OBJECTIVE EVALUATION OF SEAM PUCKER USING AN

ADAPTIVE NEURO-FUZZY INFERENCE SYSTEM

K. L. Mak and Wei Li

Department of Industrial and Manufacturing System Engineering

University of Hong Kong, Pokfulam Road, Hong Kong

Keywords: Image processing, Pattern recognition, Seam pucker, ANFIS.

Abstract: Seam pucker evaluation plays a very important role in the garments manufacturing industry. At present,

seam puckers are usually evaluated by human inspectors, which is subjective, unreliable and time-

consuming. With the developments of image processing and pattern recognition technologies, an automatic

vision-based seam pucker evaluation system becomes possible. This paper presents a new approach based

on adaptive neuro-fuzzy inference system (ANFIS) to establish the relationship between seam pucker grades

and textural features of seam pucker images. The evaluation procedure is performed in two stages: features

extraction with the co-occurrence matrix approach, and classification with ANFIS. Experimental results

demonstrate the validity and effectiveness of the proposed ANFIS-based method.

1 INTRODUCTION

Quality control is vital for garments manufacturing

industries to increase competitiveness in national

and international markets. Seam pucker evaluation is

a key requirement of quality control and assessment

in garments manufacturing. Seam pucker is defined

as the ridges, wrinkles, and corrugations running

along the seam line of garments, and has been

regarded as one of the most serious faults in garment

manufacturing. It is usually caused by improper

selection of sewing parameters and material

properties, which results in unevenness on fabrics

being stitched together, thus impairing their aesthetic

values. Due to the importance of seam pucker

evaluation, some grading measurements have been

developed. The most widely used standards are

produced by AATCC (American Association of

Textiles Chemists and Colorists). In these standards,

a set of photographs (Figure 1) shows five standard

classes in descending order of severity, from class 5

(no pucker) to class 1 (the most severe pucker).

Using this method, observers compare each seam

sample with the standard photographs and assign a

grade according to their similarity. However, this

human inspection process is known to be subjective,

inefficient and unreliable. Since quality control plays

a prominent role in garment manufacturing, the

ability to evaluate seam puckers and to solve the

seam pucker problem in the manufacturing process

becomes vital. Automated vision-based inspection of

seam puckers is therefore highly desired.

Figure 1: Photographic standards for subjective pucker

inspection by the AATCC method (Claus, 1999).

With the development of image processing and

pattern recognition technologies, some research

(Galuszynski, 1986, Inui, et.al., 1991, Kawabata and

Niwa, 1996, Park and Kang, 1997, Fan, et.al., 1999,

Claus, 1999, Aibara et.al., 2000) has been conducted

over the years to evaluate seam puckers objectively.

Nevertheless an economical and accurate method is

still absent. In this paper, an objective evaluation

method based on the technique of image processing

234

L. Mak K. and Li W. (2008).

OBJECTIVE EVALUATION OF SEAM PUCKER USING AN ADAPTIVE NEURO-FUZZY INFERENCE SYSTEM.

In Proceedings of the Third International Conference on Computer Vision Theory and Applications, pages 234-239

DOI: 10.5220/0001080902340239

Copyright

c

SciTePress

and neuro-fuzzy is presented to grade seam puckers

with high accuracy.

2 ANFIS

The combination of fuzzy logic with architectural

design of neural network led to creation of neuro-

fuzzy systems which benefit from feed forward

calculation of output and back-propagation learning

capability of neural networks, while keeping

interpretability of a fuzzy system (Jang, et.al. 1997).

Many neuro-fuzzy structures have been proposed

and some were widely used, among which Jang’s

ANFIS (Adaptive Neuro-Fuzzy Inference System)

(Jang, 1993) structure is probably the most famous

one. ANFIS has good ability and performance in

system identification, pattern recognition and control,

and has been applied in many different systems. The

ANFIS has the advantage of good applicability as it

can be interpreted as local linearization modeling

and conventional linear techniques are directly

applicable.

