A MULTIOBJECTIVE CONSTRAINT OPTIMIZATION MODEL FOR

MULTIMODE REPAIR PLANS

I. Barba, C. Del Valle and D. Borrego

Dpto. Lenguajes y Sistemas Inform´aticos, Universidad de Sevilla, Spain

Keywords:

Planning, Scheduling, Constraints, Repair, Multiobjective optimization, Multimode project scheduling.

Abstract:

This work presents a constraint based model for the planning and scheduling of disconnection and connection

tasks when repairing faulty parts. The problem involves the ordering and the selection of tasks from a set of

alternatives. The goal of the plan is the minimization of the repair duration and cost. The model considers,

apart from the durations, costs and resources for the tasks, the necessary delays and costs due to auxiliary tasks.

The tasks can be executed in several operating modes, each one using a different machine or configuration and

possibly different duration and cost. The set of all feasible plans are represented by an extended And/Or graph.

1 INTRODUCTION

There is an increasing interest for integrating plan-

ning and scheduling since real-world problems in-

volve both of them (Boddy et al., 2004). Some of the

applications involving such issues are maintenance

and repair planning, where there may be a cascad-

ing set of choices which affect different features of

the plan, such as duration or cost (Smith et al., 2000).

Many problems can involve multiple conflicting ob-

jectives (Deb, 2008) that should be considered at the

same time.

This work presents a CSP (Constraint Satisfaction

Problem) model for solving a planning problem corre-

sponding to the optimal sequencing of disconnection

and connection tasks for repairing faulty components.

The objective is the minimization of the total repair

time and cost, considering different factors that can

have an influence on it. The tasks can be executed in

several operating modes (Kolisch and Drexl, 1999),

each one using a different machine or configuration,

and possibly different duration and cost.

The rest of the paper is organized as follows: Sec-

tion 2 details the considered repair problem, Section

3 states the CSP model for planning the reparation

of faulty components and, finally, Section 4 presents

some conclusions and future work.

2 REPAIR PLANNING

In order to repair a faulty part, a sequence of discon-

nection tasks must be executed to get it, then a repair

action would repair the component, and lastly some

connection tasks must reconnect the system.

