CONTACTLESS TORQUE SENSOR

Mechatronic Principle and Prototype Development for Automotive Applications

Manfred Brandl

Austriamicrosystems AG, Schloss Premstätten, Austria

Franz Haas, Reinhard Marik

FH CAMPUS 02, Department of Automation Technology, Körblergasse 126, Graz, Austria

Keywords: Torque sensor, Inductive principle, Electric steering system, Finite element method.

Abstract: In this paper fundamentals and the prototype development of a new contactless torque sensor are presented.

The whole device can be divided into a mechanical and an electromagnetic system. The prototype is

designed for the torque range of an electric power assisted steering. The basic idea is the transformation of

the shaft twist under torque load into a translational movement of the middle part of the sensor sleeve that is

measured by an inductive measuring device. An additional aspect is the low cost manufacturing and

assembling of the whole system. The interface electronics ensures high linearity and accuracy and is

therefore very suitable for this application. This new sensor concept is very robust and self-compensating

for all kinds of relative positioning tolerances ranging from temperature change to external forces.

1 INTRODUCTION

The object of this publication is to present a new

contactless torque sensor concept based on a highly

reliable inductive sensing principle for automotive

applications to overcome the drawbacks of present

solutions.

Recent automotive fuel saving and power train

techniques are requiring highly reliable but low cost

torque sensors. One example application is electric

power assisted steering system (Graßmann, 2003) to

measure input torque. Others are open or closed loop

drive train applications such as torque vectoring,

power control or power assisted bicycles.

2 TORQUE SENSOR PRINCIPLE

Torque measurement on rotating shafts leads to a

specific design requirement. The torque information

has to be transmitted in a wireless non-contact

manner from the rotating shaft to the static readout

environment. The technical solution is to pick up the

torque information on the rotating shaft and transmit

it to a stationary receiver either through electric,

magnetic or electromagnetic field.

Today’s sensing techniques are:

Strain gauge or magneto-elastic sensor on

shaft surface to measure strain in 45-degree

direction versus shaft axis;

A compliant torsion bar with optical, resistive,

inductive or magnetic (Angleviel, 2005)

measurement of the relative angle between

both ends. This principle is used in modern

electromechanical steering systems (Heißing,

2008) and fulfils the requirements of safety

and reliability.

At present torque sensors are mostly used in

industrial drive train applications, in robotics and in

bench test measurement equipment.

For this new concept the system can be divided into

two domains:

Mechanical domain;

Electromagnetic domain.

