VISION-BASED OBSTACLE AVOIDANCE FOR A SMALL,

LOW-COST ROBOT

Chau Nguyen Viet and Ian Marshall

Computer Science Department, University of Kent, Canterbury, United Kingdom

Keywords:

Obstacle-avoidance, robot vision.

Abstract:

This paper presents a vision-based obstacle avoidance algorithm for a small indoor mobile robot built from

low-cost, and off-the-shelf electronics. The obstacle avoidance problem in robotics has been researched ex-

tensively and there are many well established algorithms for this problem. However, most of these algorithms

are developed for large robots with expensive, specialised sensors, and powerful computing platforms. We

have developed an algorithm that can be implemented on very small robots with low-cost electronics and

small computing platforms. Our vision-based obstacle detection algorithm is fast and works with very low

resolution images. The control mechanism utilises both visual information and sonar sensor’s measurement

without having to fuse the data into a model or common representation. The robot platform was tested in an

unstructured office environment and demonstrated a reliable obstacle avoidance behaviour.

1 INTRODUCTION

Obstacle avoidance is one of the most fundamental

problems in the field of mobile robotics. Despite the

problem being studied extensively, a reliable obstacle

avoidance behaviour in a dynamics and unstructured

environment, i.e. an environment that is not modi-

fied specifically to suit the robot, is still very hard

to achieve especially for small robots. Vision can

be used to detect obstacles and one of the developed

class of algorithms is based on colour-based terrain

segmentation (Lorigo et al., 1997; Lenser and Veloso,

2003; Ulrich and Nourbakhsh, 2000). If we can as-

sume that a robot with a digital camera pointing for-

ward is operating on a flat surface and all objects have

their bases on the ground, then the distance from the

robot to an object is linear to the y-axis coordinate

of the object’s appearance in the perceived image.

We have developed a similar algorithm that utilises

a low resolution digital camera and a low powered

micro processor. What makes our algorithm different

from existing algorithms is the use of a lookup map

for colour classification and a reduced colour space.

Lookup map is a very fast classification method. On

a Gumstix computer clocks at 200 MHz, our algo-

rithm can process more than 500 frames of 87 ∗ 44

pixels per second. The vision algorithm presented in

(Lenser and Veloso, 2003) uses 3 array access opera-

tions and an AND bitwise operations for each pixel.

Our algorithm uses only one array access operation.

Lugino and her group developed an algorithm that can

work with low resolution image 64*64 pixels frame in

(Lorigo et al., 1997). Our algorithm works with even

lower resolution of 22*30 pixels frame. This reduces

the computing cycle required for the vision algorithm

and enables our algorithm to run on embedded com-

puting devices. Our robot is small, less than a kilo,

and energy efficient; it is powered by AA batteries.

We present both the vision algorithm and the robot

design.

Due to the camera’s narrow field of view (FOV),

two sonar sensors were added to expand the robot’s

FOV. The control mechanism is reactive, it has no

memory and acts upon the most current sensor read-

ings only. This allows the robot to respond quickly to

changes in the environment. The approach we used

is inspired by the subsumption architecture (Brooks,

1985) and Braintenberg vehicles (Braitenberg, 1984).

The obstacle avoidance algorithm might be used as a

module in a more complex system e.g. the first level

275

Nguyen Viet C. and Marshall I. (2007).

VISION-BASED OBSTACLE AVOIDANCE FOR A SMALL, LOW-COST ROBOT.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 275-279

DOI: 10.5220/0001648302750279

Copyright

c

SciTePress

of competence in a subsumption architecture. It can

be used on it own in applications such as exploration,

surveillance. Because only a small fraction of the

CPU is required for obstacle avoidance, more spaces

are available for complex behaviours.

This paper is organised as follows. In section II,

we present the vision algorithm and control mecha-

nism. Section III describes the hardware configura-

tion and software implementation. The experiments

and results are reported in section IV.

2 VISION AND CONTROL

ALGORITHM

2.1 Ground and Obstacles

Segmentation

In our classification algorithm, pixels are classified

according to their colour appearance only. The colour

space we use is the RGB colour space. Each colour

in the colour space is set to be a ground or obsta-

cle colour. This classification information is stored

in a binary lookup map. The map is implemented as

a three dimensions vector of integers. To classify a

pixel, its RGB components are used as indices to ac-

cess the class type of the pixel. The classification pro-

cess is very fast since for each pixel only one array

lookup operation is needed.

