BONE QUALITY TESTING DURING DENTAL IMPLANT

SURGERY

A Novel Device for Intraoperative Compressive Testing of Alveolar Bone

Werner Winter

Department of Mechanical Engineering, University of Erlangen-Nuremberg, Egerlandstrasse 5, 91058 Erlangen, Germany

Tim Krafft

Oral and Maxillofacial Surgeon, Woerthstrasse 7, 92637 Weiden, Germany

Matthias Karl

Department of Prosthodontics, University of Erlangen-Nuremberg, Glueckstrasse 11, 91054 Erlangen, Germany

Keywords: Bone quality, Compressive testing, Dental implant surgery.

Abstract: Based on theoretical considerations, a mathematical equation was set up describing a correlation between

density and mechanical properties of both, cortical and trabecular bone. Simulating the clinical situation of

dental implant placement, finite element analysis was applied to test the validity of compressive testing of

alveolar bone following implant site preparation. As a final step, a loading device was constructed

accordingly and tested in human cadaver bone.

1 INTRODUCTION

Precise evaluation of alveolar bone quality is a

prerequisite for successful implant therapy as dental

implants are subject to masticatory loads of varying

magnitude (Brunski, 1988). The type and

architecture of bone are known to influence its load

bearing capacity, and it has been shown that

implants placed in poor quality bone have higher

failure rates (Norton and Gamble, 2001). In clinical

reality, bone quality does affect treatment planning

and the choice of loading protocols for a specific

patient.

This topic has been addressed by numerous

authors and various techniques for evaluating bone

quality have been described including preoperative

radiographs, subjective hand feeling during drilling

(Alsaadi, 2007; Trisi, 1999; Shapurian, 2006),

implant insertion torque (Beer, 2003; Friberg,

1999a; Johansson, 2004), different forms of

computed tomography (Aranyarachkul, 2005; Ikumi,

2005; Lagravere, 2006; Lindh, 1996) as well as

measurement systems for the determination of

primary implant stability (Friberg, 1999b; Nkenke,

2003; Al-Nawas, 2006) such as the Periotest

®

(Medizintechnik Gulden, Modautal, Germany) and

Osstell

®

(Osstell AB, Gothenburg, Sweden) device

(Meredith, 1998; Schulte, 1992; Aparicio, 2006).

However, a recent literature review pointed out

that a single objective evaluation method for bone

quality is not available so far and that there is only

sparse evidence for the efficacy of clinical methods

to assess jawbone tissue prior to and during

endosseous dental implant placement (Ribeiro-Rotta,

2007).

As compressive testing of human bone

specimens has been successfully used in

experimental research (Giesen, 2003; Giesen, 2004),

it was planned to develop a system capable of

conducting compressive tests on human alveolar

bone during dental implant surgery (Figure 1).

Therefore, the purpose of this study was to

design a method for the non-destructive

determination of bone quality following implant site

preparation. Using mathematical considerations and

finite element analyses it has been clarified which

140

Winter W., Krafft T. and Karl M..

BONE QUALITY TESTING DURING DENTAL IMPLANT SURGERY - A Novel Device for Intraoperative Compressive Testing of Alveolar Bone.

DOI: 10.5220/0003132601400145

In Proceedings of the International Conference on Biomedical Electronics and Devices (BIODEVICES-2011), pages 140-145

ISBN: 978-989-8425-37-9

Copyright

c

2011 SCITEPRESS (Science and Technology Publications, Lda.)

mechanical parameters have to be determined in

order to obtain information on the elastic properties

of bone at a specific site. Based on these findings, a

clinically applicable device for bone quality testing

was fabricated and used for preliminary testing in

human cadaver bone.

