SMART DIELECTRIC ELASTOMERS

AND THEIR POTENTIAL FOR BIODEVICES

Todd A. Gisby, Iain A. Anderson

Biomimetics Laboratory, Auckland Bioengineering Institute, The University of Auckland, Level 6, 70 Symonds Street

Auckland, New Zealand

Emilio P. Calius

Industrial Research Limited, P.O. Box 2225, Auckland, New Zealand

Shane Xie

Mechatronics Engineering, Department of Mechanical Engineering, The University of Auckland, New Zealand

Keywords: Dielectric Elastomers, Artificial Muscles.

Abstract: Dielectric Elastomer (DE) actuators are compliant, ultra light-weight electromechanical devices that can be

used as actuators, sensors, and power generators. While a relatively new technology, DE actuators can be

produced using biocompatible materials and have already exhibited excellent performance in terms of

strain, speed, pressure, specific energy density, and efficiency when compared to conventional actuation

technologies and natural muscle. Further research is required in order for promising laboratory results to be

translated into real-world applications, particularly in the areas of modelling and control, but the potential

for multiple functions to be integrated into a single element is an exciting prospect for flexible smart

structures and biodevices.

1 INTRODUCTION

Dielectric Elastomer (DE) actuators are compliant,

ultra-light weight electromechanical devices that are

emerging as an attractive emerging technology for a

range of biomedical applications. They are

fabricated from inexpensive biocompatible polymers

that have highly tuneable material properties. They

are also scale invariant, operate silently and

efficiently over a range of speeds, and are capable of

being used not only as actuators, but also as sensors

and power generators (Kornbluh, 2004).

DE actuators have demonstrated remarkable

performance characteristics in terms of active stress,

strain, strain rate, energy density and

electromechanical efficiency. Their unique

properties offer a number of advantages with respect

to weight, scalability, and simplicity of design over

conventional transducer technologies such as

electrostatics, piezoelectrics, electromagnetics, and

shape memory alloys (Bar-Cohen, 2004; Kornbluh

et al., 2004; Madden et al., 2004). They also

compare very favourably with human skeletal

muscle (Hunter and Lafontaine, 1992).

Table 1 compares the key performance figures of

DE actuators with those of other tranducer

technologies. While it is apparent that DEs do not

excel in every category, it is clear that their key

strength lies in their excellent overall performance.

