DETECTION OF A FAULT BY SPC AND IDENTIFICATION

A Method for Detecting Faults of a Process Controlled by SPC

Massimo Donnoli

DSEA – Dept. Electrical Systems and Automation, University of Pisa, Italy

Keywords: Statistical process control, Multivariate Hotelling statistic, System identification.

Abstract: A method for detecting the nature of a fault of a process controlled by SPC ( Statistical Process Control) is

presented. The method use the integration of SPC , traditional APC (Automatic Process Control) and the

System Identification technique . By a statistical on line control of the parameters of a transfer function and

the identification of the transfer function itself, the case of a fault due to a change in the system is

recognised. An algorithm called ‘batch control’ for the implementation of the method in a real plant is

proposed.

1 INTRODUCTION

The objective of Statistical Process Control (SPC) is

to detect situation of change of the natural behaviour

of a process by monitoring on line the key product

variables and detecting the cause of the fault,

indicating which variable or group of variables

contributes to the signal.

A lot of technique has been developed especially

due to the large and different areas where the SPC

could be applied.

If, traditionally, the SPC has been developed

especially to monitor the complicated processes of

chemical plants, after that, the big growth of the

information technology in the industries and the

large amount of process measures collected in the

data base of the control systems, has allowed the

implementation of SPC on almost every kind of

plant. By the way the common goal for the most

application is still to monitor the quality of the

process, treating the manufacturing process itself as

a black box, of which we know the inputs and

outputs, ignoring the others information of the

nature of the process.

In fact traditionally SPC and APC (Automatic

Process Control) have been developed in parallel

and only in the last years there has been works

where researchers have made the integration of the

two areas ( Tsung,1999).

Another point to remark is that the traditional

SPC approach, that is still the most diffused in many

kind of industries, is essentially the univariable SPC:

by the implementation of control charts like

Shewhart, Cusum, etc.. we look the magnitude of the

deviation of each variable independently of all

others as they are perfectly independent in the

process.

But the being ‘in control’ of a process is

essentially a multivariable property : in the modern

industrial processes the variables are non

independent of one another and only if the

simultaneous state of them all is in the joint

confidence region defined for the system, we could

say that the system is in control : by examining one

variable at time with the traditional charts it could

be that every variable is in the correct range but the

common state is not (Kourti & MacGregor,1994).

For this have been developed multivariable

methods that can treat all the variables

simultaneously.

The principal is the Hotelling or

2

T

statistic : it

transforms the state of all the variables in the

calculation of the value of a single variable which

can be monitor for detecting faults.

If this is a great effort to solve the problem in a

very useful way, on the other hand we have now the

problem to detect the cause of the fault, the variable

responsible.

This paper is organized as follows: in the next

section the basic concepts of SPC multivariable, the

Hotelling statistic and the interpretation of a

2

T

value are recalled. In sections 3 and 4 the main

advantages of SPC - APC integration and SPC -

System Identification integration are presented.

371

Donnoli M. (2009).

DETECTION OF A FAULT BY SPC AND IDENTIFICATION - A Method for Detecting Faults of a Process Controlled by SPC.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 371-375

DOI: 10.5220/0002203603710375

Copyright

c

SciTePress

In section 5 a method for statistically monitoring

the points of a system transfer function is presented.

In section 6 are given the simulation results for a

typical industrial APC. In section 7 an algorithm

called ‘batch control’ for the implementation of the

technique in some kind of industrial processes is

presented . Finally some conclusions are given.

2 SPC MULTIVARIABLE

Suppose that our process has 2 measures represented

by 2 random variables x1,x2 uncorrelated, with

mean value

2,1

μ

μ

and variances

2,1

σ

σ

respectively. Consider the distance of an observation

point from the mean point in the plane (x1,x2).

