A MULTI-LAYERED MICROFLUIDIC DEVICE

FOR MAGNETOPHORETIC CELL SEPARATION

Hye-Lyn Lee, Suk-Heung Song, Hee-Taek Lim, Hyung-Joon Kim, Min-Suk Park and Hyo-Il Jung

School of Mechanical Engineering, Yonsei University, Seoul, Republic of Korea

Keywords: Multi-layered microfluidic channel, Magnetophoretic cell separation, Microelectromagnet, Microbeads,

Magnetic field.

Abstract: In this paper, we present the design and experimental results of a multi-layered microfluidic electromagnetic

cell separation device. Our channel consists of top and bottom layers in order to separate magnetically

labeled cells in the vertical direction. Rapid separation of magnetic beads in top and bottom channel can be

used in high throughput screening to monitor the efficacy and drug compounds. The experiments using the

device were carried out with 4.5μm magnetic bead and magnetic labeled Jurkat cell under electromagnetic

field of 1.55mT. Without the magnetic field, the magnetic labeled cells started to flow from the bottom inlet

and exit out of the bottom channel outlet. In the presence of the magnetic field, the cells started in bottom

channel are attracted upward by the electromagnetic field and flow through the top layered. Finally, the

labeled cells flow out the top channel outlet. The separation efficiencies of the multi-layer structured

microfluidic channel showed more than 95%. We found that the multi-layer structured microfluidic channel

was very effective in enhancing the separation. This microfluidic channel can be potentially applied to Lab-

on-a-chip system because of its attractive features such as high throughput, continuous sorting, simple and

rapid fabrication.

1 INTRODUCTION

There is a growing interest of microfluidic cell

separation systems as they are useful for high

throughput drug screening and medical diagnosis

(Inglis at al. 2004) (Pamme and Wilhelm, 2006).

The Fluorescent Activated Cell Sorter (FACS) is one

of the most common methods to detect and separate

cells but the bench-top volume of the device is a

barrier to its miniaturization. A microfluidic device

is a proven way of minimization and there have been

several reports regarding the separation of specific

cells in an optical microfluidic system (Wolbers et al.

2004). However, optical systems have the

disadvantage of requiring external observation and

are not suitable for opaque samples like blood.

A Magnetic Activated Cell Sorter (MACS) can

overcome all the defects of cell sorters. It is simple

to operate and is generally not affected by the

electrical properties of a solution, pH, temperature or

impurities (Pamme 2006). Separation of human

peripheral T lymphocytes has been reported using

MACS with permanent magnets and quadropole

fields (Sun et al. 1998). Microfluidic MACS for

HeLa cell and macrophage sorting have recently

been developed (Pamme and Wilhelm 2006).

It is a generally, thought that conventional

magnetophoretic separating devices produce small

magnetic fields in the microfluidic channel. Also,

most use mono-layered channel that separate in the

horizontal direction (Kim at al. 2007).

In this research, we demonstrate a new

microfluidic channel consisted of top and bottom

layers in order to separate in the vertical direction.

This device can get easily high degree of separation

efficiency although in the small magnetic fields.

