EXPLOITING VISUAL OBSERVATIONS FOR EFFICIENT

WORKFLOW SCHEDULING IN PRODUCTION

ENVIRONMENTS

Anastasios Doulamis

Technical University of Crete, D5 building, University Campus, Chania, Greece

Keywords: Visually observed industrial operations, Workflow scheduling, Tracking, Incremental spectral clustering.

Abstract: This paper proposes a new production scheduling algorithm that exploits (a) visual observations of

industrial operations to estimate the actual completion times for tasks and (b) incremental graph

partitioning-based clustering algorithms. The latter are implemented through an incremental implementation

of the spectral clustering. Computer vision tools are applied to identify industrial operations via visual

observations.

1 INTRODUCTION

Production scheduling/planning is probably one of

the most critical managerial tasks within an industry

with many benefits for the production. In particular,

it (i) can determine whether delivery promises can

be met and identify time periods for preventive

maintenance, (ii) gives personnel an explicit

statement of what should be done so that supervisors

and managers can measure their performance, (iii)

minimizes the average flow time through the system,

(iv) minimizes setup times and (v) maximizes

machine and/or worker utilization.

The main difficulty of production

scheduling/planning stems from the fact that many

real-world manufactories are complex in nature and

it is a real challenge to find an efficient scheduling

method that satisfies the production requirements as

well as utilizes the resources efficiently. To

overcome these difficulties, simulation approaches

have been proposed to “model” complex real-world

systems. Simulations develop models for generating

detailed plans to control the real-world industrial

operations. However, usually the real world

(severely) differs than the idealized computer

models so that scheduling/planning derived through

simulation (significantly) deviates from the actual

conditions.

One possible way to monitor current

processes/operations is through the use of Radio

Frequency Identification -RFID sensors (Gonzalez

Fernandez et. al, 2010) (Ilic et al., 2010). These,

however, are efficient only for specific industrial

environments, while their reliability under harsh

industrial conditions is questionable. Another

possibility is the use of cameras. Nevertheless,

cameras that do not support machine learning

technologies and computer vision methods actually

result in a manual survey of the industrial operations

fact that eliminates any possibility for a dynamic

(non-rigid) industrial planning. It is impossible for

the survey employees to continually concentrate on

monitors that display different activities in different

areas. Additionally, there is a subjective

interpretation as far as humans’ behaviours are

concerned, let alone additional cost and exploitation

of humans’ resources.

The recent advances in computer vision and

machine learning society have endowed the cameras

with smart capabilities. They can detect salient

objects, track moving entities, interpret important

events taking place in the industry and finally adapt

their performance to environmental changes. Thus,

they can endow modern factories with new cognition

capabilities transforming them to “smart industries”.

Most of the current approaches for industrial

scheduling exploit concepts derived from

computational processors (Shaik et. al. 2007),

(Drotos et; al., 2009). The incorporation of computer

vision tools able to understand the actual (real-time)

execution of industrial processes is rather limited. A

survey of industrial vision systems has been reported

531

Doulamis A..

EXPLOITING VISUAL OBSERVATIONS FOR EFFICIENT WORKFLOW SCHEDULING IN PRODUCTION ENVIRONMENTS.

DOI: 10.5220/0003305905310537

In Proceedings of the 3rd International Conference on Agents and Artificial Intelligence (ICAART-2011), pages 531-537

ISBN: 978-989-8425-40-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

in (Malamas et. al., 2003), while extraction of salient

features for defining and detecting industrial events

has been discussed in (Motai, 2005). Assistance

towards an efficient visual supervision of an

industrial plant can be achieved by exploiting

distributed cameras as well as communication issues

among them (Karakaya and Hairong Qi, 2009).

Surveying industrial tasks and workflows using web

services has been presented in (Idoughi et. 2010).

The main objective of that work is to handle

complex and concurrently executed services on

large-scale industries. The adoption of Service

Oriented Architectures (SOA) and the use of web

services enable a flexible and transparent interaction

between the field devices and human operators

(Doulamis and Matsatsinis, 2011).

