THE BEES ALGORITHM

AND MECHANICAL DESIGN OPTIMISATION

D. T. Pham, M. Castellani, M. Sholedolu

Manufacturing Engineering Centre, Cardiff University, Cardiff, U.K.

A. Ghanbarzadeh

Mechanical Engineering Department, Engineering Faculty, Shahid Chamran University, Ahvaz, Iran

Keywords: Bees Algorithm, Optimisation, Mechanical Design.

Abstract: The Bees Algorithm is a search procedure inspired by the way honey-bees forage for food. A standard

mechanical design problem, the design of a welded beam structure, was used to benchmark the Bees

Algorithm against other optimisation techniques. The paper presents the results obtained showing the robust

performance of the Bees Algorithm.

1 INTRODUCTION

Researchers have used the design of welded beam

structures (Rekliatis et al., 1983) as a benchmark

problem to test their optimisation algorithms. The

welded beam design problem involves a nonlinear

objective function and eight constraints. A number

of optimisation techniques have been applied to this

problem. Some of them, such as geometric

programming (Ragsdell and Phillips, 1976), require

extensive problem formulation; some (see, for

example, (Leite and Topping, 1998)) use specific

domain knowledge which may not be available for

other problems, and others (see, for example,

(Ragsdell and Phillips, 1976)) are computationally

expensive or give poor results.

The Bees Algorithm has been applied to

different optimisation problems (Pham et al., 2005,

Pham et al., 2006b, Pham et al., 2006a). The design

problems discussed in this paper are constrained

optimisation problems to be solved using this new

algorithm.

The remainder of the paper is structured as

follows. Section 2 explains the main features of the

foraging process and the steps of the Bees

Algorithm. Section 3 describes the welded beam

design problem. Section 4 presents the results

obtained using the Bees Algorithm and other

optimisation procedures. Section 5 concludes the

paper.

2 THE BEES ALGORITHM

2.1 The Foraging Process in Nature

During the harvesting season, a colony of bees keeps

a percentage of its population as scouts (Von Frisch,

1976) and uses them to explore the field surrounding

the hive for promising flower patches. The foraging

process begins with the scout bees being sent to the

field where they move randomly from one patch to

another.

When they return to the hive, those scout bees

that found a patch of a sufficient quality (measured

as the level of some constituents, such as sugar

content) deposit their nectar or pollen and go to the

“dance floor” to perform a dance known as the

“waggle dance” (Seeley, 1996). This dance is the

means to communicate to other bees three pieces of

information regarding a flower patch: the direction

in which it will be found, its distance from the hive,

and its quality rating (or fitness) (Von Frisch, 1976,

Camazine et al., 2003). This information helps the

bees watching the dance to find the flower patches

without using guides or maps. After the waggle

dance, the dancer (i.e. the scout bee) goes back to

250

T. Pham D., Castellani M., Sholedolu M. and Ghanbarzadeh A. (2008).

THE BEES ALGORITHM AND MECHANICAL DESIGN OPTIMISATION.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - ICSO, pages 250-255

DOI: 10.5220/0001506102500255

Copyright

c

SciTePress

the flower patch with follower bees recruited from

the hive. The number of follower bees will depend

on the overall quality of the patch. Flower patches

with large amounts of nectar or pollen that can be

collected with less effort are regarded as more

promising and attract more bees (Seeley, 1996,

Bonabeau et al., 1999). In this way, the colony can

gather food quickly and efficiently.

2.2 The Bees Algorithm

This section summarises the main steps of the Bees

Algorithm. For more details, the reader is referred to

(Pham et al., 2006b, Pham et al., 2006a, Pham et al.,

2005). Figure 1 shows the pseudo code for the Bees

Algorithm. The algorithm requires a number of

parameters to be set, namely: number of scout bees

(n), number of sites selected for neighbourhood

searching (out of n visited sites) (m), number of top-

rated (elite) sites among m selected sites (e), number

of bees recruited for the best e sites (nep), number of

bees recruited for the other (m-e) selected sites

(nsp), the initial size of each patch (ngh) (a patch is a

region in the search space that includes the visited

site and its neighbourhood), and the stopping

criterion. The algorithm starts with the n scout bees

being placed randomly in the search space. The

fitnesses of the sites visited by the scout bees are

evaluated in step 2.

1. Initialise population with random

solutions.

2. Evaluate fitness of the population.

3. While (stopping criterion not met)

//Forming new population.