2.1 Mechanical Domain

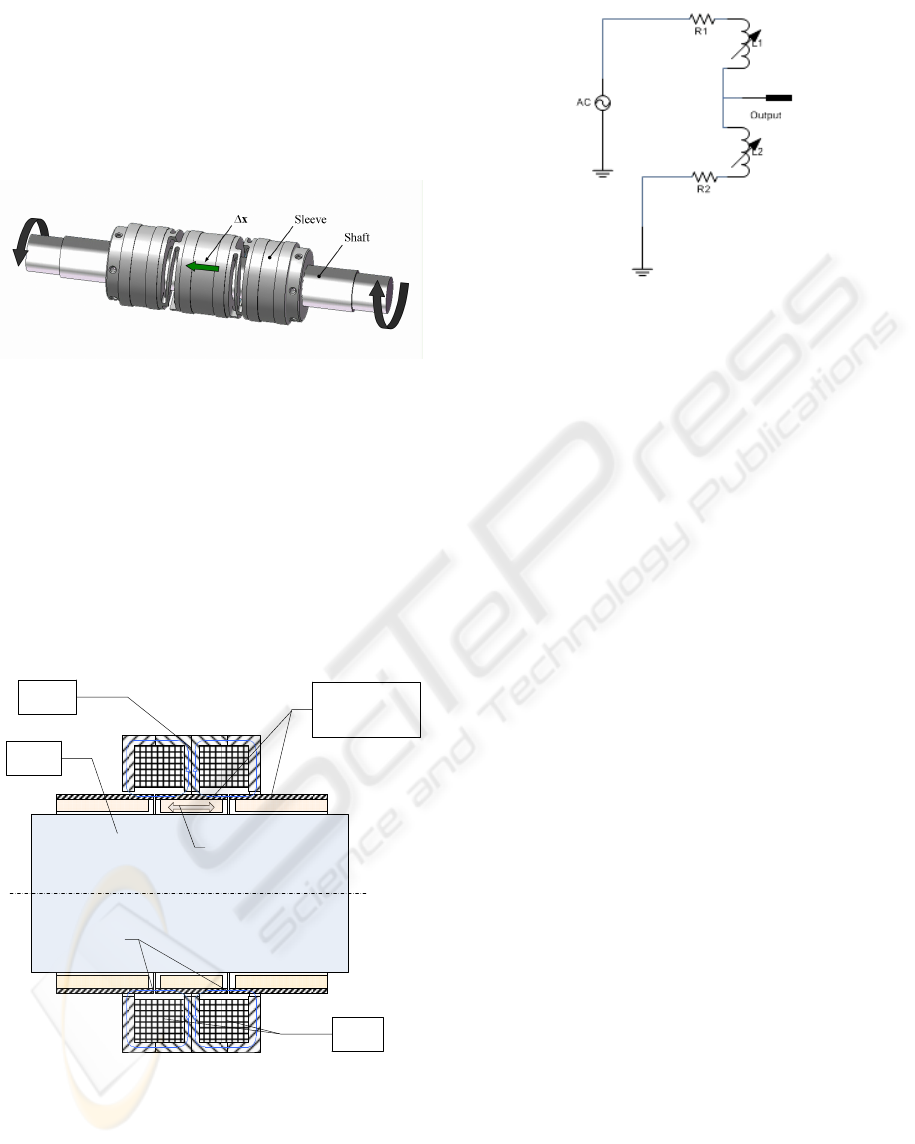

The twist of a steel shaft under load is transformed

to an axial displacement (Jacobsen, 1944). This

effect and the core part of the torque sensor are

shown in Figure 1. The applied torque causes a shaft

55

Brandl M., Haas F. and Marik R. (2009).

CONTACTLESS TORQUE SENSOR - Mechatronic Principle and Prototype Development for Automotive Applications.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 55-61

DOI: 10.5220/0002208300550061

Copyright

c

SciTePress

twist that is induced into a specially designed sleeve.

This part, for instance made of aluminium, is

perfectly attached to the shaft at two cylindrical

faces with a constant distance. The connections of

the middle part to the outside parts represent thin

rods that translate the twist into a translational

movement (Δx) along the shaft rotation axis.

Figure 1: Sleeve with the fixation parts, middle part and

connection rods.

Possible manufacturing processes are chipping

technologies (turning and milling), powder injection

moulding or welded composite from punched parts

depending on the production volume.

2.2 Electromagnetic Domain

Two fixed ferromagnetic sleeves, one displaceable

centre sleeve and the two axial air gaps as part of the

rotor are shown in Figure 2.

Stator

Rotor

ferromagnetic

sleeves

Coils

Air gaps

displacable center

part of spring sleeve

Figure 2: Electro magnetic circuit formed by sensor rotor

and sensor stator.

The rotor forms a differential inductive half

bridge circuit (see Figure 3) with two fixed coils and

its respective ferromagnetic field concentrators as a

stator.

Figure 3: Sensor inductances and its parasitic resistances

connected in series to form a half bridge.

The stationary coils and their ferromagnetic

housings are placed concentric to the shaft in the

middle of the rotor with the two air gaps. When

torque is applied, one air gap increases and the other

one gets smaller by the same amount. The two coils

are connected in series and excited by a common

electrical signal. The reluctance ratio determines the

output voltage of the inductive half bridge. The

magnetic circuit is designed in such a way that a

significant portion of the total reluctance is

determined by the axial air gaps between the rotor

sleeves. Any differential change of air gap due to

applied torque leads to a non-balanced bridge and an

output signal linear with displacement in case of

small deflections.

