DEVELOPMENT OF AN AUTOMATED DEVICE

FOR SORTING SEEDS

Application on Sunflower Seeds

Vincent Muracciole, Patrick Plainchault

INRA;ESEO;LISA;GEVES-SNES, Université d’Angers, Angers, France

CER ESEO, Angers, France

Dominique Bertrand, Maria Rosaria Mannino

ENITIAA-INRA, Sensométrie - Chimiométrie, Nantes, France

GEVES-SNES, Beaucouzé, France

Keywords:

Machine vision, computer vision, seed identification, grain quality, seed quality, embedded systems.

Abstract:

Purity analysis and determination of other seeds by number are still made manually. It is a repetitive task based

upon visual analysis. Our work objective is to create and use a simple and quick automated system to do this

task. A first step of this machine has been reached by validating the image acquisition and feeding process.

The principle of this machine is based on a seeds fall with stroboscopic effect image acquisition. This article

presents the first step of creating a dedicated and autonomous machine which combines embedded constraints

and real time processes.

1 INTRODUCTION

In most countries, seeds cannot be commercialized

without an assessment of their quality. Quality control

tests generally includes the evaluation of unwanted

materials in the batches. This control is currently

performed manually by operators able to separate the

pure seeds from impurities.

In France, the official assessment of seeds is per-

formed by GEVES (Groupe d’Etude et de contrle des

Varits; Variety and seed study and control group). The

standardized methods of the ISTA (International Seed

Testing Association) and of the AOSA (Association

of Official Seed Analysts) are applicable to two kinds

of analyses of the seeds: purity analysis and deter-

mination of other seeds by number. In the analytical

analysis of purity, all the elements in a sample (pure

seeds (PS), inert matter (IM) and seeds of other plants

(SOP)) are identified, separated and weighed. The re-

sult is then given as percentage of each part’s weight.

In the determination of other seeds by number

analysis, only the impurities are separated, identified

and counted. The standardized methods of purity

analysis are very requiring since a one hundred per-

cent correct identification is expected. The visual in-

spection of seeds is time-consuming and needs oper-

ators to be trained. It is thus very desirable to develop

an automaton making it possible to do such controls.

Some mechanical devices are commonly used to

clean commercial seeds and separate them according

to their qualitative nature. It seems possible to add an

artificial vision system for completing the mechani-

cal step. The artificial vision domain follows closely

the quick growth of computer power. This evolu-

tion allows creating new applications which was not

possible until today. (Jayas D.S and Bulley, 1999)

(Moltó Enrique, 1998) (Egelberg P., 1994) (Pearson,

1994) (Wan, 2002) (Bennett, 2005)

Image analysis is not currently restrained to sim-

ple geometrical shapes and can be applied to complex

objects such as biological materials.

All the work dealing with the identification of

seeds proceed in two steps: extraction of features

from a digital images of seeds, processing the fea-

tures for building up a discriminant model. In most

of the published studies, the proportions of correctly

classified seeds reported by the authors hardly exceed

95 percent. Such figures are encouraging but proba-

bly not sufficient to allow the replacement of human

operators by machines.

Most of the recent studies are based on the

use of very complex discriminant methods involv-

311

Muracciole V., Plainchault P., Bertrand D. and Rosaria Mannino M. (2007).

DEVELOPMENT OF AN AUTOMATED DEVICE FOR SORTING SEEDS - Application on Sunflower Seeds.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 311-318

DOI: 10.5220/0001626103110318

Copyright

c

SciTePress

ing neural or Bayesian approaches (Chtioui, 1997)

(Granitto P.M. and Ceccatto, 2003) (Granitto

Pablo M and Ceccatto, 2003) (Majumdar S., 2000b).

These methods are often efficient but involve a very

time-consuming training phase. The parameters of

these predictive models (Kernels, neural weights) re-

quire to be stored in computer memories.

In a previous work, a vision system for the auto-

matic acquisition of images of individual seeds has

been designed and developed. Unlike other systems,

our device is based on dedicated hardware. This ded-

icated hardware has some limitations. These limi-

tations are directed by the embedded constraints: a

limited code size implementation, a low memory size

available, a limited binary mathematical operation, a

low frequency compared to a PC processor, limited

temperature dissipation and a limited integrated cir-

cuit size. Design and development of the vision sys-

tem include these different constraints (Plainchault P.,

2003). This is why it is not possible to implement

very complex algorithms for discrimination into an

embedded board and some choices have been made

in the design and the development of system.

A linear discriminant analysis (LDA) has been

chosen as a decision algorithm. LDA is applied on the

features extracted from the individual image of seeds.

