A NEW LOAD ADJUSTMENT APPROACH FOR JOB-SHOPS

Z. Bahroun

LIP2, Faculté des Sciences de Tunis, Dép. des Sciences de l’Informatique, 2092 Manar II, Tunis, Tunisie

J.-P. Campagne

Laboratoire LIESP, INSA-LYON, F-69621 Villeurbanne Bat B. Pascal, 7 av J. Capelle, France

M. Moalla

LIP2, Faculté des Sciences de Tunis, Dép. des Sciences de l’Informatique, 2092 Manar II, Tunis, Tunisie

Keywords: Load adjustment, Finite capacity, overlapping production planning, margins management, job-shop.

Abstract: This paper presents a new load adjustment approach by overlapping for a set of jobs in a job-shop contex

t,

guaranteeing the existence of a limited capacity schedule without scheduling under the assumption of pre-

emptive tasks. This approach is based on the exploitation of the tasks scheduling time segments overlapping

and on the distribution of the job’s margins between tasks in a just in time context. First, we present a

literature review concerning load adjustment approaches. Second, we introduce the overlapping load

adjustment approach. Third, we present an original heuristic to use this approach in the case of job-shops

organized firms. After that, we present the scheduling approach. Finally, we will discuss a more general use

of this approach and the possible extensions.

1 INTRODUCTION

Generally, the production planning is made in a

hierarchical way in two planning and scheduling

decision levels. In the first step, we decide which

products to supply, in which quantities and delays,

in the second step, we adjust load to the capacity and

schedule the tasks on the machines.

There are three main and classical load

adj

ustment approaches. First of all, we have the

placement. This approach consists in calculating a

detailed tasks schedule. A new task is integrated in

the planning if we find a gap in the planning which

is bigger than the duration of this task. This

approach estimates only one schedule which can be

destructed by any disturbance. The second approach

is the periodic and cumulative approach. It consists

in calculating the cumulative load and capacity for a

latest loading and for each period. This approach

does not guarantee the existence of a scheduling

solution because it does not take into consideration

the ready dates constraints. The third approach is the

periodic and non cumulative approach. It consists in

assigning tasks to periods and comparing period by

period the available and the required capacities. This

method estimates only the solutions in which the

tasks are fixed in a specific period.

Some researchers studied the problem of

seq

uencing decisions in production planning and

scheduling. Dauzere-Peres and Laserre (1999) think

that it is better in some cases to integrate the

scheduling decision level in the lot sizing decision

level and propose an iterative approach for planning

and scheduling production. Some researchers

integrated the scheduling and capacity constraints in

their lot sizing model (see for example, Fleishmann

and Meyr, 1997). We can also find a survey on lot

sizing and scheduling in Drexl and Kimms (1997).

However, most of these approaches consider

generally a single machine and are difficultly

applicable for real and industrial context.

Many researchers studied also the problem of

finite

capacity planning. We can state very briefly H.

Hillion and Proth (1994) who studied the problem of

276

Bahroun Z., Campagne J. and Moalla M. (2007).

A NEW LOAD ADJUSTMENT APPROACH FOR JOB-SHOPS.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 276-283

Copyright

c

SciTePress

a finite capacity flow control in a multi-stage/multi-

product environment or Gunther (1987) who also

developed two heuristics for the lot sizing in the

context of finite capacity. Néron et al (2001)

developed an approach for solving hybrid flow shop

problem using energetic reasoning. This approach

has some similarities in the concept with our

approach. Indeed, the energetic reasoning was

developed to solve “cumulative scheduling

problems”. The approach aims to develop

satisfiability tests and time-bound adjustments to

ensure that a given schedule is not feasible or

derives some necessary conditions that any feasible

schedule must satisfy.

In comparison with all these approaches, the

overlapping load adjustment approach allows to

distinguish two main phases. The first phase consists

on establishing a long or mid term production

planning where the feasibility is ensured without

scheduling and tasks placement, which allows us to

characterize a set of feasible scheduling solutions.

The scheduling will be done only in the second

phase.