The lookup map is populated from example pic-

tures of the ground. First, the algorithm counts the

number of pixels of each colour in the example pic-

tures. Then if the number of pixels of a colour is

more than 5% of the total number of pixels in those

pictures, that colour is set to be a ground colour. The

5% threshold is used to eliminate noises in the im-

ages. Procedure 1 describes this calibration process.

A lookup map is also very efficient for modification.

At the moment, the calibration process is done once

before the robot starts moving and the lookup map

remains unchanged. We anticipate that the colour ap-

pearance of the ground and the lightning condition are

likely to change if the robot operates for a long period

or moves into different environments therefore any

classification technique is required to adapt to these

changes. In the near future, we plan to implement an

on-line auto-calibrating algorithm for the vision mod-

ule. Procedure 2 describes how a pixel is classified

during the robot’s operation.

In a constrained platform the amount of memory

needed to store the full 24 bits RGB space is not avail-

able. To overcome this problem, we reduce the origi-

nal 24 bits RGB colour space to 12 bits and decrease

A B

C

D

Figure 1: The images processed by the vision module. A

is a full resolution colour image. B is the binary obstacle-

ground image of A. C is a low resolution image from A and

D is its corresponding binary image.

the size of lookup table from 2

24

elements to 2

12

ele-

ments. Effectively, we make the classifier more gen-

eral since each element of the reduced table represents

a group of similar colours in the original space. We

also use very low resolution images of 22∗ 30 pixles.

Fig. 1 has two examples of the outputs from this seg-

mentation procedure. At the top row is a picture taken

from the camera mounted on our robot at the max-

imum resolution and the binary image produced by

the segmentation procedure. At the bottom row is the

down-sampling version of the top row picture and its

corresponding binary image.

The output of the image segmentation is a binary

image differentiating obstacles from the ground. As-

suming all objects have their bases on the ground,

the distance to an object is the distance to its base.

This distance is linear to the y-coordinate of the edge

between the object and the ground in the binary im-

age. For obstacle avoidance, we only need the dis-

tance and width of obstacles but not their height and

depth. Therefore a vector of distance measurements

to the nearest obstacles is sufficient, we call this ob-

stacle distance vector (ODV). We convert the binary

image to the required vector by copying the lowest y-

coordinate of a non-floor pixel in each column to the

corresponding cell in the vector. Each element of the

vector represents the distance to the nearest obstacle

in a specific direction.

2.2 Control Algorithm

The control algorithm we adopted is reactive, deci-

sions are made upon the most recent sensory readings.

The inputs to the controller are the obstacle distance

vector, produced by the visual module, and distance

measurements from the two sonar sensors pointing at

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

276

Procedure 1 PopulateLookupMap ( n: number of

pixels , P : array of n pixels.

for i = 0 to n− 1 do

(R,G,B) =⇐ rescale(P[i]

r

,P[i]

g

,P[i]

b

)

pixel counter[R][G][B] ⇐

pixel

counter[R][G][B] +1

end for

for (R,G,B) = (0,0,0) to MAX(R,G,B) do

is

ground map[R][G][B] ⇐

pixel

counter[R][G][B] > n∗ 5%

end for

return is

ground map

Procedure 2 is ground(p : pixel ).

(R,G,B) ⇐ rescale(p

r

, p

g

, p

b

)

return is

ground map[R][G][B];

the sides of the robot. The ODV gives a good resolu-

tion distance map of any obstacle in front of the robot.

Each cell in the vector is the distance to the nearest

obstacle in a direction of an angle of about 2.5

◦

. The

angular resolution of the two sonar sensors are much

lower. So the robot has a good resolution view at the

front and lower at the sides. The controlling mecha-

nism consists of several reflexive rules.

• If there are no obstacles detected in the area mon-

itored by the camera, run at maximum speed.

• If there are objects in front but further than a trig-

ger distance, slow down.

• If there are objects within the trigger distance,

start to turn to an open space.

• If a sonar sensor reports a veryclose object, within

5 cm, turn to the opposite direction.

