A PRECISE APPROACH FOR RECOVERING POSES OF DISTAL

LOCKING HOLES FROM SINGLE CALIBRATED X-RAY

IMAGE FOR COMPUTER-ASSISTED INTRAMEDULLARY

NAILING OF FEMORAL SHAFT FRACTURES

Guoyan Zheng and Xuan Zhang

MEM Research Center – ISTB, University of Bern, Stauffacherstrasse 78, CH-3014, Bern, Switzerland

Keywords: Model-based fitting, parameter decomposition, computer-assisted intramedullary nailing.

Abstract: One of the most difficult steps of intramedullary nailing of femoral shaft fractures is distal locking – the

insertion of distal transverse interlocking screws, for which it is necessary to know the position and

orientation of the distal locking holes of the intramedullary nail. This paper presents a precise approach for

solving this problem using single calibrated X-ray image via parameter decomposition. The problem is

formulated as a model-based optimal fitting process, where the to-be-optimized parameters are decomposed

into two sets: (a) the angle between the nail axis and its projection on the imaging plane, and (b) the

translation and rotation of the geometrical models of the distal locking holes around the nail axis. By using a

hybrid optimization technique coupling an evolutionary strategy and a local search algorithm to find the

optimal values of the latter set of parameters for any given value of the former one, we reduce the multiple-

dimensional model-based optimal fitting problem to a one-dimensional search along a finite interval. We

report the results of our in vitro experiments, which demonstrate that the accuracy of our approach is

adequate for successful distal locking of intramedullary nails.

1 INTRODUCTION

It has been recognized that one of the most difficult

steps of intramedullary nailing of femoral shaft

fractures is distal locking – the insertion of distal

interlocking screws, for which it is necessary to

know the positions and orientations of the distal

locking holes (DLHs) of the intramedullary nail

(IMN). Complicating the process of locating and

inserting the distal interlocking screw is the nail

deformation with insertion. It has been reported that

deformation occurs in several planes due to medial-

lateral (ML) and anterior-posterior (AP) flexion of

the distal nail after it has been inserted. Using a

magnetic tracking system in a cadaveric study,

Krettek et al. (1998) reported following deformation

measurement results for small-diameter nails and

large-diameter nails, respectively: lateral translations

of 18.1

±

10.0 mm and 21.5

±

7.9 mm, dorsal

translations of -3.1

± 4.3 mm and 0.4 ± 9.8 mm,

and rotation about the longitudinal axes of -0.1

±

0.2 degrees and 10.0

± 3.1 degrees. The reason for

the wide variations of the insertion-related femoral

nail deformation is due to the fact that the nail has to

deform to the shape of the medullary canal upon

insertion. The shape of the canal varies widely from

person to person. It is not possible to predict how the

nail will deform accordingly. Therefore, it is very

difficult, to determine what the resultant locations

and orientations of the DLHs will be relative to their

initial position before it is deformed. The surgeon

depends heavily on intra-operative X-ray means in a

conventional surgical procedure for providing

precise locations and orientations of the DLHs. It

requires positioning the axis of the fluoroscope

perpendicular to the locking holes so that these holes

appear perfectly circular in the images. This is

achieved through a trial-and-error method and

requires long time X-ray exposure for both the

surgeon and patient. It has been reported that the

surgeon’s direct exposure to radiation for each

conventional surgical procedure was 3 – 30 min, of

which 31% - 51% was used for distal locking

(Sajeldal and Backe 1987).

The desire to target accurately with as little as

possible X-ray exposure has led to various attempts

120

Zheng G. and Zhang X. (2007).

A PRECISE APPROACH FOR RECOVERING POSES OF DISTAL LOCKING HOLES FROM SINGLE CALIBRATED X-RAY IMAGE FOR COMPUTER-

ASSISTED INTRAMEDULLARY NAILING OF FEMORAL SHAFT FRACTURES.

In Proceedings of the Second International Conference on Computer Vision Theor y and Applications, pages 120-127

DOI: 10.5220/0002066101200127

Copyright

c

SciTePress

to develop image-based methods for recovering the

positions and orientations of DLHs (Zhu et al. 2002,

Leloup et al. 2004, Yaniv and Joskowicz 2005).

These methods require either multiple calibrated

images or single image but with perfectly circular

holes in the image, which normally requires the X-

ray technician to use a try-and-move method several

times to achieve.

This paper presents a precise approach for

solving this problem using single calibrated

fluoroscopic image via parameter decomposition.

We do not ask for an image with perfectly circular

holes but we do put a constraint on its acquisition,

i.e., the reduced patient shaft should be roughly

parallel to the image intensifier (II) of the

fluoroscopy machine, which is much easier to be

achieved intraoperatively. We then formulate the

pose recovery of the DLHs as a model-based fitting

problem and decompose the to-be-optimized

parameters into two sets: (a) the angle between the

nail axis and its projection on the imaging plane, and

(b) the translation and rotation of the geometrical

models of the DLHs around the nail axis. By using a

hybrid optimization technique (Zheng et al. 2006)

coupling an evolutionary strategy and a local search

algorithm to find the optimal values of the latter set

of parameters for each give value of the former one,

we reduce the multiple-dimensional optimal fitting

problem to a one-dimensional search along a finite

interval.

The paper is organized as follows. Section 2

describes image calibration, geometrical models, and

preprocessing. In Section 3, we describe the

proposed approach in details. Section 4 presents our

in-vitro experimental results, followed by

conclusions in Section 5.