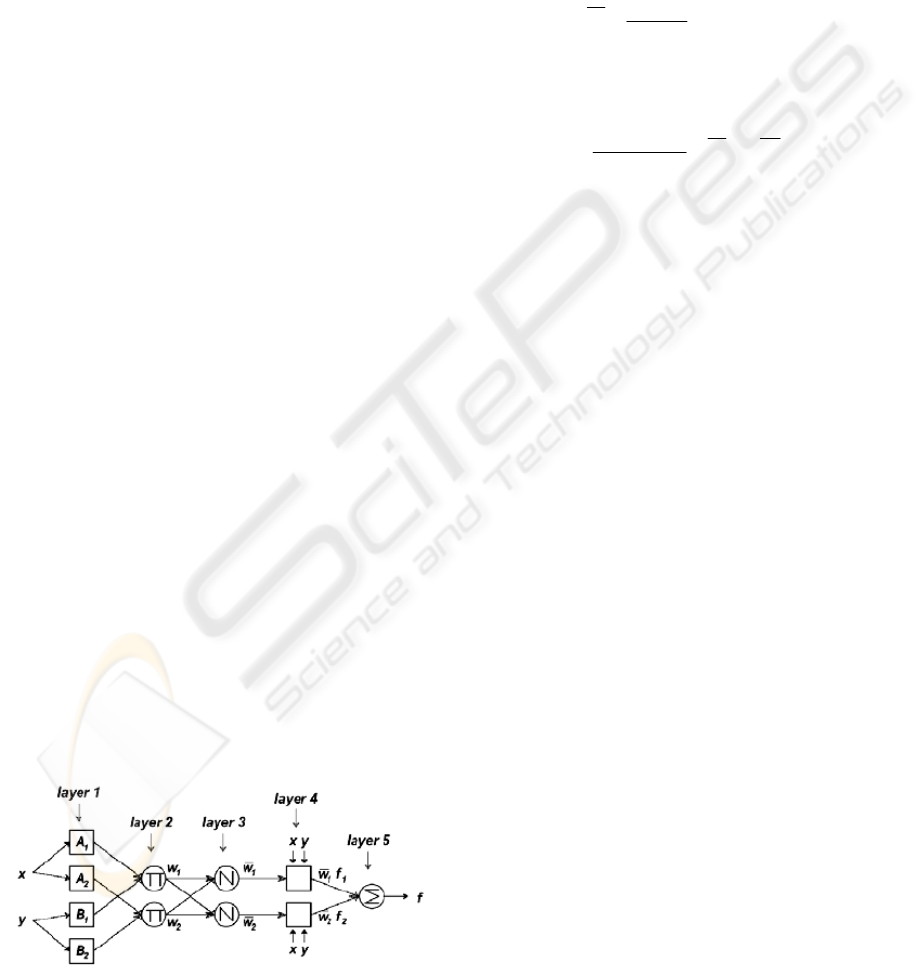

To present the ANFIS architecture, two fuzzy if-

then rules based on a first-order Sugeno fuzzy model

are considered:

Rule 1: If (x is

1

A

) and (y is

1

B ) then

(

11 11

f

px qy r=++)

Rule 2: If (x is

2

A

) and (y is

2

B ) then

(

22 22

f

px qy r=++)

where x and y are the inputs,

i

A

and

i

B are the fuzzy

sets,

i

f

are the outputs within the fuzzy region

specified by the fuzzy rule,

i

p ,

i

q and

i

r are the

design parameters that are determined during the

training process. The network structure of ANFIS to

implement these two rules is shown in Figure 2, in

which a square node (adaptive node) has parameters

while a circle node (fixed node) has none. The first

layer executes a fuzzification process, the second

layer executes the fuzzy AND of the antecedent part

of the fuzzy rules, the third layer normalizes the

Figure 2: ANFIS architecture (Jang J. R, 1993).

membership functions, the fourth layer executes the

consequent part of the fuzzy rules, and finally the

last layer computes the output of fuzzy system by

summing up the outputs of layer four.

