INTEGRATED ELECTRONIC PRESCRIBING AND ROBOTIC

PHARMACY DISPENSING

Are there Any Benefits?

R. J. Beard

Principal Pharmacist, Sunderland Royal Hospital,

Kayll Road, Sunderland, SR4 7TP, U.K.

Keywords: Electronic prescribing, Automated dispensing Robot, Benefits.

Abstract: Sunderland Royal Hospital (1,000 beds) has used an integrated electronic prescribing (EP) system for 8

years, and recently (2009) linked 2 robotic dispensing machines to the pharmacy module. The impact on

dispensing error rates (quality) and efficiency (costs) were assessed. The implementation delivered staff

efficiencies above expectation, whilst not adversely affecting the dispensing error rates. It was significant

that although the combination of EP plus robot did eliminate dispensing errors, some errors continue to

occur for items not stocked in the robot (e.g. part-packs). In achieving this, the professional pharmacy

model changes.

1 BACKGROUND

In 2005, the Department of Health issued a report

authored by the Chief Pharmacist ‘Building a safer

NHS for patients. –Improving medication safety’

(Smith J. M. 2005). This was a detailed paper on

medication errors, the causes, and potential

remedies, and stemmed from the paper ‘An

Organisation with a memory’ (Donaldson L. 2001).

‘Building a safer NHS for patients’ made many

suggestions to design out errors through use of a

systems approach to medication systems. Electronic

prescribing and robotic dispensing were put forward

as potential tools to help reduce dispensing errors.

However, the advantages of electronic prescribing

and robots are not systematically documented in the

literature, and it remains unclear as to what features

provide the greatest safety. There is a variety of

design in electronic prescribing (EP) and robotic

dispensing systems, and it is important when

surveying the literature to consider the context of the

medication system in a hospital.

The Chief Pharmacist (Smith J. M. 2005) quoted

a study from the dispensing error analysis scheme

[DEAS] published by Cardiff and Vale NHS trust in

his paper. This paper analysed errors from 66

contributing hospitals from 1991 to 2001, and

looked at 7000 errors. As such, it represents one of

the biggest surveys of its kind in the UK. The

following categories of errors was recorded by

frequency as shown in table 1.

Table 1: Frequency and type of dispensing errors.

Type of error Proportion %

wrong drug supplied 23%

wrong strength of correct drug supplied 23%

wrong quantity 10%

wrong warnings or directions 10%

wrong drug name on the label 9%

wrong strength on label 8%

wrong form 7%

wrong patient name on label 7%

Beard (Beard R. J. 2009) described the benefits

of EP, and what features would contribute to the

benefits of EP. His study demonstrated that the

greater the integration of EP with other hospital

systems, the greater the benefit. Similarly, over the

last 10 years, robots have seen increasing use in

hospitals, and whilst some of the benefits seem

obvious, the precise features of a robot which yields

the greatest benefit are yet to be identified. City

Hospitals Sunderland has the following profile;

376

Beard R..

INTEGRATED ELECTRONIC PRESCRIBING AND ROBOTIC PHARMACY DISPENSING - Are there Any Benefits?.

DOI: 10.5220/0003191603760381

In Proceedings of the International Conference on Health Informatics (HEALTHINF-2011), pages 376-381

ISBN: 978-989-8425-34-8

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

Table 2: Types of errors prevented by EP and robots.

Type of error

Proportion % EP prevents

Robot

prevents

EP + Robot

prevents

wrong drug supplied

23% Y Y

wrong strength of correct drug supplied

23% Y Y

wrong quantity

10% Y Y

wrong warnings or directions

10% Y Y

wrong drug name on the label

9% Y Y

wrong strength on label

8% Y Y

wrong form

7% Y Y

wrong patient name on label

7% Y Y

• It serves a general population of 350,000

• It serves a sub-regional population of

750,000

• It has 1,000 acute beds

• It employs 5,000 staff

• It has an income of £300 million

The pharmacy has been operating and integrated

EP system for over 8 years, and recently

implemented a robotic dispensing machine. In doing

so, medication safety was a feature of the business

case. Using EP and robotic dispensing as per

implemented at Sunderland, we can regard

medication errors prevention in the same way as the

DEAS study documented in Table 2.