2 THE OVERLAPPING LOAD

ADJUSTMENT APPROACH

The time scale is divided into time periods. Each

task of a job has got a processing time, requires one

or more resources and has to be realized during a

scheduling time segment associated with one or

more consecutive periods. The scheduling time

segments of consecutive tasks of the same job

cannot overlap From now on and throughout this

paper a lapse of time called here lapse, designates a

succession of a number of n consecutive periods. Let

(a,b) be a lapse composed of a succession of periods

which are limited by the periods a and b including

them. The shortest lapses are composed of only one

period, for instance (a,a). Such a lapse (a,a) is called

a basic lapse. The longest lapse is noted (1,H) in

which number 1 is associated with the first period of

the planning time frame and the letter H the last one.

From such a planning time frame, the total number

of different lapses is equal to H*(H+1)/2.This

number is of course to be multiplied by the number

of existing processors. The sub-lapse of a lapse is a

subset of one or more consecutive periods of this

lapse. For instance, the sub-lapses of [1,3] are [1,1],

[2,2], [3,3], [1,2] and [2,3]. Every lapse containing a

lapse [a,b] is called the over-lapse of [a,b]. For

instance, [1,3] is an over-lapse of [1,1]. Each lapse is

characterized by:

- An accumulated capacity: sum of the capacities of

each period included in this lapse.

- A direct capacity requirement: sum of the

capacities required by the tasks whose scheduling

time segment is exactly equal to this lapse.

- An accumulated capacity requirement: sum of the

capacities required by the tasks whose scheduling

time segment is fully included in this lapse. It is the

sum of the direct capacity requirements of this

lapse and its sub-lapses.

Dillenseger (1993) sets the following proposition

out: for any lapse, its accumulated capacity

requirement must be equal or smaller than its

accumulated capacity. He proves that it is a

necessary and sufficient condition for the existence

of a loading solution of the set of tasks (within the

limits of their scheduling time segments and

considering the capacity levels), according to pre-

emptive possibility.

Let’s consider the following example of a

production plan composed of 7 jobs which will be

treated on a single processor with ready and due

dates as shown in Table 1 below. The considered

period for this example is the week composed of five

days (the day is the unit time):

Table 1: Example 1.

Job processing

time (days)

Ready date (beginning

of the week)

Due date (ending

of the week)

A 2 3 4

B 4 2 4

C 4 4 5

D 1 3 3

E 2 3 3

F 2 2 3

G 4 4 5

Periods

(

weeks

)

Week 1

A

(

2

)

G

(

4

)

C

(

4

)

D

(

1

)

E

(

2

)

F

(

2

)

B

(

4

)

Load in days

Scheduling time

se

g

ment

Week 2

Week 3 Week 4

Week 5

Day1 of week 2

22

33

44

55

23

34

45

24

35

25

0

0

5

3

3

2

0

0

5

0

0

5

5

2 5

5

2

5

8

8

2

11

4 4

13

0 2

19

0 1

A

ccumulated ca

p

acit

y

(

da

y

s

)

5

10 15 20

Legend:

23

5

2 5

Accumulated

capacity requirement

(days)

Lapse [2,3]

Direct capacity

requi rement

(days)

Remai n in g

capacit y

(days)

Figure 1: Capacity requirements planning (CRP) and

Planning feasibility control graph (PFCG).

Figure 1 represents a capacity requirement

planning (CRP) corresponding to the example of

Table 1. For instance, task G needs a load of 4 days

A NEW LOAD ADJUSTMENT APPROACH FOR JOB-SHOPS

277

(time units) and have a time scheduling segment

composed of weeks 4 and 5 (it means that this task

should be scheduled and produced in any time inside

the weeks 4 and 5). The capacity of a period is 5

days. The margin of task G is so equal to 6 days (10

days of weeks 4 and 5 minus its load of 4 days). The

associated planning feasibility control graph (PFCG)

is shown in Figure 1. For each lapse of weeks we

calculate the direct capacity requirement, the

accumulated capacity requirement and the remaining

capacity. For instance, the lapse [2, 3] composed of

weeks 2 and 3 has a direct capacity requirement

equal to 2 days (task F), an accumulated capacity

requirement equal to 5 days (tasks with a scheduling

time segment included in the lapse: D, E and F) and

a remaining capacity equal to (10-5) days. The

planning feasibility control graph proves the

feasibility of this set of jobs (all the remaining

capacities are positive).

