MULTIPARAMETER SINGLE LOCUS INTEGRATED

MULTILAYER POLYMER MICROSENSOR SYSTEM

Yindar Chuo and Bozena Kaminska

School of Engineering, Faculty of Applied Science, Simon Fraser University, 8888 University Drive, Burnaby, Canada

Keywords: Biosensor, multiparameter, microintegration, flexible polymer system-in-package, MEMS, health

monitoring, wireless senor, cardio health monitoring.

Abstract: Miniaturization and microintegration is well known for their potentials in providing microsystems and

sensors with unmatched performance, reliability, and lower costs. Current technologies in implementation

of microsensors, however, span a large variety of platforms. It is thus common for microsensors measuring

differing parameters to exist on different combinations of substrates, not to even mention the associated

signal conditioning, processing, and data communication electronics. It remains a challenge to integrate

multiple sensors with complex electronics into a single high-density microsystem, particularly for certain

applications in medical diagnostics and healthcare, where mechanical flexibility of the substrate and

biocompatibility also becomes crucial considerations. Traditional microintegration technologies such as

system-in-package, system-on-chip, and advanced assembly and packaging, may often be inadequate. A

mutliparameter single locus integrated multilayer polymer microsensor system is proposed to address the

fundamental issues of high-density integration, flexibility, biocompatibility, easy application, high

sensitivity, and reliability for medical grade diagnostics and other physiological applications. The

architecture of the multilayer system is discussed, as well, implementation and fabrication of the

multisensor layer is demonstrated, and the results on performance discussed.

1 INTRODUCTION

Miniaturization and microintegration of sensors

through novel microelectronics and

microelectromechanical systems (MEMS)

technologies have demonstrated large potentials in

providing unmatched performance, reliability, and

cost effectiveness (Wang, 2002) over the recent

years in many applications. Particularly, in

applications involving physiological monitoring and

healthcare, microintegrated sensors have been able

to provide the combination of high analyte

sensitivity, electrical responsiveness, precise

temporal control, small feature sizes, and low power

consumption, that otherwise is often very difficult to

achieve through traditional technologies (Richards

Grayson, 2004).

Current technologies in miniaturization of

sensors span a large domain. Much research has

focused on microfabrication of sensors through

microelectronics and MEMS (Richards Grayson,

2004). Methods in fabrication include various

lithographic techniques, stereolithography,

lithographie galvanoformung abformung (LIGA),

and micro injection molding, to just name a few.

Processes are often different and specific to each

type of microsensor. As a result, integration of

various microsensors and microelectronics is

difficult.

Thus far, technologies for microintegration

include system-on-chip (SoC) (Kundert, 2000),

system-in-package (SiP) (Matthews, 2003), and

advanced assembly and packaging (Fraunhofer

Institut Zuverlassigkeit und Mikrointegration). SoC

concepts allow designers to combine sensors and

system electronics on the same substrate, on a single

chip. An example is the popular lab-on-chip

technologies (Pai, 2001); however, often in

biological and environmental applications, it is

inherently difficult to design sensors on the same

substrate as the remaining electronic system (Zhang,

2007). SiP technology provides integration of

multiple sensors and system electronics from

differing substrates at the board level. Commonly,

unpackaged chips are placed and connected on one

single substrate or printed circuit board (PCB). This

36

Chuo Y. and Kaminska B. (2008).

MULTIPARAMETER SINGLE LOCUS INTEGRATED MULTILAYER POLYMER MICROSENSOR SYSTEM.

In Proceedings of the First International Conference on Biomedical Electronics and Devices, pages 36-43

DOI: 10.5220/0001047200360043

Copyright

c

SciTePress

allows for a high-density integrated system, but is

often limited by its rigid integration substrate, and

board ‘real-estate’.

In this paper, a multiparameter single locus

microintegrated sensor system is proposed for, but

not limited to, cardiac physiological signal

acquisition in diagnostics and health monitoring.

This novel integration technology platform proposes

higher density integration through multilayering of

mechanically flexible polymer substrates, while

providing a thin flexible profile for skin tissue

conformity. A complete system including multiple

microsensors, filtering, digitization, processing, and

communication electronics is proposed. In this

manner, the microintegration platform provides

advantages of high sensitivity, high actuation-to-

sensor coupling, and noise reduction through local

filtering and immediate digitization, for a system

that can provide medical diagnostic grade precision,

yet is flexible, compact and robust.

One particular implementation includes a surface

biopotential electrode integrated along with a

MEMS 3-axis accelerometer and signal filtering

electronics all together forming the multiparameter

sensor layer of the multilayer system. In this

implementation, parameters of interest include

electric potential and motion of the heart, recorded

simultaneously, in what is known as

ballistoelectrocardiography (BECG).