It follows that provided EP and robotic

dispensing are integrated in a specific way, many

dispensing errors can be ‘designed out ‘by skilful

application of technology.

However, at Sunderland we have realised to

achieve such a system, the professional model for

pharmacy changes. It is the purpose of this report to

identify and document those changes, and to suggest

the pros and cons of such a model.

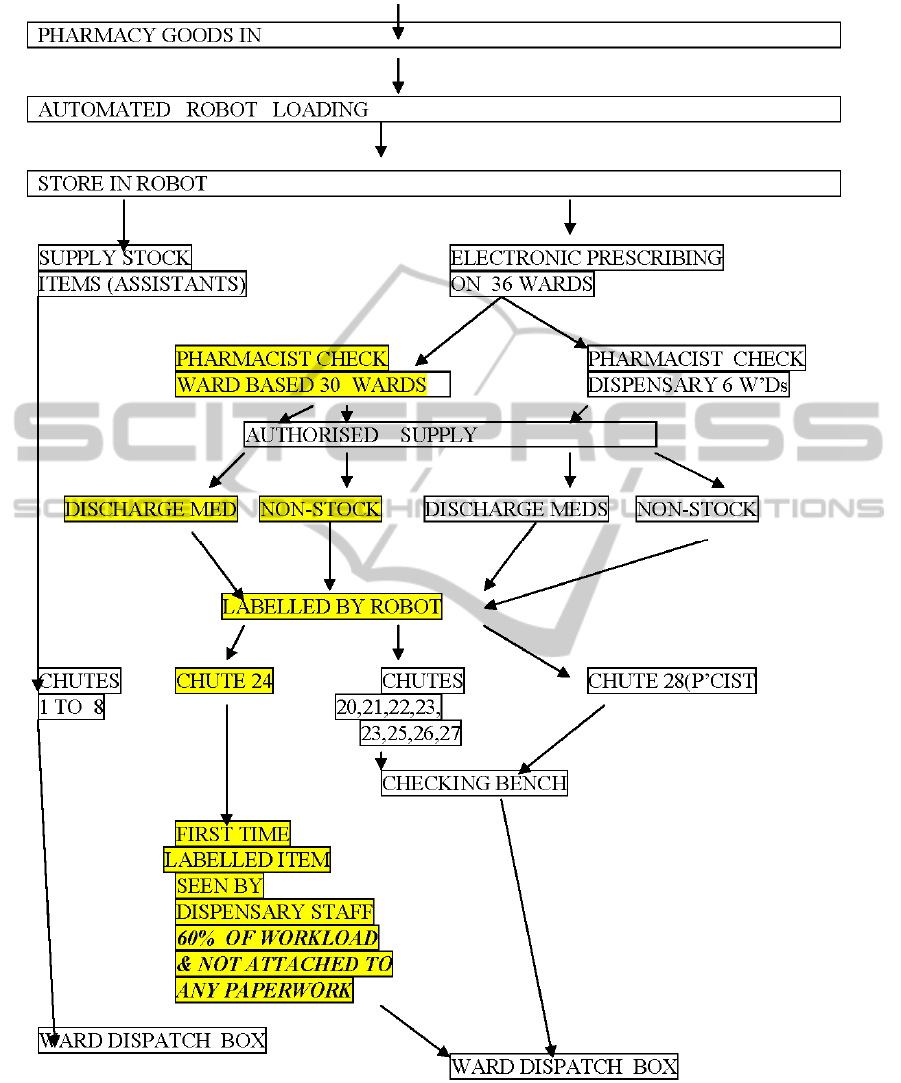

Traditional Pharmacy Dispensing Models

In the typical dispensing model, and the process is as

follows in the numbered sequence.