Firstly, this load adjustment approach was

applied to plan the activities of a make-to-order

company in a mono-level context (Dillenseger,

1993). This approach was applied then to a flow-

shop composed of m processors (Bahroun, 2000a),

to a generalised flow-shop (Bahroun, 2000b) and for

the cyclic production context (Bahroun, 1999).

3 APPLICATION FOR JOB-SHOP

ORGANIZED FIRMS

Processor 1

Processor 3 Processor 4

Processor 4

Processor 2

Processor 1

Processor 2

Processor 1

Processor 4

Job 1:

Processor 1

Processor 3 Processor 4

Processor 2

Job 2:

Job 3:

Job 4:

Job 5:

Figure 2: Example of a job shop.

Let us consider N jobs with their due and ready

dates. Each job is composed of one to m tasks

realized on one to m processors with a certain order

which is not necessarily the same for all the jobs

(Figure 2).We suppose that these jobs are the results

of a products supply calculation in an M.R.P. based

system for instance. We aim at adjusting the load

resulted by these jobs in a finite capacity way by

adapting the overlapping load adjustment approach

to the job shop case.

We will first calculate the scheduling time

segment of each task, considering the due and the

ready dates of their job, their precedence constraint

and the capacity constraints. After that, we will try

to exploit the existing margins. They will be

distributed on the different job’s tasks and will be

assigned with priority to the tasks corresponding to

overloaded processors. We have developed a

heuristic which tries to share out judiciously the

job’s margins on their tasks. For this, we calculate a

latest loading on all the processors without margins

(we only assign the margins of jobs with a unique

task). We classify in the load decreasing order the

processors. We then assign all the margins to the

most loaded processor and after that we keep only

the necessary margins to validate the processor

loading (for any lapse, its accumulated capacity

requirement must be equal or smaller than its

accumulated capacity) and transfer the unused

margins to the next processor accordingly to the load

classification. Then, we reiterate the same treatment

to the next processor until reaching the last

processor.

We define the following parameters:

• N = number of jobs

• m = number of processors

• Ma

i

= the global margin of job i

• p

ij

= processing time of the task corresponding to

job i on processor j.

• p

ij

= 0 if there is not a task of job i on processor j.

• r

i

= release or ready date of job i

• d

i

= due date of job i

• b

ij

= beginning of the scheduling time segment of

the task corresponding to job i on processor j

• e

ij

= ending of the scheduling time segment of the

task corresponding to job i on processor j

• ACCP[a,b]

j

= accumulated capacity of the lapse

[a,b] for processor j

• ACCPR[a,b]

j

= accumulated capacity requirement

of the lapse [a,b] for processor j

• RC[a,b]

j

= remaining capacity of the lapse [a,b]

on processor j

• d

p

= duration of an elementary period.

We note ⎡x⎤ the smallest integer which is greater

than or equal to x and ⎣x⎦ the biggest integer which

is smaller than or equal to x.

Our approach is based on four main steps (we

will illustrate our approach with the example of

Table 2):

1

st

step :

We calculate the global job’s margins:

Ma

i

= d

i

- r

i

- (

j

m

=

∑

1

⎡(p / d )⎤ ) + 1

ij p

(1)

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

278

Table 2: Exemple 2.

Job Processing

order

Process. time

on proc. 1

(days)

Process. time

on proc.2

(days)

Process. Time

on proc. 3

(days)

ready date

(beginning of the

period)

due date

(ending of the

period)

Global margins

in periods

(weeks)