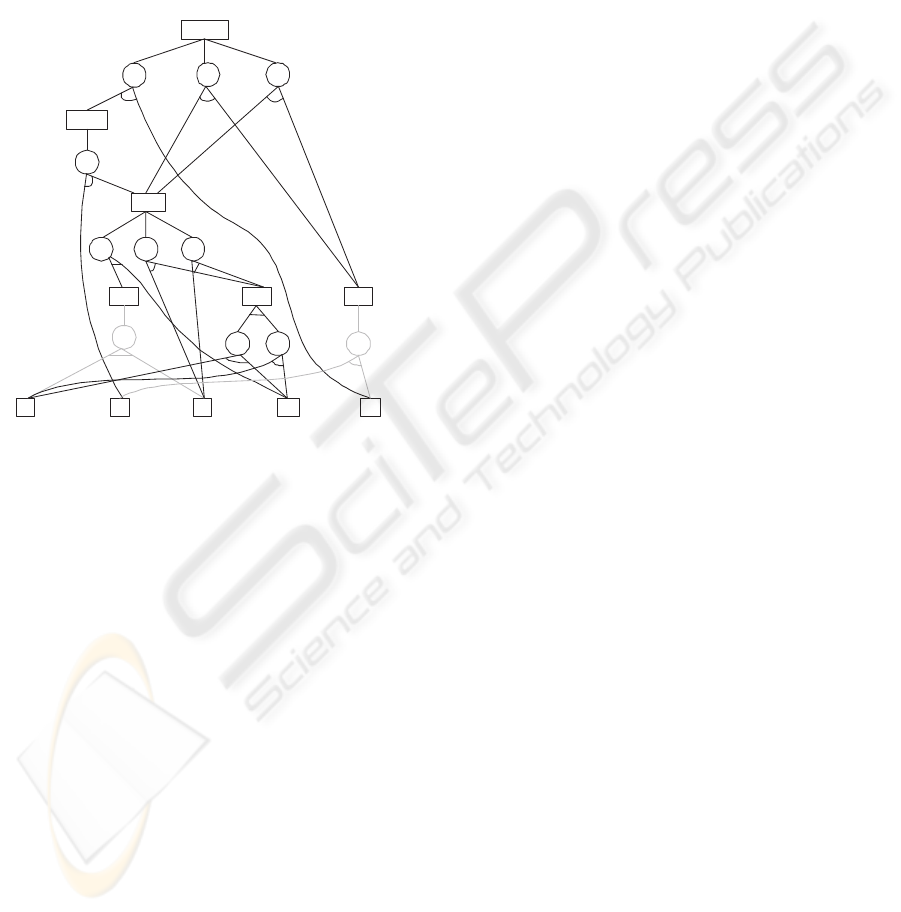

The use of And/Or graphs (Homem de Mello and

Sanderson, 1990) allows to represent the set of all fea-

sible plans in a natural way. An important advantage

of And/Or graph is that it shows the tasks that can

be executed in parallel (Fig. 1). Furthermore, both

precedence constraints and those related to the selec-

tion of tasks for obtaining a correct plan, can be easily

obtained from this representation.

A feasible repair plan can be seen as a set of

tasks that have to be executed, containing: Connec-

tion/Disconnection tasks, that are executed on an es-

tablished machine with a particular configuration and

Auxiliary tasks (set-up operations, that change the

configuration of a machine when two successive tasks

with different configuration use it; and transportation

operations, that transport the subsystems between ma-

chines when the machine where the subsystem is ob-

tained is different from the one where is required).

The tasks can be executed in more than one op-

erating mode, each one using a different machine or

configuration and possibly different duration and cost,

and will be represented by differentAnd nodes (i.e. T

′

2

and T

′

3

in Fig. 1).

A repair graph is a subgraph of the And/Or graph

which only contains the tasks that could be necessary

to repair some components. Another important con-

sideration is that a connection (disconnection) task T

is reversible if its corresponding disconnection (con-

nection) task T

′

is feasible. The model supposes two

355

Barba I., Del Valle C. and Borrego D. (2009).

A MULTIOBJECTIVE CONSTRAINT OPTIMIZATION MODEL FOR MULTIMODE REPAIR PLANS.

In Proceedings of the 6th International Conference on Informatics in Control, Automation and Robotics - Intelligent Control Systems and Optimization,

pages 355-358

DOI: 10.5220/0002192003550358

Copyright

c

SciTePress

assumptions: (A1) All tasks are reversible and (A2)

Subsystems that do not include the faulty components

are not disconnected. Taking into account this, other

subsystems different from the ones generated by the

disconnection process can appear in the connection

process. Moreover, disconnection tasks only handle

subsystems that contain the faulty component. Al-

though the disconnection process is linear, the con-

nection can contain tasks that may execute in parallel

with others.

ABCDE

ABCD

ACD

AC

A

AD BE

B C D E

T’

3

T’

2

T’

1

T’

7

T’

9

T’

4

T’

5

T’

6

T’

10

T’

8

T’

11

Figure 1: A simplified disconnection And/Or graph.

3 THE CSP MODEL

Constraint Programming (CP) has been evolved in the

last decade to a mature field because, among others,

of the use of different generic and interchangeable

procedures for inference and search, which can be

used for solving different types of problems (Rossi

et al., 2006). Once a problem is modelled by a CSP, a

generic or specialized CSP solver can be used in order

to obtain the required solution.