Instead of the usual Euclidean distance we consider

the relationship :

2

2

2

2

2

)(

2

)22(

1

)11(

SD

XX

=

−

+

−

σ

μ

σ

μ

(1)

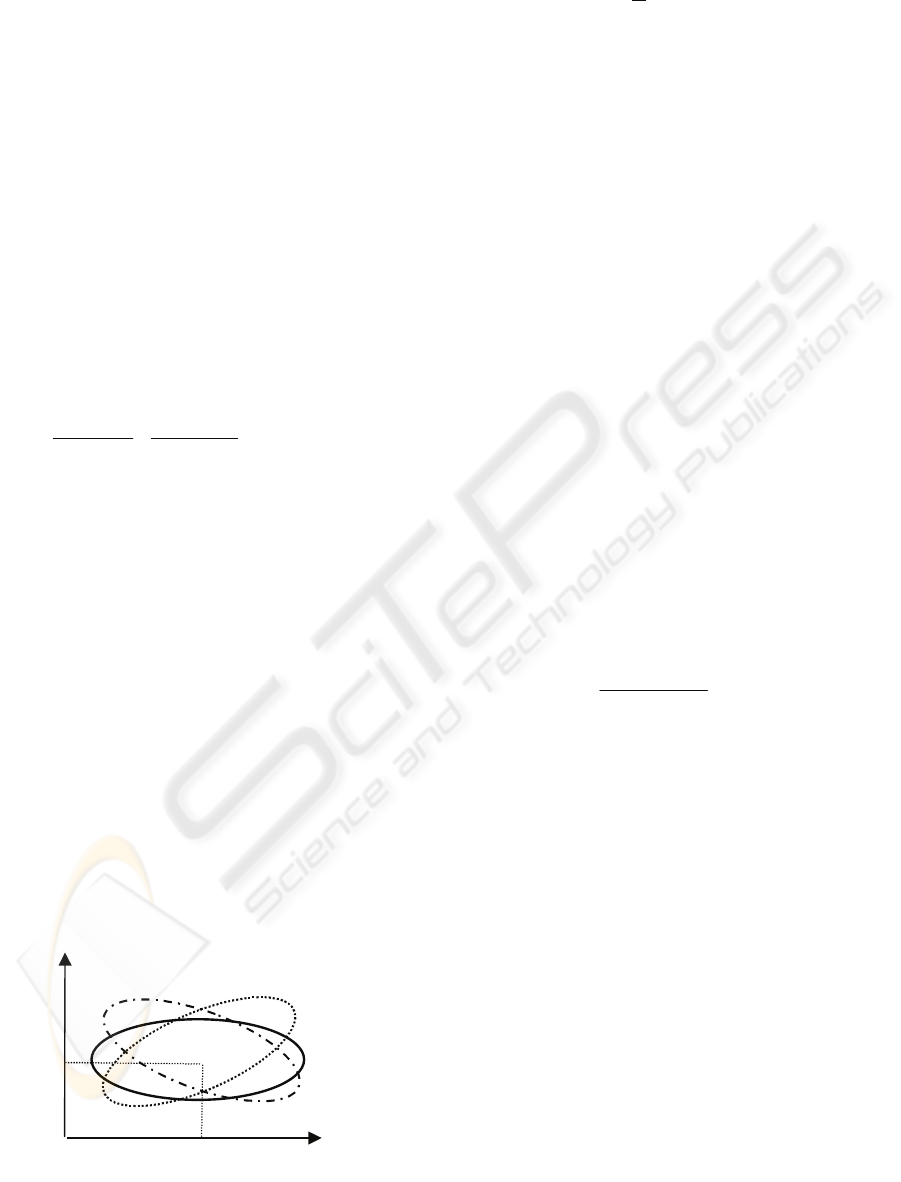

This is called ‘statistical distance’ (SD) . For an

observation the contribution of each coordinate to

determining the distance is weighted inversely by its

standard deviation, that means that a change in a

variable with a small standard deviation will

contribute more to the statistical distance than a

change in a variable with a large standard deviation.

It follows that the statistical distance is a measure of

the respect of the statistical behaviour of the two

variables.

