HYDROGEN POWERED CAR CONTROL SYSTEM

Srovnal Vilem, Koziorek Jiri, Horak Bohumil

Department of Measurement and Control, FEECS,VSB

Technical University of Ostrava, 17. listopadu 15, 708 3, Ostrava-Poruba, Czech Republic

Adam George, Garani Georgia

Technological Educational Institute of Larissa, Greece

Keywords: Vehicle Control System, Distributed Control System, Multi-agents, Learning, Optimizing.

Abstract: The main goal of the research project was designing and realization a distributed control system of the

hydrogen powered prototype car. Next goals of project were real time control, speed and final time

optimizing with minimal fuel consumption and monitoring of driver biomedical parameters. The control

system was realized by several mobile embedded systems and one central system. The embedded systems

hardware was realized with Freescale processors and communication CAN bus. Central system hardware

was realized by notebook and communication with embedded systems in car was realized by GSM

communication. Control system software using of multi-agent technology with dynamic mutual negotiation

of mobile system parts. This task allows in a form of control system for prototype race car modelling of

distributed control system. The real hardware and software model is also important motivation for extended

research.

1 INTRODUCTION

A team of several specialists and students of

Department of Measurement and Control, VSB-

Technical University of Ostrava have designed and

realized a prototype of hydrogen powered car based

on fuel cell technology and electrical DC drive. The

project is called HydrogenIX and the works and

testing activities came through between October

2004 and today.

Figure 1: The HydrogenIX car.

The motivations for the project are following:

• There is The Laboratory of Fuel Cells at

Department of Measurement and Control. The

development of mentioned car is first

application of fuel cell in mobile system at the

laboratory.

• Activation of the interest of students, Ph.D.

students, researchers and public in renewable

and alternative energy sources.

• Involve students to design and development

activities in interesting area and demonstrate the

result of the project in a competition of

economization of energy in mobile vehicles.

The competition is called Shell Eco-Marathon.

The Shell Eco-Marathon is a competition

organized by Shell Company and take place at race

circuit in Nogaro, France. Teams of whole Europe

try to reach highest distance with 1 liter of petrol, in

the other words to have lowest consumption of the

fuel. Even if the majority of teams use petrol engines

in their vehicles, there are also vehicles powered by

diesel, LPG, hydrogen and other alternative

energies. The results are obtained by recalculating

using calorific value of each type of fuel. So that it is

possible to compare different types of fuel.

62

Vilem S., Jiri K., Bohumil H., George A. and Georgia G. (2008).

HYDROGEN POWERED CAR CONTROL SYSTEM.

In Proceedings of the Fifth International Conference on Informatics in Control, Automation and Robotics - RA, pages 62-66

DOI: 10.5220/0001485900620066

Copyright

c

SciTePress

2 CONTROL SYSTEM

The vehicle powered by hydrogen fuel cell needs

electronic a control system assuring operation of its

different parts. The complex electronic control is

necessary already for basic operation of the vehicle,

because there are lots of subsystems that have to be

coordinated and controlled. The control system

assures especially following tasks:

• Control of fuel cell operation – hydrogen input

valve control, combustion products output valve

control, fuel cell fan control, coupling of

produced electrical energy to electric DC-drive

system.

• Control of DC-drive system – motor current

control, speed control.

• Processing security tasks – assuring safe

operation of fuel cell system and drive system,

processing of hydrogen detector information,

temperature measuring.

• Managing the driver control panel – complete

interface to pilot that allows controlling the car

– start/stop, speed set point, time measuring,

emergency buttons and indicators.

• Creating data archives with saved process

variables – saving important process data to

archives that can be then exported and analyzed.

• Sending actual data to display panel in car –

display panel in the car is the “process”

visualization of the system. All important data

are online displayed on it.

• Communication with PC monitoring station –

control system send data and receive commands

from PC monitoring station using wireless

communication system.

The car onboard control system is built on

embedded system with Freescale HC12

microprocessors. The control system has distributed

architecture and it is divided into two parts:

• A fuel-cell control block that controls whole

installation of the fuel-cell, DC drive system

and security tasks.