Because of the symmetric arrangement of the

magnetic ring elements all air gap changes due to

shaft bending, shaft expansion or shaft compression

won’t lead to an output signal. Nor will concentricity

errors of the rotor influence the output signal. Even

axial simultaneous displacement of the entire rotor

like a bearing play will not lead to reluctance

difference in the first instance. Most important is

that also shaft rotation doesn’t affect the balance of

the electromagnetic circuit, either.

An important point is the matching of both air

gaps at zero torque. Any offset would lead to

unbalanced bridge and therefore to a temperature

drift of the sensor zero point. Also, non equal air gap

size over the circumference would lead to 2

nd

order

effects causing small output changes with angular

rotor position. Therefore it is proposed that the

ferromagnetic sleeves are separated exactly after

bonding by laser cutting.

As a conclusion it is obvious that this sensor

concept is very robust and self-compensating for all

kinds of relative positioning tolerances ranging from

temperature change, bearing play and forces applied

to the stator or rotor shaft.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

56

3 SENSOR OPTIMIZATION

This chapter describes the basic kinematical

principle and the FEM-optimization of the torque

sensor geometry (Marik, 2008). Optimization

criteria are the translational movement Δx, but also

the costs for manufacturing and assembling.

3.1 Kinematical Principle

Basically the sensibility of the torque sensor depends

on the translation ∆x which is directly linked to the

current torsion angle. The formal correlation of the

torsion angle (φ), the torque (Mx), the length of the

casing (l), the modulus of rigidity (G) and the polar

area moment (Ip) is shown in equation (1).

(1)

In most cases the shaft diameter, the external

torque, the material of the shaft and the possible

casing length are given values and cannot be

changed. Concerning the example of an 18mm

diameter steering shaft, a torsion angle φ from 0.05

to 0.06 degrees leads to a twist movement on the

shaft surface of 0.02mm. According to that point the

only way to achieve a maximum ∆x is to optimize

the design of the mechanical sleeve.