2 MATERIALS AND METHOD

2.1 Theory

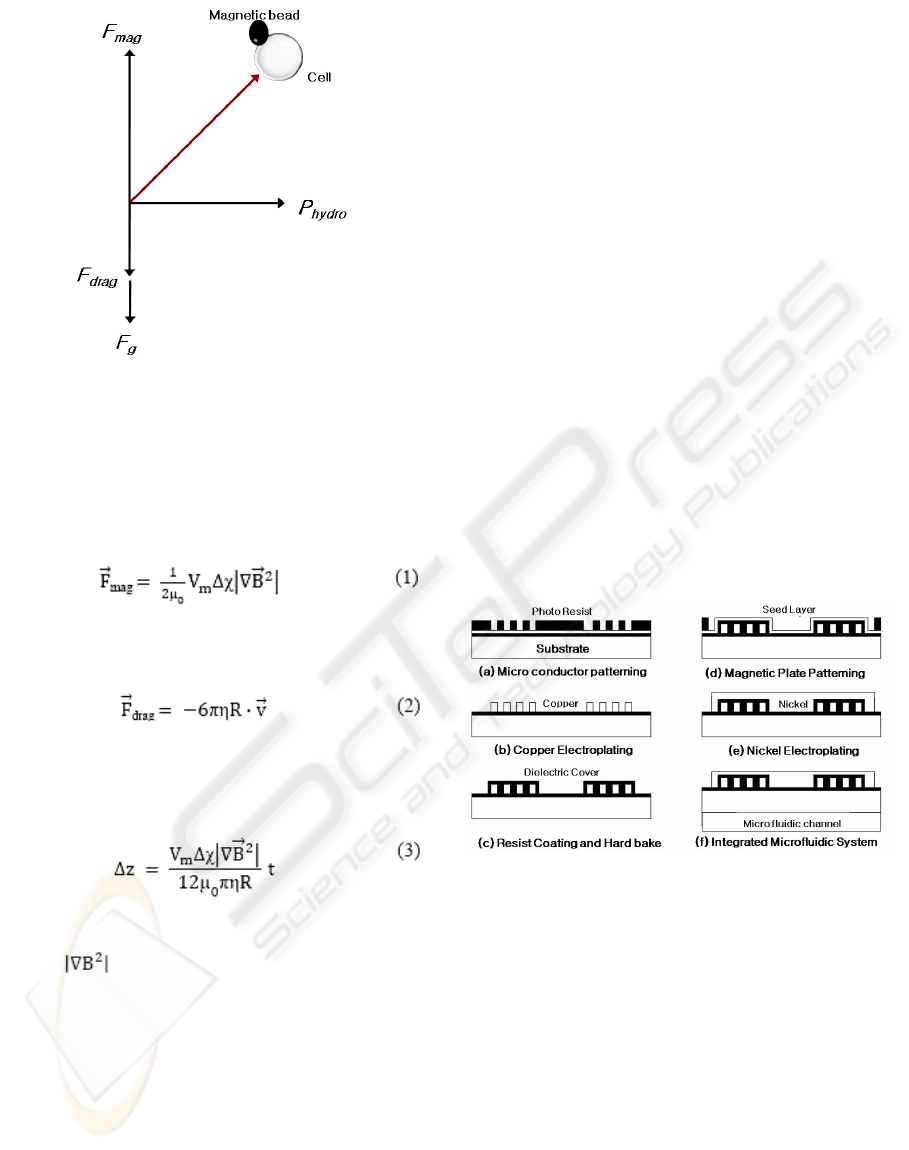

There are three forces acting on a magnetically

labeled cell surface: magnetic force, drag and

gravity as shown in Fig.1.

Because the effect of gravity is negligible owing

286

Lee H., Song S., Lim H., Kim H., Park M. and Jung H. (2009).

A MULTI-LAYERED MICROFLUIDIC DEVICE FOR MAGNETOPHORETIC CELL SEPARATION.

In Proceedings of the International Conference on Biomedical Electronics and Devices, pages 286-289

DOI: 10.5220/0001776702860289

Copyright

c

SciTePress

Figure 1: Three forces acting on the surface of a cell.

to the small size of the magnetic bead labeled cell

(Qasem et al. 2004), the forces responsible for

deflection of cells coated with magnetic beads are

magnetic and drag forces. The magnetic force

exerted on a magnetic bead in magnetic field can be

calculated as follows (Williams et al. 1999):

Hydrodynamic drag force is estimated according to

the Stokes drag equation:

Finally, considering the force balance between

magnetic and hydrodynamic drag (neglecting the

inertial term of Newton’s law), the deflection of the

cell is given by (Qasem et al. 2004):

In Eq. (3), V

m

is a volume of magnetic beads. Δχ

was calculated from the literature (Lagae et al. 2005).

Finally,

as determined by measuring magnetic

fields with a gauss meter (LakeShore 475 DSP) and

calculating based on the inverse square law. The

deflection of the cell, Δz, generated by one magnetic

bead attached on the cell surface was 4.5 μm. In

most cases, the number of magnetic beads bound

with cell was more than 1, so the vertical deflection

should be more than 17.5 μm. We fabricated a

microfluidic device to separate cells assuming that

Δz is more than 17.5 μm.