• An interface control block that assures interface

to the pilot, a wireless communication with PC

monitoring station. This block contains the text

display, which is used to monitor important

parameter of the car and makes possible to do

important settings.

Both part of control system are connected via

CAN communication network. The wireless

communication between the car and with PC

monitoring station is realized by GSM

communication – GPRS data transfer. The data

transfer is realized by dial-up connection.

The PC monitoring station operates a process

visualization application that is realized by SCADA

system Promotic. The process visualization displays

all parameters measured during the car operation, all

the system states and alarms, make possible to

display trends of required values and log measured

data in data archives.

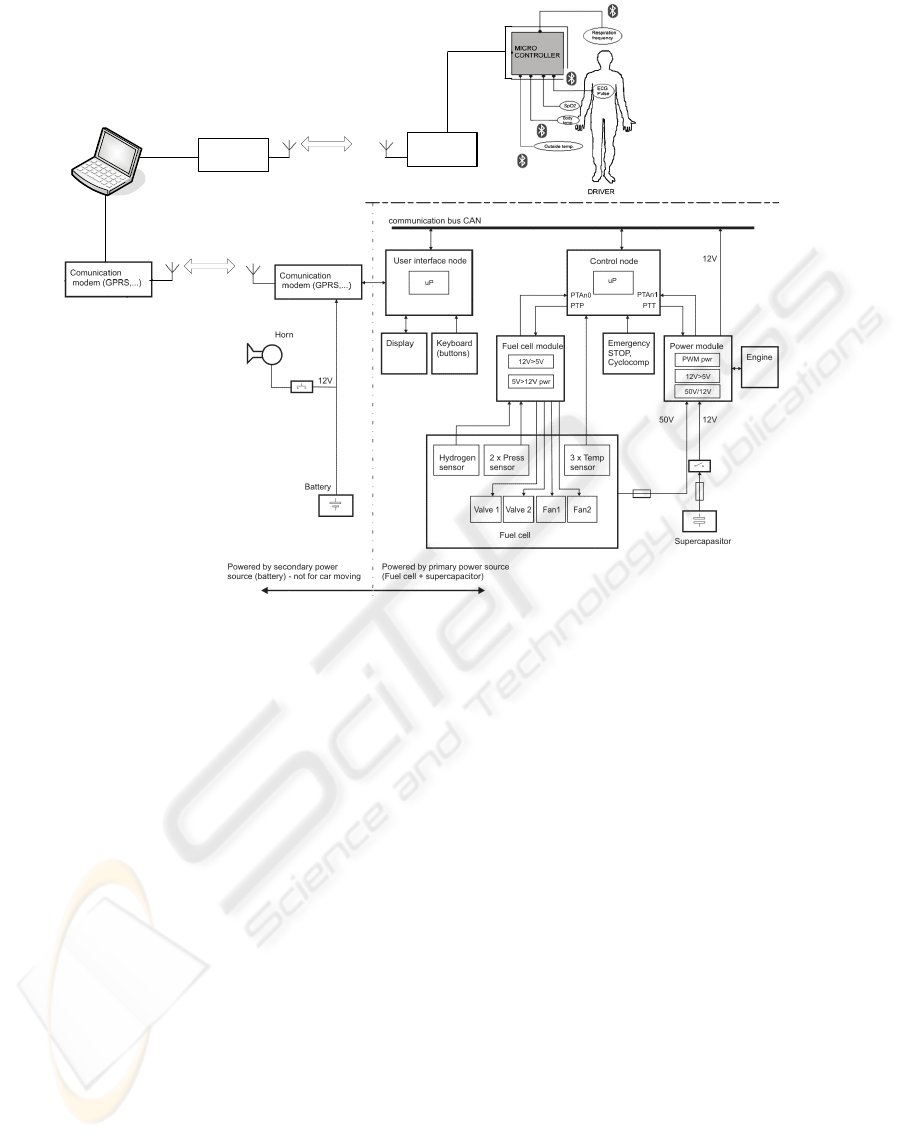

The complete block diagram of the car control

system is demonstrated in figure 3 and realization in

figure 2.