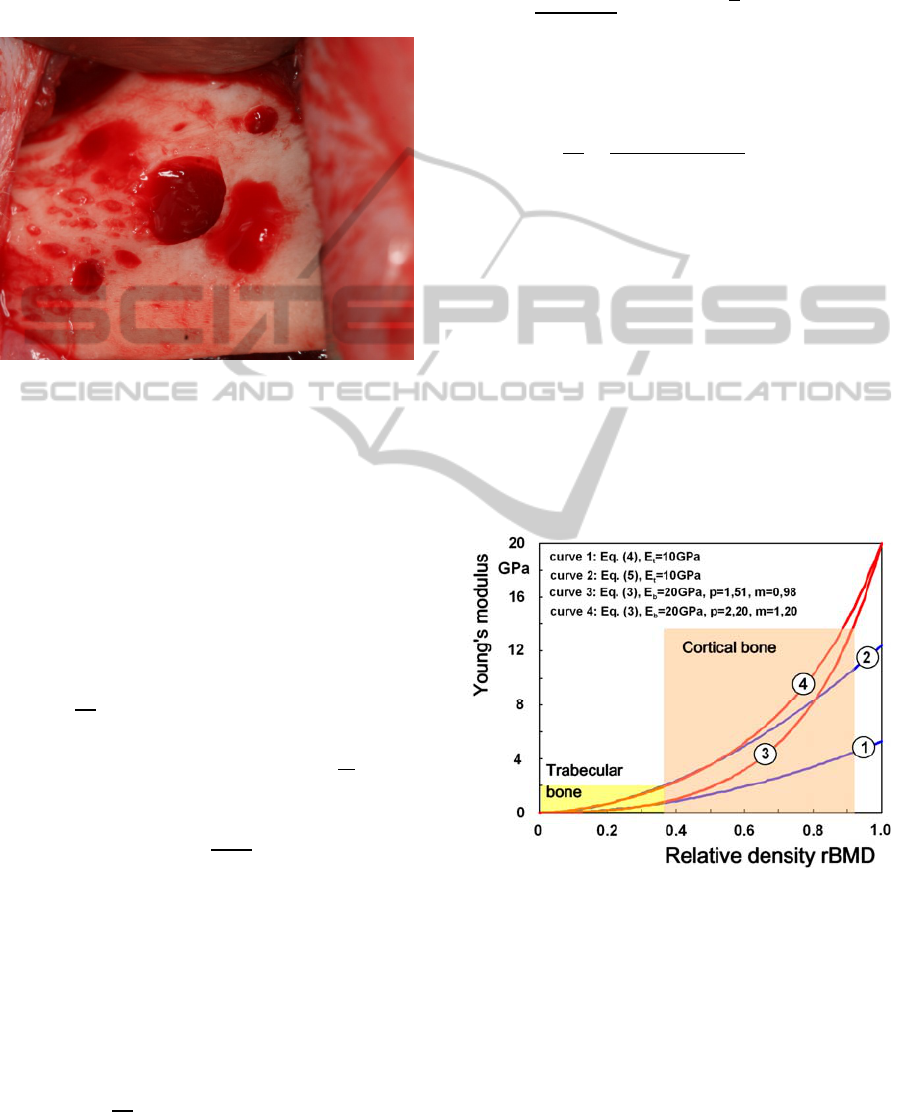

Figure 1: Clinical situation during dental implant surgery

after preparation of an implant site using a series of twist

drills. Note: Areas of decortication surrounding the

implant site provide blood supply for local bone

augmentation in this case.

2 STUDY PARTS AND FINDINGS

2.1 Theoretical Considerations

G Given the non-homogeneous structure of both

cortical and trabecular bone comprising hard tissue

and bone marrow, volumetric bone mineral density

=

(

: bone mass,

: bone volume)

appears to be inadequate for describing bone.

Apparent bone mineral density =

(: total volume with bone mass and marrow) which

takes marrow space into account and relative bone

mineral density =

appear to be more

appropriate.

For biomechanical considerations, bone can be

described as a cellular structure or as a porous

structure with a specific distribution of hollow

spaces. In either situation, can be described

as a function of geometric parameters describing

unit cells.

For an analytical model, the relative elastic

modulus for cellular structures may be described as

= ()

(1)

with E standing for the apparent elastic modulus and

b and n representing material characteristics. E can

also be described as a function of apparent density

=

()

()

=b ()

.