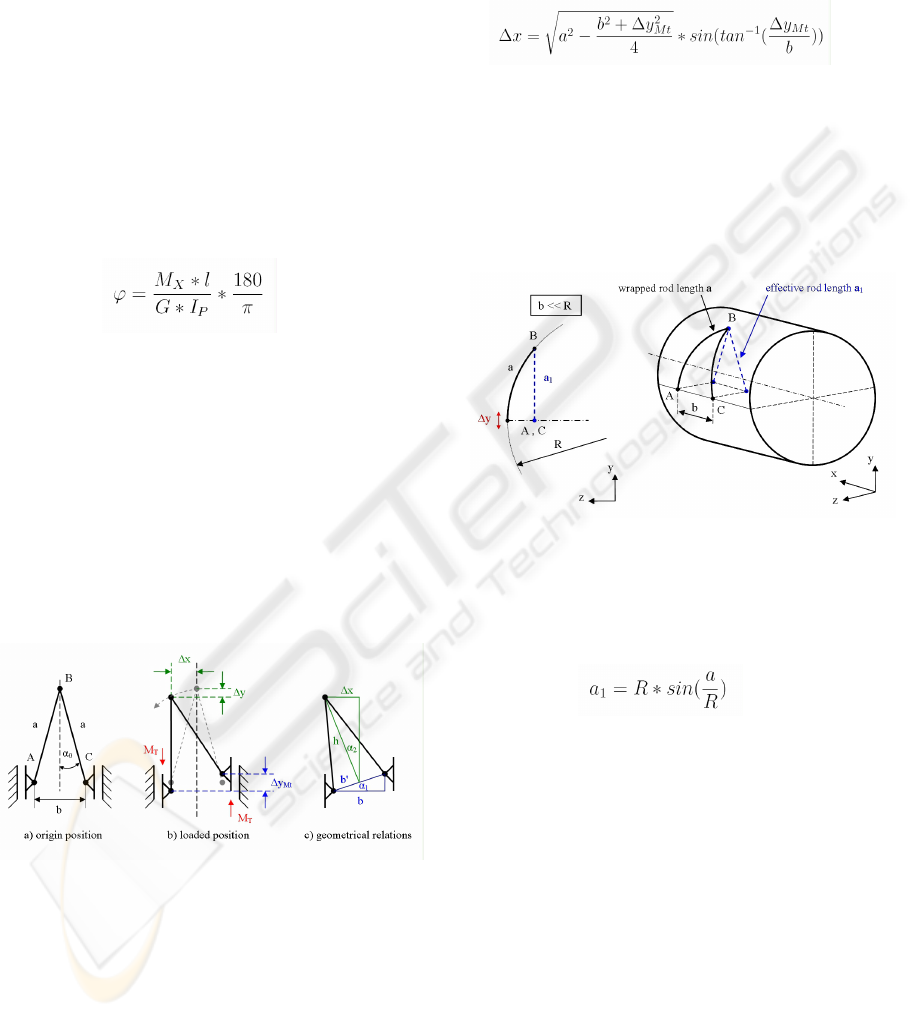

The simplified function model of the sleeve is a

two rod system with three revolute joints. Figure 4

shows the situation on a flat surface to demonstrate

the geometrical relationships more easily.

Figure 4: Simplified function model of the sleeve on a flat

surface.

Two rods with the length (a) are connected to

each other at joint (B) and to the surrounding at

joints (A) and (C) (see Figure 4a). The connection

points A and B are only moveable in the y-direction

but fixed in the x-direction. When the system gets

loaded due to a torque the points A and C move

contrarily along the y-direction (∆y

Mt) and hence the

joint B moves from its origin position along a

circular path with the radius (a) (see Figure 4b).

The geometrical relations in x-direction are

shown in Figure 4c and can be described in equation

(2).

(2)

From equation (2) it is obvious that the achieved

Δx is linear depending on the length (a) and

nonlinear to the geometric relation of Δy

M and the

width (b), the tilt angle of the system. But when the

two rod system gets wrapped around a cylinder

surface the interacting rod length will be scaled

down by the influence of the cylinder radius R as

shown in Figure 5.

Figure 5: Function model on a cylindrical surface.

Consequently to that effect the linear impact of

length (a) gets nonlinear according equation (3)

under the precondition that the distance (b) is very

short in relation to the radius (R) (b << R).

(3)

It is obvious that (a

1) has its maximum value

when (a) is the quarter of the cylinder

circumference, which is an important fact for the

geometry of the rotor rod elements.

3.2 FEM-Studies

Based on the kinematical principle the final CAD-

design has to be defined. The optimized shape of the

measuring sleeve (see Figure 1) is characterized by a

maximum Δx and a light structure with high

stiffness. Simulation helps to accelerate the

development process and to increase the quality of

the first prototype (Seiffert, 2008). The stresses in

critical regions near the revolute joint positions must

be under the fatigue limit of the chosen aluminium

alloy. The prototype sleeve is to be made as a

turning-milling part. Therefore the minimum cutting

CONTACTLESS TORQUE SENSOR - Mechatronic Principle and Prototype Development for Automotive Applications

57

tool diameter and the attainable lowness of the inner

undercuts also have to be considered.

Figure 6 shows the displacement (dx) in the

direction of the shaft axis. It is the result of a static

FEM analysis with the external torque at one side

and the fixation at the other side as model

constraints.

Figure 6: FEM result of displacement dx.