In the present work, the features include morpho-

logical, colour and texture characteristics. Accord-

ing to the application, the discriminating power of

variables may change. Another way to reduce the

algorithms complexity is to select a few predictive

variables adapted to a given application. Moreover

in practical applications, a large part of the sample

can be accurately identified and it may remain only a

small proportion in which the discrimination is more

difficult. A relevant approach consists in using an au-

tomated system for a first screening and let the more

difficult part of the sample to be manually analysed.

Instead of computers, we propose to use an FPGA

(Field Programmable Gate Array). These hardware

components allow the implementation of a dedicated

architecture for vision chain. FPGA gives the pos-

sibility to apply massively parallel processes. We

present below the chain of vision and the mechanism

of image acquisition already in place. We finish by

the presentation of the method and the results.

2 ARTIFICIAL VISION

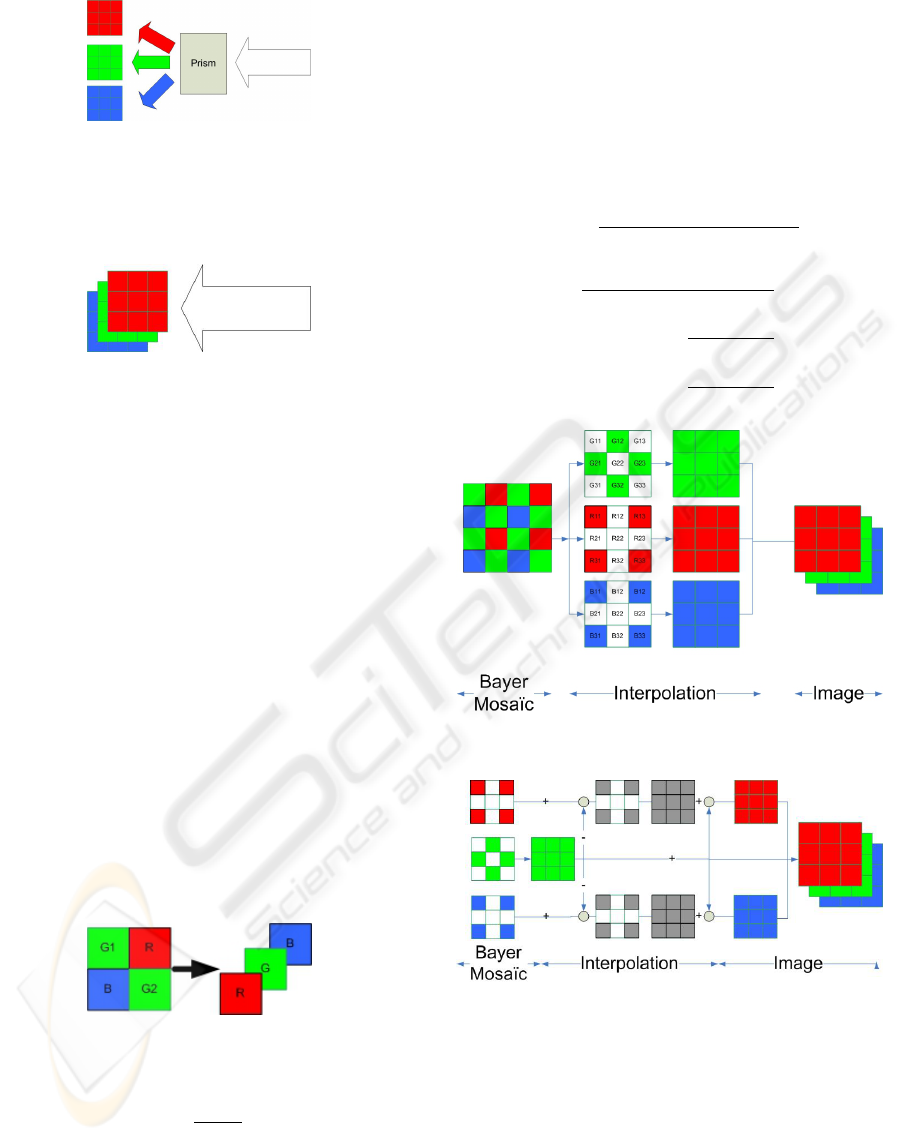

The chain of artificial vision (Figure 1) includes sev-

eral phases: acquisition, image processing, feature

extraction and decision. Each element of this chain

must be optimised in order to reduce computing time

and increase efficiency.

Figure 1: Vision chain.

2.1 Image Acquisition

Acquisition is a very important part of the perfor-

mance system. It determines the quality of the image

and the image processing time. A good image quality

is without noise and without defect of illumination.

These conditions are determinant for the image pro-

cessing speed and the level of the results.

The quality depends on the choice of three princi-

pal types of sensor, on the choice of the lighting sys-

tem and the selected background.

2.1.1 Sensor

The general principle of the sensors lies in the pro-

jection of a 3D scene on a 2D matrix where each cell

carries out the summation of the photons reflected by

the object into the scene.