2.2 Fabrication

2.2.1 Electromagnet

The microelectromagnet was fabricated using

MEMS technology. The fabrication process for on-

chip microelectromagnet is in Fig. 2: (a) SiO2 was

deposited 1μm on a double-side-polished Si wafer

by furnace and the microconductor was patterned

using UV-lithography; (b) a copper microcoil, as a

conductor for the microelectromagnet, was

manufactured by 25μm thick electroplating with a

photoresistor mold. For the electrical insulation, the

dielectric layer based on polymer material (AZ 4620,

Clariant, Korea) was deposited between the

microcoil and the magnetic plate; (c) The polymer,

as a dielectric layer, was encapsulated on the

microcoil and was hard-baked; (d) The seed layer,

Ti/Ni 500/3000Å, was deposited onto the dielectric

layer for electroplating of the nickel plate; (e) the

nickel, as a magnetic plate, was electroplated 25μm

thick and (f) the PDMS microfluidic channel system

was integrated.

The size of the electromagnet is 4 x 4 mm

2

and

the height of the magnetic plate is 25 μm.

Figure 2: Fabrication processes of the microelectromagnet

and microfluidic system.

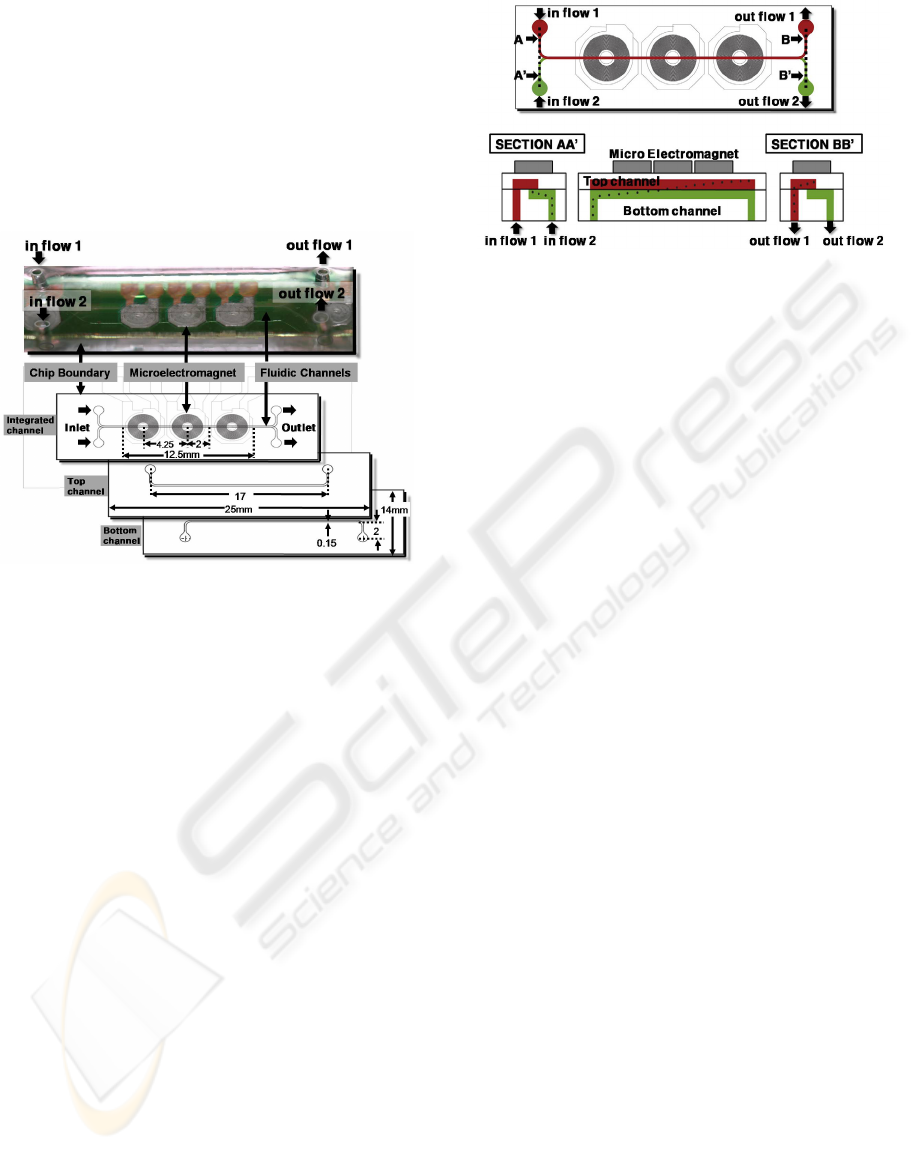

2.2.2 Microfluidic Channel

A microfluidic channel was fabricated according to

standard softlithography and replica molding process.

The silicon wafer was washed first by methanol,

followed by acetone, and de-ionized water, then a

SU-8 negative epoxy-based photoresist (SU-8 2100,

MicroChem Corp.) was spin-coated on the wafer.

The spin-coated wafer was baked using a hot plate

(95°C, 35 min) to remove unwanted area from the

photoresist. The wafer was then exposed to UV light

(λ = 365 nm, 60 s), baked again in two steps (65°C,

1 min and 95°C, 15 min), and developed by the SU-

8 developer (Sigma Aldrich) for 15 min. The result

was a 130 μm high photoresist mold. After

A MULTI-LAYERED MICROFLUIDIC DEVICE FOR MAGNETOPHORETIC CELL SEPARATION

287

preparing the SU-8 mould, a PDMS gel mixture (DC

184-A:B = 9:1, Dow Corning) was poured on the

wafer, the gel mixture was baked in an oven (80°C,

45 min) and detached from the mold. The PDMS

microfuidic channel was finally treated with O