The control algorithm does not calculate how far the

robot should turn. It will keep turning until the area

in front is clear. The robot looks for an open space

by first looking in the opposite direction to the per-

ceived obstacle, if the half image in that side is free

of obstacles, the robot will turn to this direction. If

there are obstacles in both left and right half of the

image, the two measurements from sonar sensors are

compared and the robot will turn to the direction of

the sonar sensor that reports no existence of obstacles

or a biger distance measurement. There is no attempt

to incorporate or fuse data from the camera and sonar

sensors together into a uniformed representation. The

algorithm uses the sensor readings as they are.

15cm

15cm

A

B

D C

E F

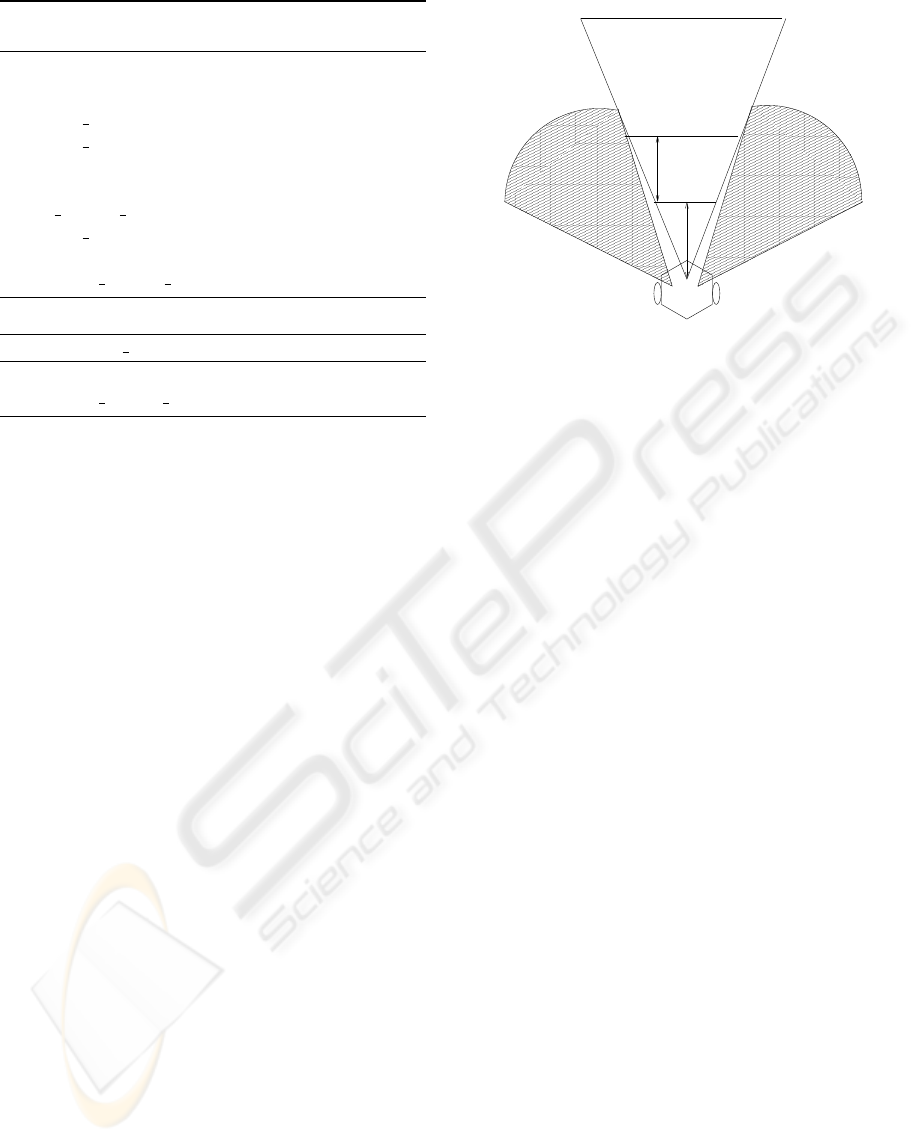

Figure 2: A visualisation of the monitored area. ABCD :

the area captured by the camera. Shaded areas represent

the sonar sensors views. Segment EF is the trigger distance

line.