2 IMAGE CALIBRATION,

GEOMETRICAL MODEL AND

PREPROCESSING

2.1 Image Calibration

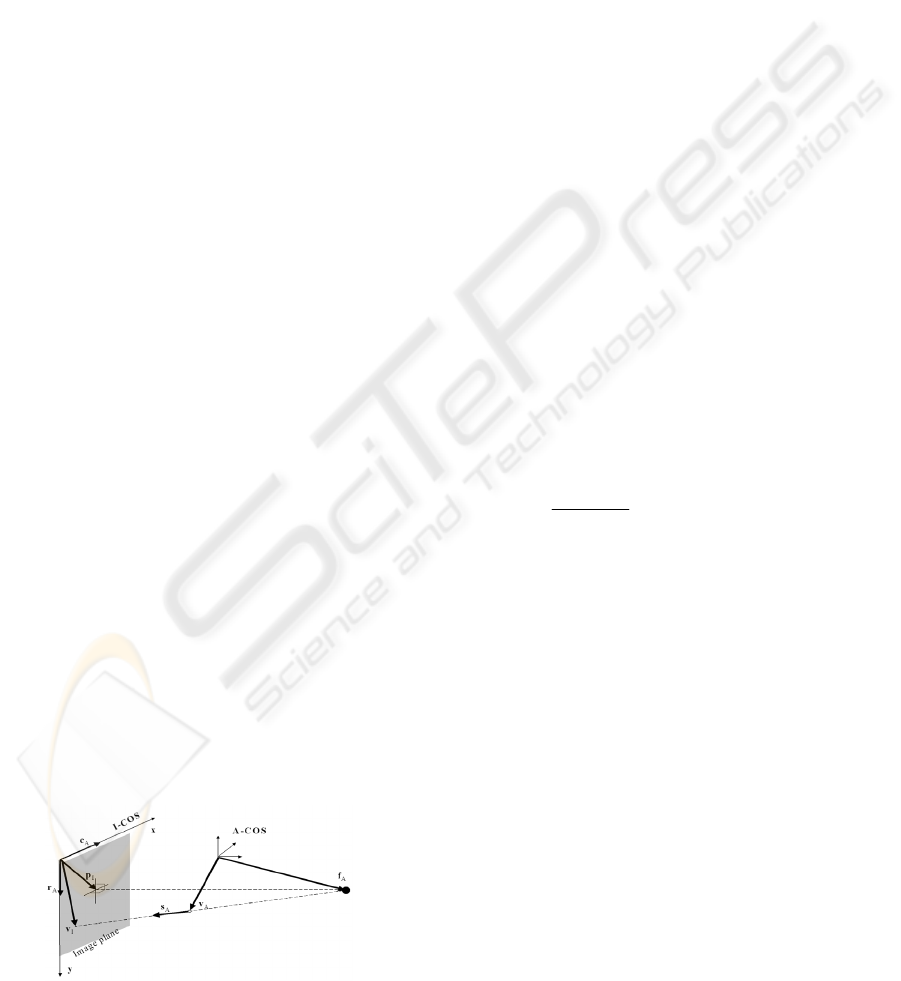

Figure 1: Weak-perspective pin-hole camera model.

In reality, the proximal fragment, the distal

fragment, and the nail may be treated as three rigid

bodies and registered independently. The rigid

transformations between these three rigid bodies can

be trivially obtained from a navigator such as an

optoelectronic tracker, a magnetic tracker, or even a

medical robot (Langlotz and Nolte 2004). As this is

not our focus in this paper, here we assume that the

fractured femur has already been reduced and the

proximal fragment and distal fragment are kept fixed

relative to each other at the time of image

acquisition. We also assume that the nail has been

inserted till the distal end of the femur and has been

locked proximally by screw so that the complete

femur and the nail can be treated as one rigid body.

A local coordinate system (COS) is established on

this rigid body through a so-called dynamic

reference base (DRB) technique (Nolte et al. 1995).

In the following description, let’s denote this patient

COS as

COS

A

−

. All computations are done in this

reference COS.

To relate a pixel in the two-dimensional (2D)

projection image to

COS

A

−

, the acquired image

has to be calibrated for physical projection

properties and be corrected for various types of

distortion. We have chosen a weak-perspective pin-

hole camera model as shown in Figure 1 for

modeling the C-arm projection (Gremban et al.

1988). Using such a camera model, a 2D pixel V

I

is

related to a three-dimensional (3D) point V

A

by

following equations:

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎣

⎡

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

=

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

−

−

=

1

S

S

S

1000

p

pccc

1

V

V

;

||fV||

)f(V

S

z

y

x

yzyx

xzyx

y

x

A,

A,

A,

I,A,A,A,

I,A,A,A,

I,

I,

AA

AA

A

rrr

(1)

where

||||

⋅

means to calculate the length of a vector

and the vectors f

A

, r

A

, c

A

and p

I

represent the

position of focal point, the vector along image row

increasing direction, the vector along image column

increasing direction, and the 2D position of piercing

point, respectively. They are projection parameters

used to describe the projection properties of the C-

arm and need to be calibrated preoperatively

Eq. (1) can be used for both forward and

backward projections. For example, if we want to

calculate the direction

A

S of the forward projection

ray of an image point V

I

, an additional constraint

1

A

=

||S|| can be used together with Eq. (1) to solve

for it. The forward projection ray of point V

I

is

defined by the focal point and the direction.