2

plasma and bonded with a glass substrate. The size

of this device is 25mm x 14mm x 5mm and the

microfluidic channel length is 17mm, the width is

150μm and the depth is 100μm.

Figure 3: Illustration of the multi-layered microfluidic

channel with on-chip electromagnet.

2.3 Cell Culture

Jurkat clone E6-1 cells (Organ: acute T cell

leukemia/ human blood) were cultured under

standard conditions (37°C, 5%CO

2) in RPMI-1640

medium comprised of 10% (v/v) fetal bovine serum

(FBS) and 1% antimycotic antibiotic (all purchased

from Cambrex, USA).

2.4 Sample Preparation

Dynabeads

®

CD3 are superparamagnetic, micro

sized particles with a characteristic polymer surface

for coupling with CD3 T-Cells, thus making it

possible to sort out the human T cells in this

experiment. Dynabeads

®

CD3 (4x10

8

bead/ml, 25 μl)

and Jurkat clone E6-1 cells (1x10

7

cell/ml, 1ml)

were incubated for 10 min at 2-8°C with gentle

tilting and rotation. Finally, Jurkat cells (13 µm

diameter) are bound with magnetic beads CD3 (4.5

µm diameter).

2.5 Experimental Set-up

A schematic view of the multi-layered microfluidic

channel using on-chip electromagnet is illustrated in

figure 4. The multi-layered microfluidic channel is a

Figure 4: Schematic diagram of the multi-layered

microfluidic channel.

straight type with a square cross-section. The fluid is

assumed incompressible the flow will be laminar

and boundary condition is the no-slip on the channel

walls. The magnetic beads and cell mixture started

in bottom channel at flow rate of 5μL/min are

attracted upward by the electromagnetic field and

flow through the top layered. Finally, magnetic

beads flow out the top channel outlet.

A syringe pump (KDS scientific, CMA

instruments) is connected to the microfluidic

channel to supply different types of fluid through

two syringes (sample solution syringe and buffer

solution syringe). The syringes and channel inlets

were linked by Teflon tubes (500 μm, Nano Port).

The microfluidic channel was placed on an optical

microscope and monitored by a CCD camera. We

used a microelectromagnet of 1.55mT (Tesla) placed

on the top of the main channel.