In this paper, we propose a new production

scheduling algorithm which is related on defining

events, actions and workflows on visual surveyed

areas of an industry. The algorithm is based on a

new dynamic spectral clustering methodology. This

means that instead of using the conventional spectral

clustering algorithm (Bach and Jordan, 2004), we

adopt a modified version of it so that dynamic

arrivals of tasks’ workflows and dynamic deviations

of the actual to the estimated completion times are

allowed (Huazhong Ning et. al, 2010).

In particular, the proposed algorithm initially

statically schedules the submitted industrial

workflows by constructing a graph whose nodes

refer to the industrial operations while the edges to

the non-overlapping degree among the tasks. The

main, however contribution of the presented paper is

the fact that it incorporates computer vision and

pattern recognition algorithms in the industrial

process so as to approximate as much as possible the

actual completion times of the already executed

tasks, or in other words, to estimate possible

deviations between the actual and the requested

completion times. To accomplish this,we introduce

visual trackers able to self-correct their performance

with respect to environmental changes (Section 4),

and part-to-whole curve matching techniques

(Section 5), so as to estimate the delays or

accelerations in the actual task execution.

2 OVERVIEW OF PROPOSED

ARCHITECTURE

Figure 1 shows an overview of the proposed

industrial scheduling algorithm which exploits

events analysis and detection tasks. Initially, we

consider that the requested start and finish times for

a set of industrial operations are available to the

architecture. Based on this static information, we

calculate the overlapping degree among the

submitted tasks (or equivalently the non-overlapping

degree). Then, we construct a graph and we solve

the static scheduling problem as a graph partitioning

problem considering the spectral clustering

algorithm (Bach and Jordan, 2004). At this point the

process resembles our earlier work of (Delias et. al,

2011) in which the spectral clustering algorithm has

been adopted to allocate complex business

workflows into the available resources. However,

this results in a static scheduling.

Figure 1: Overview of the methodology.

In this paper, we improve the static workflows

scheduling by incorporating computer vision

algorithms in the process. In particular, a set of

cameras’ sensors observe the trace of an industrial

task as it is executed by the workers. This

identification is carried out by the use of a tracking

algorithm, which “observes” the industrial processes

by tracing the trajectory that the persons follow. For

tracking, a new self-initialized tracking algorithm is

proposed to trace the trajectory of the moving

objects in a scene. The algorithm automatically

selects new confident data from the current image

frame whenever the tracker performance is not

adequate so as to re-initialize its performance, and

thus to improve the object’s tracing in harsh

industrial environments. Towards this direction, we

propose a modification of the data selector algorithm

of (A. Doulamis, 2010) so as to be robust to

industrial applications by using an adaptive non-

linear classifier (Section 4). A modification of (A.

Doulamis, 2010) has been also proposed in

(Doulamis and Matsatsinis, 2011) to fit the

particularities of an industrial environment.

However in (Doulamis and Matsatsinis, 2011),

linear adaptive methodologies are proposed in

contrast to the current work.

Then, we apply a curve matching algorithm to

predict the deviations of the estimated execution

durations based on the visual observations. Part-to-

whole curve matching methods are implemented so

as to estimate the current completion time for

executing a job based on the current on-going

process. Instead of the part-to-whole approach

adopted in the Service Oriented Architecture of

ICAART 2011 - 3rd International Conference on Agents and Artificial Intelligence

532

(Doulamis and Matsatsinis, 2011), in this paper, a

guided search algorithm is adopted to improve the

minimization of the optimal criterion so that better

matched points are firstly identified.

Apart from the computer vision and pattern

analysis techniques, a new dynamic scheduling

algorithm is applied to take into account the

dynamic modifications of the start and finish times

for the executed tasks. This is achieved in this paper

by incrementally refining the static scheduling

results (Huazhong Ning et. al, 2010). Instead, the

“from scratch” application of a static spectral

scheduling algorithm would be computationally very

expensive, making its use preventable. We also

extend the work of (Doulamis and Matsatsinis,

2011) by proposing an optimized method for data

scheduling in terms of dynamicity and optimality.