• Mono CCD:

A mono-CCD sensor is generally organized ac-

cording to the Bayer mosaic. This matrix rep-

resents an alternation of separating cells of red,

green and blue colours organized as shown in Fig-

ure 2. This matrix indeed leaves zones where the

two others colours are not represented. In order

to fill this absence, some methods of interpola-

tion have been presented in this article (Gunturk

Bahadir K., 2005) . Some methods can privilege

certain features like anti-aliasing, shape enhance-

ment or noise reducing.

Figure 2: Mono CCD Sensor : Bayer Mosa ic.

• Three CCD:

Three ccd sensors do not need an interpolation

phases. Colour separation is made by a prism

which projects it onto three two-dimensional ma-

trices, one red, one green, one blue as presented

in Figure 3.

• Mono-chip Multichannel CCD:

This sensor has been developed by the Foveon

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

312

Figure 3: Three CCD Sensor.

company. It performs colour separation on the sil-

icon. This sensor comes back to the photosensi-

tive film principle as represented in Figure 4.

Figure 4: X3 Sensor.

2.1.2 Illumination Scene

Illumination is an important part to reduce image pro-

cessing time. The more homogeneous illumination,

we have. The quicker image processing, we have.

In our case, a good separation between background

and object is needed to maintain the real-time pro-

cess. The illumination system can be composed of

incandescent light, discharge lamps or light-emitting

diodes. The choice of these systems is determined by

the application and their characteristics.

2.1.3 Interpolation

The interpolation is a demosaicing phases for mono-

CCD sensors. There are two methods to obtain im-

ages in three channels. The first method, is to reduce

image size by calculating the average of green chan-

nel (1) and leave the red and blue channel as repre-

sented in the figure 5. The second is to use interpola-

tion methods that can maintain sensor size.

Figure 5: Representation of the image into the three chan-

nel.

G =

G1+G2

2

} (1)

The requirements of embedded systems are elemen-

tary binary mathematical operators. For that reason,

only bilinear and associated interpolation methods

have been retained. These methods are totally inde-

pendent and deterministic which respect the real time

and parallel processing system objectives. These in-

terpolations are reversible, avoid memory overloading

and reduce image transfer time.

There are two possible methods : the bilinear in-

terpolation represented in figure 6 and equation 2 and

5 (equation for red and blue channels are the same)

and the constant-difference-based interpolation repre-

sented in Figure 7.

G22 =

G12 + G32 +G21 + G23

4

(2)

R22 =

R11 + R13 + R31 + R33

4

(3)

R12 =

R11 + R13

2

(4)

R21 =

R11 + R23

2

(5)

Figure 6: Bilinear Interpolation

.

Figure 7: Constant-difference-base Interpolation.

2.1.4 Color Space

In general, the embedded systems operate using the

sensor’s RGB color space. Each channel in this space

are strongly correlated. The choice of the colour

space is dependant on the colour background. Gen-

erally a blue background is used for seed inspection.

This background needs a new color space to perform

seed extraction. The RGB space does not perform

DEVELOPMENT OF AN AUTOMATED DEVICE FOR SORTING SEEDS - Application on Sunflower Seeds

313

very well this process, so the conversion in the YCbCr

(equation 6) space can be possible and is the best to

perform this process. The choice of this space has

been made for the following reasons:

1. It is a matrix based conversion

2. It is a reversible transformation (linear transfor-

mation)

3. The distance between seed and background is

maximized

Y

Cb

Cr

=

0.299 0.587 0.114

−0.169 −0.331 0.5

0.5 −0.419 −0.081

∗

R

G

B

(6)

2.2 Feature Extraction

The extraction aims at defining object based on its

morphology, its colour and its texture. For this ex-

traction we need to extract the object and define his

position, we use for that a segmentation task and a

labelling task.

The segmentation algorithms used to perform

the seed positionning task is a variance-based algo-

rithm (Otsu, 1979).

The extracted features defining seeds are detailled

by many publications. These features are summa-

rized in (Majumdar S., 2000a) (Majumdar S., 2000b)

(Majumdar S., 2000c) and in the thesis of Younes

Chtioui (Chtioui, 1997). These features are around

110. There are three groups: morphological, colour

and textural. In the morphological group, there is

dimension, invariant moment and fast fourrier trans-

form type. In the colour group, there is standard de-

viation, mean, variance. In the textural group, there is

descriptor of texture, co-occurence, entropy, kurtosis

etc...