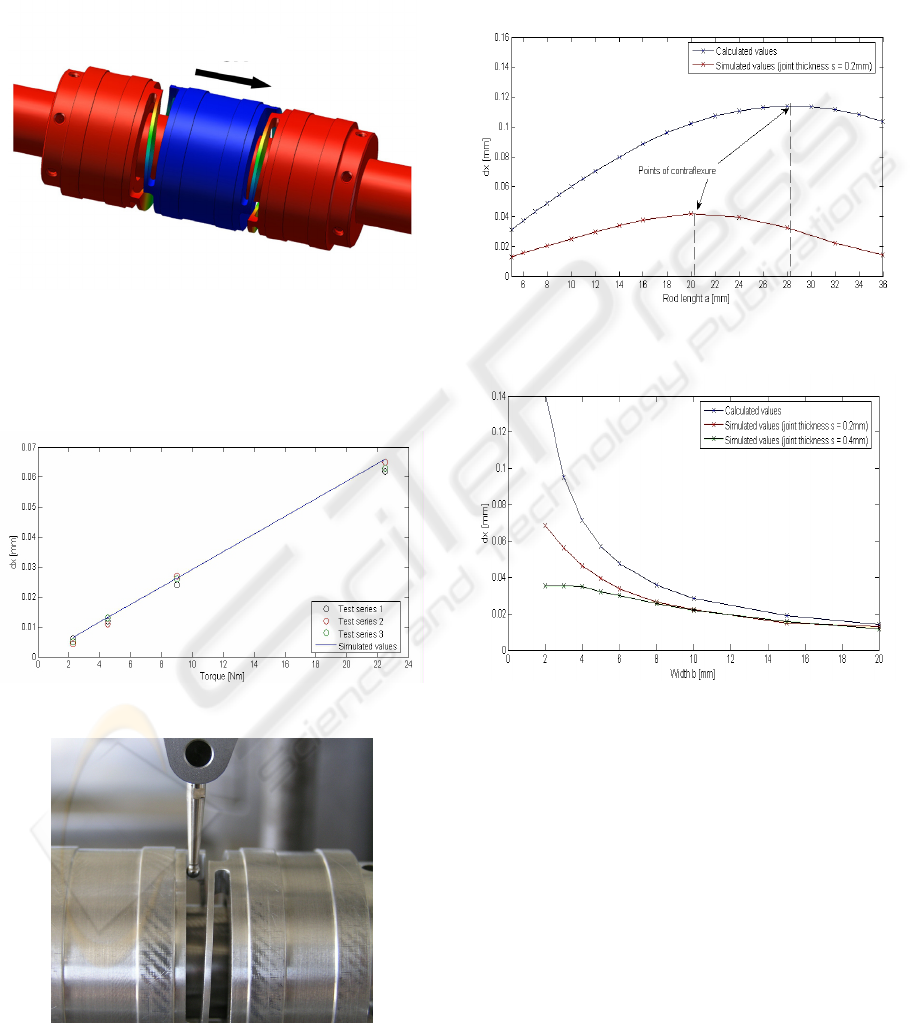

A satisfying compliance between measurement

results and simulation has been found (see Figure 7).

The measurement setup is illustrated in Figure 8.

Figure 7: Comparison between measuring and simulation.

Figure 8: Measurement setup.

In addition theoretical considerations can be

proved by reducing the dimensions of the joint

connections. Figure 9 shows the differences between

the results of the basic kinematic model and the

FEM simulations by varying rod lengths (a). Figure

10 gives an overview about changes of (dx) with

different values (b).

Figure 9: Displacement values with various rod lengths.

Figure 10: Displacement values with various values b.