PRECISE APPROACH FOR RECOVERING POSES OF DISTAL LOCKING HOLES FROM SINGLE CALIBRATED

X-RAY IMAGE FOR COMPUTER-ASSISTED INTRAMEDULLARY NAILING OF FEMORAL SHAFT FRACTURES

121

The position of the imaging plane in

COS

A

−

and the focal length in our camera model is

implicitly determined using the calibrated focal

point f

A

and the vectors r

A

and c

A

. Any 2D image

point V

I

corresponds to a 3D spatial point I

A

in this

imaging plane, which is the intersection between its

forward projection ray and this plane.

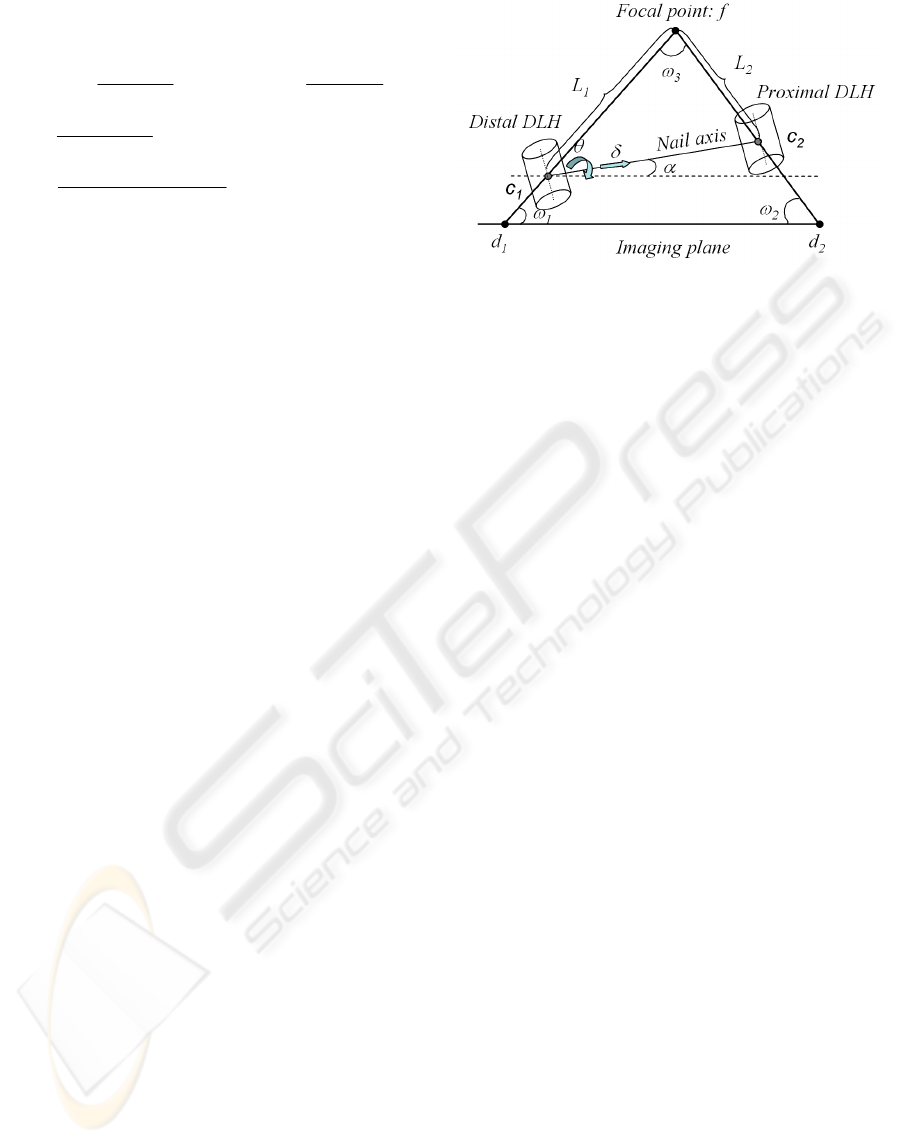

2.2 Geometrical Models

The distal part of IMN containing the two DLHs,

which is what we are interested in, is modeled as a

cylinder (Figure 2, left). The distance L between the

centers of the two DLHs can be accurately extracted

from its product information. The geometrical model

of each DLH is represented by two circles as shown

by Figure 2, right, and is used later to simulate X-ray

projection of the DLH model.

To obtain the coordinates of those points

(visualized as red dots in Figure 2, right) used to

describe the model of the DLH, a local COS

uvwC'

is established by taking the intersection point C (it is

also called the center of the DLH) between the axis

of the DLH and the axis of the IMN as the origin,

the axis of the IMN as the u axis, and the axis of the

DLH as the

v

axis (see Figure 2 for details).

Figure 2: The geometrical model of the distal part of the

IMN (left) and the geometrical model of the DLH (right).

Figure 3: Feature point detection. The detected projection

points (red dots) of the centers of both DLHs are displayed

together with the edge pixels of the DLHs (yellow).

The coordinates of those points expressed in this

local COS can be directly measured from the nail

using a caliber, thanks to the symmetrical property

of the DLH; or extracted from the engineering

drawings of the nail, if they are available.