2 MULTIPARAMETER SENSOR

SYSTEM ARCHITECTURE

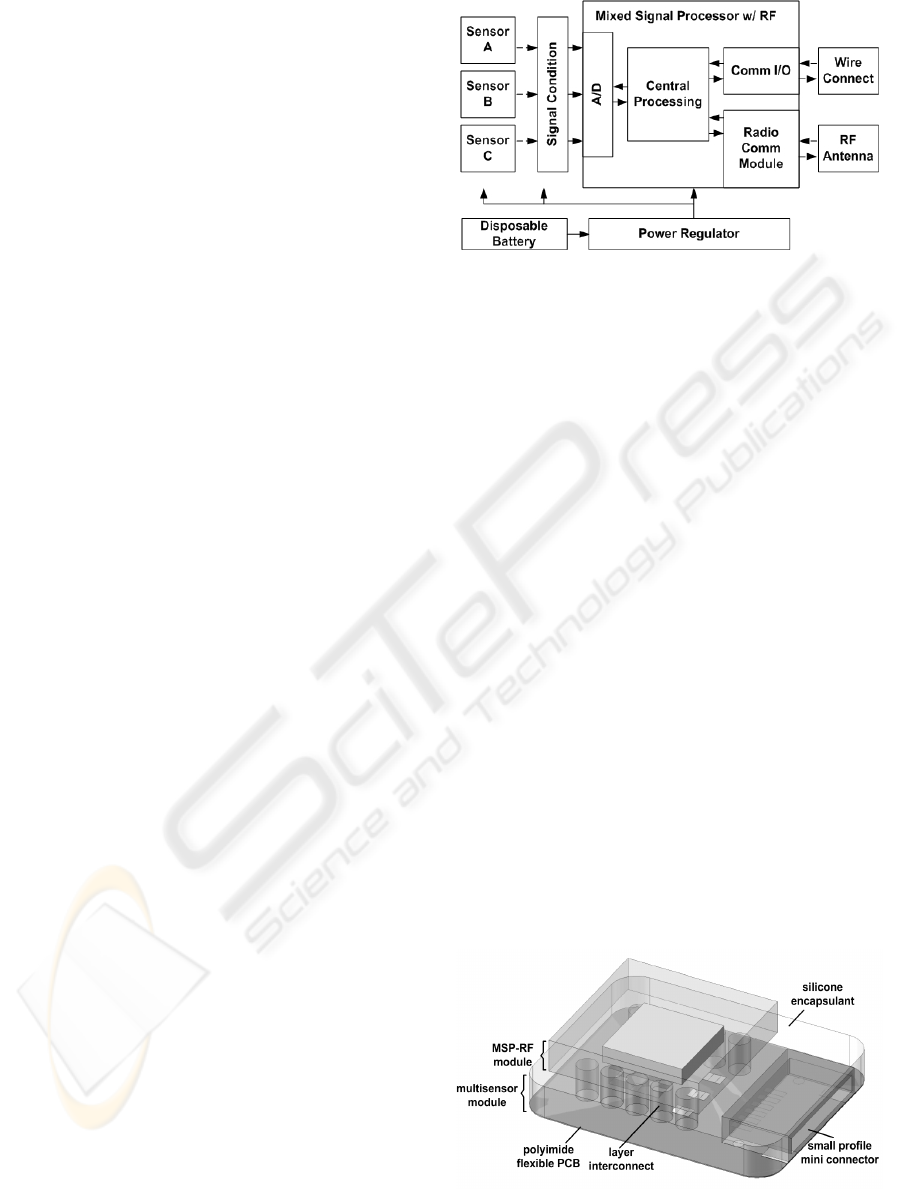

The multiparameter single locus integrated

multilayer sensor system consists of five functional

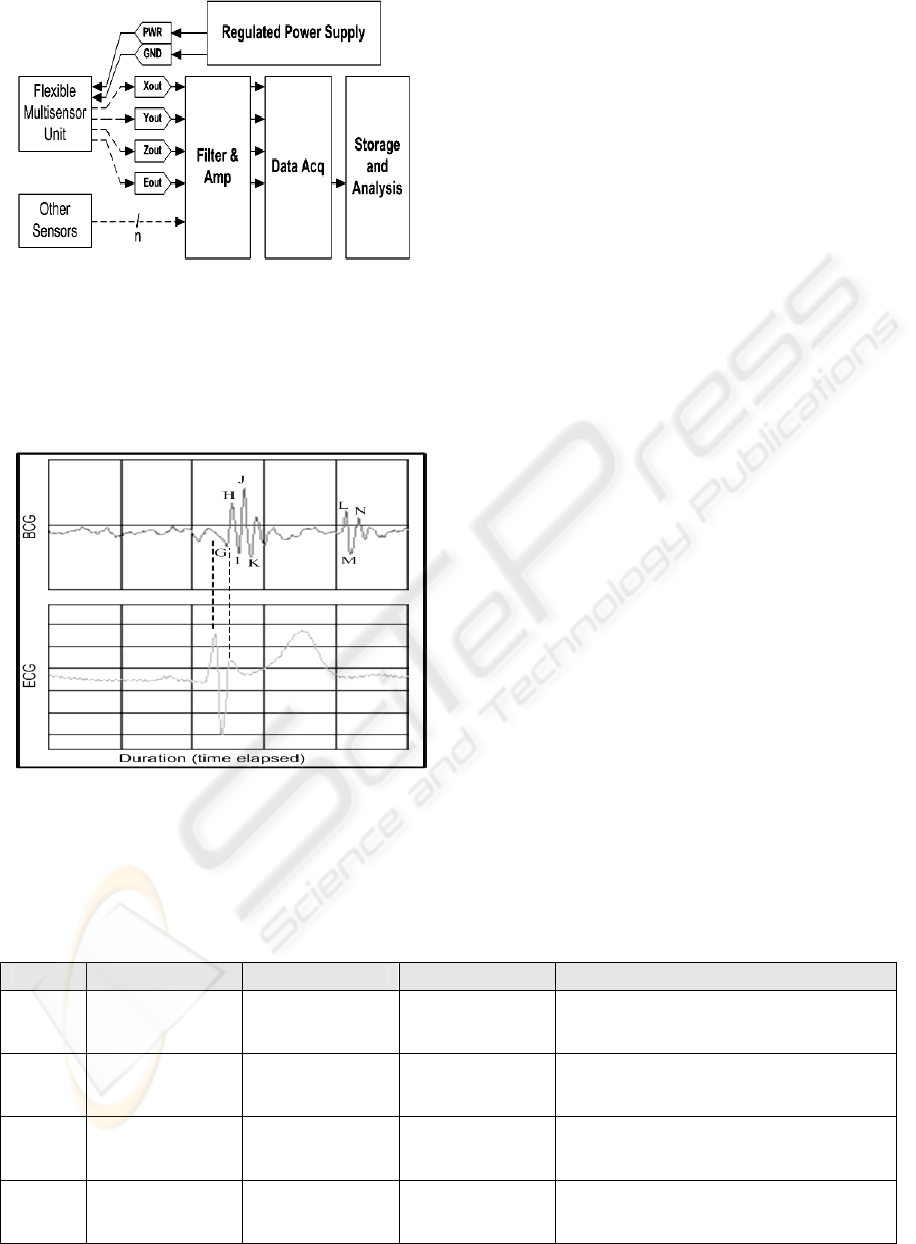

groups (Figure 1); the multisensors, signal

conditioning, microprocessor, communication

terminals, and powering. Multiple sensors acquire

signals of different parameters, and convert the

signals to electrical outputs. The signals are

conditioned through appropriate filters and

amplifiers, as close to the sensing elements as

possible, to minimize noise. Signals are then routed

to the mixed signal microprocessor (MSP) where it

is digitized, processes, and transmitted through radio

or wired communication portals. The system is

powered through either permanent or disposable

micro-batteries.

Figure 1: Modules of the integrated sensors system.

The conceptual assembly of the system is shown in

Figure 2. The system consists of two layers, with

option to be detachable from each other, and is

connected through columnar interconnects. Each

layer is composed of a flexible substrate (e.g.

polyimide), on top of which the electronic system is

placed and routed. Intermediate and encapsulating

each layer is a flexible material (e.g. silicone) acting

as insulation, structural support, and mechanical

protection. The intermediate layer can be shaped and

is electrically patternable such that electrical

interconnects, inter-layer attachment anchors, and

sensing element windows can be designed.

Here, with reference to both Figure 1 and Figure

2, the multiple sensors and signal conditioning

electronics are shown on the lower layer, which

allows the sensing elements to be closer to their

corresponding physiological actuations. Also

situated on the lower layer is a mini-connector for

applications requiring wired connections. The MSP

with build-in radio-frequency (RF) communication

module and the RF antenna are both placed on the

upper layer. Signals from the conditioning module

on the bottom layer are routed to the processor on

the top layer through the interconnects. Signals

between the processor to and from the wired

connection are also routed through the interconnects.

Figure 2: The multiparameter single locus integrated

multilayer polymer microsensor system.