2 DIELECTRIC ELASTOMER

OPERATING PRINCIPLE

2.1 Basic DE Structure

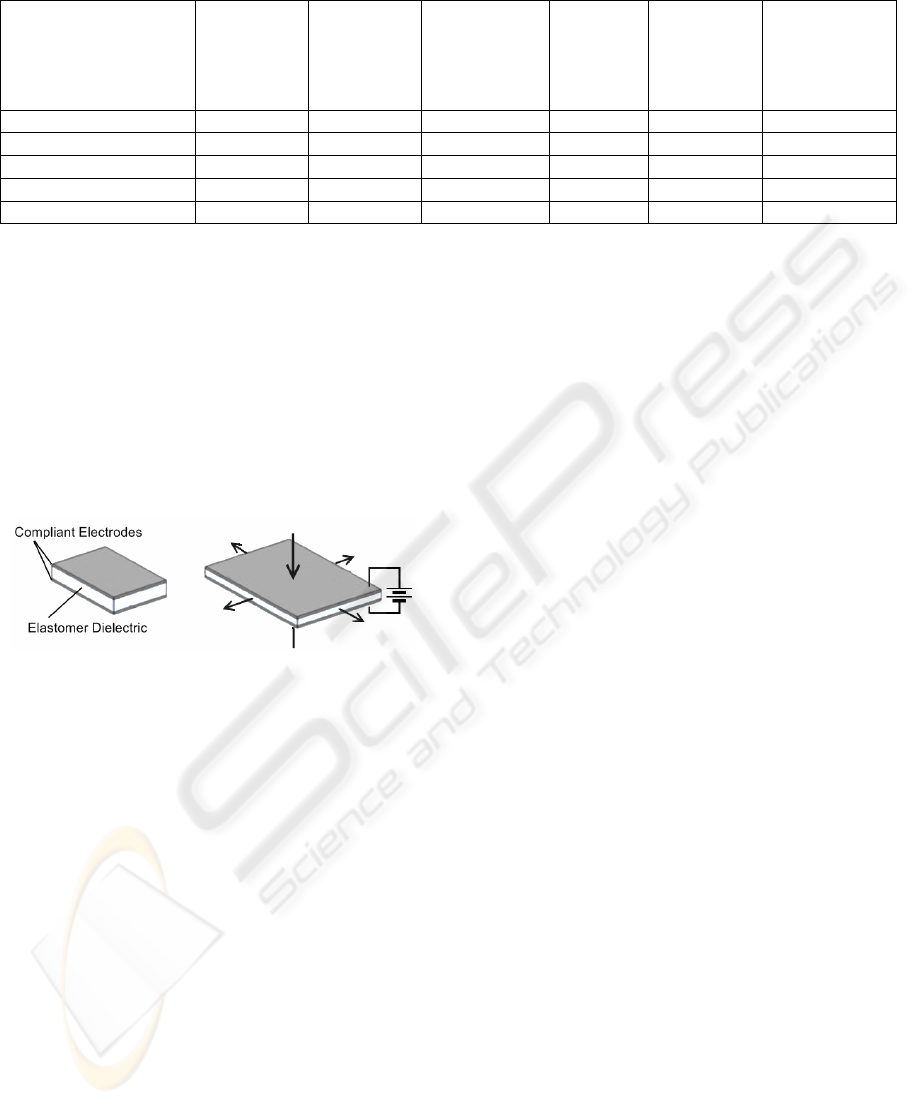

A DE actuator is a compliant capacitor consisting of

an incompressible soft polymer membrane dielectric

with compliant electrodes applied on both sides.

When used as an actuator, the charge

accumulated on the electrodes when a voltage is

285

A. Gisby T., A. Anderson I., P. Calius E. and Xie S. (2008).

SMART DIELECTRIC ELASTOMERS AND THEIR POTENTIAL FOR BIODEVICES.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 285-290

DOI: 10.5220/0001054702850290

Copyright

c

SciTePress

Table 1: Actuator Technology Comparison.

*figures taken for a VHB dielectric membrane (see section 2.4). Stress, strain, strain rate and energy density figures vary

depending on membrane material.

applied gives rise to electrostatic forces that generate

deformation in the DE. The opposite charges act to

draw the positive and negative electrodes together

while the like charges on each electrode act to

expand the area of the electrode. When the charge is

removed, the elastic energy stored in the dielectric

returns it to its original shape (Fig. 1). The linear

motion produced by this electromechanical response

can be used for actuation purposes.

Figure 1: Deactivated (left) and activated (right) states of a

simple DE actuator.

2.2 Pressure Capabilities

DEs are driven by electric fields. The pressure that

can be generated in a DE is widely accepted to be

defined by the following equation (Kofod, 2001):

P = ε

r

ε

0

(V/d)

2

(1)

Where P is the electrostatic Maxwell pressure, ε

r

is the relative permittivity of the dielectric material,

ε

0

is the permittivity of free space (ε

0

= 8.854 x 10

-12

F/m), V is the voltage and d is the thickness of the

dielectric membrane. This is twice the pressure

generated by a rigid plate electrostatic device due to

the addition of the area expansion to thickness

compression upon activation. The level of

deformation achieved at any given electric field is

dependent on the combined stiffness of the polymer

dielectric and electrode materials. The peak field

that can be applied is limited by the dielectric

breakdown strength of the DE membrane.

2.3 Power Generation

The phase difference between the electrical and

mechanical stimulus applied to a DE determines

whether it acts as an actuator or a generator. When

the mechanical deformation leads the electrical

excitation the DE will generate electrical power.