A P1→P2→P3 3 2 2 1 6 3

B P1→P2→P3 2 3 1 1 5 2

C P1 3 0 0 3 5

2

D P2 0 2 0 2 4 2

E P3 0 0 2 4 6

2

F P3→P2→P1 3 3 2 2 5

1

G P3→P2→P1 1 1 1 2 6 2

H P3→P1→P2 2 2 2 3 5

0

I P3→P1→P2 1 2 2 3 5

0

J P2→P1 3 3 0 2 5 2

K P2→P3 0 3 4 3 6

2

L P3→P1 2 0 3 4 6

1

For our example, we consider a production

system composed of three processors (P1, P2 and

P3) and a set of jobs (Table 1, d

p

= 5 days). We

calculate the global margins using the last formula

and we obtain the results reported in the last column

of Table 2. After that, we determine the scheduling

time segment of each task according to a latest

loading without margins (we assign only the margins

of jobs with a unique task like jobs C, D and E, in

fact, these margins will be used only on a unique

processor and will not be distributed on several

processors). For instance, for job A, the last task on

processor P3 will have a scheduling segment that

ends at the end of week 6 and will begin so, at the

beginning of the same week (because the processing

time of this task is inferior to a week), the task

number 2 for the same job A on processor P2 will

have a scheduling segment that begins and ends at

week 5. The first task of Job A on processor P1 will

have a scheduling segment that ends and begins at

week 4. Job C is composed of only one task, so we’ll

assign its margin and the time scheduling segment

will begin at week 3 and ends at week 5. We

calculate the scheduling segments of the other jobs

in the same way and we obtain the capacity

requirement planning of P1, P2 and P3 as shown in

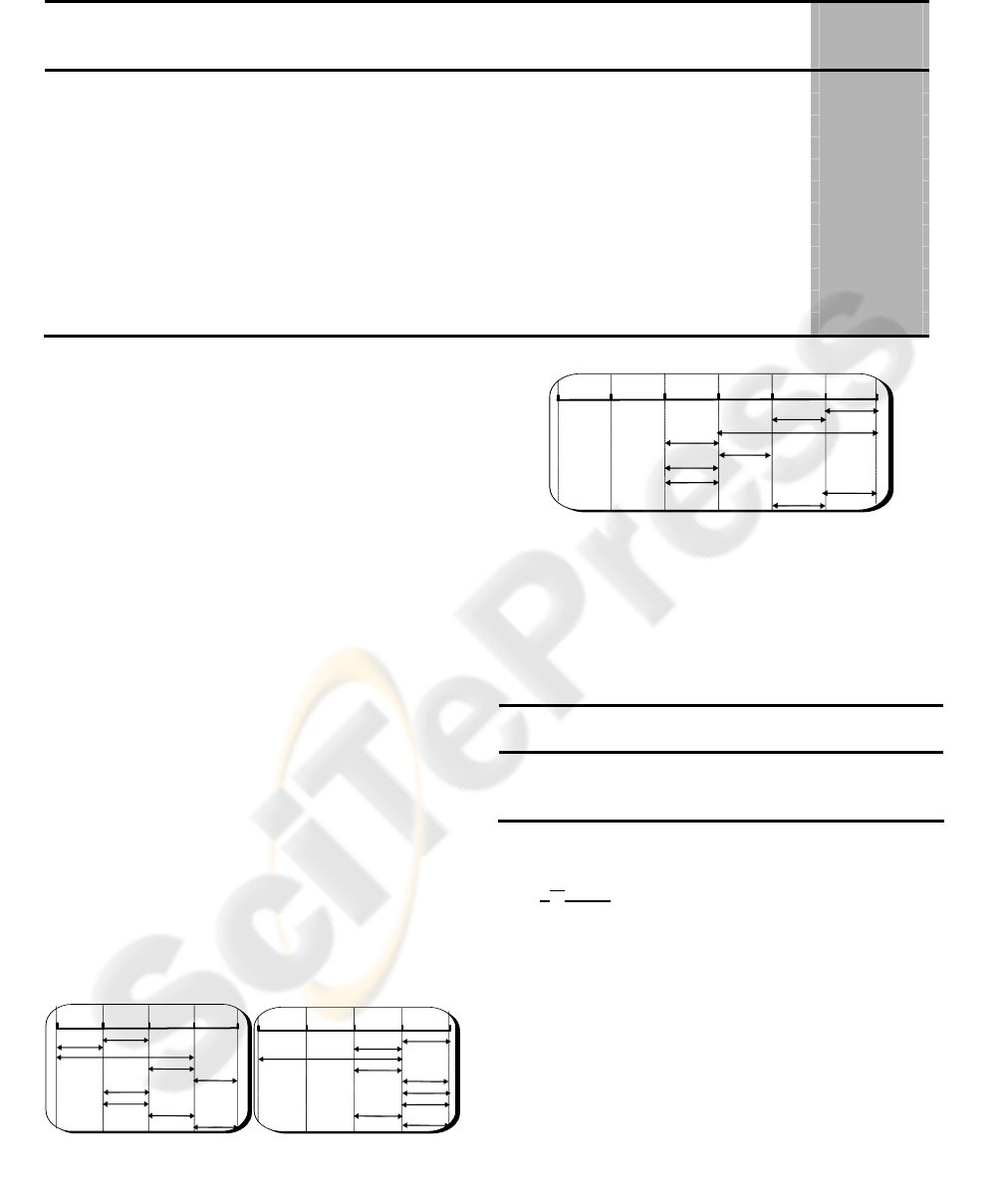

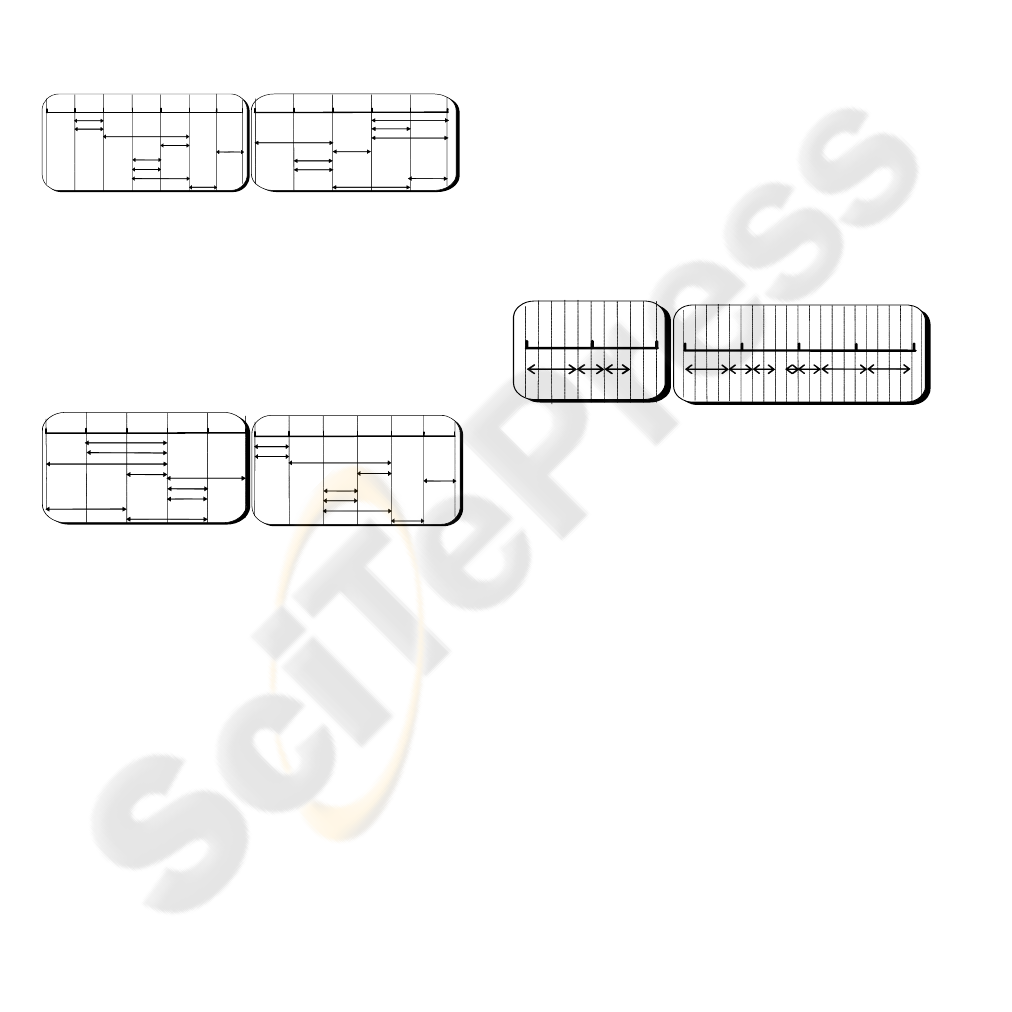

Figures 3 and 4.