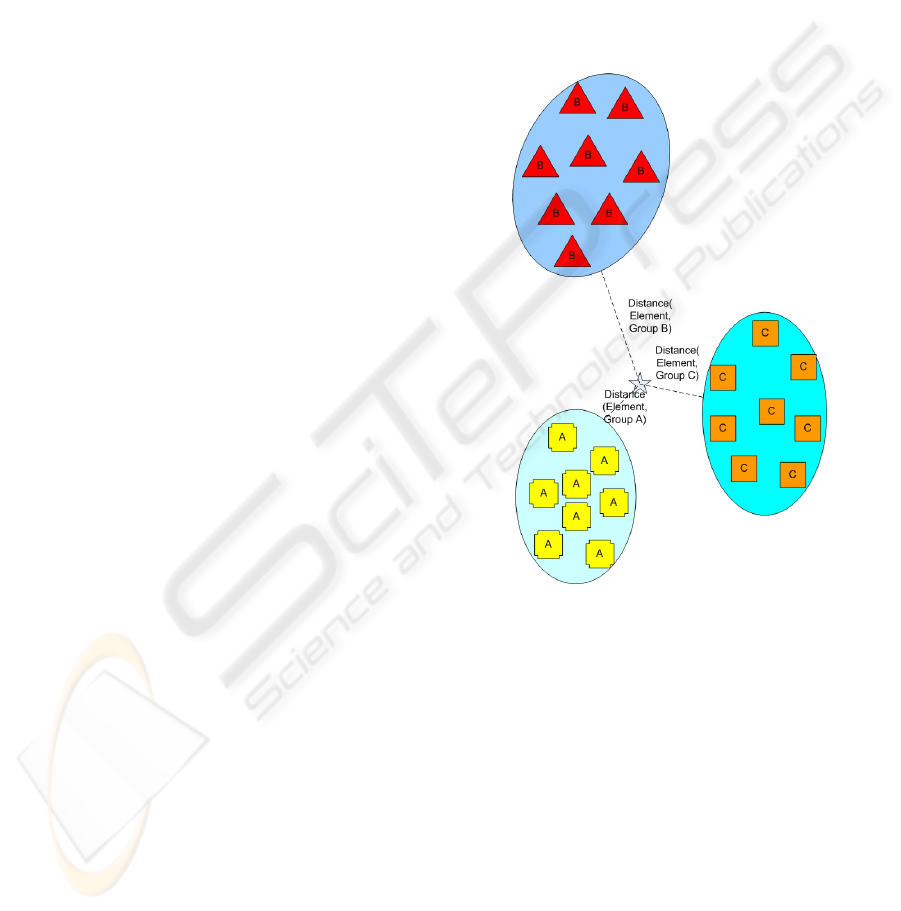

2.3 Pattern Recognition: Linear

Discriminant Analysis

Many identification methods (Chtioui, 1997)

(Visen N.S., 2002) (Majumdar S., 2000d) in the

domain of seeds are presented. Some of them cannot

be retained because they do not answer the embedded

constraints. This is why we privilege the simple

methods based on the distances between groups and

the methods of the regression type.

Some previous work show the feasibility of pat-

tern recognition in FPGA based systems (Miteran J.,

2005). An LDA method has been chosen. This

method is based on the principle of the minimal dis-

tance to a group of a given seed as shown in figure

8 and the equation. It is the type of decision algo-

rithm easily parallelisable, where each class are inde-

pendent of its neighbours. These methods and algo-

rithm has been associated to the Mahalanobis distance

(equation 7) in order to increase the distance between

classes. The x vector is the unknown seed to be clas-

sified. The µ vector is the mean value of a labelled

group features. The Σ value is the covariance matrix

for multivariate vector.

d

2

(x) = (x − µ)

T

Σ

−1

(x − µ) (7)

Figure 8: Principle of Linear Discriminant Analysis.

2.4 Hardware

The architectures presented in this section allow the

creation of dedicated systems based on work from the

computer world. They combine good computing effi-

ciency with low power consumption, low memory and

device monitoring constraints. These various points

make them the ideal components for the embedded

world.

2.4.1 MCU

Microcontrollers are circuits largely used for the man-

agement of the automated control processes. Al-

though not intended for mathematical computation,

the new evolutions of these components integrate

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

314

more and more mathematical calculating units (ex-

ample EP9315A from Cirrus Logic with mathemati-

cal coprocessor), and even cores DSP (example archi-

tecture OMAP Texas Instrument(TI)). However their

performance is still limited for signal processing.

2.4.2 DSP

DSP are processors dedicated to signal processing.

They combine the flexibility of a programmable pro-

cessor with performance in real time signal process-

ing. The new evolutions of these architectures saw the

capacities of calculation increased to the detriment of

consumption. However now they represent now a true

general purpose processor for the embedded domain.

2.4.3 FPGA

FPGAs see their uses and their applicability grow.

They combine the performances of a dedicated archi-

tecture and the flexibility of programming. FPGAs

are composed of independent logical cells which have

to be activated to create dedicated processes. Nowa-

days some signal and image processing are imple-

mented into these components and represent new ap-

plication for high efficiency and low cost systems.

