HIERARCHICAL MULTI-RESOLUTION MODEL

For Fast Energy Minimization of Virtual Cloth

Le Thanh Tung and Andr

´

e Gagalowicz

INRIA Rocquencourt, France

Keywords:

Hierarchical multi-resolution, gradient conjugate, virtual cloth prepositionning, energy minimization, collision

detection.

Abstract:

In this paper we present a method for fast energy minimization of virtual garments. Our method is based upon

the idea of multi-resolution particle system. When garments are approximately positioned around a virtual

character, their spring energy may be high, which will cause instability or at least long execution time of the

simulation. An energy minimization algorithm is needed; if a fixed resolution is used, it will require many

iterations to reduce its energy. Even though the complexity of each iteration is O(n), with a high resolution

mass-spring system, this minimization process can take a whole day. The hierarchical method presented in this

paper is used to reduce significantly the execution time of the minimization process. The garments are firstly

discretized in several resolutions. Once the lowest resolution particles system is minimized (in a short time),

a higher resolution model is derived, then minimized. The procedure is iterated up to the highest resolution.

But at this stage, the energy to minimize is already much lower so that minimization takes a reasonable time.

1 INTRODUCTION

With advances in computer graphics over the last few

decades, virtual garment simulation became popular

in many applications, from movie industry to fashion

and textile. Many papers in the area of virtual cloth-

ing have been published, from simplified cloth models

(Jerry, 1986), (C.Feynman, 1986), to more accurate

ones (Baraff and Witkin, 1998) (Lafleur et al., 1991)

(Choi and Ko, 2002) (Philippe Decaudin, 2006), some

surveys and comparisons of recent researches are

available in (Hing N.Ng, 1996), (House and Breen,

2000). A virtual garment is normally represented by

its two-dimensional patterns. These patterns can be

used to produce real garments in the textile industry

(CAD systems), or produced by a fashion designer.

More information is needed to be added to the 2D

patterns in order to produce garments. The automatic

pre-positioning of a garment around a digital body

is a difficult and challenging problem as we have to

sew the different pieces correctly. Some approaches

for dressmaking have been proposed. Some have

been introduced in the literature (Lafleur et al., 1991),

(Clemens Gross, 2003). In this approach, 2D patterns

are positioned by hand around the body and then,

sewing is performed automatically. We developed an

automatic virtual dressing system (T. Le Thanh, 2005)

which can be used easily by a normal user who wants

to try garments virtually. This technique proposes a

2D manipulation method which will be coupled to a

3D mapping technique allowing to reach the final po-

sitioning. Even though this method gives a fully au-

tomatic pre-positioning, the springs used in the parti-

cle system are usually very deformed, which implies a

very hight energy that the system has to dissipate; this

requires a very small time step in the simulator lead-

ing to a long simulation time, so that an energy mini-

mization algorithm for the particle system is needed.

In this paper we introduce an efficient method for

the energy minimization using hierarchical decompo-

sition. The garment is firstly discretized in various

resolutions (from lowest to highest). Then the lowest

resolution particles system is minimized using a local

minimization algorithm, since the complexity of this

algorithm is O(n), it requires a short time to perform

the minimization. Next, a higher resolution of the gar-

453

Thanh Tung L. and Gagalowicz A. (2007).

HIERARCHICAL MULTI-RESOLUTION MODEL - For Fast Energy Minimization of Virtual Cloth.

In Proceedings of the Second International Conference on Computer Vision Theory and Applications - IU/MTSV, pages 453-458

Copyright

c

SciTePress

ment is reconstructed from the previous minimization

result and the spring deformation are further reduced.

This procedure is iterated until the highest resolution

garment is minimized.

1.1 Related Work

Hierarchy decomposition methods have been pro-

posed to accelerate simulation for deformable objects

using finite element methods (Demetri Terzopou-

los and Fleischer, 1987), subdivision frameworks

(Steve Capell, 2002b), skeleton driven deformations

(Steve Capell, 2002a), physically based subdivisions

(Chouraqui and Elber, 1996), multi-resolution colli-

sion handlings (Nitin Jain, 2005), etc. Multi-level

optimization algorithms have also been proposed in

(Dave Hutchinson, 1996) to accelerate the perfor-

mance of a nonlinear optimizer. Li and Volkov in (Li

and Volkov, 2005) also introduce an adaptive method

to refine and simplify the cloth meshes locally.