If they are correlated it will be an additional term

in x1 x2 and in the plane the curve with constant SD

will be an ellipse, eventually tilted according to the

correlation sign.

In general if we have a process of p variables

and we have n observation vector of the p variables

with the system ‘in control’ (or what is called the

Historical Data Set (HDS) of the system) we can

calculate an estimation of the main vector and of the

covariance matrix of the random variables :

X1

X2

1

μ

2

μ

0

12

=

σ

0

12

>

σ

0

12

<

σ

Figure 1: Curves with constant SD for two variables.

∑

=

=

n

i

i

X

n

1

1

μ

(2)

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

=∑

pppp

p

p

σσσ

σσσ

σσσ

"

#"##

"

"

21

22221

11211

(3)

For a generic observation we can then compute

the quantity :

)()(

12

μμ

−∑−=

−

i

T

i

XXT

(4)

This is an univariate quantity that is called

Hotelling Statistic or

2

T

. It is clear that this is the

multivariable generalization of the statistic distance,

in words a measure of the closeness (in a statistical

way) of the observation to the behaviour of the

system expressed by the HDS .

The curves with constant

2

T

are then hyper-

ellipsoids in the p dimensional space.

Considering

2

T

like a random variable we can

see that , in the case of

μ

and

∑

estimate by the

observations, it follows the distribution of an F

random variable of p, n-p degrees of freedom.

Let

α

be the first type error and let

),,( pnp

F

−

α

be the value f of F | P(F<=f) = 1-

α

( P : probability

of) we can then calculate an Upper Control Limit

(UCL) for

2

T

:

),,(

)(

)1)(1(

pnp

F

pnn

nnp

UCL

−

−

−

+

=

α

(5)

We can say that if we are under the UCL we

have a probability 1-

α

to say that the system is in

control when really it is .We can see that choosing

an

α

smaller led to have a second type error

β

bigger, that is a greater probability to not detect a

fault when it really exists.

In the industrial processes both errors are

important:

α

is the representation of the false alarms

that can led to stop the production in vain, while

β

,

if large, can led to not detect situations of real out of

control.

Generally

β

is set low because is preferable to

have some false alarm than to not detect a fault .

In our examples we have chosen

α

= 0.1.

2.1 Interpretation of

2

T

Signals

The

2

T

converts a multivariable problem to the

calculation of an univariate quantity. But signal

interpretation requires a procedure for isolating the

responsible of the fault because the contribution

could be attributed to individual variables being

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

372

outside their allowable range of operation or to a

fouled relationship between two or more variables.

Several solutions have been presented for the

problem of interpreting a multivariate signal.

One that we show here for example is the MYT

decomposition (Mason –Young 2002), that uses an

orthogonal transformation to express the

2

T

values

as two orthogonal equally weighted terms :

2

1,2

2

1

2

TTT +=

(6)

2

1

2

11

2

1

/)(

σ

xxT −=

(7)

2

1,2

2

1,22

2

1,2

/)(

σ

xxT −=

(8)

where x2,1 is the estimate of the conditional main of

x2 for a given value of x1 and

1,2

σ

is the

corresponding estimate of the conditional variance

of x2 for a given value of x1. A large value of the

first term (called ‘unconditional term’) implies that

the observed value of the variable is outside his

operational range as was on HDS, while a large

values of the second term (‘conditional term’)

implies that the observed value of one variable is not

where it should be relative to the observed value of

the others variables.

By subsequently eliminations of the

unconditional terms that signal and iterative

decomposition of the conditional terms that signal, it

is possible to isolate the variable or group of

variables responsible of the fault. We can say that

all this methods have in common iterative

procedures and sometimes great computational

efforts to reach the scope.