3 MATERIALS AND METHOD

The automaton is based on a principle of free fall

seed (Plainchault P., 2003). It acquires an image of

each seed. It adds to it a stroboscopic effect breaking

up the movement of fall. In the long term, the au-

tomaton must reach a sorting at the rate of one seed

per second. The sorting in the broad sense covers ac-

quisition, the image processing, the extraction of the

parameters, the identification and, finally, the sorting

at the same time.

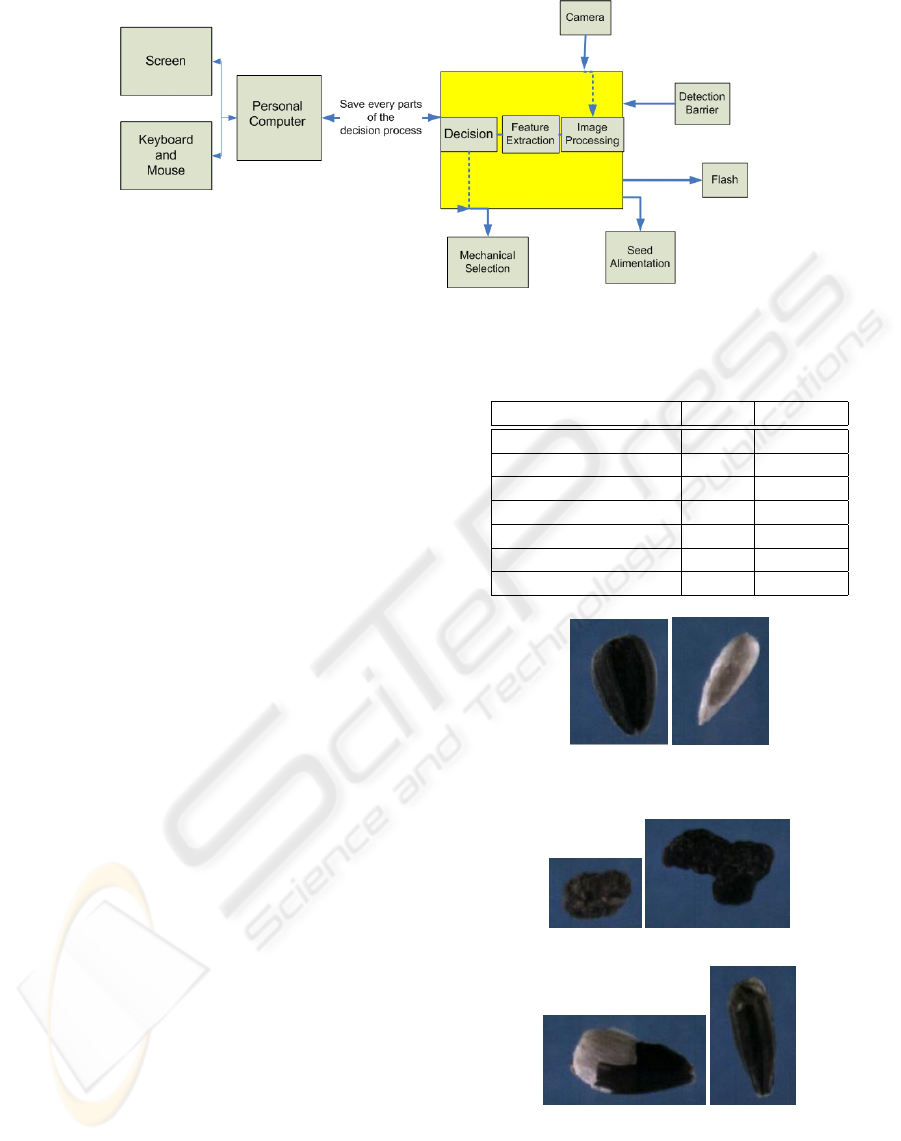

3.1 Device

The automaton is composed of a sensor, a flash, a

detection barrier, a background, an electronic system.

Figure 9 shows this association.

3.1.1 Seed Sorting System

• Mechanical feeding:

The mechanical feeding is based on an electro-

magnet which attracts a support heightened by

blades of metal.

• Sensor :

The sensor provides the frame grabbing function.

It is a Kodak KAC-1310 sensor with a resolution

of 1280*1024 and a clock frequency of 10MHz.

It has the advantage of having a window activa-

tion authorizing the activation of only a part of

the sensor. This function can increase speed of

acquisition because this speed is proportional to

the activated dimension.

• Flash Light :

The flash is ensured by 8 diodes luxeon lumileds

with a unit power of one Watt. This choice has

been done for the response time and robustness of

this component for the rate of one seed per sec-

ond.