4. Select sites for neighbourhood search.

5. Determine the patch size.

6. Recruit bees for selected sites (more

bees for best

e sites) and evaluate

fitnesses.

7. Select the fittest bee from each patch.

8. Abandon sites without new

information.

9. Assign remaining bees to search

randomly and evaluate their fitnesses.

10. End While.

Figure 1: Pseudo code of the Bees Algorithm.

In step 4, the m sites with the highest fitnesses

are designated as “selected sites” and chosen for

neighbourhood search. In step 5, the size of

neighbourhood around the selected sites is

determined. In step 6, the algorithm conducts

searches around the selected sites, assigning more

bees to search in the vicinity of the best e sites.

Selection of the best sites can be made directly

according to the fitnesses associated with them.

Alternatively, the fitness values are used to

determine the probability of the sites being selected.

Searches in the neighbourhood of the best e sites –

those which represent the most promising solutions -

are made more detailed. As already mentioned, this

is done by recruiting more bees for the best e sites

than for the other selected sites. Together with

scouting, this differential recruitment is a key

operation of the Bees Algorithm.

In step 7, for each patch, only the bee that has

found the site with the highest fitness (the “fittest”

bee in the patch) will be selected to form part of the

next bee population. In nature, there is no such a

restriction. This restriction is introduced here to

reduce the number of points to be explored. In step

8, sites which have not shown improvements in

fitness values over a number of recruitment cycles

are abandoned. This is because it is assumed that

such sites correspond to stationary points. The

locations of the sites are recorded. In step 9, the

remaining bees in the population are assigned

randomly around the search space to scout for new

potential solutions.

At the end of each iteration, the colony will have

two parts to its new population: representatives from

the selected patches, and scout bees assigned to

conduct random searches. These steps are repeated

until a stopping criterion is met.

As described above, the Bees Algorithm is

suitable for unconstrained optimisation problems. If

a problem involves constraints, a simple technique

can be adopted to enable the optimisation to be

applied. The technique involves subtracting a large

number from the fitness of a particular solution that

has violated a constraint in order drastically to

reduce the chance of that solution being found

acceptable. This was the technique adopted in this

work. As both design problems were minimisation

problems, a fixed penalty was added to the cost of

any constraint-violating potential solution.