1 Decision to discharge patient

2 Doctor writes prescription

3 Prescription delivered to pharmacy

4 Professional check of prescription

5 Prescription dispensed

6 Prescrition checked

7 Prescription placed ready for delivery to ward

This process can take up to 4-8 hours (Beard J.{

not this author} and Wood D. 2010) for non-urgent

items for a variety of reasons. The key point to

remember is that in the pharmacy, the prescription

and dispensed item can always be seen together until

bagged for ward delivery. Below is the process

model at Sunderland is shown in figure 1.

The key points to remember are:

• Because EP is integrated, when the doctor

prescribes the medicine on the computer, he

is also in fact writing the label to attach to

the medicine. This means the label is

always what the doctor requested

• Because the label is always accurate to the

prescription there is no transcription error

• Drugs can only be stored in the robot by bar

code identification. There is a direct

electronic link between the medicine, bar

code, and item selected on the electronic

prescription, and

the label that the robot

applies. These are the crucial links in

deriving safety benefits from technology

• To design in these links is to design out

potential errors.

• Once designed, the system works from

anywhere in the hospital. This allows 60%

of dispensing activity to be triggered

outside the pharmacy at Sunderland

• Automatic labelling is a critical component

of this system

• Once medication has been checked by a

pharmacist (usually at ward level at

Sunderland) the dispensing becomes nearly

instantaneous. The remaining bit of the

process is to get the medication from

pharmacy to the ward.

INTEGRATED ELECTRONIC PRESCRIBING AND ROBOTIC PHARMACY DISPENSING - Are there Any Benefits?

377

Figure 1: Diagram of dispensing processes at Sunderland.

• In achieving ‘instantaneous dispensing’ the

role of the pharmacist changes. No longer

are pharmacists directly in control over

the whole dispensing process. It is akin to

craftsmen producing goods being replaced

by production lines where quality control is

through process control, and each

individual is responsible for a part of the

overall process, not all of it.