Energy minimization for mass/spring systems

is used to avoid an expensive computation. As

physically-based methods require a large computation

time to compute equation 1 at each time step (See

(Baraff and Witkin, 1998)):

(M − h

∂ f

∂v

− h

2

∂ f

∂x

)4v = h( f

0

+ h

∂ f

∂x

v

0

) (1)

the simulation of a complex nonlinear and hystereti-

cal garment can require a whole day to a week (in an

early work of Breen). To avoid the use of the simu-

lator to minimize the energy of the mass/spring sys-

tem, we propose a fast geometrical minimization al-

gorithm. Adopting the idea of multi-resolution, we

introduce an efficient method to decompose the gar-

ment in several resolutions; each resolution can be re-

constructed easily from another one. Once the energy

of the lowest resolution has been minimized, we then

reconstruct the next one from this one and its mini-

mization is applied. This process loops until the high-

est resolution has been minimized.

The remainder of this paper is organized as fol-

lows: Section 2 describes input data used in our algo-

rithm. Section 3 details the principle of energy min-

imization for mass/spring systems. We present our

multi-resolution technique for virtual garment simu-

lation in Section 4, by explaining the decomposition

of garments keeping their boundaries untouched. Sec-

tion 5 briefly presents the method used for collision

detection in our system. We finally give some results

validating our approach in Section 6, before conclud-

ing in Section 7.

