A PDMS BASED INTEGRATED PCR MICROCHIP FOR

GENETIC ANALYSIS

Sandeep Kumar Jha, You-Cheol Jang, Rohit Chand, Kamrul Islam

Department of Nanoscience & Engineering, Myongji University, Yongin, 449728, Republic of Korea

Yong-Sang Kim

Department of Nanoscience & Engineering, Myongji University & Department of Electrical Engineering, Myongji

University, Yongin, 449728, Republic of Korea

Keywords: PDMS, PCR Microchip, SMAD4, Lab-on-a-chip, ITO microheater.

Abstract: An integrated continuous-flow microfluidic chip was fabricated on glass substrate with PDMS based

microchannels, cell lysis and PCR modules. Gold-microelectrodes were used to produce electrochemical

cell lysis, while, indium-tin-oxide (ITO) microheater was used for thermal cycling of PCR reaction. The

fabricated device was used for 20 cycles of PCR amplification of pancreatic cancer DNA marker (SMAD4)

from non-tumorigenic MCF10a human cell lines. The 193 bp PCR amplicon obtained through on-chip PCR

was confirmed in case of MCF 10a cells through agarose gel electrophoresis, whereas no product was

detected in case of tumorigenic MCF7 cells. The total time required for entire reaction was less than 90 min.

Therefore, we propose that such microchip can be helpful in predicting the risk of cancer by analysis of

genetic tumor markers from human samples and can also be used for other genetic analysis involving PCR

reaction.

1 INTRODUCTION

Early detection of metastasis has always remained as

elusive as necessity. Such detection often involves

invasive tissue biopsy or expensive and unreliable

tumor marker antigen study. However, the probable

occurrence of a certain forms of cancer can be

predicted as early as gastrulation using genetic

markers. SMAD4 is one such gene, which is either

deleted or mutated in more than one third of

pancreatic cancer patients (Dixit and Juliano, 2008).

These genetic markers can be identified by using

Polymerase chain reaction (PCR), which is a widely

used molecular biology technique for amplifying

specific regions of DNA using DNA polymerase

enzyme. The PCR technique is also applicable in

cloning, genotyping, drugs discovery, forensic,

environmental and ever growing application areas. A

majority of PCR applications involves analysis with

whole cells and requires the extraction of template

DNA prior to PCR. These steps are time consuming

and labor extensive and require expensive chemicals

and instrumentation.

Since, further miniaturization of this technique

is possible, we propose in this regard, a continuous-

flow PCR chip on glass substrate using indium-tin-

oxide (ITO) heater and microchannels laid in

polydimethylsiloxane (PDMS). As, cell lysis is an

important step for extraction of DNA prior to PCR

analysis, for this reason, we also integrated a cell

lysis device on the same chip. While, PDMS was

chosen for microfluidic devices fabrication as it can

easily and repeatedly be fabricated by the molding

method and requires no channel pretreatment as in

case of materials such as Poly(methyl methacrylate)

(PMMA); ITO heater electrodes were the choice for

thermal cycling due to ease of its fabrication and

linear variation of its temperature by application of

DC power.

2 EXPERIMENTAL

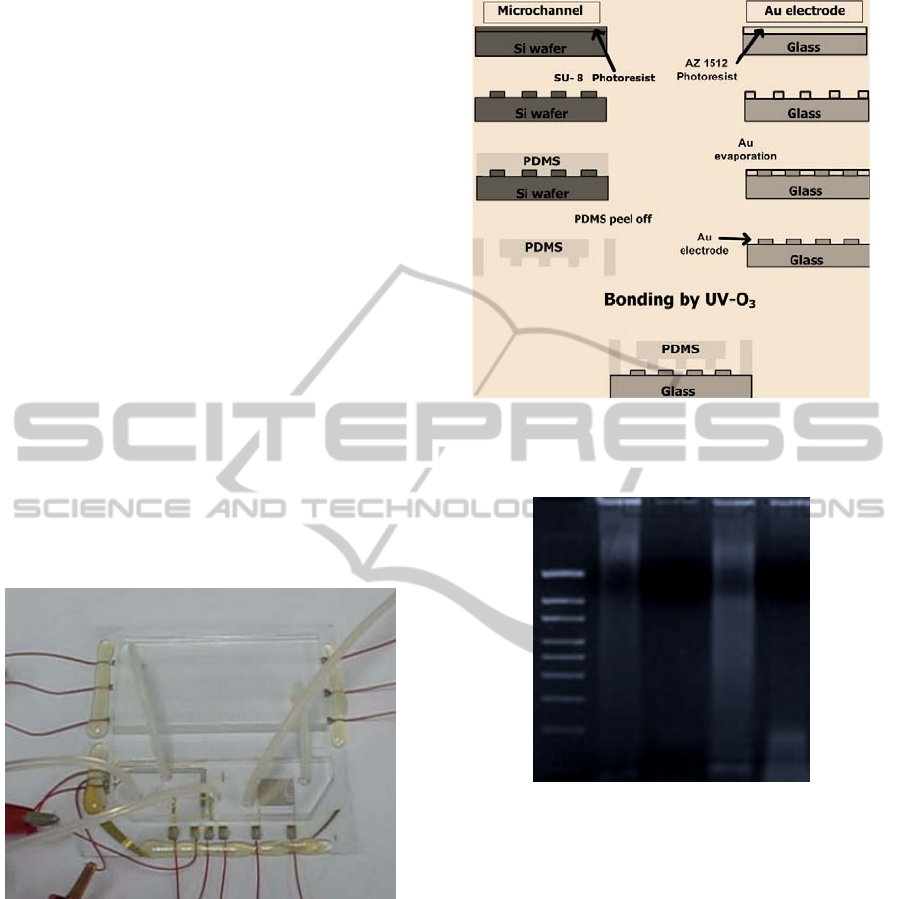

The Micro chip consisted of two parts (Fig. 1). The

273

Kumar Jha S., Jang Y., Chand R., Islam K. and Kim Y..