The electrical charge stored on a DE device (Q),

the capacitance of the device (C), and the voltage

difference between the electrodes (V) are related by

the following equation:

Q = CV (2)

And the electrical energy, e

electrical

, stored in the

DE is defined by:

e

electrical

= ½CV

2

(3)

Assuming, for simplicity, charge is kept constant

(i.e. the DE is electrically isolated) work done by an

external force acting to increase the separation

between the electrodes against the electrostatic

forces is converted to electrical energy and stored in

the DE. This is because the capacitance of the device

will decrease as the electrode separation increases

and the electrode area decreases, thereby causing the

voltage to increase. As the electrical energy stored in

the DE is related to the voltage squared a net

increase in the electrical energy is achieved; energy

that can then be used to power other electrical

devices.

2.4 Materials

Silicone and polyacrylate polymers have garnered

much attention in the field of DE research due to

their highly elastomeric nature and high breakdown

strengths. Silicones typically exhibit low viscous

Characteristic DEA*

(Madden et

al., 2004)

Skeletal

Muscle

(Hunter and

Lafontaine,

1992)

Piezoelectric

(Kornbluh et

al., 2004)

Electro-

magnetic

(Kornbluh

et al.,

2004)

Electrostatic

(Kornbluh

et al., 2004)

Shape Memory

Alloy

(Hunter and

Lafontaine,

1992)

Stress (MPa) 7.7 0.35 131 0.1 0.03 200

Strain (%) 380 >40 1.7 50 50 5

Relative Strain Rate Medium Medium Fast Fast Fast Slow

Energy Density (kJ/m

3

) 34,000 40 0.13 0.003 0.003 10,000

Efficiency (%) 60-80 35 >90 >90 >90 2-3

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

286

losses and some can operate in temperatures ranging

from -100ºC to 260ºC, making them well suited to

dynamic, high speed applications in harsh

environments. Their availability in monomer form

(e.g. NuSil CF19-2186, Dow Corning Sylgard 184)

enables the tuning of material properties (e.g.

stiffness, elongation at break, and geometry) and

facilitates the creation of silicone based composites

through the incorporation of additional material

prior to polymerization.