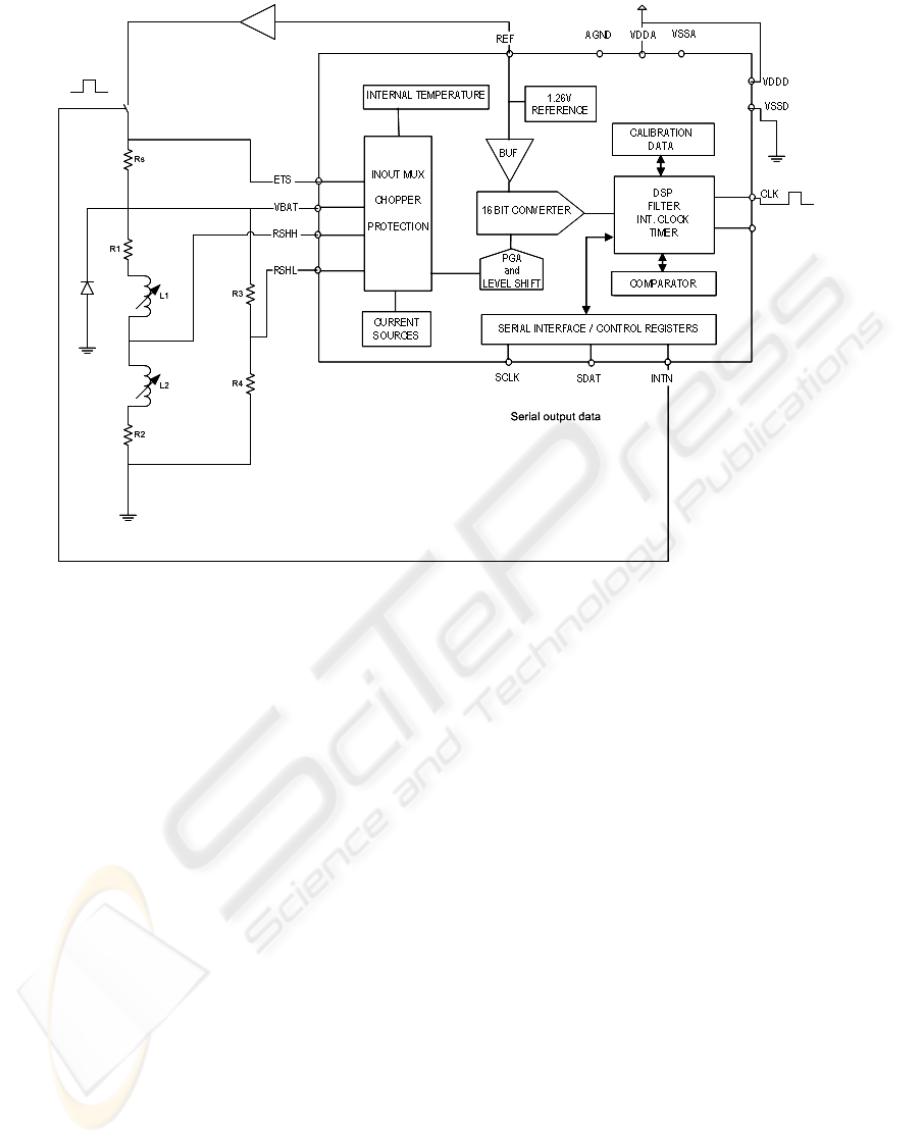

4 INTERFACE ELECTRONICS

The inductive half bridge is supplemented by a

resistive voltage divider to form a Maxwell bridge.

Its output signal is amplified and converted to digital

output with high precision by an integrated data

acquisition circuit. The block diagram in Figure 11

shows the setup of the interface electronics.

Today’s semiconductor circuit design techniques

enable us to conquer new domains in precision and

ultra low drift signal conditioning unreachable just a

few years ago.

For this torque sensor an integrated data

dx

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

58

Figure 11: Block diagram of sensor interface electronics.

acquisition device was used which was specifically

designed to convert very small voltages to digital

domain with very high precision.

This data acquisition device offers two

multiplexed fully differential input channels, a

programmable gain amplifier, a 16 bit analog to

digital converter and a serial interface for device

configuration and result read-out.

Special auto zero offset architecture offers

virtually zero offset below 0.5µV and very low

noise. The analog to digital converter is of Sigma-

Delta type, an architecture which offers high

linearity without any missing codes.

The device has an integrated trim-able precision

reference and a temperature compensation for the

entire measurement path. The integrated circuit also

offers a measurement-ready signal which is used to

excite the transducer bridge with a pulsed DC

voltage in conjunction with a diode which is to

discharge the energy stored in the coils after each

applied pulse.

The second channel can be used to measure the

bridge current to compensate the temperature

coefficient of the copper coil which would otherwise

lead to a scaling error. If the digital representation of

the bridge voltage is multiplied by compensation

factor proportional to the bridge current in an

external micro controller, the final output signal can

be made independent from temperature. In that case

the coil wires are acting as a temperature sensor.

The development of the electronic system was

carried out at the Department of Automation

Technology at FH CAMPUS 02 in collaboration

with austriamicrosystems Corporation applying the

newest chip generation (Pauritsch, 2008).