2.3 Preprocessing

The task of the preprocessing is to determine the

projection points of the centers of the DLHs. To

extract these feature points from the image, Hough

transform (Jain and Schunk 1995) is used to find the

two mostly parallel edge lines of the projection of

the distal part of the IMN after applying a Canny

edge detector to the image. The projection of the

axis of the distal part of the IMN is considered as the

middle line between these two mostly parallel edge

lines. To determine those edge pixels belonging to

DLHs, the method reported in (Yaniv and Joskowicz

2005) is modified for our purpose. A parallelpiped

window, whose sizes are equal to the distance

between the detected edge lines, is swept along the

middle line to find two locations which contain the

maximum number of edge pixels and whose distance

is greater than a pre-selected distance threshold T

(e.g. the width of the window). The centroids of the

detected edge pixels in both locations are then

calculated. The projection of the center of each DLH

is then determined by finding the closest point on the

middle line to the associated centroid. An example

of feature point detection is shown in Figure 3.

3 THE PROPOSED APPROACH

3.1 Model-based Fitting for Pose

Recovery

Using above detected feature points, we can find

their corresponding spatial points on the imaging

plane. Let’s denote them as d

1

corresponding to the

projection point of the center C

1

of the distal DLH

(the DLH that is closer to the nail tip), and d

2

corresponding to the projection point of the center

C

2

of the proximal DLH, respectively, as shown in

Figure 4. These two points define a line in A-COS.

This line together with the focal point f defines a

plane where the axis of the distal part of the nail

should fall in. As we know the coordinates for point

f, d

1

, and d

2

, we can calculate three internal angles

ω

1

,

ω

2

, and

ω

3

of triangle fd

1

d

2

. Assume the angle

between the nail axis and its projection in the

VISAPP 2007 - International Conference on Computer Vision Theory and Applications

122

imaging plane is

α

, then the coordinates of the

centers of both DLHs are calculated as following:

)/,/(

)cos(

)sin(

)cos()sin(

)sin(

)sin(

||||

)(

;

||||

)(

22

2

3

32

2

3

2

1

2

2

22

1

1

11

ππα

αω

ω

ωαω

ω

αω

−∈

+⋅+

⋅+

⋅=

+

⋅=

−

−

⋅+=

−

−

⋅+=

where

LLL

LL

fd

f

d

LfC

fd

f

d

LfC

(2)

where L is the distance between the centers of two

DLHs. It can be measured or extracted from the

product information.

According to equation (2), the coordinates of

both centers only depends on the parameter

α

, so as

the direction of the nail axis (n

x

, n

y

, n

z

).

Assuming that the coordinates of the center C of

one of the DLHs is denoted as [C

x

, C

y

, C

z

]

T

, the

problem to estimate the pose of the DLH in A-COS

is now changed to find the rotation angle

α

, rotation

angle

θ

, and translation distance

δ

of the geometrical

model of the DLH along the nail axis [n

x

, n

y

, n

z

]

T

so

that the simulated X-ray projection of the DLH can

be fitted to its real X-ray projection (see Figure 4 for

details). This constrained transformation around the

parameterized nail axis could be described by a

33× rotation matrix ),,(

δ

θ

α

rot

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎣

⎡

+++−−−

−−+++−

+−−−++

)cos()()sin())cos(()sin())cos((

)sin())cos(()cos()()sin())cos((

)sin())cos(()sin())cos(()cos()(

θθθθθ

θθθθθ

θθθθθ

222

222

222

11

11

11

yxzxzyyzx

xzyzxyzyx

yzxzyxzyx

nnnnnnnnn

nnnnnnnnn

nnnnnnnnn

(3)

and a translational vector trans(α,

θ

,

δ

) = [t

x

, t

y

, t

z

]

T

:

⎪

⎪

⎪

⎪

⎪

⎪

⎪

⎩

⎪

⎪

⎪

⎪

⎪

⎪

⎪

⎨

⎧

⋅⋅+−⋅⋅+

++⋅⋅+−⋅⋅++⋅⋅+⋅

+⋅⋅++⋅⋅+⋅−+⋅⋅+=

⋅⋅+−⋅⋅+

++⋅⋅+−⋅⋅++⋅⋅+⋅

+⋅⋅++⋅⋅+⋅−+⋅⋅+=

⋅⋅+−⋅⋅+

++⋅⋅+−⋅⋅++⋅⋅+

⋅

+⋅⋅++⋅⋅+⋅−+⋅⋅+=

)sin())()((

)cos())()())()(((

))()(()()(

)sin())()((

)cos())()())()(((

))()(()()(

)sin())()((

)cos())()())()(((

))()(()()(

θδδ

θδδδ

δδδ

θδδ

θδδδ

δδδ

θδδ

θδδδ

δδδ

xyyzyxx

yxzzyyyxxxz

yyyxxxzyxzzz

zxxxzz

zxyyzzzxxxy

zzzxxxyzxyyy

yzzzyy

zyxxzzzyyyx

zzzyyyxzyxxx

nnCnnC

nnnCnnCnnCn

nnCnnCnnnnCt

nnCnnC

nnnCnnCnnCn

nnCnnCnnnnCt

nnCnnC

nnnCnnCnnCn

nnCnnCnnnnCt

22

22

22

22

22

22

(4)

The pose recovery problem can then be

formulated as an optimal model-based fitting:

2

||)),,(),,((||min

)(

}

*

,

*

,

*

{

δθαδθα

δθα

∑

+⋅−

=

i

iiCPj

transmrotPe

(5)

where {e

j

} are the detected edge pixels of the DLHs;

{m

i

} are the points used to describe the geometrical

models the DLHs; P(.) denotes the projection

operator; CP(.) denotes the action of finding the

closest edge pixel of the simulated projection point

into the image of a model point.

Figure 4: Schematic view of model-based fitting.