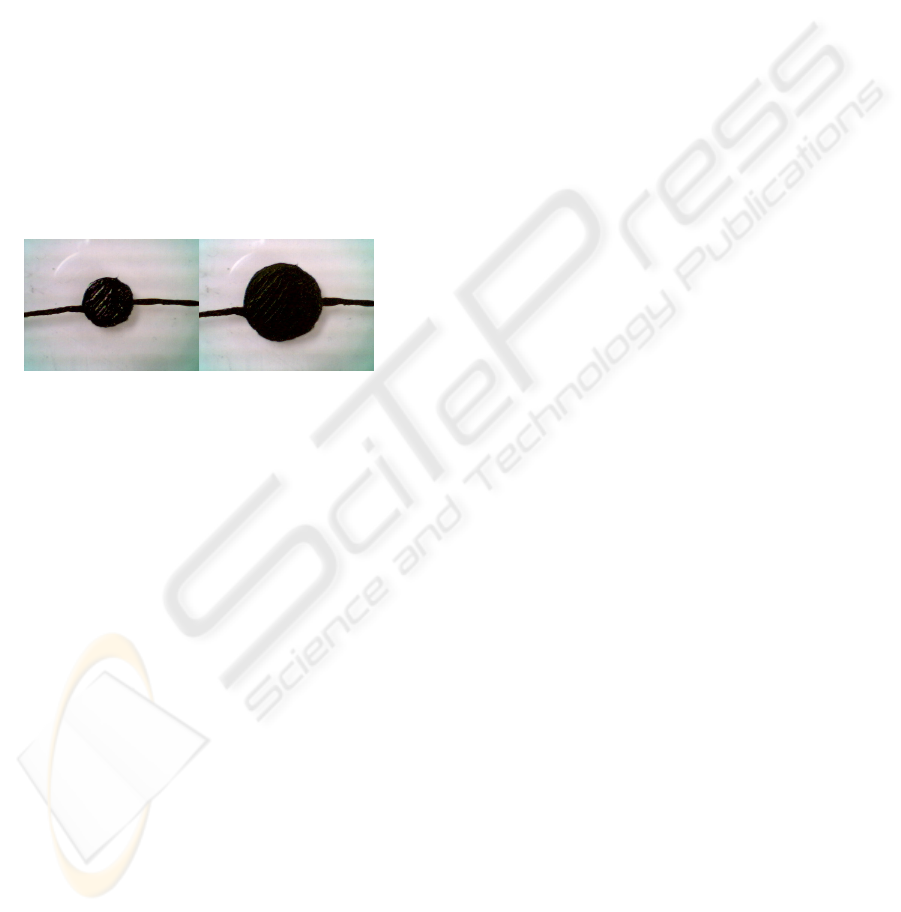

3M’s commercially available VHB4905 double-

sided polyacrylate tape has a high degree of

viscoelasticity, but at low speeds is capable of the

highest reported active displacement (380%) and

energy density (3.4MJ/m

3

) of any DE polymer. Fig.

2 illustrates a simple, easily fabricated DE made

from a prestrained, partially electroded VHB

membrane at rest (Fig. 2 left), and activated with an

electric field of 252V/µm (Fig. 2 right). The

electroded area expands by 125% at this field.

Figure 2: A VHB DE actuator at rest (left), and actuated

with an electric field of 252V/µm (right).

While silicone and VHB4905 are popular choices

for DE materials, a wide variety of other materials

can be used and which is appropriate is highly

dependent on the application. It is convenient

therefore to define a relationship between the key

properties of a material that results in an index value

that can then be used to compare materials. The DE

“Figure of Merit” relates a material’s dielectric

constant (ε

r

), the breakdown strength (E

b

), and the

Young’s modulus (Y), using the following formula

(Sommer-Larsen and Larsen, 2004):

Figure of Merit. = 3ε

r

E

b

2

/Y (4)

It is important to note that typical polymers with

suitably low stiffness and high dielectric breakdown

strengths have low dielectric constants (typically

<5). Substituting this value into Equation (1) it is

clear that high electric fields (~50-150V/μm) are

required to generate enough pressure to deform a DE

more than a few percent.

3 DIELECTRIC ELASTOMERS

IN BIODEVICES

DEs acting either in an actuator, sensor, or power

generator mode show great promise for a number of

biomedical applications. The key strength of DE

technology however is the ability for a single

lightweight device to operate in multiple modes.,

thereby reducing device volume, complexity, and

component count. This ability, coupled with their

biocompatibility, opens up a number of possibilities

not only for implantable or prosthetic devices, but

also for tools to assist both surgeons and patients

during operative and post-operative procedures.

3.1 Artificial Muscles

With performance metrics that exceed that of natural

muscle, DEs show great promise as artificial

muscles. Like natural muscle, DEs can be controlled

in terms of position, speed and stiffness. Controlling

the charge stored on a DE results in stable position

control. By controlling the rate of charging the speed

of actuation can be controlled. Similarly, utilising

the geometry of the device and the level of charge

stored on the DE, it is possible to determine the

electroactive forces, which in conjunction with

knowledge of the mechanical behaviour of the DE

itself, can be used to control stiffness.

To achieve accurate control in terms of any these

parameters it is necessary to obtain feedback data

from which a physical aspect of the device can be

inferred. Conventionally an external sensor is

required to obtain this data but applying such an

approach to DEs adds to the complexity, volume,

mass, cost and power requirements of the device.

Instead, self-sensing using inherent characteristics of

the DE eliminates the constraints an external sensor

implies and enables the creation of entirely

compliant smart devices. Such devices, with an

overall texture and consistency comparable to

natural muscle, will have a natural look and feel; a

factor that has been found to have a significant

impact on patient acceptance of such devices

(Popovic et al., 2002).

DE device properties such as electrode resistance

(O'Brien et al., 2007), capacitance (Toth and

Goldenberg, 2002), and electrical current (Bauer and

Paajanen, 2006) have all been used to infer the

physical state of a DE actuator subject to specific

operating conditions. As self-sensing develops

further and the richness of the feedback information

increases, so too will the accuracy with which DE

devices can be made to respond to a control signal.