MULTIPARAMETER SINGLE LOCUS INTEGRATED MULTILAYER POLYMER MICROSENSOR SYSTEM

37

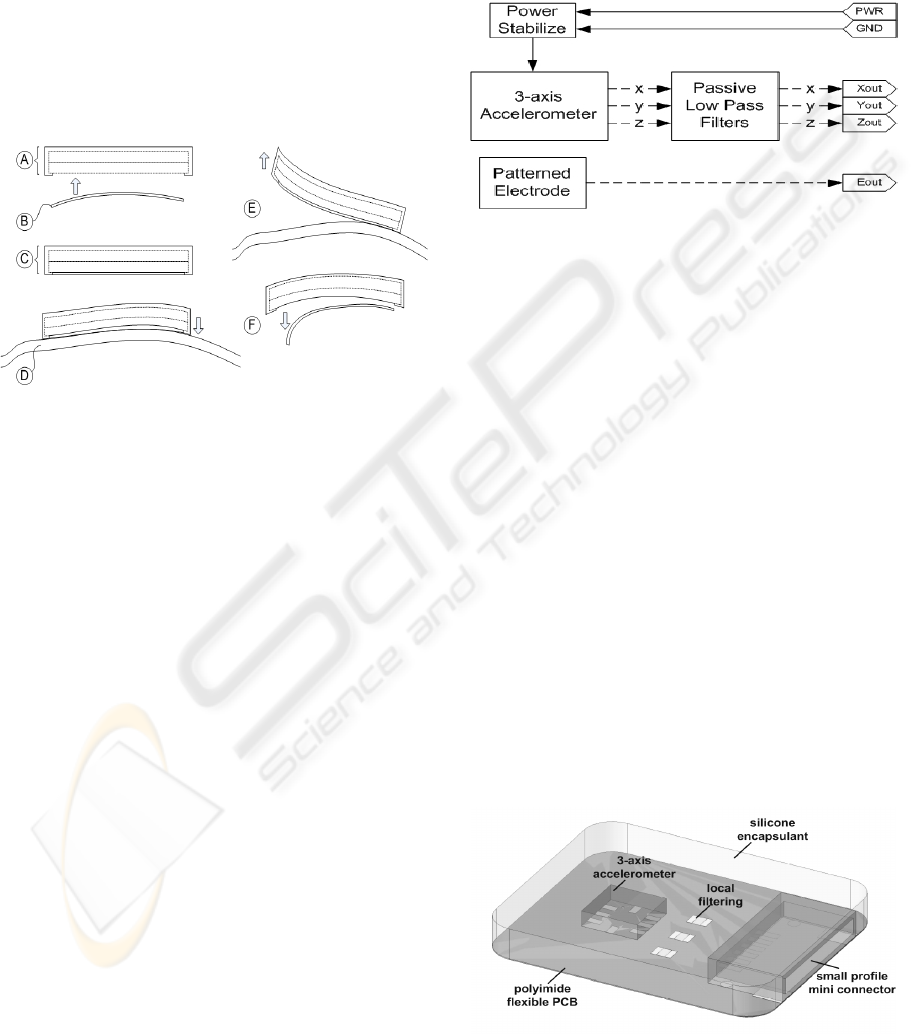

Another important part of the integrated

multilayer sensor system is the attachment

mechanism to a subject surface. Since the integrated

multilayer sensor system is designed to be flexible,

with a low profile, to conform well to the contours

of human skin surface, the attachment mechanisms

must not alter this feature. Figure 3 shows how the

integrated multilayer sensor device is conceptually

applied to a subject tissue surface by attachment of a

novel disposable adhesive. This disposable adhesive

must be very thin, attachable on both sides and

conductive at portions where it is required.

Figure 3: Application of integrated sensor device with

novel disposable adhesive: The integrated sensor device

(A) is attached on the bottom side with the disposable

adhesive (B) forming a ready-to-apply device (C), where

then it can be attached to subject skin surface (D) with

high conformity. Device is removed from subject by

simply pealing (E) off from attached surface, while

disposable adhesive can then be removed from device (F)

for hygienics.

3 IMPLEMENTATION OF

MULTISENSOR LAYER

A model of the multisensor layer of the

multiparameter single locus integrated multilayer

sensor system has been implemented and fabricated,

while the reminder of the system is underway. This

paper will only discuss the implementation and

fabrication of the multisensor layer.

Figure 4 shows the system blocks for the

multisensor layer. Two sensor modules were

included; one, a three-axis accelerometer, and the

other, a single-channel surface biopotential

electrode. Signal output from the accelerometer was

passed through passive low-pass filtering prior to the

terminal connections. There was no local filtering

implemented for the electrode signal to maintain

relative simplicity of the system such that focus at

this stage of development can be placed on overall

system integration. Power input stabilization was

included to maintain optimal performance of the

powered components. Input and output terminals of

the multisensor layer were connected via thin wires

to macro-scale connectors for testing purposes.

Figure 4: System blocks of the multisensor layer.

Figure 5 shows the model assembly of the

multisensor layer. Base substrate of this layer was

chosen to be 50-micron polyimide flexible PCB.

Polyimide is a strong thermalset with excellent tear-

resistance, thermal and chemical resistance

(Callister, 2003). The three-axis accelerometer,

filtering, and power stabilizing electronics were

placed and routed on the top-side of the polyimide

cell. The biopotential electrode was designed and

patterned on the reverse-side of the polyimide cell,

and connected to the top-side through micro-jumper

wire. Alternatively, metal-plated vias through the

polyimide substrate would be ideal, but to reduce

model fabrication complexity and costs, jumpers

were chosen. A small profile mini-connector was

placed at one end of the polyimide cell for signal

acquisition and testing. As will be further discussed

in the next section, during model fabrication and

assembly, the mini-connector was replaced with thin

wires and then joined to a larger connector, again, to

simplify fabrication and assembly complexity and

reduce costs.

Figure 5: Multisensor layer of multilayer integrated

system.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

38

Lastly, encapsulation of the polyimide cell was

chosen to be with electronic grade silicone

encapsulant. Typical electronic grade silicone

encapsulant provides good insulation and

mechanical protection for the underlying devices

while allowing for shapability. Transition to

fabrication with medical grade silicone encapsulants

would be straightforward because of the silicone’s

relatively similar compositions. Rapid prototyping

moulding techniques were applied to provide the

desired resulting shape. The total thickness of the

entire cell was targeted at 3mm to maintain the

feature of skin contour compliance.

4 FABRICATION METHOD

Fabrication and assembly of the multisensor layer

could be categorized into four sections; one,

fabrication of the polyimide circuit; two, device

component population; three, encapsulation; and

four, preparation of double-sided conducting

adhesive. This paper will focus on discussions for

the first two aspects of device fabrication. Since

fabrication was for a set of model devices,

techniques employed were mostly rapid prototyping

methods with simplified steps rather than larger

scale manufacturing processes.

4.1 Polyimide Circuit

Fabrication of the polyimide circuit is a standard

process in the industry (Egloff, n.d.). It is also

commonly known as flexible PCB circuit printing.

Printing of flexible PCB circuits is provided by

many fabrication houses around the world; however,

due to its specialty, most orders are still costly and

require large quantities not suitable for prototyping

or model trials.

Fabrication was thus contracted through the

Institute for Micromachining and Microfabrication

Research at Simon Fraser University. Layout of the

single-layer double-sided polyimide circuit was

submitted electronically, for the fabrication process

to be done with proprietary metal-on-polyimide

rapid prototyping process.

4.2 Components and Population

Components for the model multisensor layer were

carefully selected to ensure ease of assembly without

elaborate processes or tools, while maintaining

relatively small device profile. As a result, all

electronic components used were surface mount

devices with package size no greater than

5mmх5mm

2

and bonding pad pitch larger than

0.65mm. Bonding of the device was through cold

soldering (silver epoxy, conductive ink) by hand.

Heat soldering with temperatures greater than 200°C

was too hot for the thin metal film deposited on the

polyimide under the particular polyimide

metallization process carried out. Alternatively, a

thicker film metallization on polyimide circuit

would allow heat soldering, but such was not the

objective of this research.