3.2 Parameter Estimation

Various techniques have been proposed for

estimating parameters for model-based fitting. Lowe

(1991) suggests to minimize the non-linear error

function on image domain, where the perpendicular

distance between projected model line and extracted

edge point will be minimized. The correspondence

between the model projection to image edge is found

by selecting the one who has the shortest

perpendicular distance. This strategy can lead to

some ambiguity in fitting process when part of the

model line has been occluded by structure of the

model itself. This problem was solved by Fua (1996)

through applying hidden algorithm to avoid this

pitfall. All these algorithms suffer from the facts that

they are easily to be trapped by a local minimum and

that the interpretation and initialization of model

parameter values have to be done by the operator,

which is not desirable for an intra-operative

application in a sterilized environment.

Parameter decomposition approach is a powerful

optimization method that tries to decompose a high-

dimensional problem into small, low-dimensional

components and estimate the parameters for each

component separately, thus reducing the

computational complexity. The general idea of

model decomposition for parameter estimation has

bee successfully applied in many domains, e.g.,

geometrical curve fitting (Jiang and Cheng 2005)

and Bayesian model learning (Neapolitan 2003).

According to our observation that the size of the

geometrical models of the DLHs (around 10 mm in

each dimension) is relatively small compared to the

focal length of the X-ray image (around 1000mm),

we decompose the control parameters in Eq. (5) into

two sets: (a) the angle

α

between the nail axis and its

projection in the imaging plane; and (b) the rotation

and translation distance of the geometrical models of

PRECISE APPROACH FOR RECOVERING POSES OF DISTAL LOCKING HOLES FROM SINGLE CALIBRATED

X-RAY IMAGE FOR COMPUTER-ASSISTED INTRAMEDULLARY NAILING OF FEMORAL SHAFT FRACTURES

123

the DLHs along the nail axis (

θ

,

δ

). Now the original

optimization problem can be re-formulated as:

)]||)),,(),,((||min(min[

)(

}

*

,

*

{

*

2

δθαδθα

δθ

α

∑

+⋅−

=

i

iiCPj

transmrotPe

(6)

Where the term in the square brackets simply means

the minimum sum of distance for a fixed

α

and all

possibilities of (

θ

,

δ

). The advantage of such

decomposition lies in the fact that the latter set of

variables can be calculated by using a hybrid

optimization technique coupling an evolutionary

strategy and an iterative closest projection point

algorithm (ICPP) as proposed in our previous work

(Zheng et al. 2006), which then reduces the original

multiple-dimensional optimization problem to a one-

dimensional search in a finite interval.

3.2.1 Initialization

Given a fixed

α

, we can estimate the positions of

both centers of DLHs and the orientation of the nail

axis. Then, the initial transformation between the

local COS of the geometrical model of the DLHs

and A-COS can be obtained by taking the estimated

center as the origin, the estimated nail axis as the u

axis, and the normal of the imaging plane as the v

axis. All points defined in the local COS of the

geometrical model of the DLH can then be

transformed to A-COS using this transformation. The

optimal values of the rotation

θ

and the translation δ

of the models along the nail axis can be optimally

estimated by fitting the geometrical models of the

DLHs to the image as by a hybrid optimization

technique as described below

3.2.2 The Iterative Closest Projection Point

(ICPP) Algorithm

Let’s denote E be a set of N

E

detected 2D edge

pixels

},...,,{

E

N

eee

21

of the DLH projection. Further

denote M

t-1

be a set of N

M

model

point

},...,,{

11

1

1

0

−−− t

M

N

tt

mmm at iteration step t-1. Now

in the iteration step t, we perform following steps:

Simulating X-ray projection: In this step, we

simulate the X-ray projection of the geometrical

models of the DLHs to remove invisible points. Let

1−t

P be a set of

P

N 2D projection points

},,,{

11

2

1

1

−−− t

P

N

tt

ppp L obtained by simulating X-ray

projection of 3D model into the image. Normally

MP

NN << . Thus, for each 2D projection point

1−t

i

p ,

we know its associated 3D model point

1−t

i

m

.

Find closest projection point: In this step, we try

to find the closest neighbor edge pixel

i

e of each 2D

model projection point

1−t

i

p .

Establishing 3D-2D correspondence: For each

2D matched pairs

),(

1−t

ii

pe , calculate the forward

projection ray

i

BP of the 2D edge pixel

i

e . Then for

the ray

i

BP , calculate a 3D point pair

),(

111 −−−

=

t

i

t

i

t

i

mbePP , where

1−t

i

be is a point on the

line

i

BP that is closest to the 3D model point

1−t

i

m

of

the model projection point

1−t

i

p .

Estimating pose: For all calculated 3D point

pairs

}{

)( 11 −−

=

t

i

t

PPPPS

, find an optimal local

solution of all pose parameters by minimizing

following disparity function

),(

)()( 11 −− tt

S

δθ

:

∑

−−−−−−−−

−−

−−

+⋅−=

i

ttt

i

ttt

i

tt

tt

tt

transmrotbeS

S

211111111

11

11

||),(),((||),(

),(minarg

)()()()()()(

)()(

}

*)(

,

*)(

{

δθδθδθ

δθ

δθ

(7)

where we drop the symbol

α

from the expressions,

as its value is fixed.

These steps are repeated until all pose

parameters are converged.