THE BEES ALGORITHM AND MECHANICAL DESIGN OPTIMISATION

251

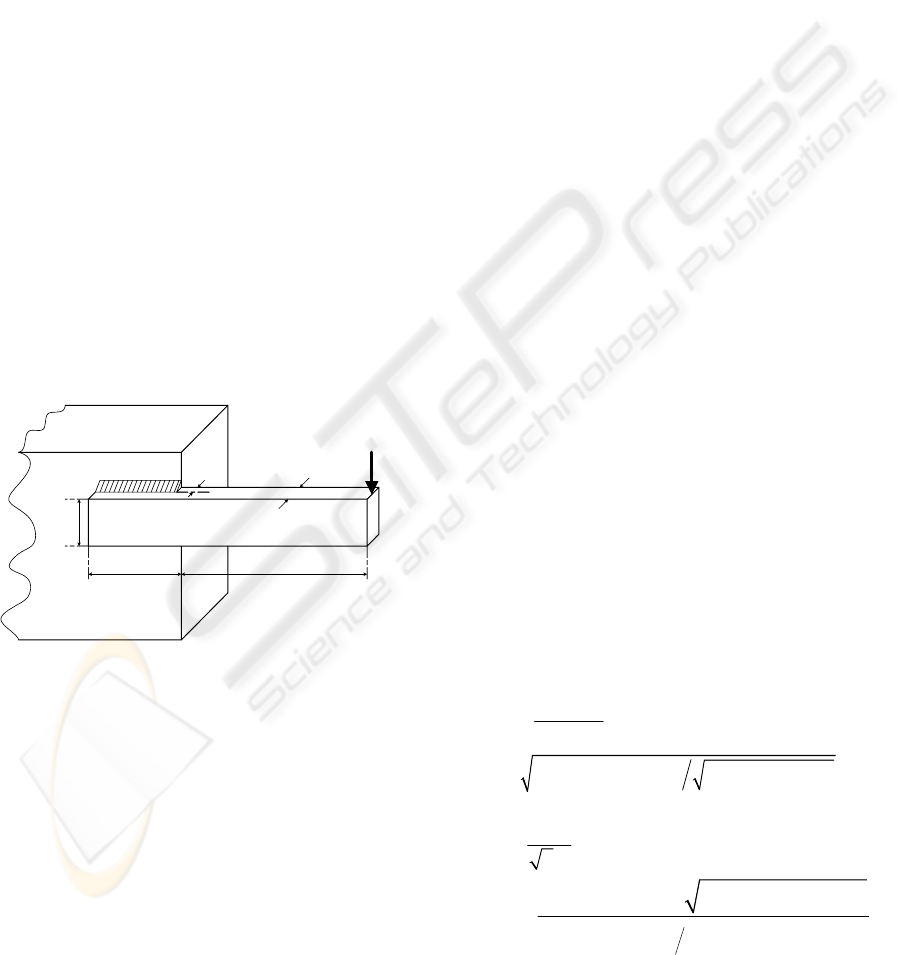

3 WELDED BEAM DESIGN

PROBLEM

A uniform beam of rectangular cross section needs

to be welded to a base to be able to carry a load of

6000 lbf

. The configuration is shown in Figure 2.

The beam is made of steel 1010.

The length L is specified as 14 in. The objective

of the design is to minimise the cost of fabrication

while finding a feasible combination of weld

thickness h, weld length l, beam thickness t and

beam width b. The objective function can be

formulated as (Rekliatis et al., 1983) :

Min

2

12

(1 ) ( )

f

chl ctbL l=+ + + (1)

where

f

= Cost function including setup cost, welding

labour cost and material cost;

1

c = Unit volume of weld material cost

=

3

0.10471 $ / .in

;

2

c = Unit volume of bar stock cost

=

3

0.04811 $ / .in

;

L = Fixed distance from load to support =

14 in

;

Figure 2: A Welded Beam.

Not all combinations of h, l, t and b which can

support F are acceptable. There are limitations

which should be considered regarding the

mechanical properties of the weld and bar, for

example, shear and normal stresses, physical

constraints (no length less than zero) and maximum

deflection. The constraints are as follows (Rekliatis

et al., 1983):

1

0

d

g

ττ

=−≥ (2)

2

0

d

g

σσ

=−≥

(3)

3

0gbh=−≥

(4)

4

0gl=≥

(5)

5

0gt=≥ (6)

6

0

c

gPF=−≥ (7)

7

0.125 0gh=− ≥ (8)

8

0.25 0g

δ

=−≥ (9)

where

d

τ

= Allowable shear stress of weld =

13600

P

si

;

τ

= Maximum shear stress in weld;

d

σ

= Allowable normal stress for beam material

=

30000

P

si

;

σ

= Maximum normal stress in beam;

c

P = Bar buckling load;

F

= Load =

6000 lbf

;

δ

= Beam end deflection.

The first constraint (

1

g ) ensures that the

maximum developed shear stress is less than the

allowable shear stress of the weld material. The

second constraint (

2

g ) checks that the maximum

developed normal stress is lower than the allowed

normal stress in the beam. The third constraint (

3

g )

ensures that the beam thickness exceeds that of the

weld. The fourth and fifth constraints (

4

g and

5

g

)

are practical checks to prevent negative lengths or

thicknesses. The sixth constraint (

6

g ) makes sure

that the load on the beam is not greater than the

allowable buckling load. The seventh constraint

(

7

g ) checks that the weld thickness is above a given

minimum, and the last constraint (

8

g ) is to ensure

that the end deflection of the beam is less than a

predefined amount.

Normal and shear stresses and buckling force

can be formulated as (Shigley, 1973, Rekliatis et al.,

1983):

3

2.1952

tb

σ

=

(10)

22 2 2

() () ( ) 0.25( ( ))llht

ττ τ ττ

′′′ ′′′

=++ ++

(11)

where

6000

2hl

τ

′

=

(Primary stress)

()

()

{}

22

2

2

6000(14 0.5 ) 0.25( ( ) )

2 0.707 12 0.25

llht

hl l h t

τ

+++

′′

=

++

(Secondary stress)

B

A

F

h

b

t

l

L

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

252

3

64746.022(1 0.0282346 )

c

Pttb=−

(12)

4 RESULTS AND DISCUSSION

The empirically chosen parameters for the Bees

Algorithm are given in Table 1 with the stopping

criterion of 750 generations. The search space was

defined by the following intervals (Deb, 1991):

0.125 5h≤≤ (13)

0.1 10l≤≤ (14)

0.1 10t≤≤ (15)

0.1 5b≤≤ (16)

With the above search space definition,

constraints

4

g ,

5

g and

7

g are already satisfied and

do not need to be checked in the code.