The feed-forward equations of ANFIS with two

inputs and two labels for each input which is shown

in Figure 2 are as follow:

(

)

(

)

,1,2.

ii

iA B

wxyi

μμ

=× =

(1)

12

,1,2.

i

i

w

wi

ww

==

+

(2)

11 11

22 22

11 2 2

11 2 2

12

fpxqyr

fpxqyr

wf wf

f

wf wf

ww

=++

⎫

⇒

⎬

=++

⎭

+

==+

+

(3)

There are two adaptive layers in this ANFIS

architecture, namely the first layer and the fourth

layer. In the first layer, the modifiable parameters

relating to the input membership functions are the

antecedent parameters. In the fourth layer, the

modifiable parameters pertaining to the first order

polynomial are consequent parameters.

The task of the learning algorithm for ANFIS is

to tune all the modifiable parameters, namely

antecedent parameters and consequent parameters,

to make the ANFIS output match the given training

data. The least squares estimate (LSE) method and

the gradient descent (GD) method is always

combined to solve this problem. The training

algorithm is composed of a forward pass and a

backward pass. The LSE (forward pass) is used to

optimize the consequent parameters with the

antecedent parameters fixed. Once the optimal

consequent parameters are found, the backward pass

starts, always using the gradient descent method, to

adjust optimally the antecedent parameters.