3 PLATFORM CONFIGURATION

AND IMPLEMENTATION

The robot control software runs on a Gumstix (gum,

), a small Linux computer that has an Intel 200 MHz

ARM processor with 64 Mb of RAM. The vision sen-

sor is a CMUcam2 module connected to the Gumstix

via a RS232 link. A Brainstem micro-controller is

used to control sonar sensors and servos. The robot

is driven by two servos. These electronic devices are

mounted on a small three wheeled robot chassis. The

total cost of all the components is less than 300 US

dollars. The robot can turn on the spot with a small

radius of about 5 cm. Its maximum speed is 15cm/s.

The robot is powered by 12 AA batteries. A fully

charged set of batteries can last for up to 4 hours.

Fig. 2 shows the area in front of the robot that is

monitored by the robot’s sensors. The CMUcam is

mounted on the robot pointing forward at horizontal

level,15 cm above the ground, and captures an area of

about 75cm

2

. Because the camera has a relatively nar-

row FOV of about 55

◦

, the two sonar sensors on the

side are needed. In total, the robot’s angle of view is

120

◦

. The robots dimensions are 20cm∗ 20cm∗ 15cm.

The hardware configuration was determined by the

trial and error method. The parameters we presented

here were the best that we found and were used in the

experiments reported in section IV.

The maximum frame resolution of the CMUCam2

is 87 ∗ 144 pixels, we lower the resolution to only

22 ∗ 30 pixels. We only need the first bottom half

of the picture so the final image has dimensions of

22∗ 15. In our implementation, the obstacle distance

vector has 22 cells, each cell corresponds to an angle

VISION-BASED OBSTACLE AVOIDANCE FOR A SMALL, LOW-COST ROBOT

277

of 2.5

◦

. The vector is then outputted to the controller.

Since the control algorithm doesn’t build a model,

there is no need to convert the pixel’s y-coordinates

to an absolute measurement e.g. cm or inch. Because

the resolution of the images is very low, the distance

estimation is not very accurate. At the lowest row of

the image, where the ratio between pixel and the pro-

jected real world area is highest, each pixel represents

an area of 2∗ 1.5cm

2

.

The distance that triggers the robot to turn is set

to 30 cm. The robot needs to turn fast enough so that

an obstacle will not be closer than 15 cm in front of it

since the distance of any object in this area can not be

calculated correctly. At maximum speed , the robot

will have about two seconds to react and if the robot

has already slowed down while approaching the ob-

ject, it will have about three seconds. We have tried

different combinations of trigger distances and turn-

ing speeds to achieve a desirable combination. The

first criteria is that the robot must travel safely, this

criteria sets the minimum turning speed and distance.

The width of view of the camera at the distance of

30 cm from the robot or 35 cm from the camera is

30 cm. The width of our robot is 20 cm, so if the vi-

sion module does not find an obstacle inside the trig-

ger range, the robot can safely move forward. The

second criteria is the robot needs to be able to go

to cluttered areas. This means it should not turn too

early when approaching objects. Also when the robot

is confronted by the wall or a large object, it should

turn just enough to move along the wall/object and

not bounce back. This criteria encourages the robot

to explore the environment.

4 EXPERIMENTS

4.1 Experiment Setup and Results

We tested the robot in two environments, a 1.5∗ 2.5m

2

artificial arena surrounded by 30cm height walls and

an office at the University of Kent Computing de-

partment, shown in Fig. 3. The surface of the arti-

ficial arena is a flat cartoon board with green wall-

papers on top. We put different real objects such as

boxes, shoes, books onto the arena. We first tested the

robot in the arena with no objects (the only obstacless

are walls) and then made the tests more difficult by

adding objects. The office is covered with a carpet.

The arena presents a more controlable environment

where the surface is smooth and relatively colour-

uniformed. The office environmnent is more chal-

lenging where even though the ground is flat its sur-

face is much more coarse and not colour-uniformed.

A B

C

D

Figure 3: Snapshots of the robot in the test environments

and its trajectories. A: the artificial arena with 4 objects.

B: A small area near the office corner. C: A path that went

through a chair’s legs. D: An object with no base on the

ground.