3 SPECTRAL CLUSTERING

FOR SCHEDULING

INDUSTRIAL WORKFLOWS

Assuming that we have calculated the requested start

(S

i

) and finish times (F

i

) for the ith workflow W

i

(let

N be the total number of operations contained in all

the workflows), we can model their relations as an

indicator of their overlapping, say

ji

a

,

. Instead of

(Delias et. al, 2011) in which the

ji

a

,

is defined as a

binary measure, in this paper we adopt a continuous

modification of the overlapping measure to make it

more robust to the dynamic changes. This means

that

⎩

⎨

⎧

=

otherwise

overlap and operations if0

,

ϕ

ji

a

ji

(1)

We introduce two objective optimization criteria,

which can measure the plan’s efficiency with respect

to the overall goal. The first one is associated with

the violation of the deadlines. The corresponding

optimization criterion is mathematically formulated

as

∑

∑

∈∈

∉∈

=

WjOi

ji

OjOi

ji

m

m

mm

a

a

V

,

,

,

,

(2)

where m indicates that the optimization metric refers

to the m

th

resource,

m

O is the set of the operations

that is planned for allocation to the m

th

resource, and

W is the set of all the operations that require to be

executed. Additionally,

m

V is a marginal

optimization criterion. The overall criterion is

calculated by the summation of these marginal

criteria over all the available resources M, and as

stated before, an efficient scheduling plan should

keep it at a minimum value.

The second optimization criterion concerns the

thriftiness of the plan, namely how resources should

be utilized so as to prevent wasteful schedules. This

criterion can be mathematically expressed as

∑

∑

∈∈

∈∈

=

WjOi

ij

OjOi

ij

m

m

mm

a

a

U

,

,

(3)

Once again

m

U is a marginal optimization criterion

(with respect to the m

th

resource). The overall

criterion is calculated similarly with the deadlines’

violation criterion, i.e., as the sum of all the

m

U

over all the M available resources.

As it is shown in a previous work (Delias et. al,

2011), it is possible to jointly optimize the above

mentioned criteria through the use of the Ky-fan

theorem (Ky Fan, 1951).

Actually, the solution matrix S needs an

additional step to provide a schedule, as it contains

real values while the assignment method requires for

values which are either 1 /0. In this paper, we

initially apply the above mentioned methodology to

get a first approximate estimate for the production

schedules, that is, a schedule based on the requested

start and finish times.

4 SELF CORRECTED TRACKING

FOR INDUSTRIAL PROCESSES

In this paper, we modify the self initialized tracker

of (A. Doulamis, 2010) so as to be appropriate for

industrial applications. More specifically, the

architecture of (A. Doulamis, 2010) is only adequate

for scenes that contain moving objects. This is not,

however, an industrial case since workers can

remain almost still for a relatively long time interval

in order to fulfil some of their activities. In addition,

the background complexity of an industrial

environment imposes significant deviations from a

good performance.

To address this difficulty, in this paper we

modify both the data selector module of (A.

Doulamis, 2010) and the object labelling adapter. In

particular, a non-linear classifier is proposed as an

efficient background model, which in the sequel is

EXPLOITING VISUAL OBSERVATIONS FOR EFFICIENT WORKFLOW SCHEDULING IN PRODUCTION

ENVIRONMENTS

533

used as a more suitable data selector. The classifier

is based on a neural network structure. Neural

network-based background modelling has been also

proposed in (Culibrk et. al, 2007). The weights,

however, of the classifier do not remain static but

they are modified during the video streaming so that

the model can be adapted to the dynamics of the

current conditions. This is achieved in our algorithm

via the object labelling adapter. In (Culibrk et. al.

2007), the observed statistics are exploited to

dynamically modify the neural network weights,

while in this paper an optimal network retraining

strategy is adopted as in (Doulamis A. D et. al,

2000).