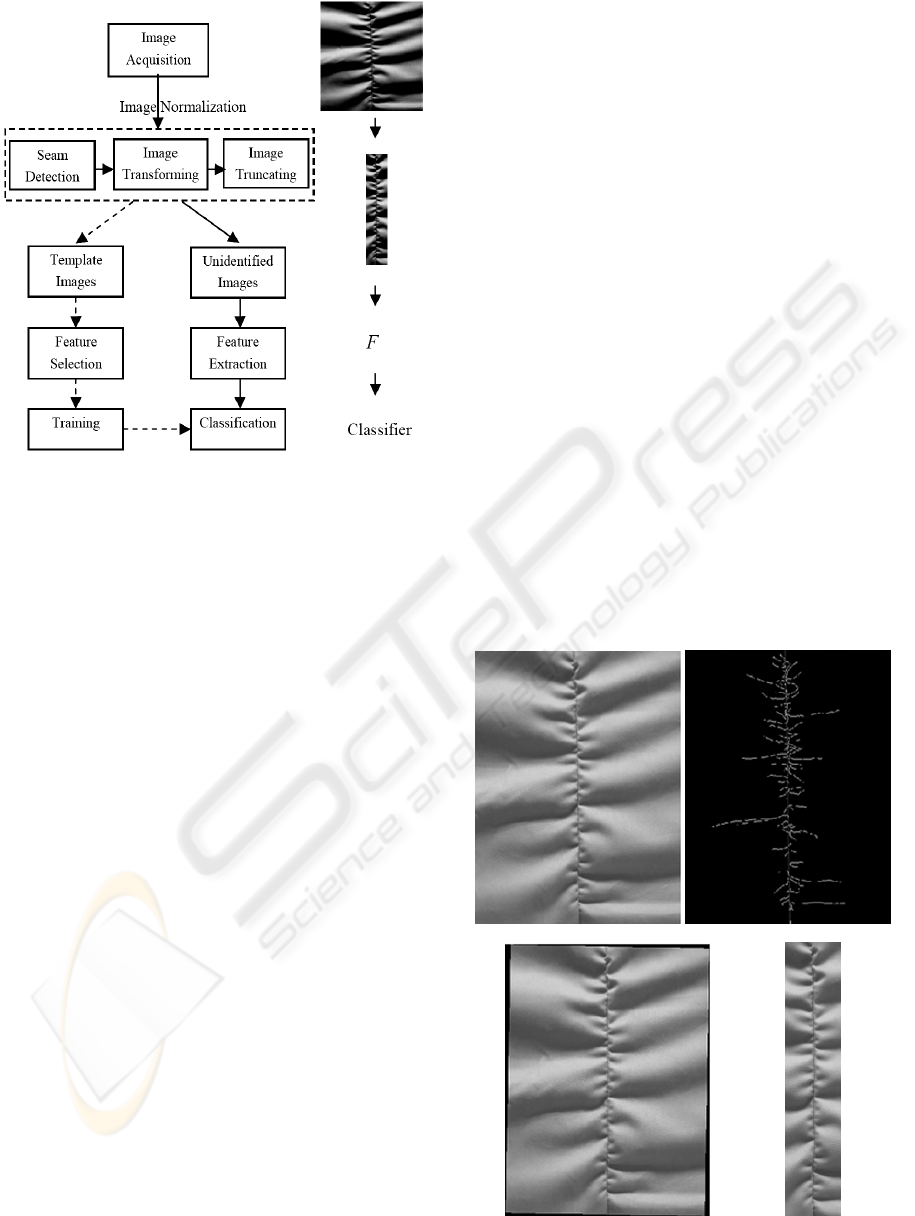

3 PROCEDURE

Figure 3 shows the procedure of our classification

system for seam puckers. The images of seam

puckers are acquired with a CCD camera system,

and then an algorithm for detecting the seam lines is

applied. Based on the defined seam lines the grey-

level images are normalized (including transforming

and truncating). The normalized images are divided

into two sets, one is for training and the other is for

testing.

OBJECTIVE EVALUATION OF SEAM PUCKER USING AN ADAPTIVE NEURO-FUZZY INFERENCE SYSTEM

235

Figure 3: Block diagram of the classification system.

The learning process uses the training sets to

develop an identification system for seam puck

grading. Finally the trained neural network can serve

as the seam pucker classifier instead of human

inspectors.

3.1 Image Acquisition

The first problem faced is to acquire surface

contours of the seam pucker samples. Two main

instruments of information acquisition of seam

pucker are CCD cameras and laser scanners. Laser

scanners have been used (Kawabata and Niwa, 1996,

Park and Kang, 1997, Fan, et.al., 1999) to obtain

geometrical profile of puckers by measuring surface

height variation. However the cost of a laser scanner

makes it too expensive for industrial applications.

Moreover the methods they used to acquire

information with laser scanner require the laser

probe move parallel with the direction of the seam.

This is not easy to execute for quality control

measurements of seam puckers are normally done on

completed garments where the garments are usually

hanged up. CCD camera system is a convenient and

low-cost way for image acquisition, which can yield

good resolution images and is more similar to

human’s judgment measure. To capture high quality

images, illumination equipment is necessary.

Halogen-tungsten lamp is inexpensive and durable,

and after setting a light filter paper the brightness is

very homogeneous, therefore it is used as the

lighting source. The sample images acquired by the

CCD camera are 210mm long and 158mm wide with

a resolution of 640×480 pixels.

3.2 Image Normalization

In order to increase the accuracy of seam pucker

evaluation, the same areas should be investigated for

classification in both sides of the seam lines of

different samples. However in practice it is very

difficult to acquire all the images with the seam lines

in the same position. Moreover since the area far

from the seam line provides little useful information

for seam pucker evaluation we only care about the

area close to the seam line. Consequently an image

normalizing (positioning, transforming and

truncating) algorithm is implemented, which is able

to define the position of seam lines and obtain the

partial images we really interested in.