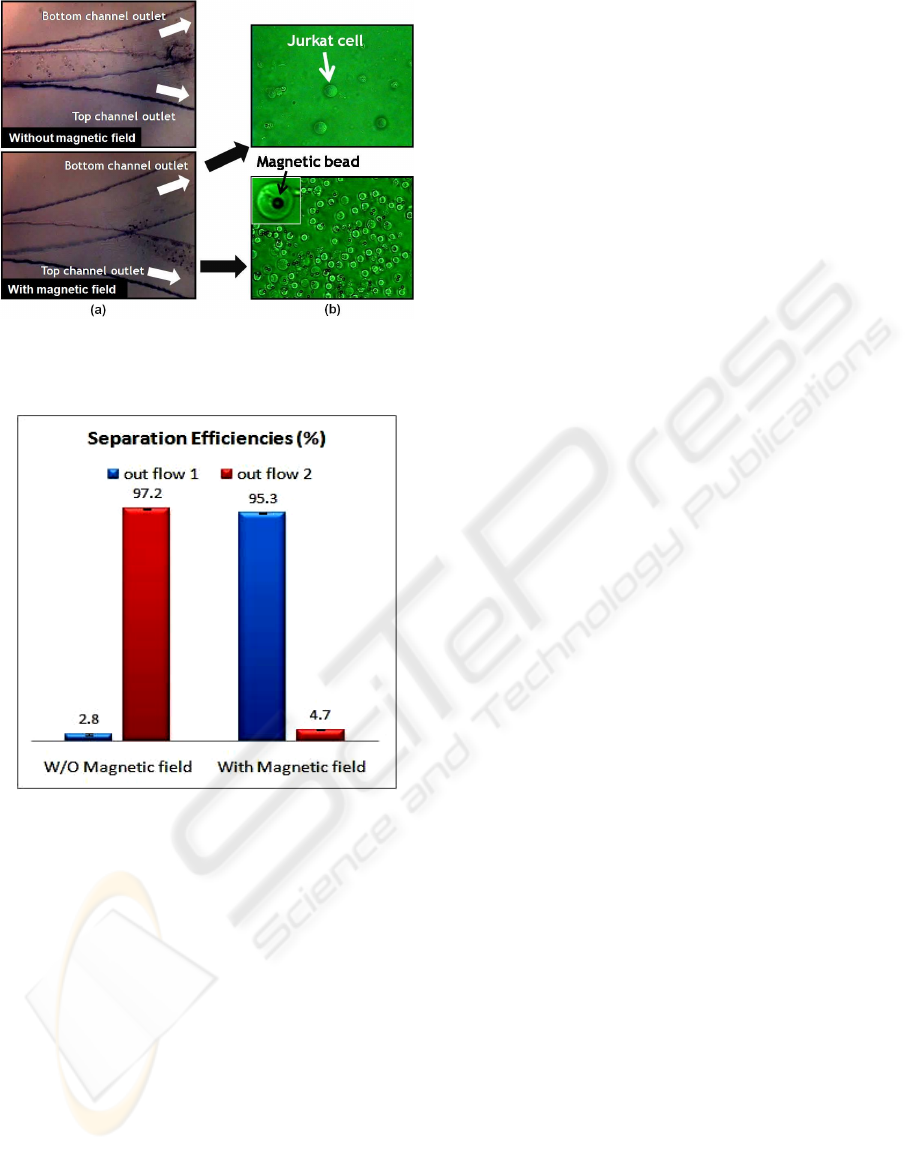

3 RESULTS AND DISCUSSION

The sample solution was flowed through a

microfluidic channel and the Jurkat cells labeled

magnetic beads were separated by a 1.55mT

microelectromagnet at 5μL/min of flow rate.

Magnetic beads are introduced to magnetic fields

and then experience a magnetic field while flowing

in the microfluidic channel.

Figure 6 shows comparison of the efficiencies

without and with magnetic field by electromagnet.