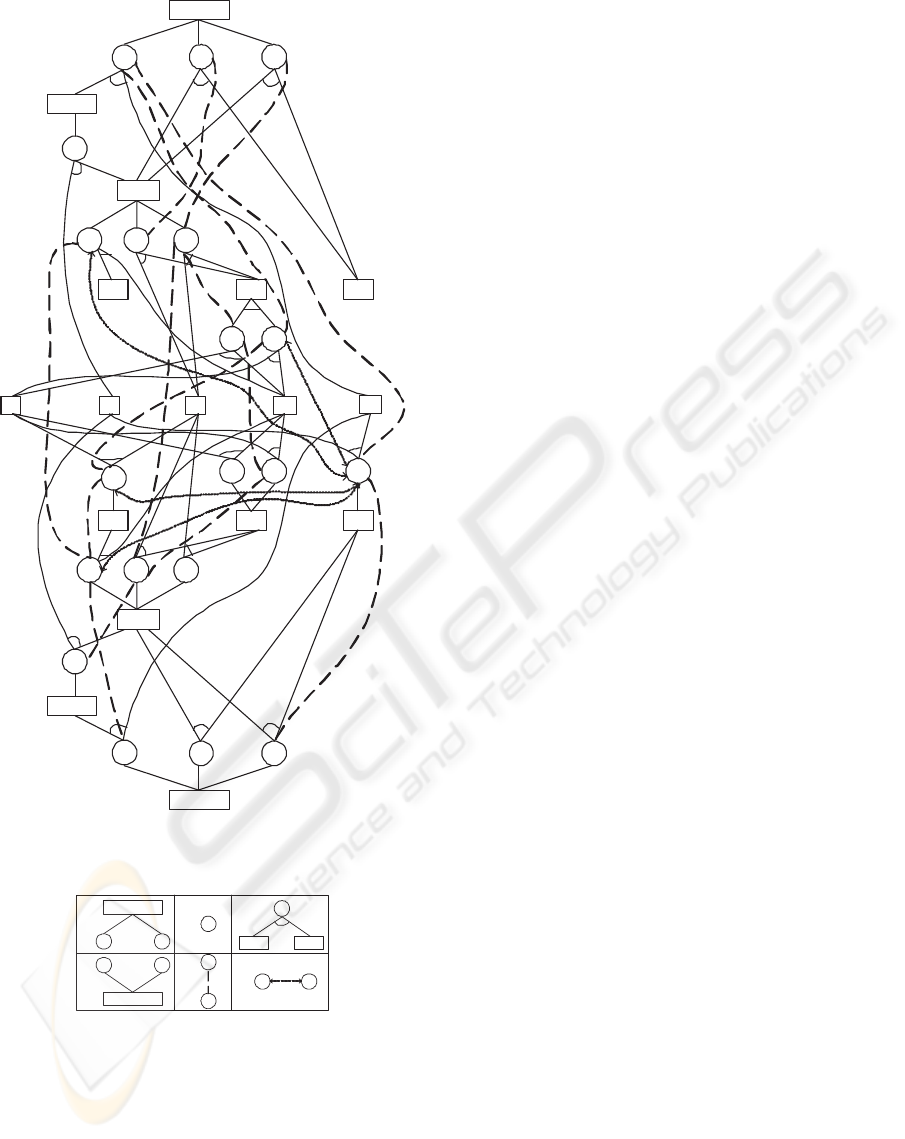

Taking into account (A1) and (A2), the graph can

be simplified removing those And nodes below the

Or nodes corresponding to subsystems which do not

contain the faulty part (Fig. 2).

3.1 Variables of the CSP

Selection Variables. For each And node, two boolean

variables represent if the connection s(T) and discon-

nection tasks s(T

′

) are selected for the solution. Fur-

thermore, for each Or node, two boolean variables

represent if the subsystem S appears in the connection

s(S) and disconnection processes s

′

(S).

Resource Variables. For each And node, M(T) and

M(T

′

) represent the machines used, and C f(T) and

Cf(T

′

) are the necessary configuration on them for

the connection and disconnection tasks respectively.

On the other hand, the machine where a subsys-

tem is obtained after the corresponding disconnection

and connection task, are represented by the variables

m

′

(S) and m(S).