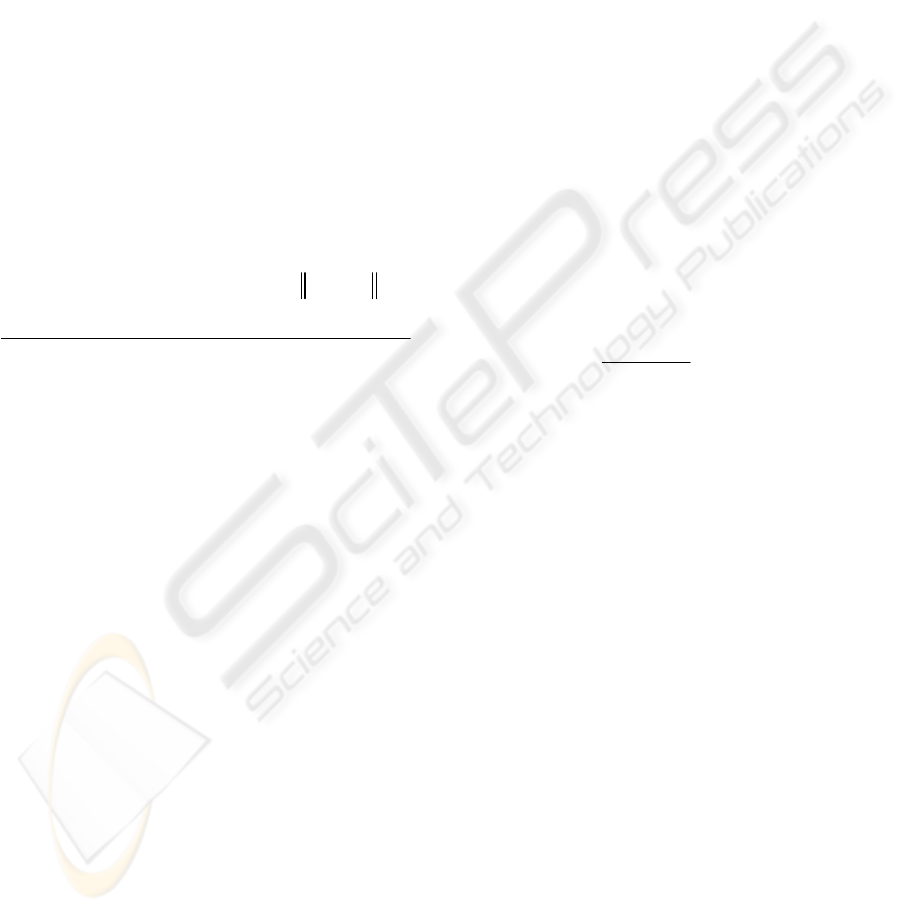

Canny edged detector is used to calculate the

binary edge images of original seam pucker images.

Afterward the seam line is found by Hough

transformation. According to the parameters of the

seam line in Hough transform the rotation and

translation can be applied to transform the seam line

to the vertical center of the image. To eliminate

redundancy and reduce data processing time, an area

of 610 × 122 pixels is acquired corresponding

200mm long and 40mm wide. The process is shown

in Figure 4.

(a) Primary Image (b) Edge image with seam line

(c) Image after rotation (d) Objective image

Figure 4: Image positioning, transforming and truncating.

VISAPP 2008 - International Conference on Computer Vision Theory and Applications

236

3.3 Feature Extraction

The most important task in the classification of seam

puckers is to extract features which can characterize

the roughness degree of various grades. In this

research feature extractions are based on three main

aspects considered in the process of inspection by

humans, they are density, depth and thickness of the

seam puckers.

Images of seam puckers can be considered as a

kind of textures, hence the co-occurrence matrix,

also known as the spatial gray-level dependence

matrix, is used for the texture analysis. A grey-level

co-occurrence matrix (GLCM) is a second-order

statistical measure of gray-level variation whose

entries are transitions between all pairs of two gray-

levels (Haralick et.al., 1973.). Let

(, ; , )Pi jd

θ

be

the transition probability from gray-level i to gray-

level j, which is defined using the following relation:

(, ; , )

(( , ),( , )) ( ) ( ): ( , )( , ) , ( , ) ( , ) ,

#

(,) ,( ,)

(,)

xy xy

Pi jd

kl mn L L L L kl mn kl mn d

Ikl iImn j

Nd

θ

θ

θ

∈××× ∠ = − =

==

=

⎧⎫

⎪⎪

⎨⎬

⎪⎪

⎩⎭

(4)

Where

∠ denotes the angle between (k, l) and (m,

n), || (k, l) - (m, n) || = d indicates that (k, l) and (m,

n) are d-pixel apart, # stands for the function

“number of”, L

x

and L

y

are the horizontal and

vertical spatial domains, I (x, y) is the image

intensity at point (x, y), and N (d, θ) is the total

number of pixel pairs in the image having angle θ

with d-pixel apart.