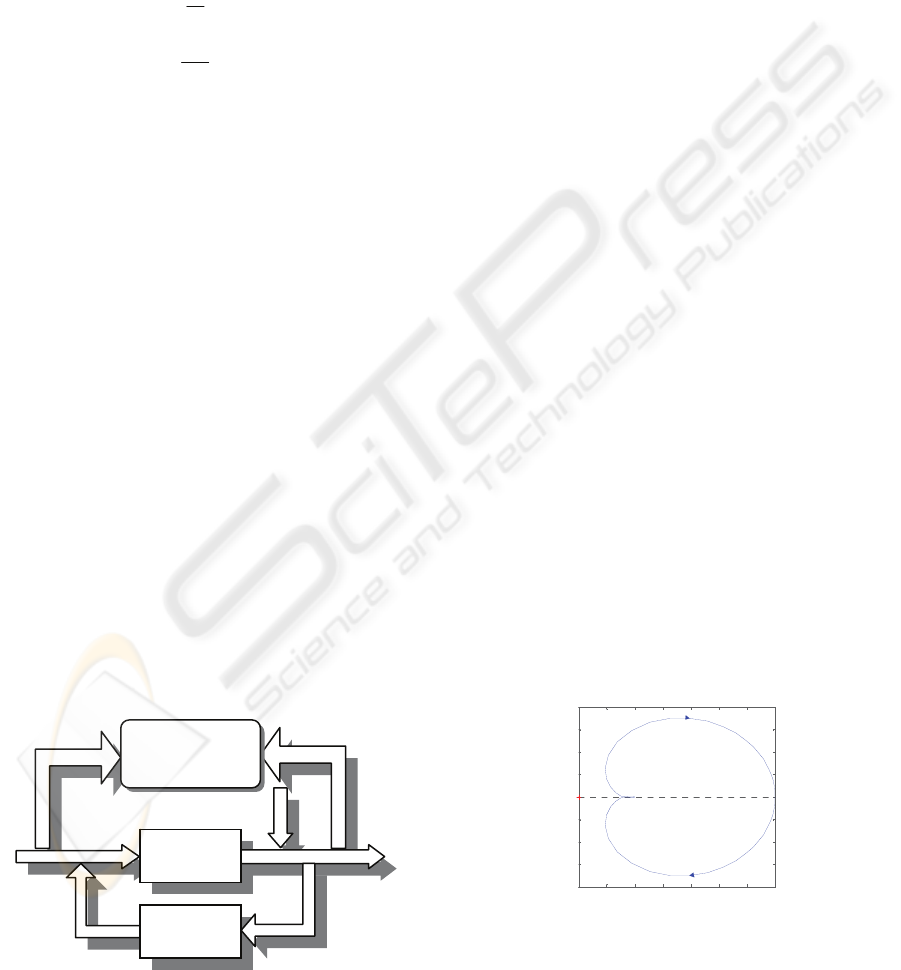

3 SPC APC INTEGRATION

Combining SPC with APC could be an improvement

of the global control of the system.

The scheme is the following :

Figure 2: SPC - APC integration.

There is an interaction between SPC and APC :

SPC controls not only the variables in and out of the

process but also the signals of the control: the result

is that the process is no more treated like a black box

but the information in the APC are used.

Our procedure uses the information of the

transfer function of the system: the change of the

system is statistically monitored controlling the

parameters of the transfer function

4 SPC – SYSTEM

IDENTIFICATION

An industrial system is typically formed by

automation systems that process the product .

We can divide the entire set of variables of the

manufacturing process into ‘process variables’,

meaning that they are measures made above the

product, (temperature, time of operations etc) and

‘control variables’ (like input - output of the motors,

signals of the electronic devices , etc.. ) that reflect

the behaviour of the automation systems.

We propose the identification of the transfer

functions of the control systems and the statistical

monitoring of the transfer functions to detect

deviation of the automation system from their

normal behaviour .

The identification at the same time allow a better

design of the control and a more easily detection of

the fault due to the automation systems and not to

the process .