Figure 2: The HydrogenIX car control electronic testing

workplace.

2.1 Operating Values Monitoring

The car control system monitors a lot of variables.

Some of these variables are used for basic control

activities, the others are used for optimization of

operation. The measured variables are following:

• Electrical variables – fuel cell voltage and

current, motor voltage and current, voltages of

super-capacitor and on-board battery.

• Non-electrical variables – temperatures and

pressures in fuel cell circuit, car speed.

• The system is ready for measurement of others

supplementary variables that can be used for

optimization of the operation – wind speed,

outside temperature, track position.

HYDROGEN POWERED CAR CONTROL SYSTEM

63

Figure 3: The HydrogenIX car control electronic block scheme.

2.2 Bio-telemetry System

The vehicle is also equipped by bio-telemetry

system that makes possible to monitor biological

functions of the pilot. The embedded portable

telemetry system of biological parameters serves for

reading and wireless data transfer of measured

values of selected biological parameters to far

computer.

The telemetric system can be used for real time

monitoring of the basic life functions of race driver.

The driver has to be very concentrated and the

reactions of driver have to be very quick. The

telemetry system provides better control of physical

and psychical condition of driver during race. It is

possible to analyze effect of a stress situations, high

speed and high psychical stress on the race driver

during the race and crisis situation, more precisely

during high physical and psychical stress.

For biophysical monitoring were chosen these

parameters: Electrocardiography – ECG, Pulse

frequency, Oxygen saturation – SpO2, Body

temperature, Outside temperature and Respiration

frequency.

3 MULTI-AGENT CONCEPT OF

CONTROL SYSTEM

The track passage optimization task of the laboratory

car with minimal energy consumption in real time is

quite complex.

Range of inputs and outputs of the control

system, communication flows and safety of

operation require the adaptability at occurred

situations and environment changes – strategy

control by multi-agent systems (MAS). Among basic

expected properties of proposed MAS belong a

strategic, targeted system behavior, robustness and

adaptability at environment changes.

This can be provided by decentralization of

control activities in the control system, by

distribution of functions and by modularity based on

fundamental elements – agents (Srovnal, V.,

Pavliska, A., 2002).

Comunication

modem

Comunication

modem

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

64

3.1 MAS Structure Description

The higher level of control system is represented by

a personal computer. In the PC the signal from

differentially GPS positioning system may be

entered, which represents the relative coordinate

system of environment – allow the precise of the

position of the race car on the circuit. At the output

is connected GPRS communication modem which

transmits commands for race car.

The algorithm of agent’s cooperation was

proposed with the control agent on a higher level.

The control agent determines the required behavior

of the whole control system as the response to the

dynamic behavior of car and to the one‘s own global

strategy in the task and knowledge about the last

situations, which are saved in the database. The

agent on a higher level controls the other agents

(Srovnal, V., Horák, B. and Bernatik, R., 2004).

The separate task is the transformation which

converts the digital data position into the object

coordinates (car position on the circuit) which are

saved in the database of the circuit. This database is

common for all agents in the control system. Each

agent sees actual the whole data and is capable of

controlling its behavior in a qualified way. The basic

characteristic of a control algorithm of a subordinate

agent is the independence on the number of decision

making agents for car on the circuit.

Agent system has a common goal, to control of

the car during race with optimizing - minimizing of

fuel consumption and control of critical speed. For

successful assertion of one’s own race strategy the

extraction and knowledge of changeable

environment and learning capabilities are very

important.

Main architecture of such hybrid agent system is

characterized via:

• Layered control. Agent is described by number

layers of abstraction and complexity.

• Layered knowledge base.

• Bottom-up activating

• Top-down execution.

Agent is connected with environment through

interface with sensors, actuators and communication

module. Control is allowed through layers at three

levels: reactive layer, layer of local planning, and

layer of cooperative planning. They are use

information from knowledge bases (“world” model,

“mental” model and “social” model), (Garani, G.

and Adam, G., 2006).