Time Variables. For each And node, the durations of

the associated tasks Dur(T) and Dur(T

′

) are estab-

lished. For the auxiliary operations, ∆

cht

(M, Cf, C f

′

)

denotes the time needed for changing the config-

uration of the machine M from Cf to C f

′

, and

∆

mov

(S, M, M

′

) denotes the time needed for transport-

ing the subsystem S from machine M to machine M

′

.

Finally, a temporal delay ∆

subst

(C) is associated to

the reparation of the faulty component. On the other

hand, for each And node: its starting and ending

times, t

i

(T) and t

i

(T

′

), t

f

(T) and t

f

(T

′

). For each Or

node, the times when it is obtained after connection,

t

OR

(S), and disconnection, t

′

OR

(S).

Cost Variables. For each And node: its connection

Cost(T

i

) and disconnection cost Cost(T

′

i

). Regard-

ing to the auxiliary operations, Cost

cht

(M, Cf, C f

′

)

denotes the cost of changing the configuration of the

machine M fromCf toCf

′

, andCost

mov

(S, M, M

′

) de-

notes the cost of transporting the subsystem S from

machine M to machine M

′

. Furthermore, a cost

Cost

subst

(C) is associated to the reparation of the

faulty component. On the other hand, for each And

node, the selection of the corresponding task T may

be associated some additional costs: first, the variable

cost

mov

(T

i

) represents the possible costs associated to

the movement of subsystems; and secondly, the vari-

able cost

cht

(T

i

) represents the possible costs of change

of configuration.

The original And/Or graph has been extended,

adding new types of links between And nodes. The

new links represent non-precedence constraints: due

to the use of shared resources by the tasks and due to

the change of configurations in the machines.

Fig. 2 shows the extended and simplified re-

pair And/Or graph of a system consisting in ABCDE

components when substituting D. A typical objec-

tive for such a problem would be the minimization

of the elapsed time of the plan, given by the variable

(t

OR

(ABCDE)). Another important issue is the total

cost of the complete repair plan. In this work, a multi-

objective optimization is pursued, encompassing both

of them.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

356

ABCDE

ABCD

ACD

AC

A

AD BE

B C D

T’

3

T’

2

T’

1

T’

7

T’

9

T’

4

T’

5

T’

6

T’

10

ABCDE

ABCD

ACD

AC AD BE

E

T

3

T

2

T

1

T

7

T

9

T

4

T

5

T

6

T

10

T

8

T

11

M

2

C

3

M

1

C

1

M

3

C

4

M

1

C

2

M

2

C

3

M

1

C

2

M

3

C

2

M

3

C

6

M

2

C

1

M

2

C

4

M

1

C

2

M

2

C

4

M

3

C

3

M

2

C

5

M

1

C

2

M

3

C

2

M

3

C

6

M

2

C

4

M

2

C

5

M

1

C

2

Figure 2: The simplified repair And/Or graph with relations

(5) and (6) between tasks

...

...

(1) (2) (3)

(4) (5) (6)

Figure 3: Types of Relations

3.2 Types of Constraints

Six types of relations are considered (Fig. 3), each

one representing a link or component of the extended

graph (Fig. 2): Relations of type (1) collect the rela-

tion between the information from an Or node and the

And nodes below it. Relations of type (2) consider the

durations of tasks, and correspond to the relations be-

tween its starting and ending times. Relations of type

(3) collect the relation between the information from

an And node and the Or nodes below it. Relations of

type (4) consider the relation between the selection of

an Or node and all the And nodes above it. Relations

of type (5) are due to the delay needed for a change

of configuration in a machine between the executions

of two successive tasks using the same machine with

precedence constraints among them. Relations of type

(6) consider the relation between some tasks that use

the same resource. Types (1), (2), (3) and (4) come

from the relations between the nodes included in the

original And/Or graph, while types (5) and (6) come

from the use of (same or different) resources by the

different tasks, and they are related to new links be-

tween tasks in the extended And/Or graph.

Taking into account the variables of the proposed

model, selection, resource, time and cost constraints

are considered. A previous work (Del Valle et al.,

2009) includes the first three kinds of constraints.

