A Technical Introduction to DPWS

http://msdn2.microsoft.com/enus/library/ms996400.as

px

Wielinga, B. and Schreiber, A. Th. and Jansweijer, W. and

Anjewierden, A. and van Harmelen, F. Framework

and formalism for expressing ontologies. ESPRIT

Project 8145 KACTUS, Free University of

Amsterdam, deliverable DO1b.1, 1994.

Yusuf, Y. Y., Sarhadi, M. and Gunasekaran, A., 1999.

Agile Manufacturing: The drivers, concepts and

attributes. International Journal of Production

Economics, 62, pp. 33–43

Zhihong Deng, Tang Shiwei, Zhang Ming, Overview of

Ontology. Acta Scicentiarum Naturalum Universitis

Pekinesis, 2002,38(5):730-738.

KEOD 2011 - International Conference on Knowledge Engineering and Ontology Development

138