• Barrier :

The detection barrier is based on infra red cells

functioning in saturated mode. It determines the

cut of the beam. For the moment, this barrier is

able to treat only sunflower seeds, sunflower ker-

nels, or sclerotia.

• Background :

A blue background was selected because it allows

a better segmentation of the object by using the

YCbCr colour space and extent the seeds varieties

• Embedded Card :

The electronic system lies on an embedded card.

It is a sundance SMT 355 card composed of a TI

DSP TMS320C32 and an ALTERA FPGA Flex

10K130E and 512 Kbytes of RAM. Its task is to

control the peripherals and perform simple pro-

cessing. Due to the architecture of the card, it

is not simple to implement image processing into

the FPGA. The FPGA does not have direct access

to memory and the memory space is too low to

implement image processing. But this card has

tested and validates the feasibility of acquisition

in free fall of object into embedded card.

3.1.2 Computer Validation of Embedded

Algorithm

• Computer

The electronic system also includes a computer.

It is a DELL computer with an Intel Pentium IV

3GHz with HyperThreading processor, 1GB of

DDR-SDRAM, a graphics board AMD/ATI X300

with dedicated memory and a 160GB hard disk.

The computer provides the Human-Machine in-

terface to control the automaton. It saves the im-

age acquired in Bitmap format on the hard disk

drive. The computer also plays a part in the al-

gorithm validation. The identification algorithm

DEVELOPMENT OF AN AUTOMATED DEVICE FOR SORTING SEEDS - Application on Sunflower Seeds

315

Figure 9: Presentation of the wanted system.

has been tested off line in order to determine its

efficiency for the sorting.

• Software

The automaton is controlled by a program imple-

mented in the computer using Visual C++. It pro-

vides a window interface to control the acquisi-

tion process. The algorithm validation is carried

out off line with the image acquired by the au-

tomaton under the environment of matrix algebra

MATLAB 7. Firstly, we calculate the parameters

for all the datasets. In order to have all the fea-

tures algorithms we just use the bwmorph func-

tion from the matlab image processing toolbox.

Secondly, we train and test the identification algo-

rithm on the dataset to select the best algorithm.