(2)

In order to be able to reflect rBMD values ranging

from 0 to 1, a unifying equation was set up (Winter,

2008)

=

()

(3 − 2 )

(3)

where p and m reflect material parameters. With the

given equation it was possible to approximate values

for trabecular bone reported by Yang and coworkers

(Yang et al, 1999)

= 528

∅

.

(4)

and

= 1240

∅

.

(5)

with ∅≡ being the fraction of bone and

= 10 being the tissue elastic modulus (Yang

et al, 1999).

In Fig. 2 a comparison of Eq. (3) with Eq. (4) and

Eq. (5) is shown over the whole range of the relative

bone mineral density .

Figure 2: Comparison of Young’s modulus over the whole

range of relative bone mineral density. Bone quality can

be characterized by the Young’s modulus of bone or bone

stiffness.

2.2 Design of a Device for Bone Quality

Testing

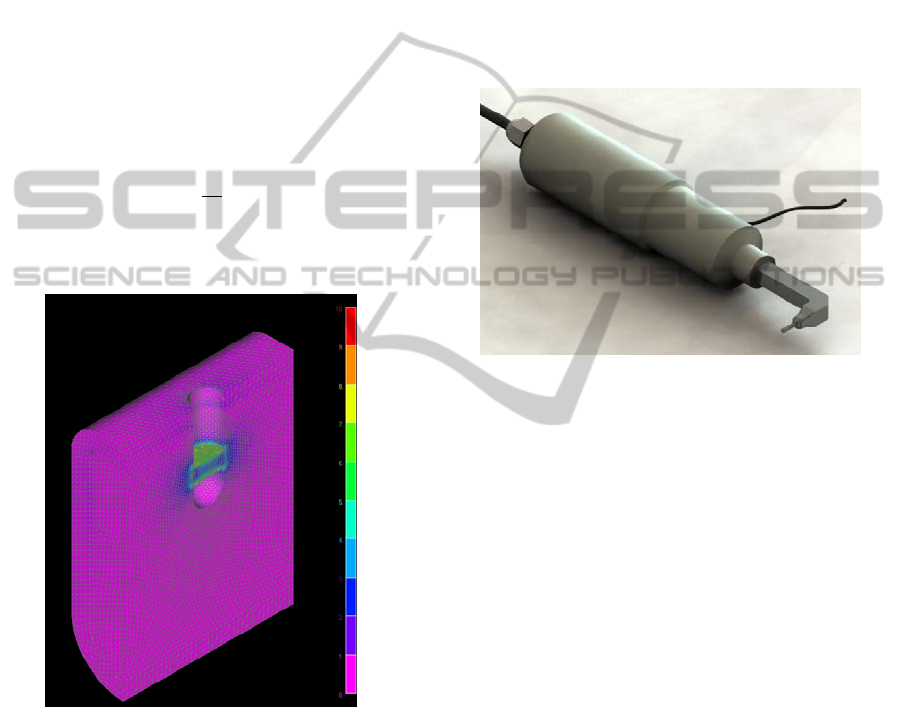

A three-dimensional finite element model

(MSC.Nastran®, MSC Software Partner Solutions,

Marburg, Germany) representing a 25mm long

BONE QUALITY TESTING DURING DENTAL IMPLANT SURGERY - A Novel Device for Intraoperative

Compressive Testing of Alveolar Bone

141

segment of a human mandible with an implant

socket (diameter: 3.5 mm; length: 11mm) was

generated (Figure 3). A peripheral layer (2mm

thickness) and a central layer were created to model

bone using tetrahedral elements. Bone was

considered as an isotropic material with an elastic

modulus of 20GPa in the cortical area and values of

either 1GPa or 3GPa for trabecular bone. Poisson’s

ratio was set to 0.3 for both, cortical and trabecular

bone and the free boundaries (anterior and posterior

segment borders) were fixed. A loading device

3.5mm in diameter was positioned in the trabecular

part of the implant socket and expanded by applying

thermal expansion until a diameter of 3.510 mm was

reached while the resulting pressure values p

1

were

recorded and used to calculate an elastic modulus E

1

applying the equation

=

(6)

with E

0

and p

0

standing for the calibration of the

device.