SMART DIELECTRIC ELASTOMERS AND THEIR POTENTIAL FOR BIODEVICES

287

In the case of artificial muscles this control signal

should be derived from human nerve signals, and

already basic proportional control of a DE device

has been achieved with the magnitude of a variety of

electrophysiological signals as the input signal

(Carpi et al., 2006). Further development of not only

artificial muscles but also of the human-device

interface, including enabling bi-directional

information flow between artificial muscle and

human, could eventually lead to a true artificial

muscle capable of being fully integrated into the

human body.

3.2 Bio-sensors

Self-sensing and the ability of a DE device to

convert mechanical energy into electrical energy

enable DEs to be used in the monitoring of various

biological functions. As discussed previously,

various electrical characteristics of a DE will change

when the DE is deformed from its rest state. These

characteristic features have been used to

demonstrate simple, highly compliant, low voltage

strain and pressure sensors (Kornbluh, 2004).

The highly tuneable nature of the mechanical

impedance and elongation of DE sensors can be

exploited to enable strains of several hundred

percent to be monitored without adding significant

mechanical resistance to the movement itself. This

would make them suitable for devices that monitor

activities such as respiration, muscle movement, or

limb articulation. For monitoring muscle movement

in particular, feedback data from lightweight

conformable sensors synchronised with relevant

electrophysiological signals could be used to analyse

the dynamic stress-strain-time behaviour of muscles.

Biocompatible DE sensors could also potentially be

used to monitor stresses/strains in vivo, whether this

is in conjunction with another implanted device or

simply to generate data that a sensor external to the

body would be incapable of providing.

3.3 Surgical Tools

Compliant smart devices offer an ideal solution for

procedures where “soft” manipulation is appropriate.

In invasive surgeries such as endoscopic procedures,

DE devices could fulfil multiple roles: they could

operate as a multiple-degree-of-freedom actuator for

directing/propelling sensory devices or fibre-optic

cables whilst also providing a compliant interface

between the patient and the device that serves to

protect both.