3.2.3 The Evolutionary Strategy

The ICPP algorithm can be regarded as a local

minimum search algorithm but we are trying to find

the global minimum of the disparity function that

may be well hidden among many poorer local

minima. In our approach, this is handled by

combining a conventional genetic algorithm

(Goldberg 1989) with the ICPP algorithm. The

genetic algorithm acts as a random generator for

possible parameter sets that solve the minimization

problem. All generated individual parameter set is

then fed through the ICPP algorithm before being

rated using the disparity function. Five best ones

become the parents of next generation. The

algorithm stops when the differences of the disparity

function values of all five best ones are smaller than

a pre-selected threshold.

VISAPP 2007 - International Conference on Computer Vision Theory and Applications

124

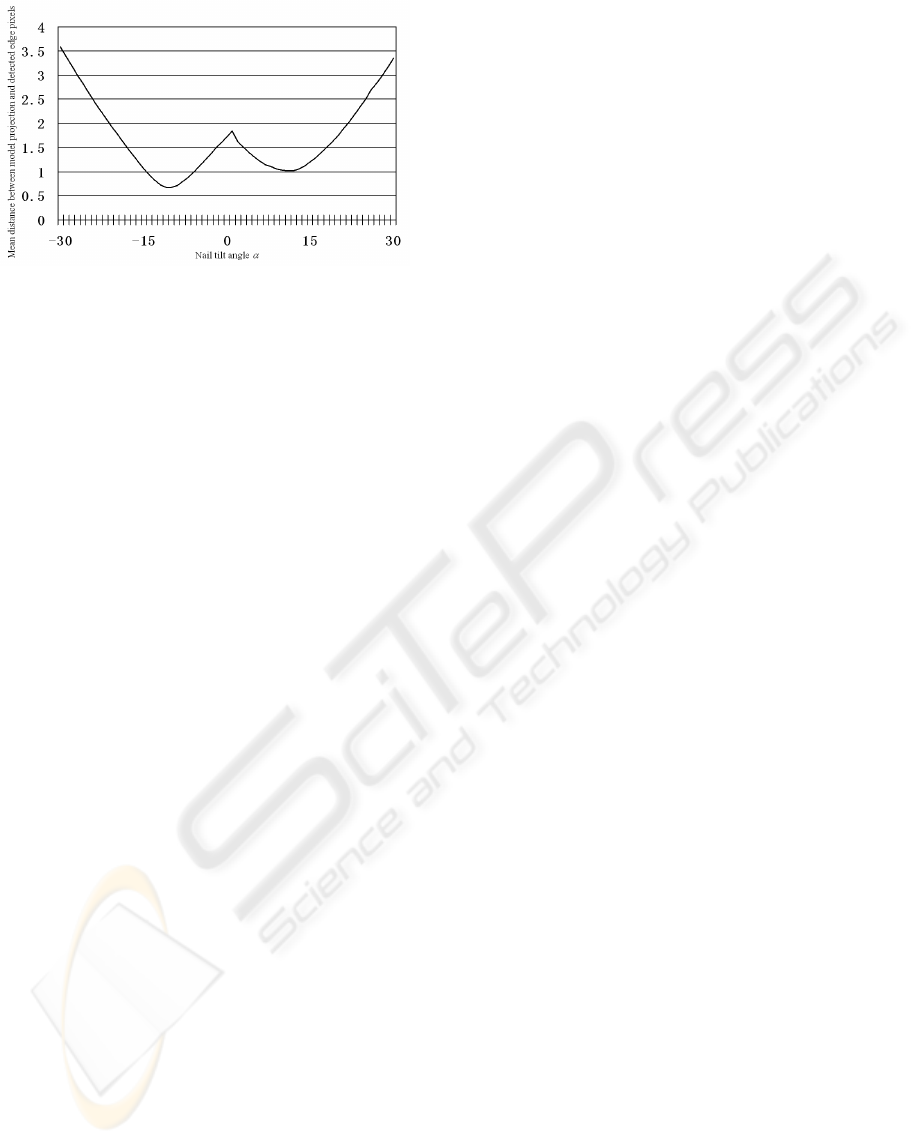

Figure 5: Optimization space of the nail tilt angle

α

.

3.2.4 Optimization of Parameter

α

We now convert a multiple-dimensional

optimization problem to a one-dimensional one,

where the parameter

α

can be optimized by a search

along a finite interval [-30

o

, +30

o

] (due to the

acquisition constraint that we put). A typical

optimization space of this parameter is shown in

Figure 5. It has a symmetrical shape and a clear

global optimum around the ground truth

α

=10.4

o

.

We could separate the optimization space into two

sub-intervals, i.e. [-30

o

, 0) and [0, 30

o

]. In each sub-

interval, the optimum of that sub-interval could be

easily found by a local search algorithm starting

from any initialization value. Actually, in all

experiments, we have simply initialized

α

by the

middle value of each sub-interval. The global

minimum is then found by taking the better one of

the two optima.