Figure 3: Finite element model used for validating

intraoperative compressive testing for the objective

classification of alveolar bone quality (scale: MPa). A

loading device was placed in a readily prepared implant

socket and the diameter of the device expanded. The stress

levels measured were used to calculate bone’s elastic

modulus in this area.

The values obtained from the simulation yielded

940MPa and 955MPa for two different finite

elements. Depending on the element considered,

maximum deviations of 6% between pre-set values

for the elastic modulus of bone and values derived

from the simulation were found.

2.3 Fabrication of a Bone Quality

Testing Device

An apparatus was constructed based on a metal

cylinder with a diameter of 3.50 mm which was split

into six segments. The cylinder could be expanded

gradually while the actual force needed was

recorded (Figure 4, Figure 5). This sensor could be

placed into sockets prepared for the placement of

cylindrically shaped dental implants and the

diameter increased to 3.52mm and 3.57mm for

measurements in the cortical and trabecular part of

the osteotomy.

Figure 4: Total view of the bone quality testing device

which is hand-held, motor driven and suitable for intraoral

measurements.

2.4 In vitro Testing in Human Cadaver

Bone

Segments of embalmed human mandibles and

maxillas were obtained from the Institute of

Anatomy, University of Erlangen-Nuremberg and

subject to cone beam computed tomography (CBCT)

scans (3D Accuitomo, J.Morita Europe GmbH,

Dietzenbach, Germany). The sites for implant

placement (number of sites: 110) as determined by

CBCT were classified according to the region in the

oral cavity (Maxilla / Mandible; Anterior /

Posterior).

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

142

Table 1: Mean values and standard deviations for all measurements conducted in human cadaver bone.

Drilling

resistance

Bone quality

testing device -

cortical bone

Bone quality

testing device -

trabecular bone

Implant

insertion torque

Resonance

frequency

analysis

Maxilla

anterior

2.83 (0.72) 21.08 (8.68) 14.33 (6.87)

16.68

(11.66)

63.75

(12.99)

Maxilla

posterior

2.85 (0.80) 14.01 (7.19) 14.70 (8.37) 9.33 (5.31)

64.92

(11.23)

Mandible

anterior

1.34 (0.70)

34.65

(18.39)

30.55

(26.71)

29.72

(13.27)

75.39 (6.31)

Mandible

posterior

1.60 (0.72)

43.66

(36.45)

21.21

(20.63)

30.53

(12.18)

78.46 (6.21)

Table 2: Pearson correlation coefficients for all combinations of measurements conducted in human cadaver bone.

Drilling

resistance

Bone quality

testing device -

cortical bone

Bone quality

testing device -

trabecular bone

Implant

insertion torque

Resonance

frequency

analysis

Drilling

resistance

1.0000 -0.4384 -0.3474 -0.6940 -0.4740

Bone quality

testing device -

cortical bone

1.0000 0.1712 0.4672 0.3321

Bone quality

testing device -

trabecular bone

1.0000 0.0621 0.1090

Implant

insertion torque

1.0000 0.4619

Resonance

frequency

analysis

1.0000

Figure 5: Sensing element of the bone quality testing

device consisting of a cylinder which is split into six

segments. The diameter of the cylinder can be increased

and the forces needed are recorded.

A socket 3.5mm in diameter and 11mm in length

was prepared for the placement of a screw-shaped

cylindrical implant with a diameter of 4.1mm and

10mm bone sink depth (Straumann Standard Plus

Implant; Institut Straumann AG, Basel, Switzerland)

in each site. The implant position was marked with a

round burr and a set of twist drills 2.2mm, 2.8mm

and 3.5mm in diameter was used in combination

with a surgical motor (KaVo INTRAsurg 1000;

KaVo Dental GmbH, Biberach, Germany) to create

standardized implant beds. During implant bed

preparation, the surgeon subjectively rated bone

quality according to the Lekholm and Zarb

classification system (Lekholm and Zarb, 1985).