Periods

(

weeks

)

3 4 5

A1

(

3

)

F1

(

3

)

G1

(

1

)

H1

(

2

)

I1

(

1

)

J1

(

3

)

L1

(

2

)

6

B1

(

2

C1

(

3

)

Periods

(

weeks

)

2 3 4 5

A2

(

2

)

F2

(

3

)

G2

(

1

)

H2

(

2

)

I2

(

2

)

J2

(

3

)

K2

(

3

)

B2

(

3

)

D2

(

2

)

Figure 3: Capacity requirements planning (CRP) of P1

and P2 before treating.

Periods

(

weeks

)

12 34 5

A3

(

2

)

F3

(

2

)

G3

(

1

)

H3

(

2

)

I3

(

2

)

K3

(

4

)

L3

(

3

)

6

B3

(

1

)

E3

(

2

)

Figure 4: Capacity requirements planning (CRP) of P3

before treating.

After that, we calculate the total load and the

load by period for each processor as follow:

Table 3: Calculation of the processor load.

Proces. Total load in

days

Number of concerned

Periods(weeks)

Load/period

P1 20 4 5

P2 21 4 5,25

P3 19 4 4,75

We classify and treat the processor in the

decreasing order of the load/period: P2, P1, P3.

2

nd

step:

We assign all the global margins to the processor

P2. Then, we calculate for each task the beginning

and the ending periods of the scheduling time

segment of this task:

∀ i and for a processor j:

e

ij

remains the same

b

ij

= e

ji

- Ma

i

- ⎡(p

ij

/ d

p

)⎤ + 1

(2)