2 INPUT DATA

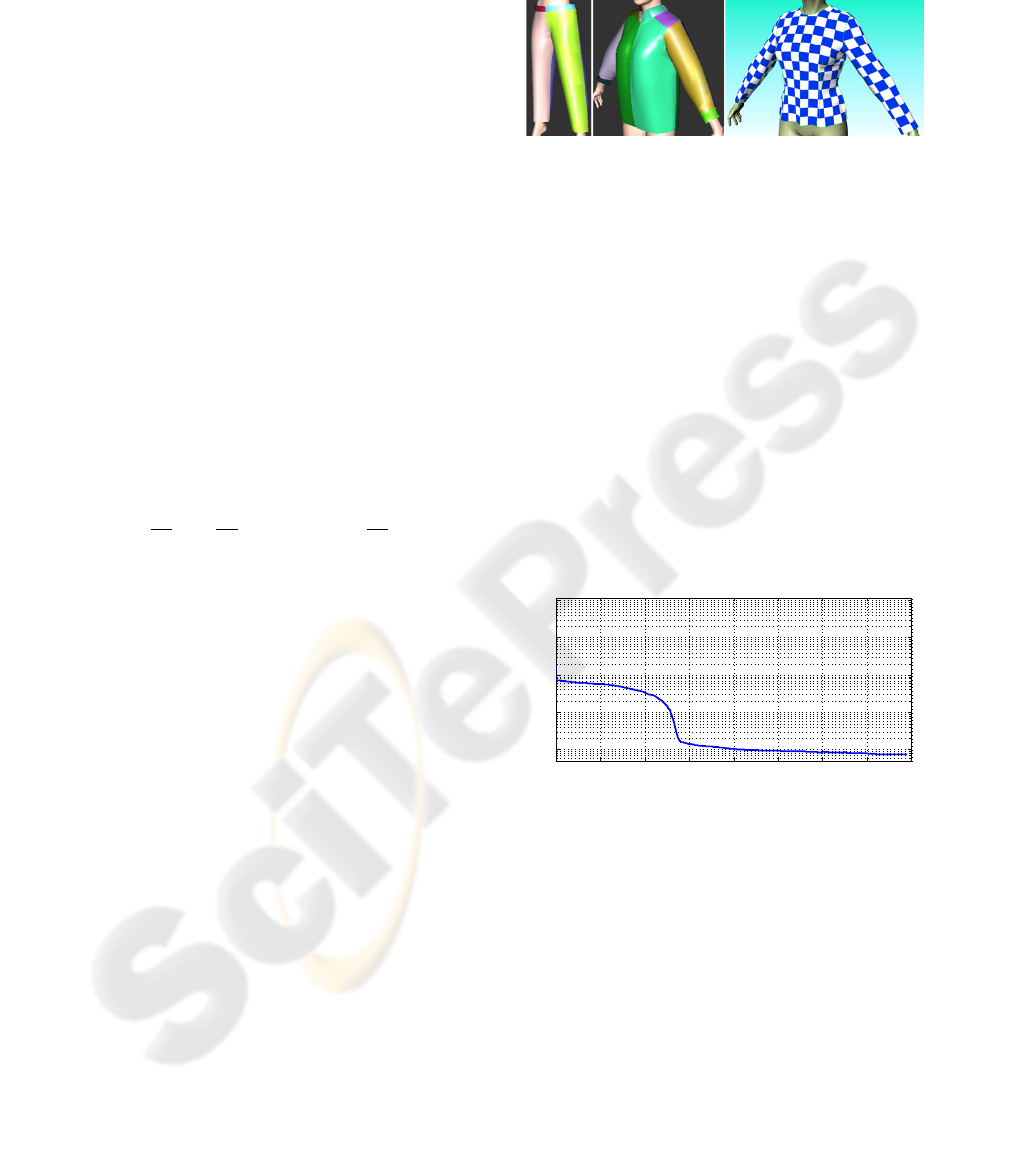

Figure 1: Input garment shape (left, middle) and output re-

sult using simulator (right).

The shape of the virtual garment is reconstructed

from a set of 2D patterns; these patterns come from

a CAD system or are created by a designer. In gen-

eral, a mass/spring system is used to model the me-

chanical behavior of cloth. Any virtual cloth mod-

eled by a mass/spring system can be applied to our

method. The input to the technique presented in this

paper is simply the output of the technique presented

in (T. Le Thanh, 2005). Such an input is visualized

on the left and middle part of figure 1. The garment

is already positioned around the body but its energy is

very high (the garment is highly deformed compared

to the final result - See the right of figure 1). There-

fore a long computation time is required to obtain an

acceptable result (stable position of the garment).

0 1 2 3 4 5 6 7 8

x 10

4

10

−3

10

−2

10

−1

10

0

10

1

Time (Seconds)

Error (cm)

Simul 10mm Error/Time

Figure 2: Simulation time (average spring error in cm) con-

vergence after 80,000 seconds, spatial resolution 10mm.

The discrete resolution of the cloth used in our

work varies from 50mm to 5mm. These resolutions

are nowadays used in most physically-based simula-

tion systems. The higher the resolution, the better the

garment is modeled, but the computing times grows

exponentially.

3 ENERGY MINIMIZATION

Garment models are modeled as triangular or rectan-

gular grids, with points of finite mass at the intersec-

tions of the grids and the mass points are joined by

VISAPP 2007 - International Conference on Computer Vision Theory and Applications

454

springs having no mass but modeling various mechan-

ical behaviors of cloth (tension, shear, bending ....).

The energy of the garment is estimated by the aver-

age elongation of all the springs of the system. We

will calculate the energy of the whole garment from

a set of equations and determine the shape of the gar-

ment by moving the points to achieve a minimum en-

ergy state. The reconstruction from 2D patterns to 3D

shape can be denoted as a function:

F : R

2

→ R

3

or (u, v) → (x, y, z)

where each particle P

i

of the garment has its 2D co-

ordinates (u

i

, v

i

) and 3D coordinates (x

i

, y

i

, z

i

). We

denote by r

i j

the spring connecting P

i

and P

j

. The

equilibrium length of r

i j

is its length in 2D coordi-

nates denoted by L

i j

, its current length is its length in

3D coordinates denoted by l

i j

. The energy equation

of the garment shape can be represented as follows :

E

total

= E

ten

+ E

sh

+ E

bend

+ E

grav

(2)