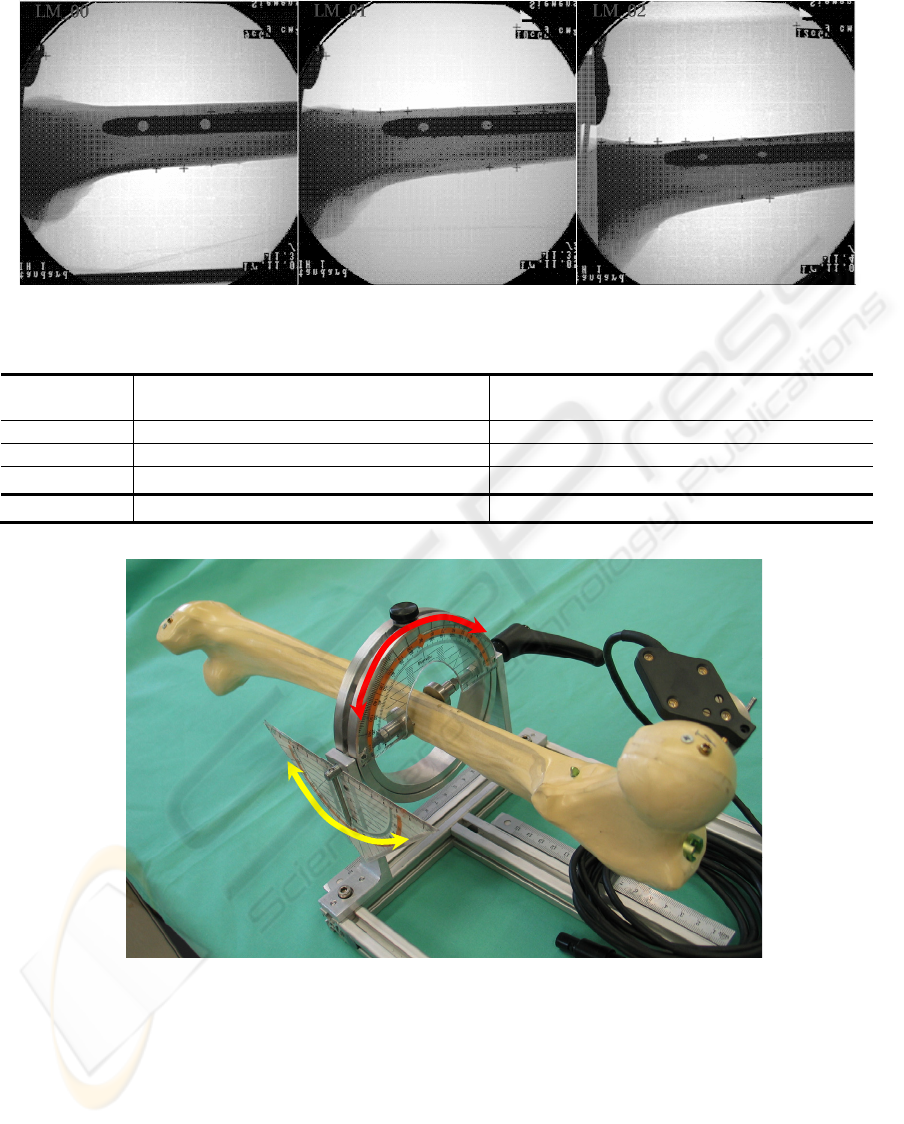

4 EXPERIMENTAL RESULTS

We designed and conducted two experiments to

analyze the accuracy and robustness of the proposed

approach. A SYNTHES® (STRATEC Medical,

Oberdorf, Switzerland) 9 mm solid titanium femoral

nail was used in our study. A Siemens ISO-C

3D

C-

arm (Siemens AG, Erlangen, Germany) was used to

acquire fluoroscopic images for our experiments.

In the first experiment, the nail was inserted into

a cadaveric human femur and was locked

proximally. The ground truth of the positions of the

DLHs was obtained after image acquisition by

inserting a custom-made steel rod through the hole

and then digitizing both top and bottom centers of

the rod using an optically trackable sharp pointer

(OPTOTRAK 3020, Northern Digital Inc, Waterloo,

Canada).

Three images acquired from different view

directions were used in our experiments, as shown in

Figure 6. For each image, we applied the proposed

approach ten times to estimate the poses of the

DLHs. The estimated results were compared to the

ground truth to compute the errors for each DLH,

which were defined as the angular difference

between the estimated hole axis and the one

obtained through pointer-based digitization, and the

positional difference of the entry point and its

ground truth along the plane perpendicular to the

hole axis (obtained by projecting the difference

vector into the plane perpendicular to the hole axis),

because the positional deviation along the hole axis

is not important for the task of insertion of distal

locking screw

In all studies, the poses of DLHs could be

automatically recovered. The angular and positional

errors are shown in Table I. Compared to ground

truths, the average angular error was found to be 1.0

o

(std=0.4

o

) and the average positional error along the

plane perpendicular to the hole axis was found to be

0.6 mm (std=0.4 mm).

In the second experiment, a test bench was

designed and implemented, which allowed rotation

and tilt of the test subject, as shown in Figure 7. The

nail was inserted tightly into the plastic bone and

was locked proximally. The plastic bone together

with the nail was then fixed to the test bench. A

dynamic reference base was fixed to the bone to

establish a local coordinate system. The ground

truths of the direction of the nail axis as well as the

positions of the centers of the DLHs and the

directions of the axes of the DLHs were obtained

from a registration-free 3D-navigation system [4]

using the SIREMOBIL ISO-C

3D

Carm.

The reference position (rotation = 0

o

, tilt = 0

o

)

was obtained using a try-and-move method until the

projections of both holes appeared perfectly circular.

We then tilted the test subject with an interval of 5

o

until 25

o

. At each tilted position, we rotated the test

subject with an interval of 5

o

until 25

o

, which results

in totally 6x6 = 36 configurations. For each

configuration (tilt, rotation), a lateral-medial image

was acquired.

We applied the present approach to these 36

images. For each image, we compared the estimated

results to the ground truths. We computed the

angular error of the estimated nail axis and the

angular errors of the estimated axes of the DLHs.