Compressive testing using the bone quality testing

device was conducted in the areas of cortical and

trabecular bone (Figure 6). The sensor was opened

to 3.57mm in the cortical area and 3.52mm in the

trabecular area of each socket The forces needed to

open the sensor were recorded in N. Implants were

then installed using the surgical motor (KaVo

INTRAsurg 1000; KaVo Dental GmbH, Biberach,

Germany) measuring the maximum torque needed to

insert the implants. Primary implant stability was

determined by means of resonance frequency

measurements (Osstell mentor, Osstell AB,

Gothenburg, Sweden). For statistical analysis,

Pearson correlation coefficients were calculated for

all combinations of parameters.

BONE QUALITY TESTING DURING DENTAL IMPLANT SURGERY - A Novel Device for Intraoperative

Compressive Testing of Alveolar Bone

143

Figure 6: Application of the bone quality testing device in

a polyurethane foam model. Following implant site

preparation, the sensing element is inserted in the

osteotomy and opened gradually both in the cervical and

apical part of the socket while the force needed for

opening the sensor is measured.

The mean values and standard deviations for all

measurements conducted are given in Table 1.

Consistent with clinical knowledge, for all

parameters greater values were recorded in the

mandible as compared to the maxilla. Good

correlations between the different measuring

techniques were found.

3 DISCUSSION

It has been shown that the newly designed device

can be used for the objective classification of human

alveolar bone based on intraoperative compressive

testing. The values obtained are consistent with

already established measurement techniques either

evaluating bone quality or primary implant stability.

The major advantage of the system proposed is that

it can be applied independent from any specific

implant system thereby allowing for objective

comparisons. As the implants have not yet been

installed when the bone quality testing device is

applied, the surgeon still has the choice to modify

the treatment plan e.g. by selecting a tapered instead

of a parallel walled implant in order to achieve

greater primary stability. Based on the values

obtained from the bone quality testing device, a

decision can also be made with more confidence as

to when a specific implant can be loaded with a

certain type of superstructure. Following preclinical

testing in animals, further prospective clinical trials

are needed for establishing and verifying the

diagnostic value of the bone quality testing device.

The ultimate goal of the development should be to

establish threshold values on when a dental implant

can be loaded immediately.

REFERENCES

Al-Nawas, B., Wagner, W., Grötz, K. A. 2006. Insertion

torque and resonance frequency analysis of dental

implant systems in an animal model with loaded

implants. Int J Oral Maxillofac Implants 21:726-732.

Alsaadi, G., Quirynen, M., Michiels, K., Jacobs, R., van

Steenberghe, D. 2007. A biomechanical assessment of

the relation between the oral implant stability at

insertion and subjective bone quality assessment. J

Clin Periodontol 34:359-366.

Aparicio, C., Lang, N. P., Rangert, B. 2006. Validity and

clinical significance of biomechanical testing of

implant / bone interface. Clin Oral Implants Res 17

Suppl 2: 2-7.

Aranyarachkul, P., Caruso, J., Gantes, B., Schulz, E.,

Riggs, M., Dus, I. et al. 2005. Bone density

assessments of dental implant sites: 2. Quantitative

cone-beam computerized tomography. Int J Oral

Maxillofac Implants 20:416-424.

Beer, A., Gahleitner, A., Holm, A., Tschabitscher, M.,

Homolka, P. 2003. Correlation of insertion torques

with bone mineral density from dental quantitative CT

in the mandible. Clin Oral Implants Res 14:616-620.

Brunski, J. B. 1988. Biomechanics of oral implants: future

research directions. J Dent Educ 52:775-787.

Friberg, B., Sennerby, L., Grondahl, K., Bergstrom, C.,

Back, T., Lekholm, U. 1999a. On cutting torque

measurements during implant placement: a 3-year

clinical prospective study. Clin Implant Dent Relat

Res 1:75-83.

Friberg, B., Sennerby, L., Meredith, N., Lekholm, U.

1999b. A comparison between cutting torque and

resonance frequency measurements of maxillary

implants. A 20-month clinical study. Int J Oral

Maxillofac Surg 28:297-303.