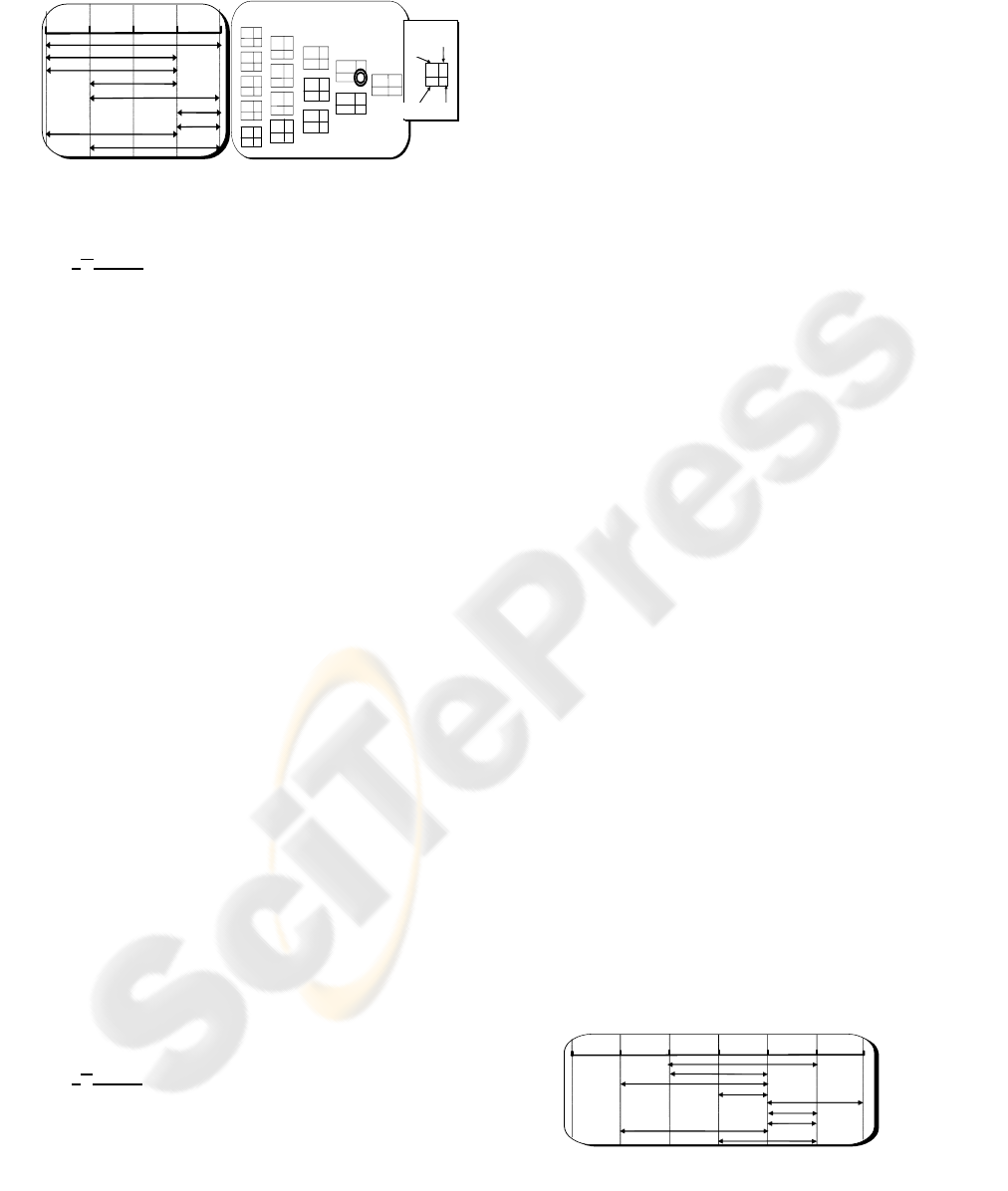

If we calculate the beginning time of the second

processor of our example, we can generate the

A NEW LOAD ADJUSTMENT APPROACH FOR JOB-SHOPS

279

corresponding capacity requirement planning (CRP)

and the planning feasibility control graph (PFGC):

Periods

(

weeks

)

2 3 4 5

A2

(

2

)

F2

(

3

)

G2

(

1

)

H2

(

2

)

I2

(

2

)

J2

(

3

)

K2

(

3

)

B2

(

3

)

D2

(

2

)

22

33

44

55

23

34

45

24

35

25

0

0

5

0

0

5

0

0

5

4

4

1

0

0 10

3

3

7

4

0

6

11

8 4

11

4 4

21

2 -1

Accumulated capacit y (days)

5

10 1

5

20

Legend:

24

11

8 4

Accumulat ed

capaci ty requi rement

Lapse [2,4]

Dir ect capaci ty

requi rement

Remaining

capaci ty

66

0

0

5

56

4

0

6

46

4

0 11

36

11

0 9

26

21

0

4

2

5

Figure 5: CRP and PFCG of the processor P2 after

assigning all the margins.

3

rd

Step:

We then check the feasibility condition. If we

find problems in certain lapses (even with all

available margins), we should lengthen the

scheduling time segment of some tasks. If for a lapse

[a,b] in the processor j, the validation condition is

not verified:

- We consider in the duration increasing order all

the tasks that b

ij

≥ a et e

ij

= b.

- In this list, we begin to treat the first task in the k

th

position in the list with a load equal or superior to

the overloading in the lapse which allows us to

delay the minimum number of tasks.

- We proceed progressively to the lengthening of

the scheduling time segment of these tasks, period

by period until the verification of the feasibility

condition or arrival to the end of the list.

- If we arrive to the end of the list we try with tasks

positioned in the (k-1)

th

, (k-2)

th

… position until

the verification of the feasibility condition.

In our example (Figure 5), we remark that we

have an overloading in the lapse [2,5] which obliges

us to delay of one period, one of the tasks included

in this lapse and which finishes in period 5 (A2, G2,

H2, I2 or K2 as we can see in CRP of Figure 5). We

choose in this example to lengthen the scheduling

time segment of task G2 from the lapse [3,5] to the

lapse [3,6].

Remark: If we do not accept to delay jobs, the

lapses with negative remaining capacity indicate

where we must increase the capacity by using for

example overtime or interims. We can also introduce

the notion of jobs priority for choosing which tasks

must be delayed.