3.2 Methods

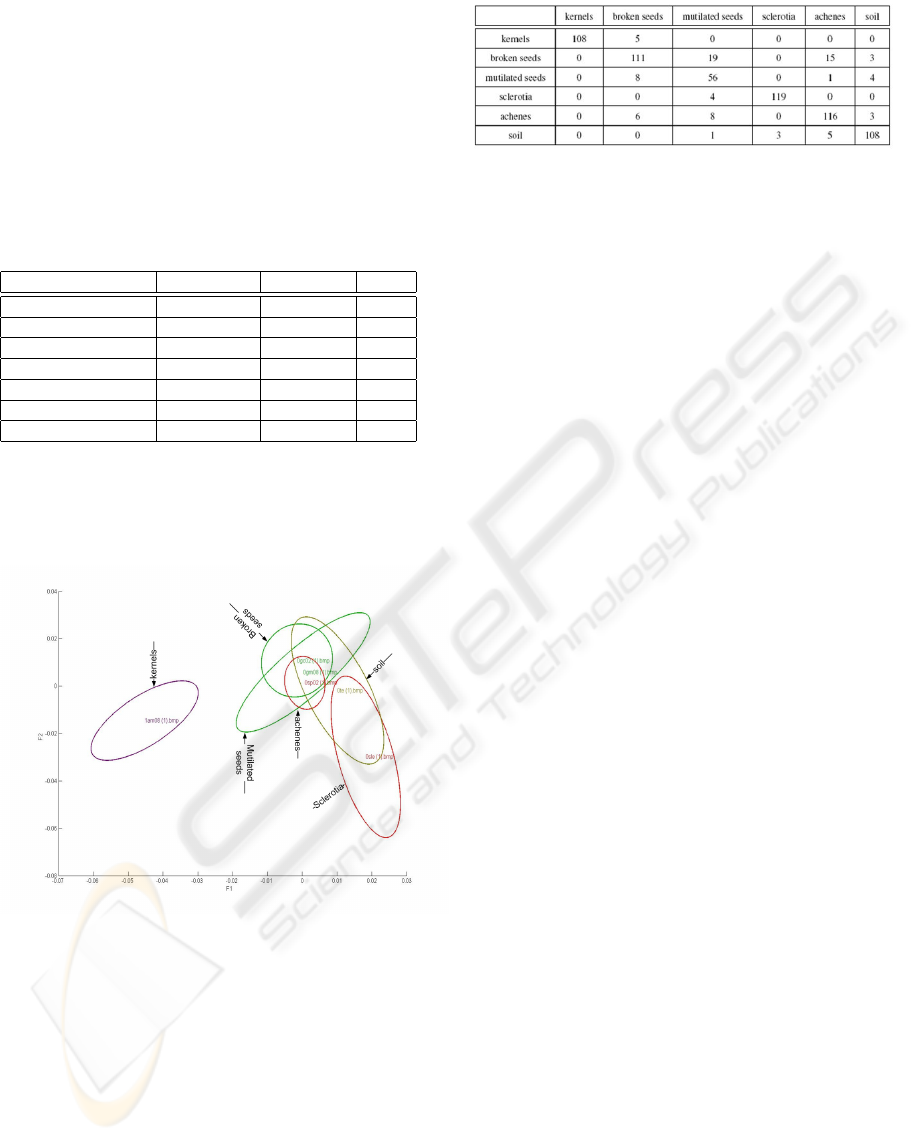

Seeds and impurities observed by the vision system

were extracted from 23 samples of sunflower seeds

representing commercial seed lots of various origins

and 18 varieties, differing by seed colour and size.

The dataset for impurities with a low frequency in the

samples was enlarged using the reference collection

of the GEVES-SNES. A dataset including 1051 im-

ages has been created. This dataset includes 6 classes:

sunflowers kernels, broken seeds (fragments of seeds

with a size higher than 50 percent of the size of the

seed), mutilated seeds (fragments of seeds with a size

lower or equal to 50 percent), sunflower achenes (in-

tact seeds), sclerotia and soil.

At this stage of the study, our dataset includes

all the categories (seeds and impurities) that have to

be identified in official analysis of commercial seed

lots (table 1) with the exception of seeds belonging

to other species than the sunflower. Figure 10 shows

colour, texture and morphology differences among

the different classes.

This dataset has been labelled by an expert of the

Table 1: Principle of the analysis in the framework of purity

and counting seed.

Object Purity counting

sunflower kernels PS

sunflower achenes PS

broken seeds PS

mutilated seeds IM

soil IM

sclerotia IM counting

Seeds of other plants SOP counting

(a) Sun-

flower

achenes

(b) Sun-

flower

Kernels

(c) Soil (d) Sclerotia

(e) Broken seeds (f) Mu-

tilated

seed

Figure 10: Image of pure seeds (a,b,e) and impurities (c,d,f).

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

316

GEVES-SNES. With this dataset we have conducted

a linear discriminant analysis using cross-validation.

We have randomly selected 348 images for the train-

ing sets and 703 for the testing sets in accordance with

table 2. We obtain a reduction of the feature space

with a stepwise canonical discriminant analysis ac-

cording to the article (Bertrand D., 1990). The selec-

tion of parameters is made incrementally by testing

the increase of identification percentage.

Table 2: Dataset representation of each groups.

Object training set testing set total

sunflower kernels 56 113 169

broken seeds 72 145 217

mutilated seeds 36 72 108

sclerotia 61 123 184

sunflower achenes 66 134 200

soil 57 116 173

total 348 703 1051

4 RESULTS

Figure 11: representation map of the sample.

The parameters selected by the LDA method show a

great extent of texture (energy, entropy, occurrence),

colour (mean, variance) and a few morphological

(perimeter, area, moments, Fast Fourier Transform)

parameters. Figure 11 shows the representation map

of the sample and table 12 indicates the identification

results for all the classes. A high percentage of each

class has been correctly identified: from 75% of bro-

ken seeds to 97% of sclerotia. Some misclassification

occurred, with the extent and importance that vary in

relation to the classes. If we seek to identify indepen-

dently each group, the selected features change but

follow what we have said before in the part 3.2.1. The

Figure 12: Differentiation sclerotia, achenes, broken seeds,

mutilated seeds, soil.

results expressed in table 12 is in accord with the map

of labelled groups (figure 11). The table 12 shows all

of the misclassifications identified on the map. Many

of the errors of classification are due to a lack of in-

formation in the image. The free fall principle with

only one camera has the same problem as on a rolling

carpet (Egelberg P., 1994): it is possible that the cam-

era does not take the image of the face bringing infor-

mation, which is the case after analysis of the badly

identified seeds. As we can note in table 12, there is

a strong confusion between broken seeds and muti-

lated seeds. The algorithm can not perform a virtual

representation of the associated pure seeds as the hu-

man expert can. From a practical point of view, we

could accept a misclassification when it affects pure

seeds (kernels, achenes and broken seeds) identified

as impurities (e.g. sclerotia classified as soil). In this

case, to achieve the analysis, the analyst will observe

only a fraction of the sample classified as impurities

by the system. Following this principle, the system

classification was less satisfactory for mutilated seeds

and soil: 13% of mutilated seeds were classified as

pure seeds (broken seeds or achene), 4% of soil as

achene. This first result shows the interest of the sys-

tem when a determination of other seeds is carried out

in sunflower: the algorithm makes possible 100% of

correct separation of pure seed (achenes or kernels of

sunflower) from sclerotia that are searched for in this

kind of analysis.