More specifically, initially the Gaussian

Mixtures are used to give approximate estimates of

the background content. These mixtures are

automatically updated from frame to frame to

capture small and/or periodic modifications of the

visual content on the background. As we have stated

above, the neural network classifier is actually used

for separating the foreground region from the

background based on a non-linear mapping of the

Gaussian mixtures information with respect to the

specific background content. However, since the

background is modified from frame to frame the

weights of the neural network classifier cannot be

considered constant. Instead, they should be

updated. The generalized neural network retraining

algorithm of (Doulamis A.D et. al, 2000) is adopted

in this paper for an optimal updating of the network

parameters. With respect to our knowledge, this is

the first time that a non-linear and dynamic classifier

with optimal retraining strategies will be applied for

background content modelling. In addition, the

exploitation of the self initialized architecture of (A.

Doulamis, 2010) for the purpose of an industrial

plant constitutes another contribution of the

proposed work.

5 ESTIMATING THE ACTUAL

WORKFLOWS COMPLETION

TIMES

In this paper, we modify the technique of (Cui et. al,

2009) by applying guided search in order to find the

most appropriate correspondence points among the

two curves. This is due to the fact that the main

challenging issues of our partial to whole match

approach is that we do not know the last point of the

partial curve but only the first (start) one. This is due

to the fact that we do not know the current execution

time.

In particular, we initially model both curves

using the integral of the curvature measures, i.e., the

integral of the norm of the second derivative,

∫

′′

=

2

1

),():(

21

s

s

dsyxsssC

(4)

where

),( yxs

′

′

is the second derivative of a curve,

that is either of t or of f. In (Cui et. al, 2009), it is

proved that

):(

21

ssC is invariant under a similarity

transform. Thus, this measure can be used to

represent the curve complexity. However, it is still

problematic to match parts of two curves, sine the

starting value of the integral of (4) can be of any

number.

To solve this problem, we initially consider that

the curvature points, as well as their averaging, are

the most characteristics points of the curve. Then,

we use a cross correlation criterion as a similarity

matching for both curves. In particular, if we have

defined the most appropriate last point of curve f,

then we could take a part of it starting from the first

point to the last one and find its correlation to the

traced curved t. Let us denote as

)(),(

0

fPfP

last

the

first and the last point of curve f and as

)(),(

0

trPtrP

last

the respective first and last point of

curve t. Then, the correlation coefficient can be

considered as a measure for their matching.

22

)]():([*)]():([

)]():([*)]():([

))(),((

tPPtrfPPf

tPPtfPPf

trPfPCorr

lastolasto

lastolasto

lastlast

μμ

μμ

−−

−−

=

=

(5)

In equation (5), ):(

lasto

PPf refers to a part of the f curve

starting from

)(

0

fP and ends to )( fP

last

. Similarly, we

define the

):(

lasto

PPtr

curve. The function )(

⋅

μ

returns the average of each curve. It is worth to note that

Corr function actually depends on the last points of both

curves since the first ones are already available and

known.

Then, the optimal last point of f is found through

the following minimization

{

}

))(),((max:)(

ˆ

trPfPCorrfP

lastlast

SP

last

f

∈

(6)

A genetic algorithm is adopted then to find an

optimized solution to the above mentioned

minimization problem.

ICAART 2011 - 3rd International Conference on Agents and Artificial Intelligence

534

6 UPDATING THE SPECTRAL

CLUSTERING

The proposed scheduling algorithm although very

efficient, is computationally expensive to be used

from scratch in every case that the start or finish

times are modified. There is a need to exploit the

updated information that comes from the visual

tracker and the curve-matching algorithm with a fast

yet reliable way. In this paper the following

approach is proposed: Since the visual tracker and

the curve-matching algorithms detect modifications

in the normal workflow (i.e., modifications of the

start and finish times of the operations), the initial

affinity matrix of operations which indicates the

overlapping among the operations is modified as

well. In fact, only some distinct elements of the

affinity matrix are affected. These changes may

induce alterations to both the degree matrix D and

the eigenvectors matrix E. As it is proved in

(Huazhong et. al, 2010), it is possible to approximate

the increment of the eigenvalues and the

eigenvectors, without needing to re-solve the

generalized eigenvalue problem.