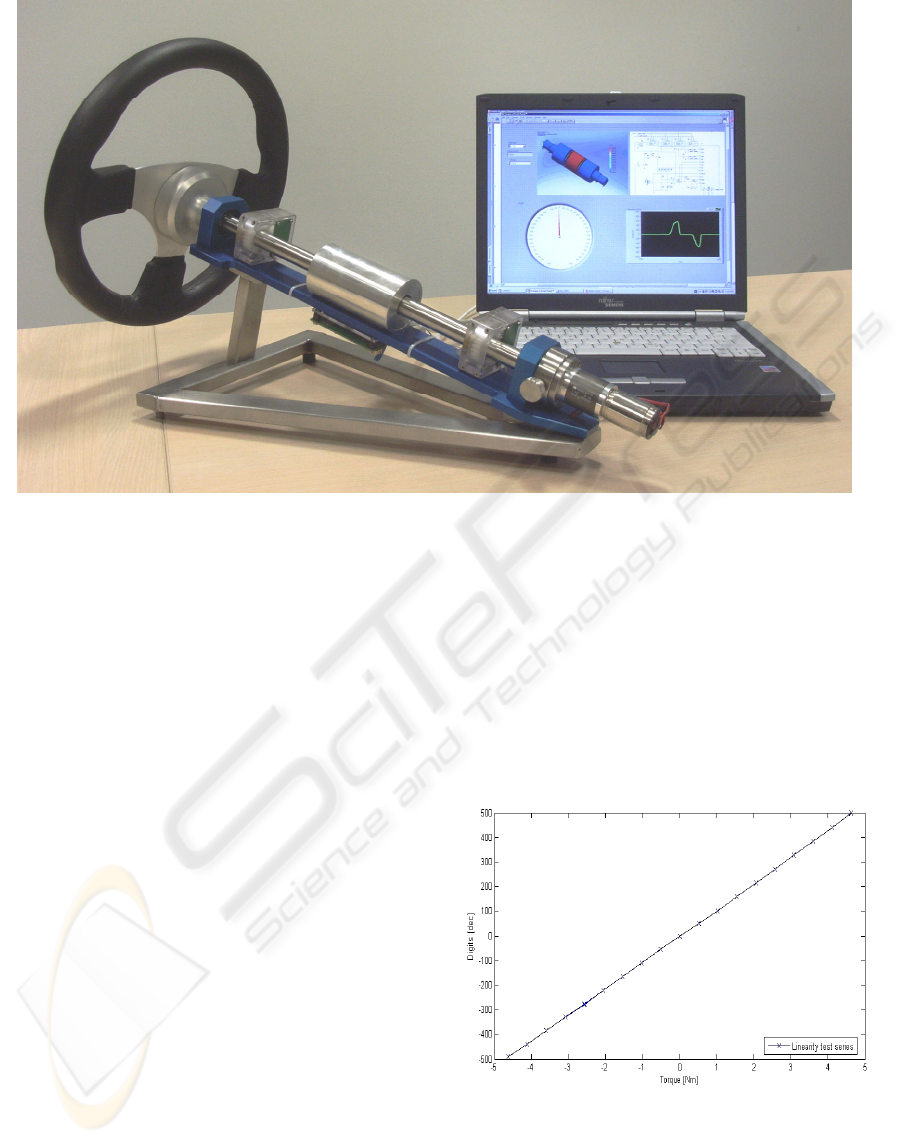

5 TEST SYSTEM

Based on the presented solution a test system has

been developed that demonstrates a steering (see

Figure 12). For that purpose the demonstrator

consists of a steering shaft with torque sensor and

rotary encoders, two bearings and a steering wheel.

5.1 Torque Sensor

The torque sensor is placed in the middle of the

bearing houses. The sensor sleeve is pinned on the

18 mm diameter shaft to induce the shaft twist into

the sleeve. The stator part consists of a casing with

two coils and four ferromagnetic concentrators

forming two inductances in the range of 10mH with

CONTACTLESS TORQUE SENSOR - Mechatronic Principle and Prototype Development for Automotive Applications

59

Figure 12: Steering demo system with one torque sensor, two rotary encoders and Graphical- User-Interface (GUI) for

torque measurement.