Selection Constraints. Collect the relations between

the boolean variables that represent if the tasks are

selected for the solution and the subsystems appears

in the repair process. A special case is for the com-

plete system and for the faulty component, which al-

ways will be part of the solution. The constraints

of type (1) include the selection of disconnection

tasks T

′

and connection tasks T with that of sub-

systems: s

′

(S) ⇔ XOR

T

′

i

∈succ(S)

(s(T

′

i

)) and s(S) ⇔

XOR

T

i

∈succ(S)

(s(T

i

)). Related to relations of type

(3), the selection of the two Or nodes if the And

node is selected: s(T

′

) ⇒ s

′

(S

1

) ∧ s

′

(S

2

) and s(T) ⇒

s(S

1

) ∧ s(S

2

). The constraints of type (4) include

the selection of tasks T

′

and T with that of sub-

systems: s

′

(S) ⇔ XOR

T

′

i

∈pred(S)

(s(T

′

i

)) and s(S) ⇔

XOR

T

i

∈pred(S)

(s(T

i

)).

Resource Constraints. Consider the relations be-

tween the machines used in the tasks, and those where

the subsystems are obtained after them. Related to re-

lations (1), the machine m where a subsystem is gen-

erated after a connection task is the machine used by

this task: s(T

i

) ⇒ m(S) = M(T

i

). Related to relations

of type (3), the machine m

′

where a subsystem is gen-

erated after a disconnection task is the machine used

by this task: s(T

′

i

) ⇒ m

′

(S

1

) = m

′

(S

2

) = M(T

′

i

).

Time Constraints. Time constraints collect the rela-

tions between the start and the end times of the tasks,

and the time when the subsystems are obtained. Re-

lated to relations of type (1), these constraints estab-

lish the disconnection t

′

OR

and connection times t

OR

of Or nodes related to the start times of the discon-

A MULTIOBJECTIVE CONSTRAINT OPTIMIZATION MODEL FOR MULTIMODE REPAIR PLANS

357

nection tasks or the end times of the connection tasks:

s(T

′

i

) ⇒ t

i

(T

′

i

) ≥ t

′

OR

(S) + ∆

mov

(S, m

′

(S), M(T

′

i

)) and

s(T

i

) ⇒ t

f

(T

i

) = t

OR

(S). Related to relations of type

(2), these constraints consider the end time of the

tasks related to the start time and the durations of

them: s(T

′

i

) ⇒ t

f

(T

′

i

) = t

i

(T

′

i

)+ Dur(T

′

i

) and s(T

i

) ⇒

t

f

(T

i

) = t

i

(T

i

) + Dur(T

i

). Related to relations (3), the

next constraints include the equality constraint be-

tween the disconnection times of the Or nodes t

′

OR

and the end time of a disconnection task T

′

above

them: s(T

′

i

) ⇒ t

f

(T

′

i

) = t

′

OR

(S

1

) = t

′

OR

(S

2

), and the

precedence between the connection time of the Or

nodes t

OR

and the start times of connection task T,

and considering the possible delays due to the trans-

portation of subsystems if the two successive tasks

involving it use different machines: s(T

i

) ⇒ t

i

(T

i

) ≥

t

OR

(S

1

)+ ∆

mov

(S

1

, m(S

1

), M(T

i

)) and s(T

i

) ⇒ t

i

(T

i

) ≥

t

OR

(S

2

) + ∆

mov

(S

2

, m(S

2

), M(T

i

)). Related to rela-

tions of type (5), these constraints establish that for

a task T

i

, and its closest predecessor task T

j

us-

ing the same machine m, taking into account the

possible change of configuration: (s(T

i

) ∧ s(T

j

)) ⇒

t

i

(T

j

) ≥ t

f

(T

i

) + ∆

cht

(m, Cf(T

i

), Cf(T

j

)). For each

two tasks T

i

and T

j

requiring the same machine

m, with no precedence constraint among them, and

which may belong to the same repair plan, the con-

straints of type (6) express the two possible orders

of execution of the tasks: (s(T

i

) ∧ s(T

j

)) ⇒ (t

i

(T

i

) ≥

t

f

(T

j

) + ∆

cht

(m, Cf(T

j

), Cf(T

i

)) ∨ t

i

(T

j

) ≥ t

f

(T

i

) +

∆

cht

(m, Cf(T

i

), Cf(T

j

))). For the Or leaf nodes t

′

OR

and t

OR

are equals, except for the faulty component

due to the delay corresponding to the reparation.