GLCM is a two dimensional matrix with the same

size as the number of grey-levels in an image. In this

study, the images have 256 distinct grey levels;

therefore the GLCM will be a matrix of size 256 ×

256. In order to reduce calculation time, the gray-

level range is transformed from [0, 255] to [0, 31] by

coarseness technique results in 32×32 GLCM, which

is used for evaluating the textural features of each

seam pucker sample. The new images with fewer

gray-levels are almost the same as the original ones

visually, but the calculation time is reduced

enormously.

To generate a suitable co-occurrence matrix, the

relative distance d plays a major role whose value is

always 1, 2, 3 or 4. The classification of fine textures

usually requires small values of d, whereas coarse

textures require large values of d. Here d = 4 is

selected and two angles (θ = 0, θ = 90) are

considered for evaluation. In this way, two GLCM

are calculated for each of the seam pucker samples.

Haralick proposed 14 feature measures derived

from the GLCM for image texture analysis, and each

represents certain image properties such as

coarseness, contrast, homogeneity and texture

complexity. In the present study, three of the

features: Contrast (CON), Inverse Difference

Moment (IDM) and Entropy (ENT) are used for

classifying the seam puckers because they are found

to show better discrimination than the other features.

They are described as below.

1. Contrast:

2

()(,|,)CON i j p i j d

ij

θ

=−

∑∑

(5)

Contrast is a measure of the image contrast or the

amount of local variations present in an image, in

which a zero-value denotes no contrast while larger

values corresponds to an increase in contrast or

coarseness.

2. Inverse difference moment:

2

1

(, | , )

1( )

ij

IDM p i j d

ij

θ

=

∑∑

+−

(6)

Inverse Difference Moment is a measure of lack

of local variability. A large value indicates few

varieties among different areas of an image and a

flat pixel distribution in local area.

3. Entropy:

(, | , )log( (, | , ))

ij

ENT pijd pijd

θ

θ

=−

∑∑

(7)

Entropy determines the degree of randomness or

lack of information contained in the co-occurrence

matrix. When the value of Entropy is zero, no

information is attributed to the matrix. As the

magnitude increases more uncertainty is associated

with the image region.

In Equations (5)-(7), i and j are the rows and

columns of the co-occurrence matrix. For two

directions (θ = 0, θ = 90) are considered there are

totally six features extracted from GLCM.

In general, it is not easy for humans to tell depth

information from an image. Since variance (a kind

of central moment feature) reflects the amplitude of

an image, it can be used as the depth feature of

images.

2

255

0

()()

i

DEP k p k

μ

=

=−×

∑

(8)

where

()pk is the probability of gray-level value k

OBJECTIVE EVALUATION OF SEAM PUCKER USING AN ADAPTIVE NEURO-FUZZY INFERENCE SYSTEM

237

in the histogram of an image derived

from

() /

k

pk n n= (n

k

is the number of pixels with

the gray-level k and n is the total number of pixels)

and μ is the mean of the grey-level image matrix.

Using these seven features, an inspected region of

seam pucker image is characterized by a seven-

dimensional feature vector F = (CON

0

, IDM

0

, ENT

0

,

CON

90

, IDM

90

, ENT

90

, DEP)'. The subscript 0 means

the feature is calculated from the 0 degree GLCM

and 90 is from 90 degree GLCM. In this way, N

feature vectors are produced from a set of N samples

and such feature vectors will be fed to a classifier to

classify these samples into different grades.

3.4 Evaluate Seam Pucker with ANFIS

600 seam pucker samples in uniform color are made

with 120 samples for each grade. The grades of the

seam samples are evaluated by observers (human

inspectors) according to the AATCC standards. The

600 samples are divided into two even sets, 300

samples (consisting of different seam pucker grades)

each for training and testing.