400 windings of 0,15mm copper wire. The entire

coil arrangement is fixed by two screwed covers.

The stator has to be aligned to the axis of the

shaft carefully.

The coil wires are led through small holes and

connected with the sensor interface. The PCB is

mounted on the base plate of the demonstrator. The

steering torque can be simulated by a DC-motor or

by a special brake with a fixation screw.

5.2 Rotary Encoder

In addition to the torque measurement the steering

angle is also measured at two positions by using

Hall-sensors.

The rotary encoder (Czichos, 2008) consists of a

small magnet disc with north/south pole, which

rotates at a very short distance to the Hall-sensor-

chip. This disc is directly mounted on a small

gearwheel. The according gear consists of the pinion

gear with the magnet and a gearwheel that is fixed

on the steering shaft. The casing of the rotary

encoder is separated into two parts for easy

assembling and also includes the sensor PCB.

5.3 User Interface

The user interface software is programmed with

“Labview” and enables various types of graphical

representation of the measurement results.

5.4 Linearity Measurement

The characteristic of the new sensor is the result of

measurements within a specified torque range of

±5Nm. Figure 13 shows the sensor output signal

which is virtually linear with torque without any

hysteresis.

Figure 13: Torque sensor characteristic without any

hysteresis.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

60

6 CONCLUSIONS

A contactless torque sensor for accurate and reliable

low frequency torque measurement on a rigid

steering shaft has been introduced. The principle is

in our opinion well suited to develop a low cost

sensor product with adequate values of repeatability,

accuracy and reliability. The cost and quality targets

can be achieved, if manufacturing techniques like

laser cutting and laser welding will be utilized.

The entire mechatronic solution is based on well

known design elements which do not lead to long

term drifts of zero point and output scale. There is

virtually no hysteresis in output signal as proven by

the demonstrator design.

It has to be pointed out that the design of a final

sensor product has to consider sufficient spring

stiffness in axial direction as well as low mass for

the displaceable centre sleeve spring/mass system to

ensure insignificant displacement when the sensor is

exposed to low frequency or constant acceleration. It

has to be ensured that its first mode resonance

frequency is higher than the frequency band of

interest.

Our contribution represents a preparatory study

for any subsequent mechatronic product

development.

Due to the number of involved technical

disciplines like mechanical-, electromagnetic-,

electronic-, manufacturing- and safety engineering it

is recommended to continue the research work as an

academic project in conjunction with other

universities and industrial partners.

We are confident that as a result of such R&D-

activities a new type of mechatronic torque sensor

device with unmatched performance versus cost

ratio can be placed on the market for many

applications.

REFERENCES

Angleviel, D., Frachon, D., and Masson, G., 2006.

Development of a Contactless Hall effect torque

sensor for Electric Power Steering. MMT S.A.

Czichos, H., 2008. Mechatronik. P 217. Vieweg+Teubner

Verlag. Wiesbaden.

Graßmann, O., Henrichfreise, H., Niessen H., and

Hammel K., 2003. Variable Lenkunterstützung für

eine elektromechanische Servolenkung. 23. Tagung

“Elektronik im Kfz”. Stuttgart.

Heißing, D., Ersoy M., 2008. Fahrwerkhandbuch. pp 209-

215. Vieweg+Teubner Verlag. Wiesbaden.

Jacobsen, A.M., 1944. Electrical Dynamometer. US Patent

Application Serial No. 561,467. Los Angeles.

Marik, R., 2008. Konturoptimierung einer Messnabe.

Bachelor Thesis. FH CAMPUS 02. Graz.

Pauritsch, M., 2008. Product documentation of the sensor

interface. Graz..

Seiffert, U., Rainer G., 2008. Virtuelle Produktentstehung

für Fahrzeug und Antrieb im Kfz. pp 7-29.

Vieweg+Teubner Verlag. Wiesbaden.

CONTACTLESS TORQUE SENSOR - Mechatronic Principle and Prototype Development for Automotive Applications

61