5 STATISTICAL CONTROL OF A

TRANSFER FUNCTION

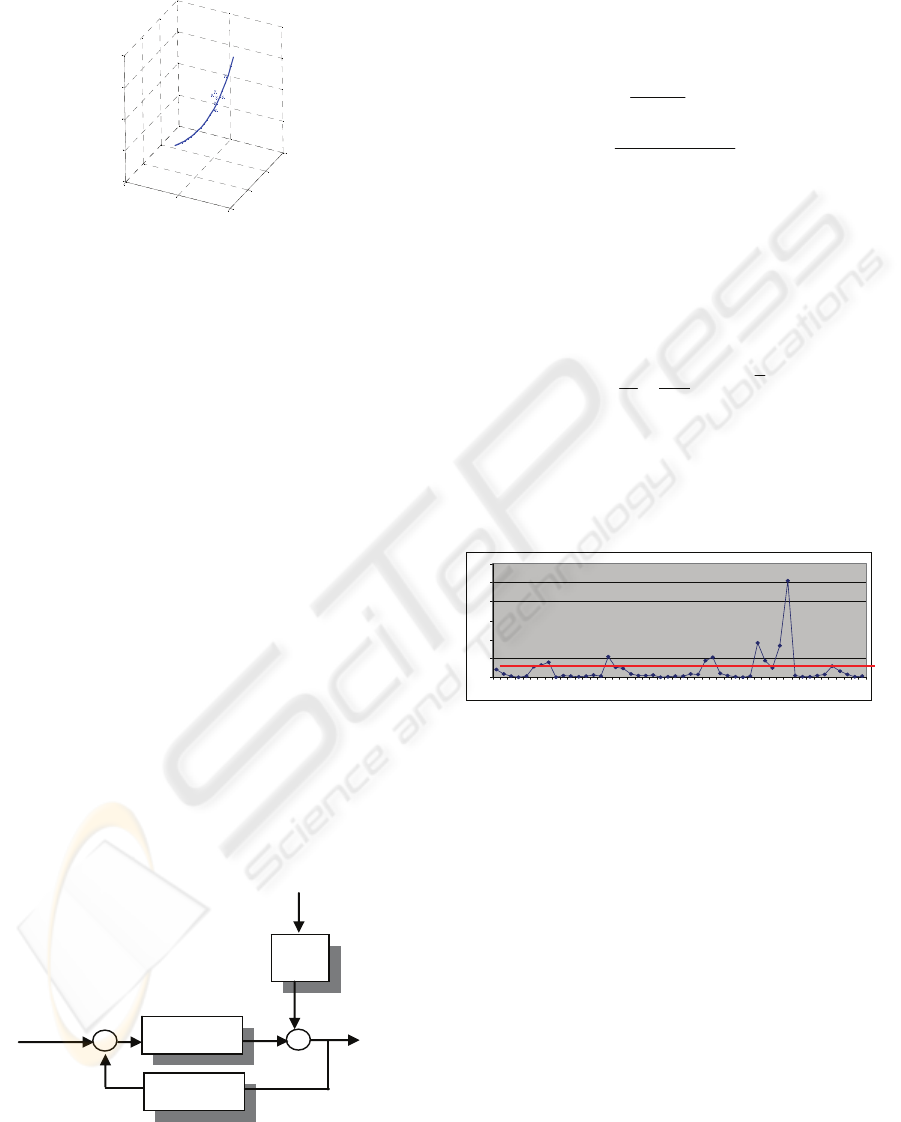

Consider the simple transfer function of a system G:

-1 -0.5 0 0.5 1 1.5 2 2.5

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

Nyquist Diagr am

Real Ax i s

Imaginary Axis

Figure 3: Nyquist plot of a transfer function G.

We can consider the transfer function as a

function of 3 parameters : amplitude, phase and

Process

Control

SPC

DETECTION OF A FAULT BY SPC AND IDENTIFICATION - A Method for Detecting Faults of a Process Controlled

by SPC

373

frequency. So we can plot the function in the 3d

space of that measures :

-1

0

1

2

-200

-150

-100

10

15

20

25

30

Mod

Fase

Freq

Figure 4: Observations of G points in the space

amplitude-phase-frequency.

If we can do measurements of that parameters our

observations will be point around the real curve of

the transfer function as shown above.