The exact sub-process of the incremental update

is described by the following steps:

(a) Get informed about the modified start and

finish times of operations (via the visual

tracker and the curve matching algorithm),

(b) Update the affinity (overlapping indicators)

matrix according to the new overlapping

conditions,

(c) Iteratively refine matrices E (eigenvectors)

and D (degree). (d) Apply the k-means

algorithm to the updated solution matrix S and

get the new schedule.

7 EXPERIMENTAL RESULTS

Our experiments are carried out on a real-life

industrial environment, the one of Nissan Iberica

Automobile Construction company in Barcelona

Spain. The dataset collected include three full days

video capturing in the industry that describe any

complex activity (www.scovis.eu).

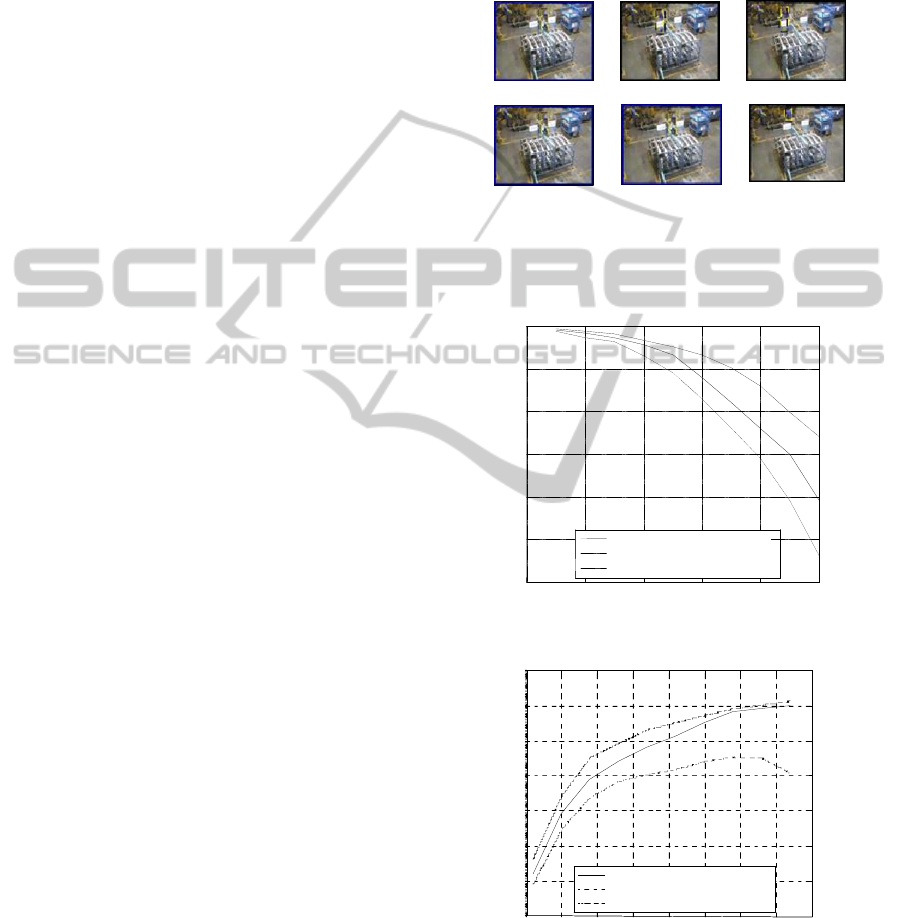

Figure 2 shows the tracking results using the

proposed modified self corrective algorithm. The

boxes have been shown in black colour. Similarly,

Figure 2 compares the tracking performance using

the methodology described in (Doulamis and

Matsatsinis, 2011) (with yellow colours). As we can

observe, a slightly better tracking improvement is

derived in our case than when the algorithm of

(Doulamis and Matsatsinis, 2011) is used. We need

to stress that the original performance of the self

initialized algorithm of (A. Doulamis, 2010) gives

much more worsened results in such complex

industrial cases.