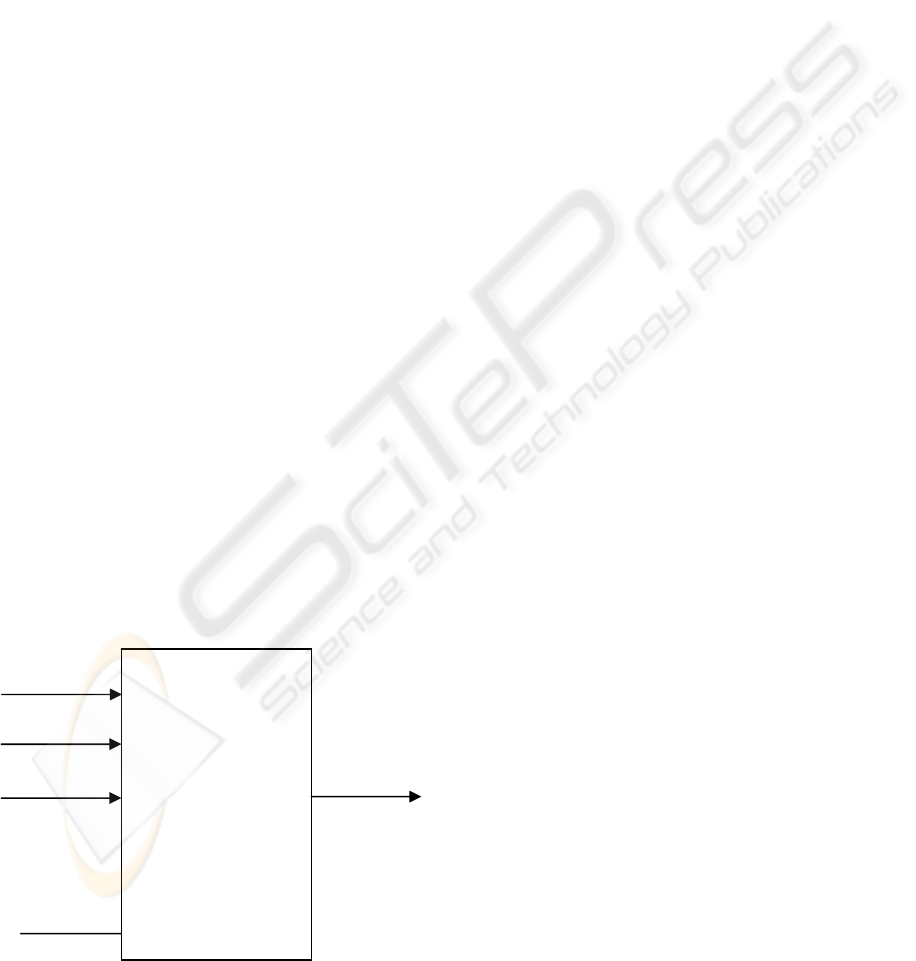

Figure 5 shows the ANFIS model of a seven-

input single-output set of seam pucker data. It should

be noted that if two linguistic terms are used in each

antecedent, which is equivalent to two Gaussian

membership functions for each input variable, then

there will be

7

2 128= fuzzy rules totally. Fixed

number of membership functions will invoke the so-

called curse of dimensionality, and causes an

explosion of the number of rules when the number

of inputs is moderately large, that is, more than four

or five. In our work, the input dimension is seven, so

an initial ANFIS structure is generated using

subtractive clustering (Chiu, 1994).

1

x

= CON

0

2

x

= IDM

0

3

x

= ENT

0

y = Grade

.

.

.

7

x

= DEP

Figure 5: A conceptual ANFIS model of seam pucker

evaluation.

Subtractive clustering is a fast and robust method

for estimating the number and location of cluster

centres for a set of data points. First the subtractive

clustering was carried out to obtain the cluster

centres which will be used as the basis for the

ANFIS to initialize fuzzy rules. The membership

functions and other rule parameters were then

optimized by the hybrid training algorithm of GD

and LSE with respect to the output error criterion,

here is the RMSE (root mean square error).