If we plot the curve at constant statistical

distance they will be ellipsoid in the 3d space with

their major axis tangent at the curve of the G in the

point we are sampling it. That tangent is the best

linear approximation of the population, because the

variables follow the relationship of the G.

So we have that schema for the identification

and statistic control of the G:

Make an HDS by collecting observations of the

points of the transfer function while the system is in

his normal behaviour.

Estimate from the HDS the covariance matrix

and the average value of the observations (2) (3).

Set an UCL for the Hotelling statistic chosen a

desired

α

(5).

Monitoring the T2 control chart build with (4).

6 SIMULATION RESULTS

We present the simulation result of a typical

industrial APC :

G(z)

C(z)

D(z)

u(t)

y(t)

d

a(t)

x(t)

Figure 5: Model for simulations.

formed by a system controlled by a PID controller

and disturbed with a coloured noise in the output,

according to the typical modelling of an industrial

noise.

))1()(()()()(

0

−−−−−−=

∑

∞

=

tytykjtyktyktx

D

j

IP

tt

a

Z

Z

D

1

1

1

1

−

−

−

−

=

φ

θ

32.02,1

9.0

)(

2

+−

=

zz

z

zG

),0(

at

Na

σ

∈

(9)

For the on line measurement of the point of the G

we have used the technique of the Descriptive

Function by inserting a relay with hysteresis h and

amplitude A in the control loop.

Leading the system in a controlled oscillation we

can see that the relationship

)(

4

1

)(

c

Y

h

arcsenj

c

c

e

A

Y

F

G

+−

=−=

π

π

ω

(10)

allow to measure a point of the G at the oscillating

frequency in amplitude and phase. By varying the

hysteresis it is possible to evaluate several points.

We show the result of 50 observations after a

change of 10% of the first pole of the system

0

20

40

60

80

100

120

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49

Figure 6:

2

T

chart of 50 observation after a change of

10% of the first pole of the system.

The

2

T

signals the change in the system with an

ARL ( Average Run Length ) of 8.