5 CONCLUSION

The widening of the dataset of image seeds to new

species is under acquisition.

The remaining work will consist of performing ac-

quisition, features extractions and decision in a com-

plete automaton. Optimisation and testing on other

varieties of the decision algorithm have to be con-

ducted.

Moreover the creation of a multi-camera system

of acquisition according to the same principle would

allow on certain ambiguities at the time of the phase

DEVELOPMENT OF AN AUTOMATED DEVICE FOR SORTING SEEDS - Application on Sunflower Seeds

317

of decision. It is also possible to make this approach

more robust by creating a unknown class for seeds at

equal distance from the various groups.

The testing on the identification algorithm on

seeds of other plants has to be made. System enhance-

ments have to be made like changing the infrared bar-

rier in order to extend seed varieties acquisition. The

design and the development of a new hardware sys-

tem have to be made in order to implement a three

camera systems.

ACKNOWLEDGEMENTS

This work was supported by the National Institut of

Agronomical Research (INRA), the variety and seed

study and control group (GEVES), the ESEO gradu-

ate school of engineering in electronic, and the LISA

laboratory of the University of Angers.

For their financial support the region Pays de Loire

and the CER Vegetal (French contract).

REFERENCES

Batlle J., M. J. (2002). A new fpga/dsp-based parallel. Real

time imaging, 8:345–356.

Bennett, T. D. K. F. M. M. M. (2005). A computer-

based system for seed identification. Seed Technology,

27:190–202.

Bertrand D., Coucroux P. Autran J.-C., M. R. R. P. (1990).

Stepwise canonical discriminant analysis of continu-

ous digitalized signals : applicatoin to chromatograms

of wheat proteins. Journal of chemometrics, 4:413–

427.

Chtioui, Y. (1997). Reconnaissance automatique des se-

mences par vision artificielle basée sur des approches

statistiques et connexionnistes. PhD thesis, IRESTE.

Davies, E. (2005). Machine Vision - Theory, Algorithms,

Practicalities.

Egelberg P., Mansson O., P. C. (1994). Assessing cereal

grain quality with a fully automated instrument using

artificial network processing of digitized color video

images. In Forestry and Biological Processing, vol-

ume 2345, pages 146–156. SPIE congress.

Granitto Pablo M, P. F. V. and Ceccatto, H. A. (2003). Au-

tomatic identification of weed seeds. ASAI.

Granitto P.M., P.A. Garralda, P. V. and Ceccatto, H. (2003).

Boosting classifiers for weed seeds identification.

JCS&T.

Gunturk Bahadir K., e. a. (2005). Demosaicking : Color fil-

ter array interpolation. IEEE Signal Processing Mag-

azine, pages 44–54.

Jayas D.S, M. C. and Bulley, N. (1999). An automated seed

presentation device for use in machine vision identi-

fication of grain. Canadian agricultural engineering,

41(2):113–118.

Majumdar S., J. D. S. (2000a). Classification of cereal

grains using machin e vision i. morphological mod-

els. American Society of Agricultural Engineers,

43:1669–1675.

Majumdar S., J. D. S. (2000b). Classification of cereal

grains using machine vision ii. color models. Ameri-

can Society of Agricultural Engineers, 43:1677–1680.

Majumdar S., J. D. S. (2000c). Classification of ce-

real grains using machine vision iii. texture mod-

els. American Society of Agricultural Engineers,

43:1681–1687.

Majumdar S., J. D. S. (2000d). Classification of cereal

grains using machine vision iv.combined morphology,

color, and texture models. American Society of Agri-

cultural Engineers, 43:1689–1694.

Miteran J., M. J. (2005). Automatic hardware implementa-

tion tool for a discrete adaboost-based decision algo-

rithm : Prototyping for machine perception on a chip.

EURASIP, 2005:1035–1046.

Moltó Enrique, Blasco José, B. J. V. (1998). Computer vi-

sion for automatic inspection of agricultural produces.

In SPIE, editor, Precision agriculture and biological

quality, volume 3543, pages 91–100.

Otsu, N. (1979). A threshold selection method from gray-

level histograms. IEEE Transactions on Systems, Man

and Cybernetics, 9:62–66.

Pearson, T. (1994). Machine vision system for automated

detection of stained pistachio nuts. In SPIE, editor,

Optics in Agriculture, Forestry, and Biological Pro-

cessing, volume 2345.

Plainchault P., Demilly D., F. A. T. S. B. D. (2003). De-

velopment of an imaging system for the high speed

identification of seeds. IEEE Sensor.

Visen N.S., J. D. (2002). Specialist neural network for

cereal grain classification. Biosystems Engineering,

82:151–159.

Wan, Y.-N. (2002). Automatic grain quality inspection with

learning mechanism. Information technology in Agri-

culture.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

318