A PDMS BASED INTEGRATED PCR MICROCHIP FOR GENETIC ANALYSIS.

DOI: 10.5220/0003288202730275

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 273-275

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

PDMS microchannel was fabricated using negative

molding method. Negative photoresist (SU-8 2075,

Micro Chem) was spin-coated onto a silicon wafer.

SU-8 was patterned to make a microchannel using

photolithography technique (Fig. 2). The PDMS

(DC-184, Dow Corning) mixture was poured on the

SU-8 patterned wafer and cured for 4 h at 72°C. The

PDMS was then peeled off and manual drilling was

performed to produce access holes. The width and

depth of the microchannel were 250 and 200 µm

respectively, and total length was 1100 mm for 20

PCR cycles. The PCR channel was divided into

2:2:3 length ratio for three different temperature

zones namely denaturation, annealing, and

extension. ITO heater/electrode for PCR was

fabricated using conventional photolithography and

wet etch process. Positive photoresist (AZ-1512,

Chariant) was spin-coated on ITO film deposited

glass. AZ-1512 was patterned to make electrode

using photolithography. ITO film was etched using

FeCl

3

/HCl solution for 1 h and photoresist was

removed. Gold electrodes for cell lysis were

fabricated using photolithography and evaporation

method. AZ-1512 was spin-coated on glass and

patterned using photolithography. After

photolithography process, Gold electrode was

Figure 1: The PCR microdevice containing microchannels

for cell lysis and PCR modules, ITO microheater and the

gold microelectrode for electrochemical cell lysis.

deposited using evaporator. For electrical isolation

of electrodes from test fluid, PDMS was spin coated

onto the ITO patterned glass and baked at 95°C for

30 min. Fabricated PDMS microchannel and

ITO/Gold electrode chip were bonded with each

other after UV-ozone treatment for 40 min. ITO

heaters were calibrated for liquid temperature

control by incorporating thermocouple (CHAL-

0001, Omega) into the microchannel during UV-

ozone bonding of PDMS to the glass substrate.

Figure 2: Fabrication process for PDMS based

microchannel and Au microelectrodes.

Lane-1 2 3 4 5

Figure 3: Gel-doc from agarose gel electrophoresis of PCR

amplicon of MCF 7 and MCF 10a cells (SMAD4 gene.

Condition: injecting sample with flow of air at 5 µl/min

rate. Lane: 1= 1.5 kb marker; 2 = Pre PCR lysate for

MCF7; 3 = PCR of MCF7; 4 = Pre PCR lysate for

MCF10a (Non-cancerous); 5 = PCR of MCF10a. The 193

base pair band on lane 5 is the desired PCR product after

20 cycles.

3 RESULTS

The fabricated device was used for lysis and PCR

amplification of genomic DNA of non-tumorigenic

MCF10a and tumorigenic MCF7 human cell lines.

Approximately 10

6

cells were suspended in 50 µl

PBS and 50 µl 2X PCR mix containing Taq-DNA

polymerase and 2 µl each of the primers against

SMAD4 gene were added. The mixture was injected

into silicone tube carrying air to microchannel with

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

274

the help of precision syringe pump. The PCR

product (193 bp) was verified by agarose gel

electrophoresis (Fig. 3) as well as spectroscopic

method and a yield of ~ 250 ng DNA/10

6

MCF 10a

cells was recorded, while no product was detected in

case of MCF7. These results suggested the success

of miniaturized PCR device for rapid PCR

amplification of SMAD4 gene in tumorigenic human

cells and therefore, early prediction of occurrence of

pancreatic cancer. In conclusion, the developed

device can also be used in almost any other genetic

analysis involving DNA extraction and PCR

amplification. Based on these preliminary results,

we propose that the integrated device will be helpful

in reducing the reaction time for DNA extraction as

well as PCR amplification of DNA in a variety of

samples. Further work is under progress to use this

integrated chip in genomic analysis from a variety of

samples.

ACKNOWLEDGEMENTS

This study was supported by grant No. ROA-2006-

000-10274-0 from the National Research Laboratory

Program of the Korea Science & Engineering

Foundation.

REFERENCES

Dixit, V. and R. L. Juliano, 2008. Selective killing of

SMAD4-negative tumor cells via a designed repressor

strategy. Mol Pharmacol. 74(1) 289-97.

Joung, S-R., Kang,

C-J. and Kim Y-S, 2008. Series DNA

Amplification Using the Continuous-flow Polymerase

Chain Reaction Chip. Japanese Journal of Applied

Physics. 47(2) 1342-1345.

A PDMS BASED INTEGRATED PCR MICROCHIP FOR GENETIC ANALYSIS

275