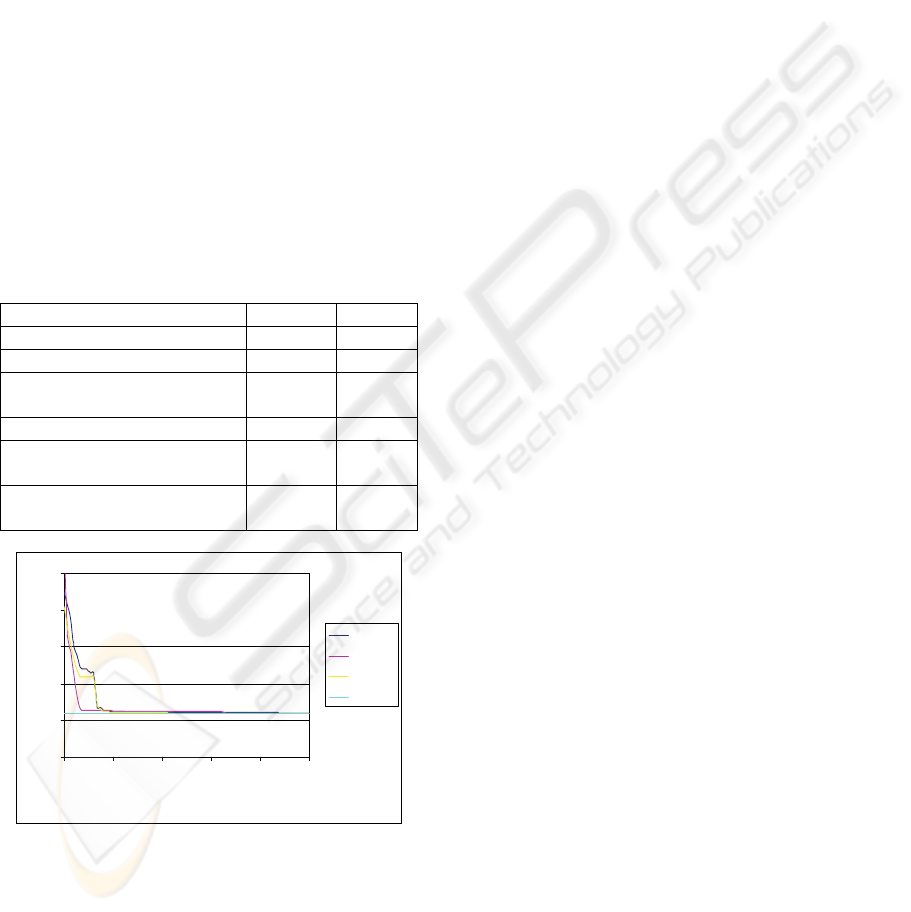

Table 1: Parameters of the Bees Algorithm for the welded

beam design problem.

Bees Algorithm parameters Symbol Value

Population n 80

Number of selected sites m 5

Number of top-rated sites out

of m selected sites

e 2

Initial patch size ngh 0.1

Number of bees recruited for

best e sites

nep 50

Number of bees recruited for

the other (m-e) selected sites

nsp 10

Figure 3: Evolution of the lowest cost in each iteration.

Figure 3 shows how the lowest value of the

objective function changes with the number of

iterations (generations) for three independent runs of

the algorithm. It can be seen that the objective

function decreases rapidly in the early iterations and

then gradually converges to the optimum value.