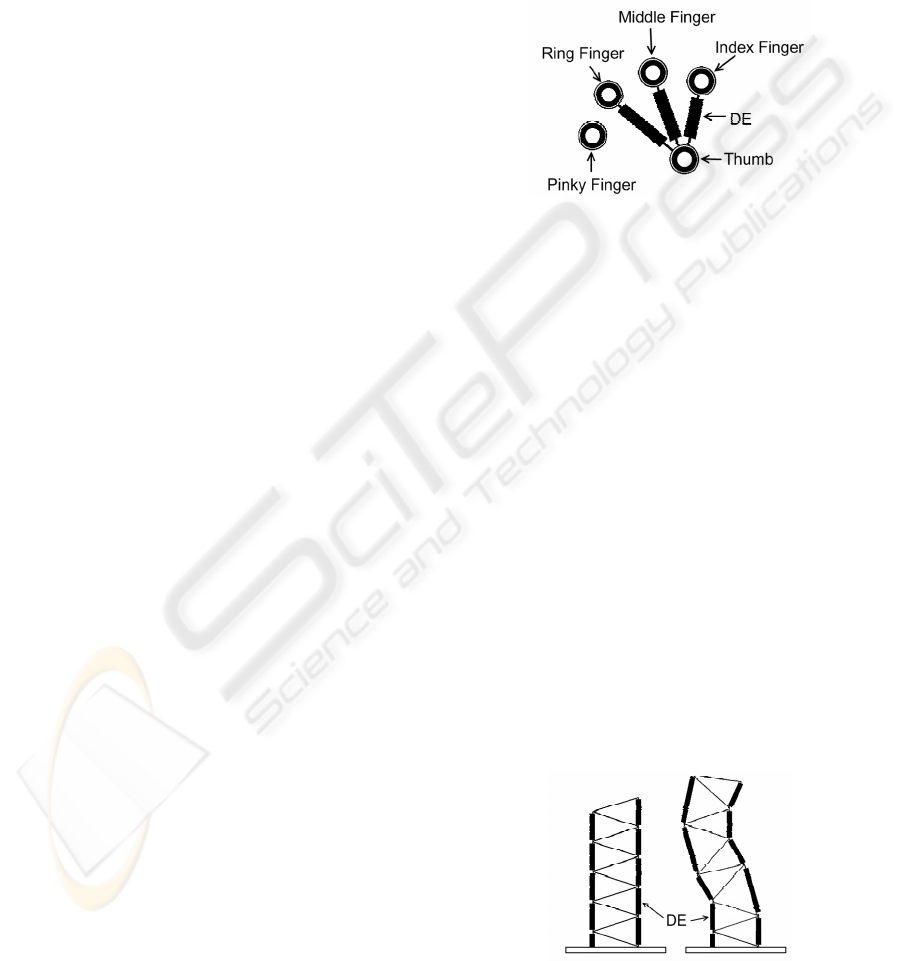

Lightweight accurate sensors and actuators could

be incorporated into portable glove-type devices

with built in force feedback for surgical training or

performing remote surgery. Already a prototype

device has been devised that has been used to

provide force feedback for a virtual reality

simulation of grasping an object (Fig. 3)(Zhang et

al., 2006). Low device mass and volume would

ensure the device is portable and able to be used for

extended periods without user fatigue.

Figure 3: Lightweight compliant actuators for virtual

reality feedback of grasping related hand gestures.

Furthermore, a smart device with the dexterity

and flexibility of a human hand could be used as the

manipulator in remote surgical operations. With

feedback from pressure sensors embedded in the

manipulator used as a control input for a DE force

feedback device a complete DE solution could be

created. An inherently muscle like actuator

combined with realistic haptic feedback would result

in an apparatus with an intuitive feel that could offer

advantages in terms of flexibility and patient safety

in comparison to heavy and rigid surgical robots

driven by electromagnetics or hydraulics.

Other features of DE actuators such as their low

current requirements and non-magnetic nature also

provide advantages with regard to surgical tools. A

prototype serpentine, DE based manipulator for

needle positioning in close proximity to an MRI

machine has been developed (Fig. 4)(Plante, 2006).

Similar devices incorporating ferromagnetic

materials or that use high currents would degrade the

quality of the MRI scan.

Figure 4: A conceptual design for a serpentine needle

positioning device.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

288

In the longer term there is the possibility of using

nanoscale DE actuators in biology to stimulate the

growth, migration and differentiation of stem cells.

Mechanically deforming these cells can expose or

activate different functional sites on their proteins,

thereby affecting the biochemical reactions and

intracellular pathways that ultimately regulate cell

development (Vogel, 2006). Such a process may

even create new opportunities for the treatment of

diseases associated with mechanical cell dysfunction

such as cancer, cardiac hypertrophy, genetic

malformation, and immune disorders.