5 RESULTS AND EVALUATION

5.1 Flexibility

A total of four devices were populated, assembled

and encapsulated using the fabrication method

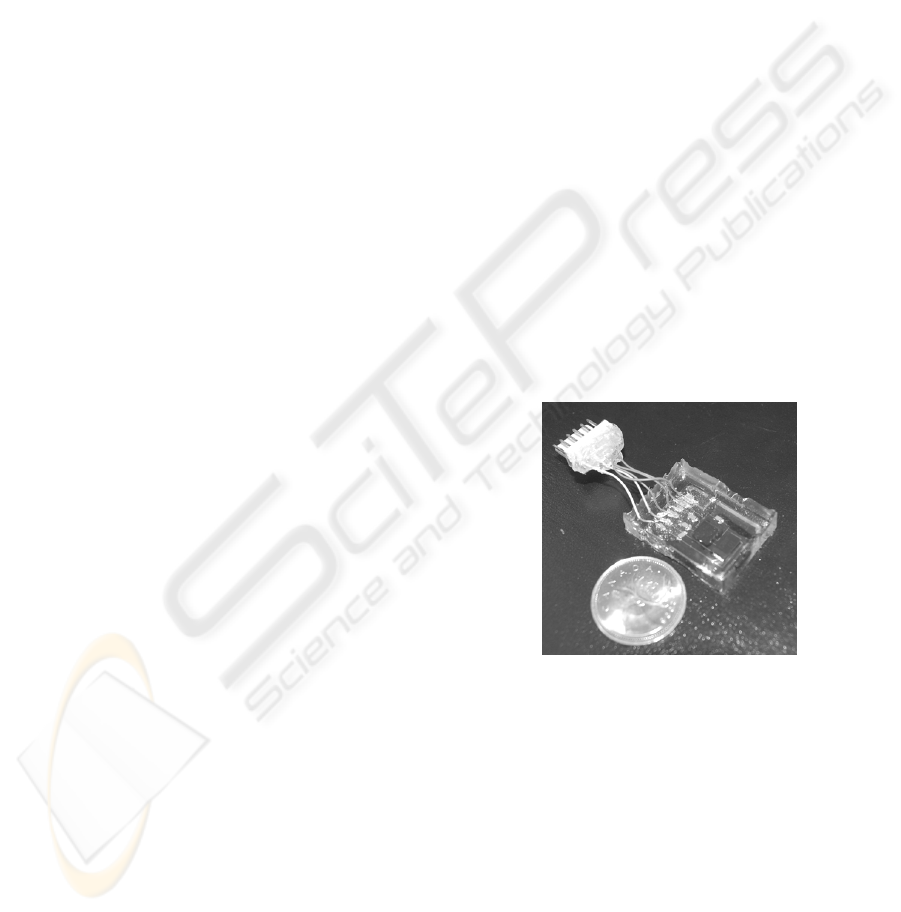

described in the previous section. Figure 6 shows

one of two devices encapsulated in 5mm thick

silicone encapsulant. Although it was 2mm thicker

than the 3mm that was planned, the device was

flexible enough to bend up to 30° without any

visible cracking or detachment between the substrate

and encapsulant.

Figure 6: Encapsulated multisensor layer with macro-scale

connector for testing attached, comparison with a

Canadian quarter.

The remaining two of the four devices were

encapsulated in 0.5mm thick silicone. Figure 7

shows one of the two devices wrapped around a

finger demonstrating its flexibility. With the 0.5mm

encapsulation thickness, although no quite enough to

form a levelled-surface over the larger components,

it was sufficient to provide electric insulation on

most parts and some degree of mechanical

protection. The device was able to bend up to 90°

without any visible cracking or detachment between

the substrate and encapsulant.

MULTIPARAMETER SINGLE LOCUS INTEGRATED MULTILAYER POLYMER MICROSENSOR SYSTEM

39

Figure 7: Thin encapsulation of multisensor layer allowing

for extra flexibility; Top, sensor device wrapped around

the first digit of a finger; Bottom, close-up of sensor

wrapped around finger.

5.2 Size and Dimensions

The model multisensor layer devices were

approximately 2.0cmх2.5cm. As can be seen in

Figure 6 and Figure 7, the metal traces were

relatively thick, components were relatively large,

and spacing between components was maintained

such that assembly by hand without any precision

tools can be managed. Should the devices be

populated on the substrate without the manufacturer

packaging, and/or smaller footprints and traces

applied, the device dimensions should be easily

reduced to half the model size, say 1.0cmх1.5cm.

5.3 Comparative Functional

Assessment

Initial comparative function assessment was

conducted to provide quick insight into how the

novel device’s sensing capabilities compared to

traditional devices in the particular application. The

comparative assessment gave an overview of the

device functional performance prior to engaging into

more detailed studies of its performance

characteristics, which will be topic of another

discussion.