The ANFIS tool in the Fuzzy Logic Toolbox of

Matlab 7.0 (The MathWorks, Inc.) was used as a

modelling method. A maximum number of 50

epochs for training was applied and the cluster

radius for subtractive clustering is set as 0.7.

4 RESULTS AND CONCLUSIONS

The trained ANFIS classifier established the

relationship between seam pucker grades and texture

features of the seam pucker images, thus new

samples not presented for training can be evaluated

given the texture parameters. The training and

testing processes are performed 100 times with seam

pucker samples randomly divided 100 times, and the

average classification accuracy rate is 89.2%.

This paper proposed an automatic vision-based

method to evaluate seam puckers using image

analysis and pattern recognition instead of the

traditional method. The system consists of image

acquisition, image normalization, feature extraction

and neuro-fuzzy classifier (ANFIS), which showed

good behavior to evaluate the data of seam puckers.

The accuracy rate of classifications outperform that

of subjective method, which can be measured by the

“disagreement” (Claus, 1999) among a set of

subjective evaluation grades from an expert group.

This system can effectively evaluate seam puckers,

and will have a significant impact on garment

factories in alleviating problems in the evaluation

the surface quality of garments, a difficult yet

important quality control process, and assist garment

manufacturers to remain competitive in the

worldwide global market.

REFERENCES

Aibara T., Mabuchi T. and Izumida M., 2000. Automatic

evaluation of the appearance of seam puckers on suits.

IEICE Trans. Inf. & Syst, vol. E83-D, no. 7, pp. 1346-

1352.

Rule 1:

.

.

.

Rule i: If (

1

x

is

1i

A

)

and (

2

x

is

2i

A

)

and,…,

and (

7

x

is

7i

A

),

Then

7

0

1

ji j i

j

Gwxw

=

=+

∑

.

.

.

VISAPP 2008 - International Conference on Computer Vision Theory and Applications

238

Canny J.F., 1986. A computational approach to edge

detection.

IEEE Transactions on Pattern Analysis and

Machine Intelligence

, vol. 8, no. 6, pp. 679-698

Claus B., 1999. Artificial neural networks for automated

quality control of textile seams. J.of pattern

recognition

, vol. 32, pp. 1049-1060

Chiu S., 1994. Fuzzy model identification based on cluster

estimation. J. of Intelligent and Fuzzy Systems, vol. 2,

pp. 267-278.

Fan J., Lu D., MacAlpine J.M.K., andn Hui C.L.P., 1999.

Objective evaluation of pucker in 3-dimensional

garment seams.

Tex.Res. J, vol. 69, pp. 467-472.

Galuszynski S., 1986. Objective measurement of seam

pucker. In

Proc. Symposium on New Technologies for

Textiles

, July 21-23, pp. 100.

Haralick R.M., Shanmugam K., Dinstein I., 1973. Textural

Features for Image Classification.

IEEE Trans Syst,

Man Cybernet

, vol. 3, pp. 610.

Inui S., Shibuya A., and Aisaka N., 1991. Ultrasonic

measurement and quantitative evaluation of seam

puckering.

Sen-I Gakkaishi, vol. 47, no. 6, pp. 299.

Jang J. R, Sun C, and Mizutani, 1997.

Neuro-Fuzzy and

soft computing

. prentice hall.

Jang J. R., 1993. ANFIS: Adaptive-Network-Based Fuzzy

Inference System. IEEE Trans. on System, man, and

cybernetic

, vol. 23, no. 3, pp. 665-685

Kawabata S., Niwa M., 1996. An experiment on human

sensory measurement and its objective measurement:

case of the measurement of a seam pucker level.

Proceedings of 25th Textile Research Symposium on

Mount Fuji, Japan

, pp. 85-88.

Park C.K., Kang T. J., 1997. Objective rating of seam

pucker using neural networks, 1997. Text. Res. J., vol.

67, pp. 494-502.

OBJECTIVE EVALUATION OF SEAM PUCKER USING AN ADAPTIVE NEURO-FUZZY INFERENCE SYSTEM

239