HEALTHINF 2011 - International Conference on Health Informatics

378

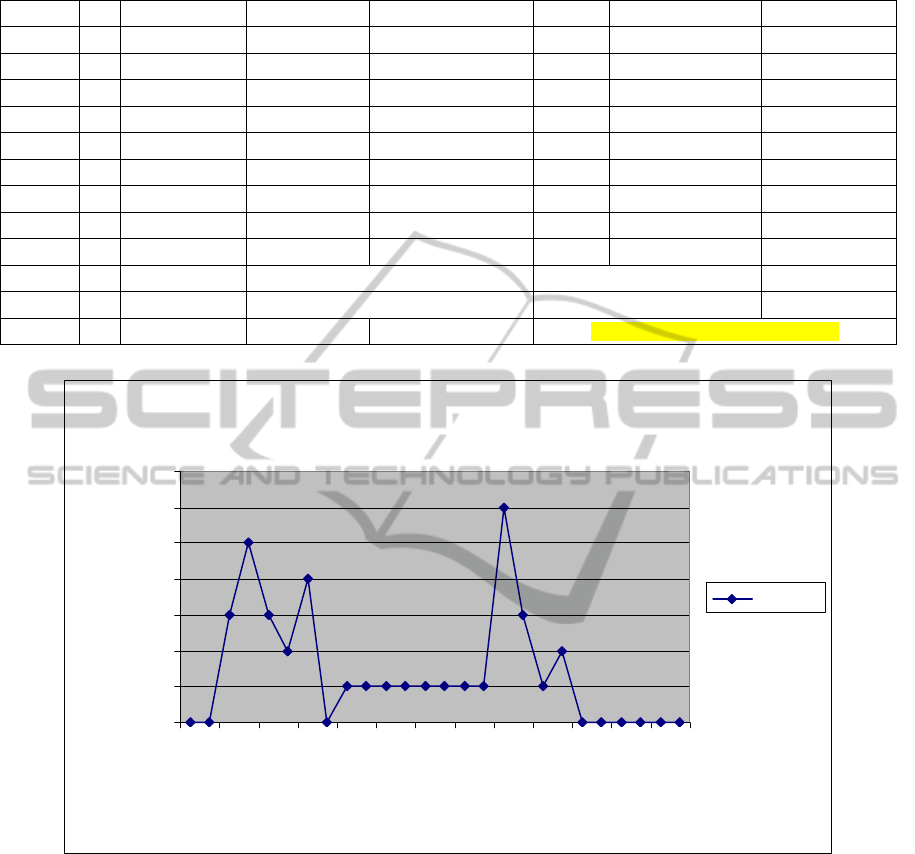

2 MEASURING THE BENEFITS

Setting. Sunderland Royal Hospital is a 1,000 bed

hospital in Northern England. The hospital operates

2 dispensaries, including a smaller discrete out-

patients pharmacy dispensing around 5000 items per

month. Control charts have been widely used by

industry for many years to manage process variation,

but the literature for healthcare in Europe suggests

this method of process control is less widely used.

This paper uses of control charts to look at the

impact on out-patient dispensing errors when robotic

dispensing and skill mix reductions are introduced.

Method. Dispensing errors per month was plotted

on a control chart for 12 months prior and

subsequently to the installation of the first

dispensing robot ( March 09). On installation, staff

was reduced by 1.4wte ( in line with business case).

Skill mix was also adjusted (not in business case) to

meet overall operation needs of the department. All

NHS Hospitals in the UK pay staff on a banding

system that equates all jobs on their value. The

higher the job band, the more highly skilled the post.

The job band and whole time equivalents for staff

were determined, and used as a measure of the

‘quantity of skill’ to run the Outpatient pharmacy.

The monetary value of the ‘skill quantity’ changes is

calculated from the mid-point salary scale.

Results. The change in skill mix was 50% ; (Table.

3). On installing the robot, band 5 technical staff

could be replaced with lower banded dispensing

staff, without adversely affecting the quality of the

dispensing process. This was 16% more efficient

than the business case required.

Discussion. Changes in skill mix equates to an

additional saving on top of staff reduction more than

the business case. Early data from the control chart

suggests de-skilling the dispensary workforce using

robots has a no worse impact on dispensing errors.

However, towards the end of 2009, there was an

increase in dispensing errors. This is where control

charts are useful to monitor the processes, when

dealing with small numbers. There is no EP function

at present in the Out-patient pharmacy, and analysis

of the ‘blip’ was undertaken by looking at the errors

and other factors. An audit of the prescriptions

received was undertaken, revealing that 25% of the

written prescriptions required further clarification by

the pharmacist.

It should be noted that the out-patient dispensary

does not yet have EP, but uses traditional pharmacy

prescriptions. The impact on errors, efficiency and

skill mix apply without any of the EP benefits. A

previous paper (5) listed the different types of

dispensing methods at CHS, and the error rates

associated with them. The same approach has been

taken for looking at errors for in-patient dispensing.

The results to date are shown in figure 2.

Figure 2 shows a spike in errors just after

installation. Error analysis showed them to be non-

robot errors,i.e. they were picking errors from those

shelves of the pharmacy where items cannot go into

robots ( part packs, round tubs of medicines, or

items too small (e.g. eye drop bottles) to be labelled

by robot.

Significantly, we have found zero errors for the

robot plus EP system combined, based on around

800,00 items per annum. Potentially a huge benefit

in safety. However, dispensing is not risk-free, since

not all items are supplied and labelled from the

robot. Clearly though, the opportunity for errors is

significantly reduced.

Turn Around Time for Prescriptions. Speed of

turnaround time taken from clinical check is nearly

instantaneous, very different from many hospitals.

At busy periods dispensing times can rise to up to 20

to 30 minutes, but this situation tend not to last

beyond about half an hour. Normally dispensing

times can often be up to 4 hours for non-urgent

dispensing. (Beard J. and Wood D 2010). These

authors quotes how be using lean processes they

reduced the dispensing time of the prescription from

4 hours to around 2 hours. ( These times include the

time it takes a signed prescription to get from ward

to pharmacy.). This is not untypical of non-EP –

robotic system. The concept of instantaneous

dispensing is not currently part of hospital pharmacy

culture, nor is dispensing triggered from over 36

different points in the hospital.