Figure 2: The tracking performance of the proposed

algorithm (black boxes) as being compared with the

results of the (Doulamis and Matsatsinis, 2011) approach

(yellow boxes).

0 0.2 0.4 0.6

0.8

1

0.4

0.5

0.6

0.7

0.8

0.9

1

N

ormalized Number of Industrial Operations (in %)

Percentage in Gain Decrease (in %)

Scheduling Performance vs Number of Industrial Operations

MBF with Prediction Capabilities

MBF with Prediction Capabilities

Incremental Spectral Clustering

(a)

0 0.5 1 1.5 2 2.5 3 3.5 4

0.4

0.5

0.6

0.7

0.8

0.9

1

Standard Deviation by Mean Value (in %)

Percentage in Gain Decrease (in %)

Scheduling Performance vs Standard Deviation of Work flows Duration

MB F with P rediction Capa biliti es

EDF wit h Prediction C apa bilit ies

Incre ment al S pec tr al Cluste ring

(b)

Figure 3: Comparison of scheduling performances.

In the following, we compare the performance of

the proposed incremental spectral clustering

EXPLOITING VISUAL OBSERVATIONS FOR EFFICIENT WORKFLOW SCHEDULING IN PRODUCTION

ENVIRONMENTS

535

algorithm with the heuristic method of Maximum

Benefit First (MBF), proposed in (Doulamis and

Matsatsinis, 2011) and the Earliest Deadline First

(EDF) algorithm. We follow the same setup as in

(Doulamis and Matsatsinis, 2011). In particular, we

divide the total scheduling time horizon into 10

uniform intervals and we randomly generate 100

operations per interval, i.e., we totally create 1000

workflows. At each interval the scheduler is

activated to assign to resources the already

submitted workflows (the 100 newly generated and

the ones that have not been assigned / executed yet).

The start and finish times of the operations are

uniformly distributed within three time intervals

starting from the current one. We set as delivery

deadline per each operation a 20% time extension

beyond its finish time. Furthermore, we consider that

each operation completed before its deadline yield

the economic gain to the industry which also follows

a normal distribution, while each violation of the

operations deadline burdens with a constant

compensation of 20% of the maximum gain among

all workflows. This means that negative cost

(damages) can be derived.

Figure(a) shows the scheduling efficiency

derived by the use of the proposed incremental

spectral clustering algorithm and the MBF method

of (Doulamis and Matsatsinis, 2011) versus the

number of operations. This number has been

normalized with respect to the maximum number of

1000 for clarity purposes. We observe that the

proposed algorithm schedules better the operations

than the method of (Doulamis and Matsatsinis,

2011). We need to recall that this algorithm deviates

from (Huazhong Ning et. al, 2009) in the sense that,

due to the different nature of our problem,

incremental clustering should be followed. To

emulate the effect of the computer vision tools we

assume a delay on the 80% of the already executed

operations which is uniformly distributed between

the requested finish time and a 100% extension of it.

The remaining 20% of the currently running

workflows are left intact.

In these results, we have randomly generated

workflows of Gaussian probability density function

(pdf) which present a standard deviation equal to

their mean value. The effect of the proposed

scheduling scheme versus standard deviation values

is depicted in Figure(b). In this Figure, we have also

presents results obtained apart from the MBF along

with the EDF algorithm as well.

ACKNOWLEDGEMENTS

The author would like to thank SCOVIS, “Self

Configurable Video Supervision” European Union

Project for providing the data sets results and its

support to this work.

REFERENCES

Gonzalez Fernandez, J., Yelmo Garcia, J. C., Martin

Garcia Yo.-S., and de Gracia Santos J., “Transf-ID:

Automatic ID and Data Capture for Rail Freight Asset

Management”, IEEE Internet Computing Mag.