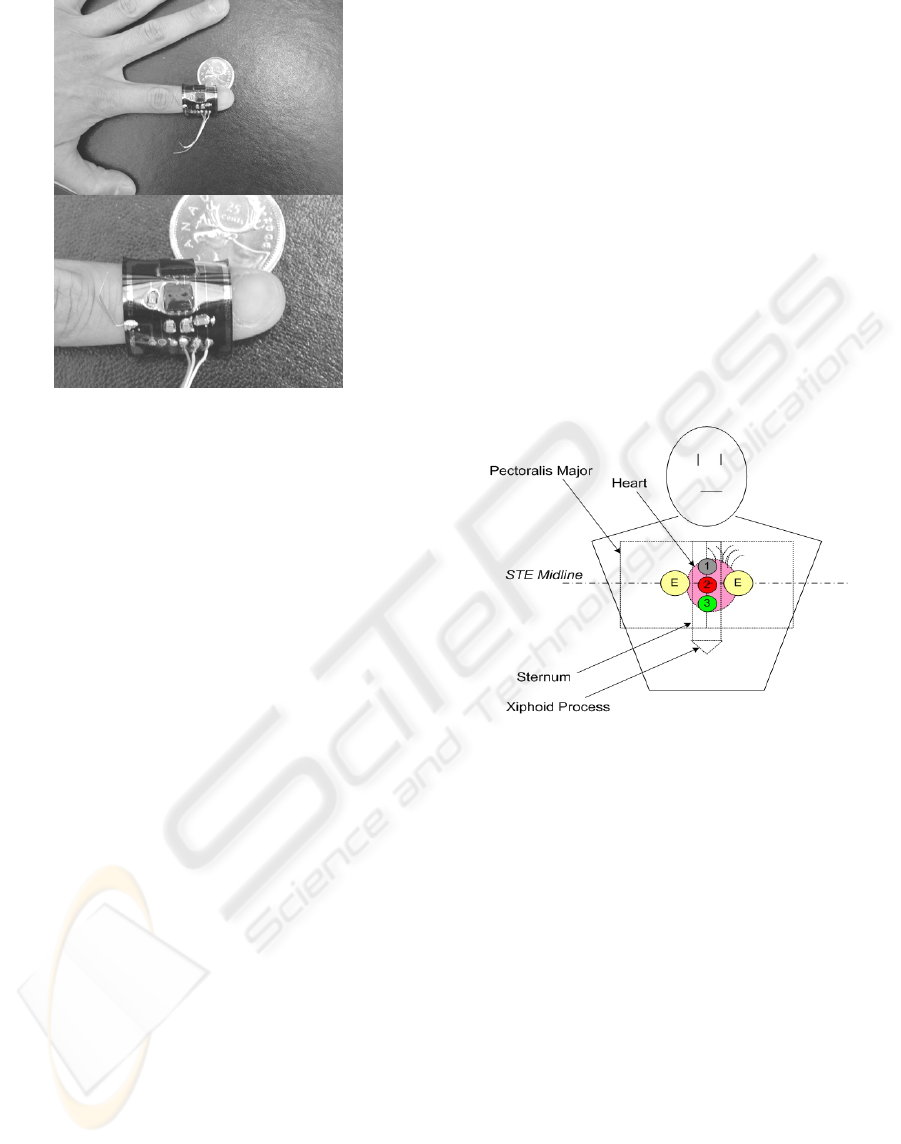

In the comparative assessment, the multisensor

was applied in the same manner as traditional

accelerometers on the chest of the subject in

obtaining BCGs (McKay, 1999). Figure 8 shows the

sensor locations and reference electrode locations

for comparative study. Locations 1, 2, 3, show the

various positions the sensors can be placed along the

subject’s sternum in recording heart motion. Ideally,

sensors should be situated simultaneously at the

same location for most accurate comparison, but

such placement is not possible. Differences in signal

outputs due to location were thus considered during

the analysis. Two electrodes, E, approximately 2”

apart were placed beside the sternum along the

sternal midline to form a reference modified-ECG-

lead in studying a subject’s BECG.

At this stage, only the motion sensing element of

the multisensor was compared with other traditional

sensors. It is important to assess first whether or not

the signal pickup by the integrated sensors suffers

any unwanted effects due to the flexible substrate.

For testing purposes, attachment of the sensors to the

subject skin surface was with common off-shelf non-

conducting double-sided medical adhesives.

Figure 8: Sensor placement locations in comparative

assessment; E denotes electrode locations, while 1, 2, 3,

denotes sensor locations.

The data acquisition system and sensor powering is

shown below in Figure 9. The flexible multisensor

was connected with power input, and signal output

routed to filtering and amplification circuits. The

conditioned signals were then passed into a data

acquisition system (National Instruments DAQ)

stored and analysed. Additional sensors included in

the comparison were also digitized and stored

through the same data acquisition system such that

precise synchronization between channels recording

incoming signals can be obtained. The reference

electrodes were connected to a standard ECG

machine (Burdick) with analog output connected to

the acquisition system as the sensors were.

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

40

Figure 9: Data acquisition system and sensor connection

setup.

Figure 10 shows the physiological signals of a single

heart-cycle recorded through the acquisition system

of the flexible multisensor with reference to

synchronized ECG.

Figure 10: BCG signal of a single heart-cycle as recorded

by the multisensor referenced to synchronized ECG.

As can be seen, all characteristic waveforms of a

classical BCG signal, denoted by letters (H, I, J,

etc.), similar to that measured through a high-

precision accelerometer in McKay (1999), can be

identified. Several feature extraction algorithms and

physiological interpretation analysis were also

developed; however, such topics were reserved for

subject of a separate discussion.

A total of four comparative recordings were taken

from a single subject. With a high-precision

reference accelerometer (Bruel&Kjaer) fixed at

location-3 (Figure 8), the flexible multisensor and a

rigid sensor, housing the same MEMS 3-axis

accelerometer on PCB, were rotated between

location-1 and location-2. Samples were taken for

duration of 30-seconds at 500Hz (each channel) over

a total of four channels (3 sensors, 1 reference ECG-

lead). Table

1 summarizes the recordings and the

different sensor placements during each trial. From

the combination of trials recorded and reference

sensor comparison, the quality of signal related to

sensor placement, and filtering differences can be

qualitatively assessed.