For each test, the robot run for 5 mins. We placed

the robot in different places and put different objects

into the test area. In general, the robot is quite compe-

tent; Table I summaries the result. The vision-based

obstacle detection module correctly identified obsta-

cle with almost 100% accuracy, that is if there was an

obstacle in the camera view, the algorithm would reg-

ister an non-ground area. Although the calculated dis-

tances of obstacles are not very accurate, they provide

enough information for the controller to react. The

simple mechanism of finding an open space worked

surprisingly well. The robot was good at finding a

way out in a small area such as the areas under tables

and between chairs. The number of false positives are

also low and only occured in the office environment.

This is because the office’s floor colours are more dif-

ficult to capture thoroughly. Further analysis revealed

that false positives often occurred in the top part of the

images. This is explained by the ratio of pixels/area

in the upper part of the image being lower than the

bottom part. At the top row of the image, each pixel

corresponds to an area of 7 ∗ 4cm while at the bot-

tom row the area is 2∗ 1.5cm. Fortunately, the upper

part also corresponds to the further area in real world.

Therefore, most false positive cases resulted in unnec-

essary decreasing of speed but not changing direction.

Because of the robot’s reactive behaviour, it is capable

of responding quickly to changes in the environments.

During some of the tests, we removed and put obsta-

cles in front of the robot. The robot could react to the

changes and altered it’s running direction accordingly.