Jan./Feb. 2010.

Ilic, A., Andersen, T., and Michahelles, F., “Increasing

Supply-Chain Visibility with Rule-Based RFID Data

Analysis”, IEEE Internet Computing Jan./Feb. 2010.

Shaik, M. A., Floudas, C. A., Kallrath, J., Pitz, H.-J,

“Production scheduling of a large-scale industrial

continuous plant: Short-term and medium-term

scheduling,” Computer Aided Chemical Engineering,

Vol. 24, pp. 613-618, 2007.

Drotos, M., Erdos, G., Kis, T., “Computing lower and

upper bounds for a large-scale industrial job shop

scheduling problem,” European Journal of

Operational Research, Vol. 197, No,1, pp. 296-306,

August 2009.

Malamas, E. N., Petrakis, E. M., Zervakis, M., Petit, L.,

Legat, J.-D., “A survey on industrial vision systems,

applications and tools,” Image and Vision Computing,

Vol. 21, No. 2, pp. 171-188, 2003.

Motai, Y., “Salient feature extraction of industrial objects

for an automated assembly system,” Computers in

Industry, Vol. 56, Nos. 8-9, pp, 943-957, December,

2005.

Karakaya M. and Hairong Qi, “Target Detection and

Counting using a Progressive Certainty Map in

Distributed Visual Sensor Networks,” 3

rd

ACM/IEEE

International Conference on Distributed Smart

Cameras, ICDSC 2009.

Idoughi, D., Kerkar, M., Kolski, C., “Towards new web

services based supervisory systems in complex

industrial organizations: Basic principles and case

study,” Computers in Industry, Vol. 61, No. 3, pp.

235-249, 2010.

Doulamis A., and N. Matsatsinis, “Visual Understanding

Industrial Workflows under Uncertainty,” submitted to

the Future Generation Computer Systems Journal.

Bach F. R., and Jordan M. I., “Learning spectral

clustering,” In S. Thrun, L. Saul, and B. Schoelkopf

(Eds.), Advances in Neural Information Processing

Systems (NIPS) 16, 2004.

Huazhong Ning, Wei Xu, Yun Chi, Yihong Gong and T.

S. Huang “Incremental spectral clustering by

efficiently updating the eigen-system,” Patter

Recognition, Vol. 43, No. 1, pp.113-127, 2010.

ICAART 2011 - 3rd International Conference on Agents and Artificial Intelligence

536

Delias, P., Doulamis A., Doulamis N., and Matsatsinis N.,

“Optimizing Resource Conflicts in Workflow,” IEEE

Trans. on Knowledge Engineering, accepted for

publication.

Doulamis A., “Dynamic Tracking Re-Adjustment: A

Method for Automatic Tracking Recovery in Complex

Visual Environments,” Multimedia Tools and

Applications, Springer Press, 1380-7501 (Print) 1573-

7721 (Online).

Ky Fan, “Maximum properties and inequalities for the

eigenvalues of completely continuous operators,”

Proceedings of the National Academy of Sciences pp.

760–766, 1951

Culibrk, D., Marques, O., Socek, D., Kalva H., Furht, B.

“Neural Network Approach to Background Modeling

for Video Object Segmentation,” IEEE Trans. on

Neural Networks, Vol. 18, No.6, pp.1614-1627,

Nov.2007.

Doulamis A. D., Doulamis N. D. and Kollias, S. D., “On

Line Retrainable Neural Networks: Improving the

Performance of Neural Network in Image Analysis

problems,” IEEE Trans. on Neural Networks, Vol. 11,

No. 1, pp. 137-155, January 2000.

www.scovis.eu

Cui, M., Femiani, J., Hu, J., Wonka, P., Razdan, A.,

“Curve matching for open 2D curves,” Pattern

Recognition Letters, Vol. 30, pp. 1–10, 2009.

EXPLOITING VISUAL OBSERVATIONS FOR EFFICIENT WORKFLOW SCHEDULING IN PRODUCTION

ENVIRONMENTS

537