Where E

ten

is the energy due to tension, E

sh

to

shear, E

bend

, the bending energy, and the gravitational

energy is E

grav

. In fact, springs strongly resist the

deformations. We aim to develop an equation so

that the elasticity energy is high when the spring is

stretched or compressed. There is a lot of research

in cloth modeling, (David E.Breen, 1994) propose a

Kawabata model, some models of cloth ((Baraff and

Witkin, 1998), (Lafleur et al., 1991)) use a linear

model for fast simulation. Kawabata model gives a

more realistic cloth simulation but it has a drawback:

its computation time. For energy minimization pur-

poses, we used successfully the function:

Er

i j

= C

s

k

i j

(

l

i j

L

i j

− 1)

2

(3)

where Er

i j

is the energy of the spring r

i j

. C

s

is an elas-

ticity constant. The function E

elast

, the part of E

total

corresponding to tension and shear is calculated by

summing over all springs:

E

elast

=

∑

r

i j

∈M

e

Er

i j

= C

s

∑

r

i j

∈M

e

k

i j

(

l

i j

L

i j

− 1)

2

(4)

where M

e

is the set of tension and shear springs, k

i j

is

the stiffness constant of the spring r

i j

. Observing that

the tension energy of cloth is always much higher than

the bending energy, we can approximate the bending

along an edge AB by a virtual spring connecting two

points of two triangles sharing the edge AB. (See Fig-

ure 3).

This presentation of the bending force makes

E

bend

simple to compute. E

bend

is simplified as:

E

bend

=

∑

r

i j

∈M

b

Er

i j

= C

b

∑

r

i j

∈M

b

k

i j

(

l

i j

L

i j

− 1)

2

(5)

0 Lij lij

0

E(rij)

Structural spring

Shear spring

Bending

spring

Figure 3: Springs structure and energy function.

where M

b

is the set of bending springs. The parti-

cle’s energy due to gravity is simply defined as:

E

grav

= C

g

N

∑

i=0

m

i

gh

i

= C

g

N

∑

i=0

m

i

g(z

i

− Z

0

) (6)

where N is the number of particles, m

i

is the weight of

particle P

i

. C

g

, Z

0

are a density constant and the ref-

erence altitude of the system respectively. The energy

of the cloth shape can be represented as:

E

total

= C

s

∑

r

i j

∈M

e

k

i j

(

l

i j

L

i j

− 1)

2

+C

b

∑

r

i j

∈M

b

k

i j

(

l

i j

L

i j

− 1)

2

(7)

+C

g

N

∑

i=0

m

i

g(z

i

− Z

0

)

In fact, we store these springs in only one array M =

M

e

∪ M

b

, each spring has its own stiffness constant,

E

total

is calculated as:

E

total

=

1

2

∑

r

i j

∈M

k

i j

(

l

i j

L

i j

− 1)

2

+C

g

N

∑

i=0

m

i

g(z

i

− Z

0

)

(8)

Note that E

total

is defined as a continuous function, if

we let a

i j

=

l

i j

L

i j

and call E as E

total

, the partial differ-

ential equation of the total energy can be easily calcu-

lated:

∂E

∂x

i

=

∑

r

i j

∈V

i

k

i j

(x

i

− x

j

)(

a

i j

− 1

a

i j

L

2

i j

) (9)

∂E

∂y

i

=

∑

r

i j

∈V

i

k

i j

(y

i

− y

j

)(

a

i j

− 1

a

i j

L

2

i j

) (10)

∂E

∂z

i

=

∑

r

i j

∈V

i

k

i j

(z

i

− z

j

)(

a

i j

− 1

a

i j

L

2

i j

) +C

g

m

i

g (11)

where V

i

is the set of springs connected to particle P

i

.

We used the conjugate gradient method to determine

the minimum of E

total

(William H. Press, 1992). The

result is given in figure 5.

HIERARCHICAL MULTI-RESOLUTION MODEL - For Fast Energy Minimization of Virtual Cloth

455

4 MULTI-RESOLUTION FOR

THE ENERGY MINIMIZATION

As presented in figure 5, the computation time for

a small resolution garment is much faster than for a

high one, but the error reached remains much higher.

The problem we want to solve is to decrease substan-

tially the computing time to reach the same minimum

as that one of the highest resolution.