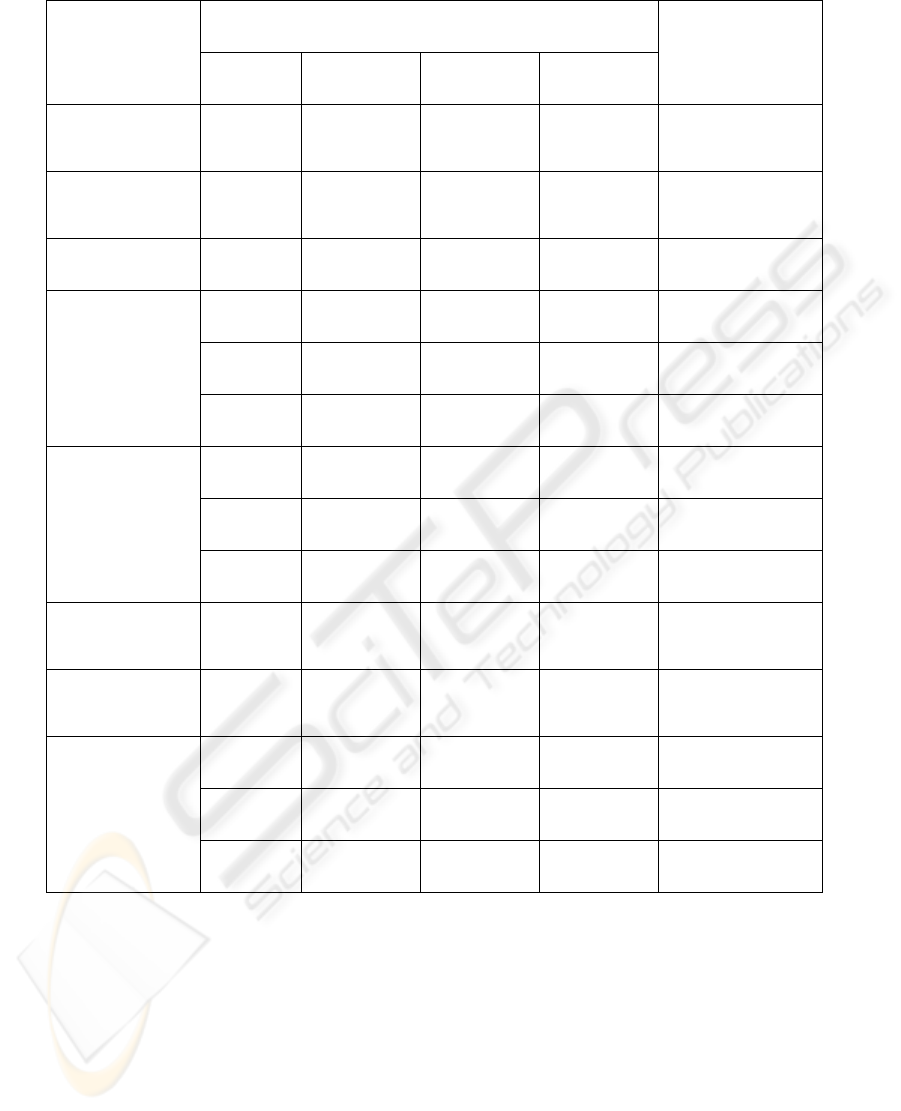

A variety of optimisation methods have been

applied to this problem by other researchers

(Ragsdell and Phillips, 1976, Deb, 1991, Leite and

Topping, 1998). The results they obtained along

with those of the Bees Algorithm are given in Table

2. APPROX is a method of successive linear

approximation (Siddall, 1972). DAVID is a gradient

method with a penalty (Siddall, 1972). Geometric

Programming (GP) is a method capable of solving

linear and nonlinear optimisation problems that are

formulated analytically (Ragsdell and Phillips,

1976). SIMPLEX is the Simplex algorithm for

solving linear programming problems (Siddall,

1972).

As shown in Table 2, the Bees Algorithm

produces better results than almost all the examined

algorithms including the Genetic Algorithm (GA)

(Deb, 1991), an improved version of the GA (Leite

and Topping, 1998), SIMPLEX (Ragsdell and

Phillips, 1976) and the random search procedure

RANDOM (Ragsdell and Phillips, 1976). Only

APPROX and DAVID (Ragsdell and Phillips, 1976)

produce results that match those of the Bees

Algorithm. However, as these two algorithms

require information specifically derived from the

problem (Leite and Topping, 1998), their application

is limited. The result for GP is close to those of the

Bees Algorithm but GP needs a very complex

formulation (Ragsdell and Phillips, 1976).

5 CONCLUSIONS

A constrained optimisation problem was solved

using the Bees Algorithm. The algorithm converged

to the optimum without becoming trapped at local

optima. The algorithm generally outperformed other

optimisation techniques in terms of the accuracy of

the results obtained. A drawback of the algorithm is

the number of parameters that must be chosen.

However, it is possible to set the values of those

parameters after only a few trials.

Indeed, the Bees Algorithm can solve a problem

without any special domain information, apart from

that needed to evaluate fitnesses. In this respect, the

Bees Algorithm shares the same advantage as global

search algorithms such as the Genetic Algorithm

(GA). Further work should be addressed at reducing

the number of parameters and incorporating better

learning mechanisms to make the algorithm even

simpler and more efficient.

0

2

4

6

8

10

0 1530456075

Gene ration x 10

-1

Cost

BA Run 1

BA Run 2

BA Run 3

Optimum

THE BEES ALGORITHM AND MECHANICAL DESIGN OPTIMISATION

253

Table 2: Results for the welded beam design problem obtained using the Bees Algorithm and other optimisation methods.