Fig. 3 shows 4 snapshots of the robot during op-

eration and its trajectory. In picture A, the robot ran

in the arena with 4 obstacles, it successfully avoided

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

278

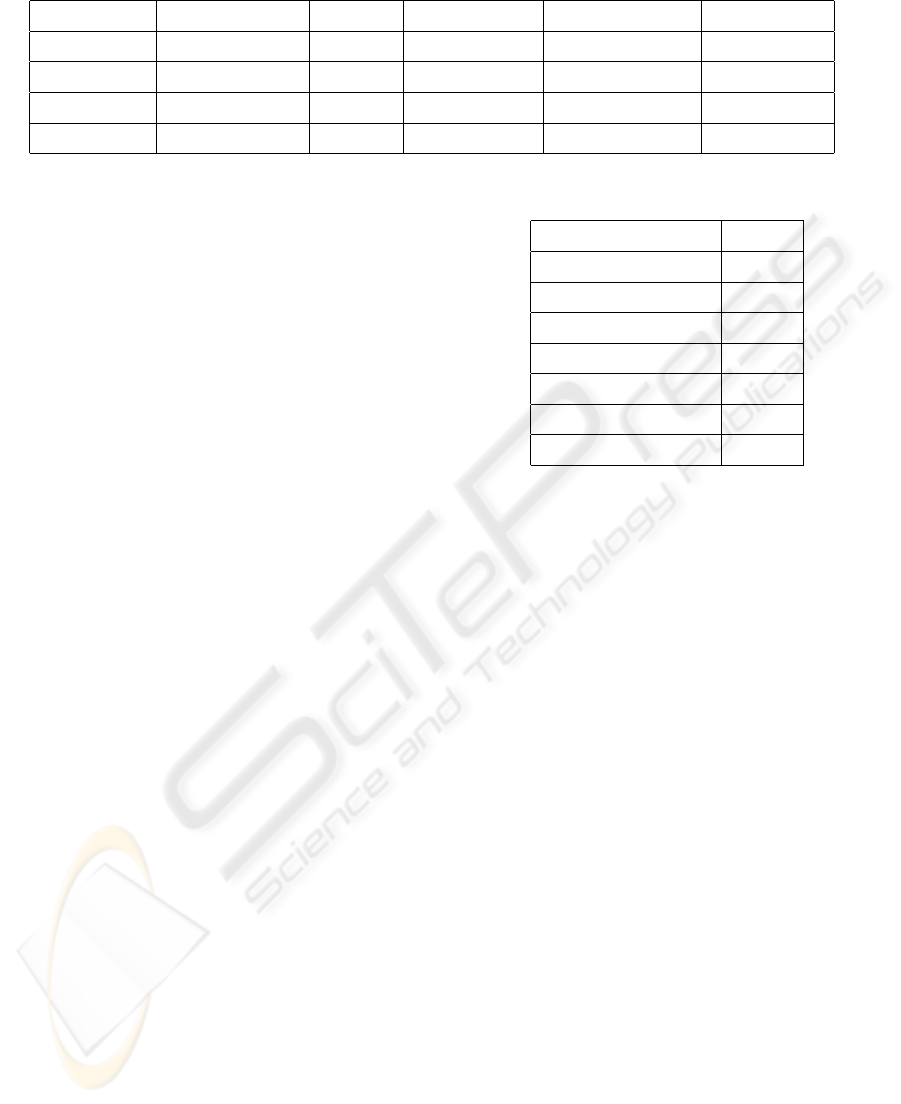

Table 1: Performance summary.

Environment No of Obstacles Duration Average speed No. of collisions False positive

Arena 0 60 min 13 cm/c 0 0%

Arena 1 60 min 10 cm/s 0 0%

Arena 4 60 min 6 cm/s 2 0%

Office > 10 180 min 9 cm/s 7 3%

all the objects. On picture B, the robot went into a

small area near a corner with a couple of obstacles

and found a way out. On picture C, the robot success-

fully navigated through a chair’s legs which presented

a difficult situation. Picture D was a case where the

robot failed to avoid an obstacle. Because the table

leg cross-bar is off the floor, the robot underestimated

the distance to the bar.

4.2 Discussion

We found that adding more obstacles onto the arena

did not increase the number of collisions significantly.

However the average speed of the robot dropped as

the arena became more crowded. The speed loss is

admitedly due to the robot’s reactive behaviour. The

robot does not do path planning therefore it can not

always select the best path. In some cluttered areas,

the robot spent a lot of time spinning around before it

could find a viable path. We can improve the robot’s

behaviour in these situations by having a mechanism

to detect cluttered and closed areas so the robot can

avoid them.

Each control cycle takes about 150ms or 7Hz. Ta-

ble II shows the time spent on each task in the cycle.

The algorithm used only 15% of the CPU during op-

eration. This leaves plenty of resources for higher be-

haviours if needed. It is possible to implement this al-

gorithm with a less powerful CPU. Since only 10% of

the CPU time is spent on processing data, a CPU run-

ning at 20 MHz would be sufficient. So instead of the

Gumstix computer we can use a micro-controller such

as a Brainstem or a BASIC STAMP for both image

processing and motion control without any loss in per-

formance. The memory usage is nearly one Mb which

is rather big. We did not try to optimise memory us-

age during implementation so improvements could be

made. We plan to implement this control algorithm

on a micro-controller instead of the Gumstix. This

change will reduce the cost and power usage of the

robot by a large amount. To the best of our knowl-

edge, there has not been a mobile robot that can per-

form reliable obstacle avoidance in unconstrained en-

vironments using such low resolution vision and slow

microprocessor.

Table 2: Speed performance.

Task Time

Image acquiring 95 ms

Sonar sensor reading 125 ms

Image processing 5 ms

Controller 1 ms

Servos updating < 1ms

Logging 3 ms

Total 150 ms

REFERENCES

http://www.gumstix.org.

Braitenberg, V. (1984). Vehicles: Experiments in Synthetic

Psychology. MIT Press/Bradford books.

Brooks, R. A. (1985). A robust layered control system for a

mobile robot. Technical report, MIT, Cambridge, MA,

USA.

Lenser, S. and Veloso, M. (2003). Visual sonar: fast ob-

stacle avoidance using monocular vision. In Intelli-

gent Robots and Systems, 2003. (IROS 2003). Pro-

ceedings. 2003 IEEE/RSJ International Conference

on, volume 1, pages 886–891.

Lorigo, L., Brooks, R., and Grimsou, W. (1997). Visually-

guided obstacle avoidance in unstructured environ-

ments. In Intelligent Robots and Systems, 1997. IROS

’97., Proceedings of the 1997 IEEE/RSJ International

Conference on, volume 1, pages 373–379, Grenoble,

France.

Ulrich, I. and Nourbakhsh, I. R. (2000). Appearance-based

obstacle detection with monocular color vision. In

AAAI/IAAI, pages 866–871.

VISION-BASED OBSTACLE AVOIDANCE FOR A SMALL, LOW-COST ROBOT

279