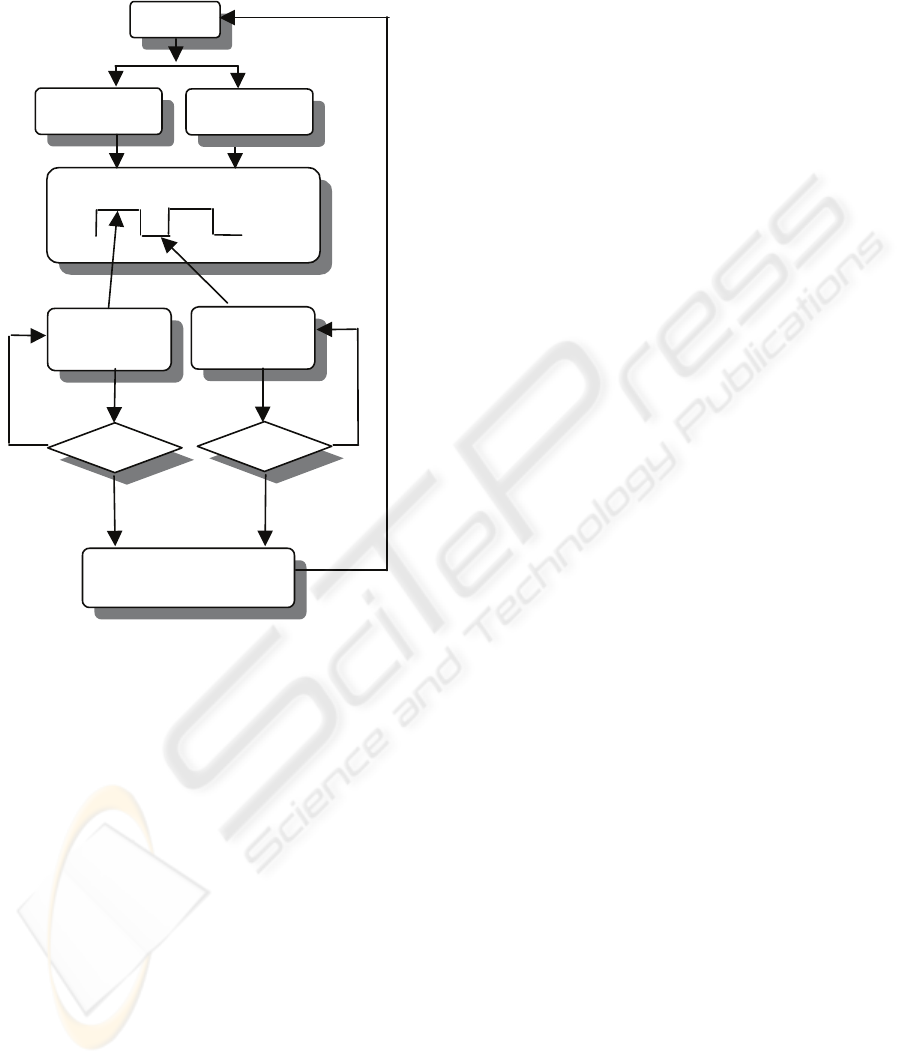

7 PROPOSED BATCH CONTROL

ALGORITHM

We have experienced several industrial process for

which the production is in two phase : a phase of

production , by the working of a material in input ,

and a phase of wait for the other material to come. In

this case we propose to apply the SPC for the

‘process variables’ during the phase of the effective

production ( say ‘batch on’ ) and to take advantage

of the waiting phase ( say ‘batch off’) for the

identification of the automation system and applying

then the SPC to the ‘control variables’. That schema

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

374

overcome the problem of detecting if the nature of a

fault is in the process or in the automation systems,

giving a separation of the two analysis at the origin.

APC

SPC Process

Monitoring

D

etec

t

Diagnostic & Improvement

HDS Process

On Line Monitoring

HDS Control

SPC Control

Monitorin

g

D

etec

t

Y

Y

N

N

Batch on

Batch off

Figure 7: Algorithm of implementation.

When a signal of the control charts is detected

we can say if it is due to the process or to a change

of the transfer function of one of the automation

systems in the manufacturing process. The phase of

diagnostic and improvement is able then to correct

the process variable signalling ( for ex. adjusting a

temperature) or operate directly on the APC that is

controlling the automation system changed to

compensate for the change, taking advantage of the

identification made of the transfer function.

8 CONCLUSIONS

In this paper a method for monitoring on line the

behaviour of an automation system is presented. The

method has the advantage of using the identification

of the transfer function of the system , so it can be

used on the APC to compensate the changes, and

with the advantage for the SPC to provide a direct

separation of the possible causes of fault.

Results of simulations are given and finally an

implementation schema of the method in a real

process is proposed . For further researches we are

applying the algorithm proposed in a rolling-mill

plant for the production of railways, that has a

production cycle on-off like the one described in the

paper.

REFERENCES

Mason, R.L., Young, J.C., 2002. Multivariate Statistical

Process Control with Industrial Application. ASA-

SIAM.

Tsung, F., Apley, D.W., 2002. The dynamic T2 chart for

monitoring feedback-controlled processes. IIE

Transactions (2002) 34,1043-1053 IIE.

Kourti, T., MacGregor, J.F., 1994. Process analysis,

monitoring and diagnosis,using multivariate projection

methods. Chemometrics and Intelligent Laboratory

Systems 28 (1995) 3-21. ELSEVIER.

Tsung, F., 1999. Improving automatic-controlled process

quality using adaptative principal component

monitoring. Qual.Rielab.Engng.Int. 15:135-142(1999)

John Wiley & Sons;Ltd.

Ljung, L., 1987. System Identification: Theory for the

user. Prentice-Hall.

DETECTION OF A FAULT BY SPC AND IDENTIFICATION - A Method for Detecting Faults of a Process Controlled

by SPC

375