Giesen, E. B., Ding, M., Dalstra, M., van Eijden, T. M.

2003. Reduced mechanical load decreases the density.

stiffness. and strength of cancellous bone of the

mandibular condyle. Clin Biomech 18:358-363.

Giesen, E. B., Ding, M., Dalstra, M., van Eijden, T. M.

2004. Changed morphology and mechanical properties

of cancellous bone in the mandibular condyles of

edentate people. J Dent Res 83:255-259.

Ikumi, N., Tsutsumi, S. 2005. Assessment of correlation

between computerized tomography values of the bone

and cutting torque val-ues at implant placement: a

clinical study. Int J Oral Maxillofac Implants 20:253-

260.

Johansson, B., Back, T., Hirsch, J. M. 2004. Cutting

torque measurements in conjunction with implant

placement in grafted and nongrafted maxillas as an

objective evaluation of bone density: a possible

method for identifying early implant failures? Clin

Implant Dent Relat Res 6:9-15.

BIODEVICES 2011 - International Conference on Biomedical Electronics and Devices

144

Lagravere, M. O., Fang, Y., Carey, J., Toogood, R.W.,

Packota, G. V., Major, P. W. 2006. Density

conversion factor determined using a cone-beam

computed tomography unit NewTom QR-DVT 9000.

Dentomaxillofac Radiol 35:407-409.

Lekholm, U., Zarb, G. A. 1985. Patient selection and

preparation. In Branemark, P-I., Zarb, G.A. and

Albrektsson, T. (eds): Tissue Integrated Prostheses:

Osseointegration in Clinical Dentistry. Chicago,

Quintessence Publishing, 1985, pp 199-209.

Lindh, C., Nilsson, M., Klinge, B., Petersson, A. 1996.

Quantitative computed tomography of trabecular bone

in the mandible. Dentomaxillofac Radiol 25:146-150.

Meredith, N. 1998. A review of nondestructive test

methods and their application to measure the stability

and osseointegration of bone anchored endosseous

implants. Crit Rev Biomed Eng 26:275-291.

Nkenke, E., Hahn, M., Weinzierl, K., Radespiel-Troger,

M., Neukam, F. W., Engelke, K. 2003. Implant

stability and histomorphometry: a correlation study in

human cadavers using stepped cylinder implants. Clin

Oral Implants Res 14:601-609.

Norton, M. R., Gamble, C. 2001. Bone classification: an

objective scale of bone density using the computerized

tomography scan. Clin Oral Implants Res 12:79-84.

Ribeiro-Rotta, R.F., Lindh, C., Rohlin, M. 2007. Efficacy

of clinical methods to assess jawbone tissue prior to

and during endosseous dental implant placement: a

systematic literature review. Int J Oral Maxillofac

Implants 22:289-300.

Schulte, W., d'Hoedt, B., Lukas, D., Maunz, M., Steppeler,

M. 1992. Periotest for measuring periodontal

characteristics correlation with periodontal bone loss.

J Periodontal Res 27: 184-190.

Shapurian, T., Damoulis, P. D., Reiser, G. M., Griffin, T.

J., Rand, W.M. 2006. Quantitative evaluation of bone

density using the Hounsfield index. Int J Oral

Maxillofac Implants 21:290-297.

Trisi, P., Rao, W. 1999. Bone classification: clinical-

histomorphometric comparison. Clin Oral Implants

Res 10:1-7.

Winter, W (2008) Bone strength in pure bending: Bearing

of geometric and material properties..Proceedings of

the 2

nd

Conference on Applied Biomechanics Regens-

burg. J. Hammer, M. Nerlich, S. Denkdorfer (eds.),

IOS Press, Amsterdam, Netherland, 230-237.

Yang, G., Kabel, J., van Rietbergen, B., Odgaard, A.,

Huiskes, R., Cowin, S. C. 1999. The anisotropic

Hooke’s law of cancellous bone and wood. J Elast

53.125-146.

BONE QUALITY TESTING DURING DENTAL IMPLANT SURGERY - A Novel Device for Intraoperative

Compressive Testing of Alveolar Bone

145