And to get a clear idea how the positional errors

were distributed, we decomposed the positional

errors along the three orthogonal directions, i.e., the

nail axis direction, the distal locking hole axis

PRECISE APPROACH FOR RECOVERING POSES OF DISTAL LOCKING HOLES FROM SINGLE CALIBRATED

X-RAY IMAGE FOR COMPUTER-ASSISTED INTRAMEDULLARY NAILING OF FEMORAL SHAFT FRACTURES

125

direction, and the cross product of the former two

directions.

It was found that angular errors in all

configurations except for two configurations (25

o

,

20

o

) and (25

o

, 25

o

) were smaller than 1.8

o

. The

positional errors along the distal locking hole axis

were bigger than those errors along other two

directions. When the tilt was smaller than 25

o

and

when the rotation was smaller than 25

o

, the average

angular error in estimating the nail axis was found to

be 0.5

o

(std=0.2

o

, max=1.2

o

), the average angular

error in estimating the axes of the DLHs was found

to be 0.7

o

(std=0.3

o

, max=1.5

o

), the average

positional error along the nail axis direction was

found to be 0.3 mm (std=0.4 mm, max=1.4 mm), the

average positional error along the distal locking hole

axis direction was found to be 1.3 mm (std=1.7 mm,

max=7.9 mm), and the average positional error

along the cross product direction was found to be 0.4

mm (std=0.5 mm, max=2.5 mm).

5 CONCLUSIONS

We have presented a novel variable decomposition

approach for automatic pose recovery of distal

locking holes from single calibrated fluoroscopic

image. Unlike previously introduced method (Yaniv

and Joskowicz 2005), our approach does not ask for

an image with perfectly circular holes. Our in vitro

experimental results demonstrate that the accuracy

of our approach is adequate for successful distal

locking of intramedullary nails.

REFERENCES

Krettek C., Mannβ J., Miclau T., et al. (1998) Deformation

of femoral nails with intramedullary insertion. J

Orthop Res, 16(5): 572 – 575.

Skjeldal S. and Backe S. (1987) Interlocking medullary

nails – radiation doses in distal targeting. Arch

Orthopaedic Trauma Surg, 106: 179 – 181.

Zhu Y., Phillips R., Griffiths J.G., et al. (2002) Recovery

of distal hole axis in intramedullary nail trajectory

planning. Proc Inst Mech Eng [H], 216(5): 323 – 332.

Leloup T., Schuind F., and Warzee N. (2004) Process for

the acquisition of information intended for the

insertion of a locking screw into an orifice of an

endomedullary device. European Patent Application

Number: 04447153.0.

Yaniv Z. and Joskowicz L. (2005) Precise robot-assisted

guide positioning for distal locking of intramedullary

nails. IEEE T Med Imaging, 24(5): 624 – 635.

Zheng G., et al. (2006) A robust and accurate two-stage

approach for automatic recovery of distal locking

holes in computer-assisted intramedullary nailing of

femoral shaft fractures. Submitted to IEEE T Med

Imaging.

Langlotz F. and Nolte L.-P. (2004) Technical approaches

to computer-assisted orthopedic surgery. Eur J

Trauma, 30(1): 1– 11.

Nolte L.-P., Visarius H., Arm E. et al. (1995) Computer-

aided fixation of spinal implants. J Image Guid Surg,

1: 88 – 93.

Gremban K.D., Thorpe C.E., Kanade T. (1988) Geometric

camera calibration using systems of linear equations.

In: Proceedings of IEEE conference on robotics and

automation, pp. 562-567.

Jain R., Kasturi R., and Schunk B. G. (1995) Machine

Vision. New York: McGraw-Hill.

Lowe F.G. (1991) Fitting parameterized three-dimensional

models to images. IEEE T Pattern Anal, 13(5): 441-

450.

Fua P. (1996) Model-based optimization: accurate and

consistent site modeling. The 18

th

Congress,

International Society for Photogrammetry and remote

sensing, Vienna, Austria, pp. 222-223.

Jiang X. and Cheng D.C. (2005) A novel parameter

decomposition approach to faithful fitting of quadric

surfaces. Pattern Recognition: 27

th

DAGM

Symposium, LNCS 3663, pp. 168-175

Neapolitan R.E. (2003), Learning Bayesian Networks. (1st

Ed) Prentice Hall

Goldberg D.E. (1989) Genetic algorithms in search,

optimization, and machine learning. Reading, MA,

Addison-Wesley.

VISAPP 2007 - International Conference on Computer Vision Theory and Applications

126

Figure 6: Three images used in our experiments. From left to right: LM_00, LM_01, and LM_02.

Table 1: Comparision results between the estimated poses of the distal locking holes and their associated ground truth.

Image Angular differences (

o

) Positional differences along the plane

perpendicular to the hole axis (mm)

LM_00 0.7 ± 0.3 0.2 ± 0.0

LM_01 0.9 ± 0.2 0.4 ± 0.1

LM_02 1.5 ± 0.2 1.1 ± 0.1

Overall 1.0 ± 0.4 0.6 ± 0.4

Figure 7: Test bench for evaluating the present approach.

Tilt

Rotation

PRECISE APPROACH FOR RECOVERING POSES OF DISTAL LOCKING HOLES FROM SINGLE CALIBRATED

X-RAY IMAGE FOR COMPUTER-ASSISTED INTRAMEDULLARY NAILING OF FEMORAL SHAFT FRACTURES

127