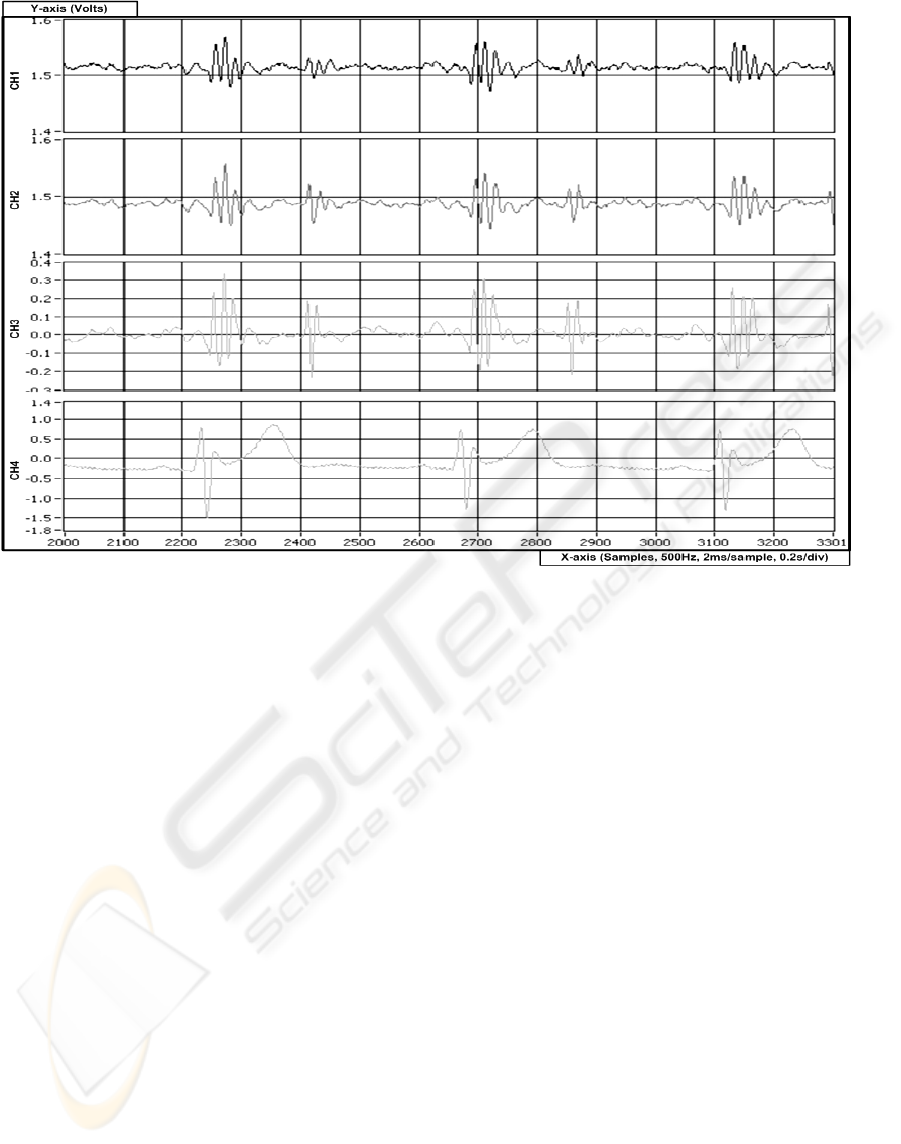

Figure 11 shows a portion of the recorded signals

from trial-I over a period of 2.6-seconds, or

approximately three heart-beats. Channel-1 shows

signal recorded from the rigid sensor, while channel-

2 shows signal recorded from the flexible

multisensor. Channel-3 and Channel-4 form the

reference BCG and ECG signals respectively, in

which the flexible sensor and rigid sensor were

compared to. Although the sensitivities of the

MEMS accelerometer is much lower than the high-

precision reference accelerometer, it was

qualitatively determined, that in general, the

morphology of the BCG signals obtained from the

flexible multisensor is very similar to that in the

reference sensor.

Table 1: Summary of sensor recordings with location, filter, and overall sensitivity-gain indicated.

Trail Sensor Location Filter Overall Sensitivity/Gain (approx.)

I Rigid 1 50Hz 3.0V/g

Flex 2 100Hz 3.0V/g

Reference 3 100Hz 9.8V/g

II Rigid 2 50Hz 3.0V/g

Flex 1 100Hz 3.0V/g

Reference 3 100Hz 9.8V/g

III Rigid 1 100Hz 3.0V/g

Flex 2 50Hz 3.0V/g

Reference 3 100Hz 9.8V/g

IV Rigid 2 100Hz 3.0V/g

Flex 1 50Hz 3.0V/g

Reference 3 100Hz 9.8V/g

MULTIPARAMETER SINGLE LOCUS INTEGRATED MULTILAYER POLYMER MICROSENSOR SYSTEM

41

Figure 11: Portion of recording comparing novel flexible multisensor with rigid sensor and reference sensor and ECG; CH1

– rigid sensor; CH2 – flexible multisensor; CH3 – high-precision accelerometer reference; CH4 – ECG. All channels

sampled at 500Hz.