Reactive layer is responsible for adequate

reactions at the stimulations from environment that

require immediate reaction and execution of called

procedures from local planning layer. Fundamental

characterization of such layer is:

• Use of effective algorithm of compare with

patterns of behavior. Serve to pick-out of the

actual situations.

• Situation description for timely actual reactions

at received stimulus.

• Hard-wired links. Recognized situations are fix-

connected with targets for reactive behavior.

Immediate execution of program actions.

• Solution request of situations not–corresponding

with couples situation-action are transmitted in

local planning layer.

• Execution liability is coming from local

planning layer activate procedures of reactive

layer patterns of behavior.

Some situations can be not solved by execution

of template action like an answer to stimulation from

environment only, but they require certain level of

deliberation. A function of plans creation for solving

of the targets performs the layer of local planning.

Local planning layer have such fundamental data

structures:

• Targets – state sets. Sets are characterized by

attributes that are fulfilled at reaching targets.

• Planning – planning from second principles.

Sets of plans are defined before in data structure

– plans library. Mapping of target sets to plans

library is existed. For each target is possible to

assign the plan for its reaching.

• Plans library – contain the plans for reaching of

agent targets.

• Scheduling – secure the timely limited plans

stratification. Be created the plan schedules like

the step sequences, to execute.

3.2 Cooperative Planning Layer

A basic control cycle of cooperative planning layer

is creation, interpretation, decision making and

execution of local plans.

In first phase the reports from nearby layers are

processed. Reactive layer sends requests to solve

new task or status of executed behavior templates.

Schedules of active plans are actualized.

Subsequently the status from reactive layer executed

procedures is checked.

In case of successful procedures finalization the

plan is erased from accumulator. Reports from

highest layer are related to creation or cancellation

of commitment for the plan execution at local base

or plan evaluation. In case of plan execution request

or his cancellation the accumulator of active plans is

actualized.

The plan availability is a result of difference of

his relative value for the agent and his costs for

execution. The plan value is derived from target

HYDROGEN POWERED CAR CONTROL SYSTEM

65

value that is possible reach by plan. The plan costs

are determined by function that assigns for every

plan a real number calculated at basis of his

fundamental action costs according to specific rules.

4 CONCLUSIONS

The algorithm of the control system should be

proposed in a way so that it would ensure the

requirements for the immediate response of control,

so that the system of race car would be controlled in

real-time. That is why, it is very important so that

the algorithm for critical speed and fuel consumption

would be optimized. The system response should be

shorter than the time between two data frames from

a GPS station. In the event that this limit is

exceeded, the frame is cut out and the control quality

may be decreased.

The main possibilities of algorithm adjustment

are as follows:

• Dynamic control in the control and decision

module of a control agent.

• The control and decision modules and

communication protocol of the decision agents.

• The strategy of planning in the control model of

the action agent.

• Learning of a race strategy and using the

extraction results for decision rules generation as

a part of the rules decision database of a decision

agent.

ACKNOWLEDGEMENTS

The Grant Agency of Czech Academy of Science

supplied the results of the project No. p.

1ET101940418 with subvention.

The paper was also supported by KONTAKT

CZ-GR Project No. 7-2006-32 – “Communication

Nets in Distributed Systems”.

REFERENCES

Srovnal, V., Pavliska, A., 2002. Robot Control Using

UML and Multi-agent System. In: Proceeding 6th

World Multiconference SCI 2002. Orlando 2002,

pp.306-311

Srovnal, V., Horák, B., Bernatik, R., 2004. Strategy

extraction for mobile embedded control systems apply

the multi-agent technology. Lecture notes in computer

science, Vol. 3038. Springer-Verlag, Berlin

Heidelberg 2004, pp. 631-637.

Garani, G., Adam, G., 2006. Qualitative Modelling of

Manufacturing Machinery. In: Proceedings of the

32nd IEEE Conference on Industrial Electronics, Paris

2006, pp. 3591-3596

ICINCO 2008 - International Conference on Informatics in Control, Automation and Robotics

66