Dispensing Rate. Whittlesea (7) quotes a Welsh

benchmark of 10 items per person per hour.

Sunderland dispenses a maximum of 360 items per

hour, equating to 36 dispensing staff. The in-patient

pharmacy operates with around 10 dispensary staff.

Sunderland’s robot chute 24 issues 60 % of the

dispensing activity, which is from the ward based

pharmacy staff. Ours is not a directly comparable

situation. However if one takes the figure of 360

items an hour the pharmacy can dispense, it has

therefore a capacity of 57,000 items per month. To

INTEGRATED ELECTRONIC PRESCRIBING AND ROBOTIC PHARMACY DISPENSING - Are there Any Benefits?

379

Table 3

Job band wte job band x wte salary paid £'s mid point salary £'s

new wte new skill amount salary total £'s

band 6 1 6 28000 28000 1 6 28000

band 6 1 6 28000 28000 1 6 28000

band 5 2.4 12 56040 23350 0 0 0

band 4 1 4 19500 19500 1 1 19500

band 3 1 3 17000 17000 1 1 17000

band 2 1 1 14360 14360 2 2 28720

totals 6.4

32

162900 5

16

121220

cost reduction 41680

wte= whole time equivalent skill reduction = 50%

BC = business case BC =£35k reduction

Additional benefit over BC = 16%

Errors ( green line = robot installed Sept 2009)

0

1

2

3

4

5

6

7

Ju

n

-08

Au

g-08

O

c

t-

08

Dec-08

F

eb

-

09

Apr-0

9

Jun-09

Au

g-09

O

c

t-

09

Dec-09

F

eb

-

10

Apr-1

0

Jun-

1

0

month

errors

Series1

Figure 2: Dispensing errors in in-patient pharmacy per month. Green line marks use of robot with EP.

put this in community pharmacy terms, a community

pharmacy needs around 7,000 items a month to be

solvent, and a very busy pharmacy might do around

20,000 items per month. The capacity of the in-

patient pharmacy is about 3 times that rate.

3 CONCLUSIONS

There are clear benefits in using electronic

prescribing and robotic dispensing, and these will be

realised so long as the following conditions are met:

• The EP system used is integrated with all

the other hospital software systems

• The robotic dispenser is integrated to the

EP system

• There are automated labellers for those

items robotically dispensed.

When the above conditions are applied several

advantages become apparent:

• For items in the robot, there is no scope to

make a dispensing error, improving patient

safety.

HEALTHINF 2011 - International Conference on Health Informatics

380

• The process is much more efficient, and the

skill mix of staff can be adjusted within the

dispensary

• The speed of the prescription process

increases dramatically.

The consequences of the above are that the

purchasing of medicines needs to be given

consideration so that items with appropriate bar

codes are purchased. There is also a change in the

professional model, as the dispensary pharmacist is

no longer in complete control of the dispensing

going on in the dispensary. The implications of this

are not within the scope of this paper.

REFERENCES

Beard J., Wood D., 2010. Pharmaceutical Journal vol 284

(17

th

April 2010) p369-371

Beard R. J., 2009. Professional Masters Thesis, University

of Sunderland

Donaldson L., 2001. An Organisation with a Memory

www.doh.gov.uk

Kelley D. Lynn, 1999. How to Use Control Charts for

Healthcare ASQ Quality Press. ISBN 0-87389-452-9

www.asq.org

Smith J.M., 2005. Building a safer NHS for patients.

Improving medication safety. . www.doh.gov.uk

Whittlesea C., Phillips C., Roberts D., Burfield R., Savage

J., Way C.. 2004. Automated dispensing- how to

evaluate its impact. Hospital Pharmacist 11 p283-285

INTEGRATED ELECTRONIC PRESCRIBING AND ROBOTIC PHARMACY DISPENSING - Are there Any Benefits?

381