Cost Constraints. The cost of a plan can be estab-

lished by the aggregated costs associated to the exe-

cution of the selected tasks. The total cost of selecting

a task T

i

involves:

• the execution cost of the task, Cost(T

i

)

• the cost associated to the possible machine move-

ment of one or two subsystems, cost

mov

(T

i

):

first, in disconnection tasks T

′

i

, the possi-

ble movement of the subsystem related to

the Or nodes above it, related to relation

(1), cost

mov

(T

′

i

) = Cost

mov

(S, m

′

(S), M(T

′

i

)); sec-

ondly, in connection tasks T

i

, the possi-

ble movement of the two subsystems related

to Or nodes below it, related to relation

(3), cost

mov

(T

i

) = Cost

mov

(S

1

, m(S

1

), M(T

i

)) +

Cost

mov

(S

2

, m(S

2

), M(T

i

)).

• the possible cost associated to a change of config-

uration on M(T

i

), cost

cht

(T

i

). If M(T

i

) has been

used before by another task with a different con-

figuration, it is necessary to change it. The cost

of the change of configuration depends of the se-

quence of tasks for each machine, so there must be

considered the precedent task executed on m(T

i

).

Taking into account this, cost

cht

(T

i

) =

Cost

cht

(M(T

i

), Cf(PM(T

i

)), Cf(T

i

)), where

PM(T

i

) is the precedent task executed on m(T

i

).

Also, the total cost of a plan can be defined as

∑

T

i

s(T

i

)(Cost(T

i

) + cost

mov

(T

i

) + cost

cht

(T

i

)).

4 CONCLUSIONS AND FUTURE

WORK

This work proposes a CSP model for the planning and

optimal sequencing of disconnection and connection

multi-mode tasks when repairing faulty components,

taking into account the minimization of time and cost.

The proposed model can be solved using conventional

methods for a generic CSP. As future work, it is in-

tended to use different strategies to solve the problem,

working with heuristic algorithms based on the result-

ing state of the constraint propagation process and on

the objective functions to be optimized.

ACKNOWLEDGEMENTS

This work has been partially supported by the Span-

ish Ministerio de Educaci´on y Ciencia through a coor-

dinated research project (Grant DIP2006-15476-C02-

01) and Feder (ERDF).

REFERENCES

Boddy, M., Cesta, A., and Smith, S. (2004). ICAPS-04 Ws.

Integrating Planning into Scheduling. AAAI Press.

Deb, K. (2008). Introduction to evolutionary multiobjec-

tive optimization. Lecture Notes in Computer Science

5252 LNCS, pages 59–96.

Del Valle, C., M´arquez, A., and Barba, I. (2009). A csp

model for simple non-reversible and parallel repair

plans. Journal of Intelligent Manufacturing. To ap-

pear (DOI 10.1007/s10845-008-0162-9).

Homem de Mello, L. and Sanderson, A. (1990). And/or

graph representation of assembly plans. IEEE Trans-

actions on Robotics and Automation, 6(2):188–189.

Kolisch, R. and Drexl, A. (1999). Local for multi-mode

resource-constrained project. IIE Transactions (Insti-

tute of Industrial Engineers), 29(11):987–999.

Rossi, F., Van Beek, P., and Walsh, T. (2006). Handbook of

Constraint Programming. Elsevier.

Smith, D., Frank, J., and J´onsson, A. (2000). Bridging the

gap between planning and scheduling. Knowledge En-

gineering Review, 15(1):47–83.

ICINCO 2009 - 6th International Conference on Informatics in Control, Automation and Robotics

358