In the absence of magnetic fields, the flow of cells

labeled magnetic beads is shown negligible in

outflow 1 of top channel with an efficiency of 2.8%.

However, in the presence of magnetic fields, the

magnetically labeled cells are dominant in outflow 1

with a high efficiency of 95.3%. It demonstrates

magnetic beads were deflected and separated

through outlet 1 when a magnetic field was

introduced.

BIODEVICES 2009 - International Conference on Biomedical Electronics and Devices

288

Figure 5: (a) Photographic image of microfluidic channel

(b) Photographic image of Jurkat cells and magnetic beads

from outlet of the channel.

Figure 6: Experimental results of the separation

efficiencies.

4 CONCLUSIONS

A new multi-layered channel for separating cells has

been introduced using microelectromagnet. Our

experiments demonstrate that specific cells can be

separated simply using a multi-layered microfluidic

channel with high efficiencies.

The efficiency of the separation by our approach

was comparable with that of conventional

magnetophoretic cell sorters (Bu at al. 2008)

(Smistrup at al. 2005). Our results identify a new

multi-layered microfluidic channel to isolate cells

for drug discovery and Lab-on-a-chip system

because of its attractive features such as high

throughput, continuous sorting, simply and rapidly

fabricated system.

ACKNOWLEDGEMENTS

This work was supported by National Core Research

Center (NCRC) for Nanomedical Technology of the

Korea Science & Engineering Foundation (Grant no.

R15-2004-024-01001-0), Seoul Research &

Business Development (R&BD Program, 11128)

and Korea Research Foundation Grant funded by the

Korean Government (MOEHRD) (KRF-2007-313-

D00073).

REFERENCES

Inglis, D., Riehn, R., Austin, R., & Sturm, J. 2004.

Continuous microfluidic immunomagnetic cell

separation. Applied Physics Letters, 85, 5093.

Pamme, N., & Wilhelm, C. 2006. Continuous sorting of

magnetic cells via on-chip free-flow magnetophoresis.

[Article]. Lab on a Chip, 6(8), 974-980.

Wolbers F, Andersson H, van den Berg A, Vermes I. 2004.

Apoptosis induced kinetic changes in autofluorescence

of HL60 cells-possible application for single cell

analysis on chip. Apoptosis 9:749–755

Pamme N. 2006. Magnetism and microfluidics. Lab Chip

6:24–38

Sun L, Zborowski M, Moore LR, Chalmers JJ. 1998.

Continuous, flow-through immunomagnetic cell

sorting in a quadrupole field. Cytometry 33:469–475

Kim, H., Son, O., Kim, K., Kim, S., Maeng, S., & Jung, H.

2007. Separation of apoptotic cells using a

microfluidic device. Biotechnology Letters, 29(11),

1659-1663.

Qasem R, Victor S, Daniel P, Chen Y. 2004. On-chip

microelectromagnets for magnetic-based bio-

molecules separation. J Magnetism and Magnetic Mat

281:150–172

Williams PS, Zborowski M, Chalmers JJ. 1999. Flowrate

optimization for the quadrupole magnetic cell sorter. Anal

Chem 71:3799–3807

Lagae L, Wirix-Speetjens R, Liu CX, Laureyn W, Borghs

G, Harvey S, Galvin P, Ferreira HA, Graham DL,

Freitas PP, Clarke LA, Amaral MD. 2005. Magnetic

biosensors for genetic screening of cystic fibrosis.

IEEE Proc Circuit Device Syst 152:393–400

Bu, M., Christensen, T. B., Smistrup, K., Wolff, A., &

Hansen, M. F. 2008. Characterization of a

microfluidic magnetic bead separator for high-

throughput applications. Sensors and Actuators, A:

Physical, 145-146(1-2), 430-436.

Smistrup, K., Hansen, O., Bruus, H., & Hansen, M. 2005.

Magnetic separation in microfluidic systems using

microfabricated electromagnets-experiments and

simulations. Journal of Magnetism and Magnetic

Materials, 293(1), 597-604.

A MULTI-LAYERED MICROFLUIDIC DEVICE FOR MAGNETOPHORETIC CELL SEPARATION

289