Multi-resolution methods are presented in many

papers as (Li and Volkov, 2005), (Dave Hutchinson,

1996), but they are restricted to the case of sim-

ple triangular meshes to model cloth. The triangular

mesh can be easily decomposed in several child tri-

angles to obtain a new unified mesh. However, these

methods cannot be applied in the case of our model

(T. Le Thanh, 2005; Provot, 1995), where the connec-

tivity of springs is more complex.

Figure 4: Multi-resolution of a shirt garments.

We developed a new decomposition method that

can work independently of the cloth structure. The

main idea is to predefine the 2D garments in several

resolutions beforehand. We then determine the corre-

spondences of each particle in a given resolution with

other particles in other resolutions. Given a 3D cloth

particle at a certain resolution, we can calculate its lo-

cation in another resolution without difficulty.

Each garment is discretized in N resolutions. Its

shape S at level n with n = 1..N is denoted by S

n

. The

shape is defined by a set of particles {P

n

}, springs

{R

n

} and triangles mesh {T

n

} : S

n

(P

n

, R

n

, T

n

). For

each particle p ∈ P

n

, we find a triangle t

i

∈ T

n−1

so

that the distance from p to t

i

is minimum:

distance(p, t

i

) =

0 if t

i

contains p

|po

i

| if t

i

does not contain p

where o

i

is the gravity center of t

i

. The correspon-

dence between p and t

i

is computed by employing

a positional constraint method. We call p

0

, p

1

and

p

2

the particles of triangle t

i

, the barycentric coordi-

nates of p on t

i

are (w

0

, w

1

, w

2

). The particle is re-

constructed so that its barycentric coordinates on the

triangle t

i

does not change. When the cloth shape S

n−1

is minimized, the new position of particle p is calcu-

lated as follows :

p = w

0

p

0

+ w

1

p

1

+ w

2

p

2

(12)

In order to reconstruct S

n

from S

n−1

, we have to

know the correspondences of all particles of S

n

on the

triangles of S

n−1

. The most time consuming task is

to compute the distance from each particle of S

n

to

the triangles of S

n−1

. A naive approach is to compute

the distance from each particle to all triangles. Since

the task has complexity O(K

2

) with K is the num-

ber of particles, the computation time is small at low

resolution. However, with a higher one (for example

about 30,000 particles), the computing time can take a

whole day. It is unacceptable even if the computation

will be performed only one time before the minimiza-

tion process starts.

We propose an efficient method to compute the

correspondences. This method uses bounding boxes

((Bergen, 1998)) for the set of triangles for each level.

Each node of the bounding box contains a linked list

of triangles. For each particle, we find the node cor-

responding to its bounding box. Distances from the

particle to all triangles contained by the node are com-

puted in order to find the minimum one.

Since the bounding box method has the complex-

ity O(n), we can compute the correspondences for

very high resolution with a reasonable time.

5 COLLISION DETECTION

The geometrically based minimization has to han-

dle self collisions and collisions between the hu-

man body and the cloth. Several methods have

been proposed in the last few years (Lafleur et al.,

1991),(Zhang and Yuen, 2000),(Robert Bridson and

Anderson, 2002). We have decided to solve the prob-

lem approximately by not testing particles against tri-

angles and edges against each other; we consider only

particles. Clearly, we now have to hold the particles

a little bit away from the human body or away from

each other to avoid artifacts of not detected intersect-

ing triangles. But this approach saves a lot of compu-

tation.

We have used a hierarchy of bounding boxes for

the garment. The hierarchy is built once at the begin-

ning and the bounding boxes are updated after each

step. For collision detection between the garment and

the human body we hold the particles away from the

body surface at a predefined distance δ. Now we are

able to determine the closest distance between the par-

ticles and the triangles. From the surface normal at

the closest distance we can determine if the particle

is inside the body or just close to it. In any case the

collision response moves the particle so that it is away

from the body by δ.

VISAPP 2007 - International Conference on Computer Vision Theory and Applications

456

tance β. The self-collision process will allow us to

obtain much better results.

REFERENCES

Baraff, D. and Witkin, A. (1998). Large steps in cloth sim-

ulation. In SIGGRAPH ’98: Proceedings of the 25th

annual conference on Computer graphics and inter-

active techniques, pages 43–54, New York, NY, USA.

ACM Press.