Further, from trials-I and III, it was observed that

altering the filtering cut-off frequencies in the signal

conditioning stage did not have astonishing effects

on the morphology of the signals as expected. On

the other hand, situating sensors further away from

the reference sensor did result in signals less similar

in morphology and smaller amplitude compared to

sensors closer to the reference sensor. That is to say,

regardless of sensor type (rigid or flexible) and

filtering cut-off frequency, a sensor placed at

location-2 provided signals closer than a sensor

placed at location-1 when compared to the reference

at location-3. Nevertheless, the filtering and location

effects observed should be subject for a more

controlled study in the future.

From the qualitative comparative observations

gathered, it can be concluded that first, the novel

flexible multisensor provided similar functional

sensitivity as the rigid PCB version housing the

same 3-axis MEMS accelerometer. This was a

preliminary indicator that suggested that the flexible

substrate proposed in the multiparameter single

locus multilayer integrated microsenor system does

not inhibit the actuation-sensor coupling due to its

flexibility. Next, the signals recorded from the

flexible multisensor were essentially similar in

morphology as the high-precision reference

accelerometer. This is an indicator that the novel

flexible multisensor has potential for applications in

BECG with medical diagnostic grade precision,

while providing a highly-integrated system in the

near future.

6 CONCLUSIONS

State-of-the-art technologies in microintegrated

multisensor systems were discussed. It was noted

that the current systems lacked several important

modules and features useful in certain specialized

healthcare monitoring and medical diagnostic

applications. A mutliparameter single locus

integrated multilayer polymer microsensor system

was proposed to incorporate high-density

multisensor and microelectronics system integration

on a flexible substrate platform that provides good

skin conformity in physiological applications.

Architecture of the proposed system was discussed,

as well as the implementation and fabrication of the

multisensor layer of the multilayer system. Model

BIODEVICES 2008 - International Conference on Biomedical Electronics and Devices

42

devices of the multisensor layer were shown and

their mechanical characteristics discussed,

particularly, it demonstrated excellent flexibility for

good skin conformity. It was also demonstrated that

information on bodily motion due to cardiac

contraction, or BCG signals, can be acquired

through sensors integrated on the proposed platform.

The system further shows potential for medical

grade diagnostic performance. Further testing and

characterization of more compact and highly-

integrated models of the proposed system is under

development, and will ultimately provide more

insightful understanding of the effectiveness of the

proposed microintegration platform.

ACKNOWLEDGEMENTS

The authors would like to thank Jasbir Patel from the

Computational Integrative BioEngineering Research

Lab and Microfluidics Lab at Simon Fraser

University for his help on silicone microfabrication.

The authors would also like to thank See-Ho Tsang

from the Institute for Micromachining and

Microfabrication Research at Simon Fraser

University for his help on polyimide circuit

fabrication. Further, the authors would like to

acknowledge CMC Microsystems for their ongoing

support in hybrid micro integration and device

fabrication assistance.

REFERENCES

Wang, L., Tang, T.B., Johannessen, E., Astaras, A.,2002.

An Integrated Sensor Microsystem for Industrial and

Biomedical Applications. IEEE Instrument and

Measurement, [online]. Available from:

http://www.see.ed.ac.uk/~aa/WanTanJohAst02b.pdf

[cited 18 June 2007].

Richards Grayson, A., Shawgo, R., Johnson, A., Flynn, N.,

Li, Y., Cima, M., Langer, R., 2004. A BioMEMS

Review: MEMS Technology for Physiologically

Integrated Devices. Proceedings of the IEEE, [online].

92 (1), pp 6-20.

Kundert, K., Chang, H., Jefferies, D., Lamant, G.,

Malavasi, E., Sendig,F., 2000. Design of Mixed-Signal

Systems-on-a-chip. IEEE Transaction on Computer

Aided Design of Integrated Circuits and Systems. 19

(12), pp 1561-1571.

Matthews, D. J., Gaynor, M. P., 2003. RF System in

Package: Considerations, Technologies and Solutions.

Amkor Technologies. [online]. Available from:

www.amkor.com/products/notes_papers/RF_SiP_Pape

r041403.pdf, [cited 18 June 2007]

Advanced Assembly and Packaging for Biomedical

Devices. Fraunhofer Institut Zuverlassigkeit und

Mikrointegration. [online].Available from:

http://www.pb.izm.fhg.de/izm/040_Publi_News/index.

html, [cited 18 June 2007]

Pai, R., Roussel, T., Crain, M., Jackson, D., Conklin, J.,

Baldwin, R., Keynton, R., Naber, J., Walsh, K., 2001.

Integrated Electrochemical Detection for Lab on a

Chip Analytical Microsystems. Proceedings of the

Fourteenth Biennial University/Government/Industry

Micro electronics Symposium. pp 167-170.

Zhang, J., Manson, A., 2007. Highly Adaptive Transducer

Interface Circuit for Multiparameter Microsystems.

IEEE Transactions on Circuits and Systems. 54 (1), pp

167-177.

Callister, 2003. Materials Science and Engineering and

Introduction 6

th

ed., Wiley & Sons, USA.

Egloff, E. R., The Art of Design and Manufacture of

Polymer Thick Film Circuits. Screen Printing and

Graphic Imaging Association International Technical

Guidebook. [online]. Available from:

www.sgia.org/pdf_server.cfm?pdf=/members/tgbArch

ive/2028.pdf, [cited 19 June 2007].

McKay, W., Gregson, P., McKay, B., Militzer, J., 1999.

Sternal Acceleration Ballistocardiography and Arterial

Pressure Wave Analysis to Determine Stroke Volume.

Clin Invest Med. 2 (1), pp 4-14.

MULTIPARAMETER SINGLE LOCUS INTEGRATED MULTILAYER POLYMER MICROSENSOR SYSTEM

43