3.4 Power Generators

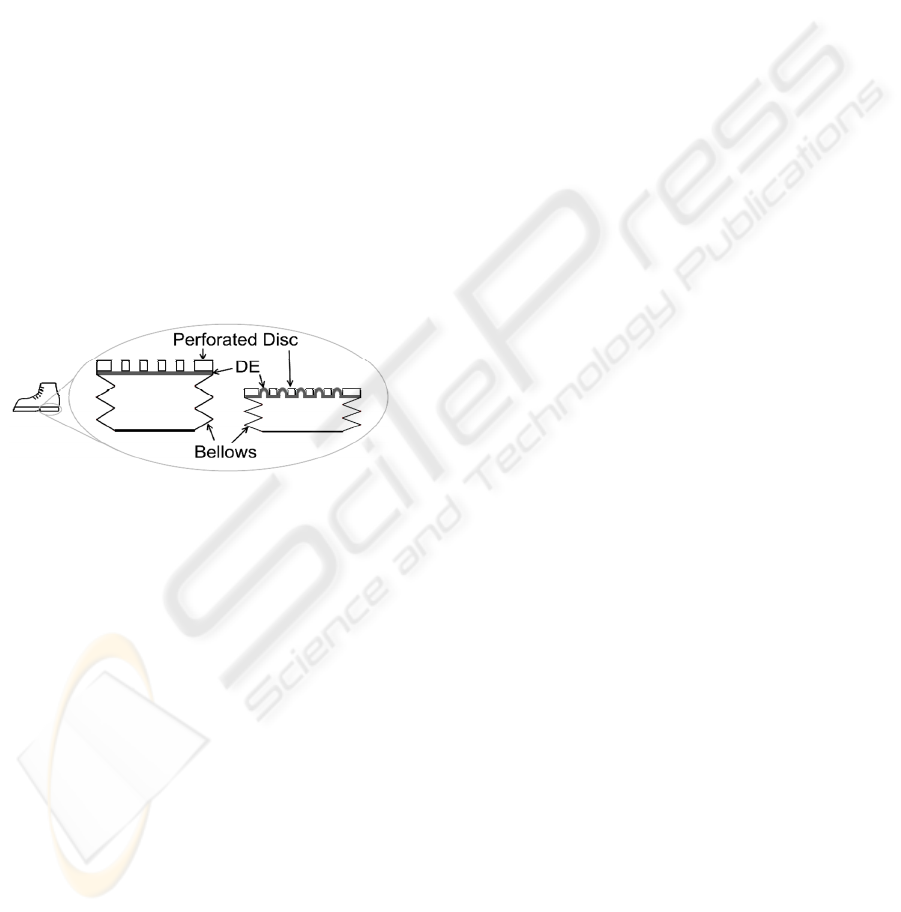

DEs are capable of operating as highly efficient

generators. With appropriate driving circuitry DEs

can be used to harvest energy from vibrations and

motions inherently present in the environment.

Already a heel-strike generator embedded in the heel

of a boot (Fig. 5), is capable of generating up to 1W

by using the downwards pressure of each footfall to

stretch a DE membrane (Kornbluh, 2004).

Figure 5: Heel strike generator capable of generating up to

1W.

The implication for biodevices is that lightweight

power generators could be used to trickle charge or

perhaps even directly power other low power

devices on or within the body. A DE based

prosthetic device subjected to intermittent usage

patterns could make use of a DE generator combined

with an energy storage device such that it would

need recharging less frequently, if at all.

Alternatively the energy storage device (e.g. battery

pack) could be downsized.

The conformable and compact nature of DE

generators means initially they could be strategically

integrated into fabrics so as to take advantage of

naturally occurring stretching as a result of human

ambulation. In the future these generators may

eventually be able to be implanted within the body

itself, enabling a completely encapsulated, low

maintenance power supply. Such a generator could

be used to power wireless implantable sensors.

4 FUTURE DIRECTIONS FOR

DIELECTRIC ELASTOMERS

As a smart material, a single DE element offers a

multi-functional platform from which devices suited

to a variety of applications can be developed. There

are a number of hurdles yet to be overcome however

and at the Biomimetics Laboratory we are actively

investigating key issues that are currently limiting

the practical implementation of DEs in biodevices.

DEs exhibit complex non-linear and hysteretic

behaviours in both the mechanical and electrical

domains that make modelling and precision control

of these devices difficult. Current models can

accurately predict behaviours based on specific

parameters (e.g. the instantaneous uniaxial stress-

strain response of a material subjected to a constant

strain rate deformation), but have such a narrow

scope that their accuracy degrades significantly if

one or more of the parameters change (e.g. strain

rate, mode of deformation, external loads,

temperature). The ability to accurately describe the

transient response of a DE device is especially

limited. Improved modelling, particularly with

respect to the electrical subsystem will greatly

facilitate the development of more robust devices.