Bergen, G. V. D. (1998). Efficient collision detection of

complex deformable models using aabb trees. In Jour-

nal of Graphics Tools.

C.Feynman (1986). Modeling the appearance of cloth. In

Master’s thesis, Dept. of EECS, Massachusetts Inst.

of Technology, Cambridge, Mass.

Choi, K.-J. and Ko, H.-S. (2002). Stable but responsive

cloth. In SIGGRAPH ’02, New York, NY, USA. ACM

Press.

Chouraqui, P. and Elber, G. (1996). Physically based adap-

tive triangulation of freeform surfaces. In CGI’96,

page 144, Los Alamitos, CA, USA.

Clemens Gross, Arnulph Fuhrmann, V. L. (2003). Au-

tomatic pre-positioning of virtual clothing. In Pre-

ceedings of the 19th spring conference on Computer

Graphics, pages 99–108, Budmerice, Slovakia.

Dave Hutchinson, Martin Preston, T. H. (1996). Adaptive

refinement for mass/spring simulations. In Computer

Animation and Simulation ’96, pages 31–45.

David E.Breen, Donald H.House, M. J. (1994). Predicting

the drape of woven cloth using interacting particles. In

SIGGRAPH ’94, New York, NY, USA. ACM Press.

Demetri Terzopoulos, John Platt, A. B. and Fleischer, K.

(1987). Elastically deformable models. In Computer

Graphics, pages 205–214.

Hing N.Ng, R. L. (1996). Computer techniques for mod-

eling cloth. In Computer Graphics and Applications,

Vol. 16 No.5, pages 28–641.

House, D. H. and Breen, D. E. (2000). Cloth Modeling and

Animation. A. K. Peters.

Jerry, W. (1986). The synthesis of cloth objects. In Pro-

ceeding SIGGRAPH’86. Vol 20, No 4, pages 49–54.

Computer Graphics.

Lafleur, B., Magnenat-Thalmann, N., and Thalmann, D.

(1991). Cloth animation with self-collision detection.

In Proceedings IFIP Conference on Modeling in Com-

puter Graphics, pages 179–187. Springer-Verlag.

Li, L. and Volkov, V. (2005). Cloth animation with adap-

tively refined meshes. In ACSC ’05: Proceedings of

the Twenty-eighth Australasian conference on Com-

puter Science.

Nitin Jain, Ilknur Kabul, N. K. G. D. M. M. L. (2005).

Multi-resolution collision handling for cloth-like sim-

ulations. In Computer Animation and Virtual Worlds.

Volume 16, Issue 3–4, pages 141–151. John Wiley &

Sons, Ltd.

Philippe Decaudin, Dan Julius, J. W. L. B. A. S. M.-P. C.

(2006). Virtual garments: A fully geometric approach

for clothing design. In EUROGRAPHICS ’06.

Provot, X. (1995). Deformation constraints in a mass-

spring model to describe rigid cloth behavior. In Proc.

Graphics Interface ’95, pages 147–154.

Robert Bridson, R. F. and Anderson, J. (2002). Robust treat-

ment of collisions, contact and friction 106 for cloth

animation. In SIGGRAPH ’02, New York, NY, USA.

ACM Press.

Steve Capell, Seth Green, B. C. T. D. Z. P. (2002a). Inter-

active skeleton-driven dynamic deformations. In SIG-

GRAPH ’02, New York, NY, USA. ACM Press.

Steve Capell, Seth Green, B. C. T. D. Z. P. (2002b). A

multiresolution framework for dynamic deformations.

In SIGGRAPH ’02, New York, NY, USA. ACM Press.

T. Le Thanh, A. G. (2005). Virtual cloth pre-positioning. In

Proceedings of Mirage 2005.

William H. Press, William T. Vetterling, S. A. T. B. P. F.

(1992). Numerical Recipes. In C : The art of scientific

Computing. Cambridge University Press.

Zhang, D. and Yuen, M. M. (2000). Collision detection for

clothed human animation. In Proceedings of the 8th

Pacific Graphics Conference on Computer Graphics

and Application, pages 328–337.

VISAPP 2007 - International Conference on Computer Vision Theory and Applications

458