Methods

Design variables

Cost

h l t b

APPROX

(Ragsdell and

Phillips, 1976)

0.2444 6.2189 8.2915 0.2444 2.38

DAVID (Ragsdell

and Phillips,

1976)

0.2434 6.2552 8.2915 0.2444 2.38

GP (Ragsdell and

Phillips, 1976)

0.2455 6.1960 8.2730 0.2455 2.39

GA (Deb, 1991)

Three

independent

runs

0.2489 6.1730 8.1789 0.2533 2.43

0.2679 5.8123 7.8358 0.2724 2.49

0.2918 5.2141 7.8446 0.2918 2.59

IMPROVED GA

(Leite and

Topping, 1998)

Three

independent

runs

0.2489 6.1097 8.2484 0.2485 2.40

0.2441 6.2936 8.2290 0.2485 2.41

0.2537 6.0322 8.1517 0.2533 2.41

SIMPLEX

(Ragsdell and

Phillips, 1976)

0.2792 5.6256 7.7512 0.2796 2.53

RANDOM

(Ragsdell and

Phillips, 1976)

0.4575 4.7313 5.0853 0.6600 4.12

BEES

ALGORITHM

Three

independent

runs

0.24429 6.2126 8.3009 0.24432 2.3817

0.24428 6.2110 8.3026 0.24429 2.3816

0.24432 6.2152 8.2966 0.24435 2.3815

ACKNOWLEDGEMENTS

The research described in this paper was performed

as part of the Objective 1 SUPERMAN project, the

EPSRC Innovative Manufacturing Research Centre

Project and the EC FP6 Innovative Production

Machines and Systems (I*PROMS) Network of

Excellence.

REFERENCES

Bonabeau, E., Dorigo, M. & Theraulaz, G. (1999) Swarm

Intelligence: from Natural to Artificial Systems, New

York, Oxford University Press.

Camazine, S., Deneubourg, J.-L., Franks, N. R., Sneyd, J.,

Theraula, G. & Bonabeau, E. (2003) Self-Organization

in Biological Systems, Princeton, Princeton University

Press.

Deb, K. (1991) Optimal Design of a Welded Beam via

Genetic Algorithm. AIAA Journal, 29, 2013-2015.

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

254

Leite, J. P. B. & Topping, B. H. V. (1998) Improved

Genetic Operators for Structural Engineering

Optimization. Advances in Engineering Software, 29,

529-562.

Pham, D. T., Ghanbarzadeh, A., Koc, E. & Otri, S.

(2006a) Application of the Bees Algorithm to the

Training of Radial Basis Function Networks for

Control Chart Pattern Recognition. IN TETI, R. (Ed.)

5th CIRP International Seminar on Intelligent

Computation in Manufacturing Engineering (CIRP

ICME '06). Ischia, Italy.

Pham, D. T., Ghanbarzadeh, A., Koc, E., Otri, S., Rahim,

S. & Zaidi, M. (2005) Technical Report MEC 0501-

The Bees Algorithm. Cardiff, Manufacturing

Engineering Centre, Cardiff University.

Pham, D. T., Ghanbarzadeh, A., Koc, E., Otri, S., Rahim,

S. & Zaidi, M. (2006b) The Bees Algorithm, A Novel

Tool for Complex Optimisation Problems. 2nd Int

Virtual Conf on Intelligent Production Machines and

Systems (IPROMS 2006). Oxford, Elsevier.

Ragsdell, K. M. & Phillips, D. T. (1976) Optimal Design

of a Class of Welded Structures Using Geometric

Programming. ASME Journal of Engineering for

Industry, 98, 1021-1025.

Rekliatis, G. V., Ravindrab, A. & Ragsdell, K. M. (1983)

Engineering Optimisation Methods and Applications,

New York, Wiley.

Seeley, T. D. (1996) The Wisdom of the Hive: The Social

Physiology of Honey Bee Colonies, Cambridge,

Massachusetts, Harvard University Press.

Shigley, J. E. (1973) Mechanical Engineering Design,

Ney York, McGraw-Hill.

Siddall, J. N. (1972) Analytical Decision-making in

Engineering Design, New Jersey, Prentice-Hall.

Von Frisch, K. (1976) Bees: Their Vision, Chemical

Senses and Language, Ithaca, N.Y., Cornell University

Press.

THE BEES ALGORITHM AND MECHANICAL DESIGN OPTIMISATION

255