Improved modelling and self-sensing techniques

will result in an increased understanding of the

behaviour of a DE system that will greatly facilitate

optimisation in terms of control, feedback, and

device efficiency. In artificial muscles especially,

owing to the desirability of ultra-thin dielectrics,

devices will consist of large arrays of

micro/nanoscale DE actuators in order to amplify

force and displacement. It will be of critical

importance therefore to develop a balance between

the volume of feedback information and the control

methodology such that the computational

requirements are not prohibitively high.

The use of high electric fields (~50-150V/µm) in

DEs also presents an issue given that current

prototype membrane thicknesses typically range

from 10μm to 50μm. While this is primarily a

limitation of current fabrication techniques it

nevertheless necessitates operating voltages in the

kilovolt range. The impact of these high electric

fields in proximity to the human body, including the

efficacy of a soft polymer insulative layer

encapsulating the device is being investigated.

SMART DIELECTRIC ELASTOMERS AND THEIR POTENTIAL FOR BIODEVICES

289

ACKNOWLEDGEMENTS

Work at the Biomimetics Laboratory is partly

funded by the University of Auckland’s VCUDF.

REFERENCES

Bar-Cohen, Y., Ed. (2004). Electroactive Polymer (EAP)

Actuators as Artificial Muscles: Reality, Potential, and

Challenges. Bellingham, WA, SPIE Press.

Bauer, S. and M. Paajanen (2006). Electromechanical

characterization and measurement protocol for

dielectric elastomer actuators. Proceedings of SPIE -

The International Society for Optical Engineering,

6168.

Carpi, F., S. Raspopovic, et al. (2006). Activation of

dielectric elastomer actuators by means of human

electrophysiological signals. Proceedings of SPIE -

The International Society for Optical Engineering,

6168.

Hunter, I. W. and S. Lafontaine (1992). Comparison of

muscle with artificial actuators. Technical Digest-

IEEE Solid-State Sensor and Actuator Workshop.

Kofod, G. (2001). Dielectric Elastomer Actuators.

Department of Chemistry, Riso - The Technical

University of Denmark. PhD.

Kornbluh, R. (2004). "Dielectric elastomer artificial

muscle for actuation, sensing, generation, and

intelligent structures." Materials Technology 19(4):

216-224.

Kornbluh, R. D., R. Pelrine, et al. (2004). Electroactive

polymers: an emerging technology for MEMS.

MEMS/MOEMS Components and Their Applications,

5344, San Jose, CA, USA, SPIE.

Madden, J. D. W., N. A. Vandesteeg, et al. (2004).

"Artificial muscle technology: Physical principles and

naval prospects." IEEE Journal of Oceanic

Engineering 29(3): 706-728.

O'Brien, B., J. Thode, et al. (2007). Integrated extension

sensor based on resistance and voltage measurement

for a dielectric elastomer. Electroactive Polymer

Actuators and Devices (EAPAD) 2007, 6524, San

Diego, California, USA, SPIE.

Plante, J. S. (2006). Dielectric Elastomers for Binary

Robotics and Mechatronics. Department of

Mechanical Engineering. Cambridge, Massachussetts

Institute of Technology. PhD: 80.

Popovic, M. R., D. B. Popovic, et al. (2002).

"Neuroprostheses for grasping." Neurological

Research 24(5): 443-452.

Sommer-Larsen, P. and A. L. Larsen (2004). Materials for

dielectric elastomer actuators. Smart Structures and

Materials 2004: Electroactive Polymer Actuators and

Devices (EAPAD), 5385, San Diego, CA, USA, SPIE.

Toth, L. A. and A. A. Goldenberg (2002). Control system

design for a dielectric elastomer actuator: The sensory

subsystem. Proceedings of SPIE - The International

Society for Optical Engineering, 4695.

Vogel, V. (2006). "Mechanotransduction involving

multimodular proteins: Converting force into

biochemical signals." Annual Review of Biophysics

and Biomolecular Structure 35: 459-488.

Zhang, R., P. Lochmatter, et al. (2006). Spring roll

dielectric elastomer actuators for a portable force

feedback glove. Smart Structures and Materials 2006:

Electroactive Polymer Actuators and Devices

(EAPAD), 6168, San Diego, CA, USA, SPIE.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

290