4

th

Step:

Now, we will try to regain margins. We begin

with the tasks corresponding to jobs with weak

global margins. Tasks of jobs without margins are

assigned to the elementary lapses ([1,1], [2,2] etc.),

those corresponding to jobs with one period margin

are assigned to the lapses of the second column of

the feasibility control graph, those corresponding to

jobs with k periods margins are assigned to the

column number k etc. Our treatment begins with the

lapses of the second column because the

corresponding jobs have only one period global

margin and we must preserve these precious margins

to validate the other processors and use the margins

from jobs that have important global margins.

A transfer of a task from the lapse [a,b] to the

lapse [a+w,b], adds load to all the over-lapses of

[a+w,b] which are not initially over-lapses of [a,b].

The transferred load must be equal or smaller than

the remaining capacity on these lapses for

maintaining the validation condition.

The proposed approach for this transfer tries to

transfer the maximum number of tasks and tries to

match in the best way the transferred load in regard

to the remaining capacity. Consequently, we

construct the set of tasks which can be transferred,

and we classify this set in the increasing order of

their load. We transfer the tasks one by one in this

order while the sum of their load is smaller than the

remaining capacity. Then, we take the last task

transferred and we try to change it by another task

from the remaining tasks of the set and which

matches better the remaining capacity. If two tasks

have the same load we can choose for example the

task corresponding to a product with a greater

carrying cost. If we take the example of PFCG in

Figure 5, we begin with the lapses of the second

column. If we try, for instance, to regain margins

from the tasks corresponding to the lapse [3,4], we

should transfer the maximum number of tasks to the

lapse [4,4]. We can transfer task F2 because the

minimum of the remaining capacity of the over-

lapses of [4,4] which are not over-lapses of [3,4] (the

lapses [4,4], [4,5] and [4,6]) is 5 and it is greater

than the load of the task F2. Then, we pass to lapses

[4,5], [5,6], and next to the lapses of the third

column (for the task G2, we succeed to regain 2

periods, the scheduling time is shortened from the

lapse [3,6] to lapse [5,6]). We reiterate this treatment

until arriving to the last column. We obtain after

treatment of the processor P2 the capacity

requirement planning of Figure 6.

Periods

(

weeks

)

12 34 5

A2

(

2

)

F2

(

3

)

G2

(

1

H2

(

2

I2

(

2

)

J2

(

3

)

K2

(

3

6

B2

(

3

)

D2

(

2

)

Figure 6: C.R.P. of processor P2 after treatment.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

280

We can generalize this step for a processor j:

∀ the lapse [x,y] / x= a and y= a+w with 1 ≤ w ≤ H

and 1 ≤ a ≤ H-w :

- Construct the set A = {set of tasks / b

ij

= a and e

ij

= a+ w} (The set of tasks that their scheduling time

segment can be shortened, this set will be ordered

in the increasing order of their load).

- Iterate then for f = w -1 → 0

¾ Cap = Min ( RC

j

[a+1+z, a+w+n] ) For n = 0

→ H - a - w, z = f → 0 (we calculate the

maximum load that can be transferred).

¾ Transfer the maximum number of tasks from A

(using the approach described in the precedent

page) that the sum of their processing times is

inferior or equal to Cap. Let C be the set of these

tasks transferred and Q the sum of their

processing time:

∀ the task ij ∈ C, we put b

ij

= a+1 + f

For n = 0 → H - a - w and for z = f → 0, we do:

RC

j

[a+1+z, a+w+n] = RC

j

[a+1+z, a+w +n ] –

Q (We update the new time scheduling segment

of the tasks and the remaining capacity of the

concerned lapses).

- We update the beginning and the ending of the

scheduling time segments of the other tasks on the

other processors as follow:

¾ If a task u precedes task j of the same job i on

the processor j, we move its scheduling time

segment in a manner that the ending time

becomes equal to the beginning time of the task

j. We effectuate the same treatment until

arriving to the first task.

¾ If a task u follows task j of the same job i on the

processor j, we update in a symmetrically

manner the scheduling time segment of this

task and all the other tasks up to the last one.

5

th

step:

We assign all the unused margins to the next

processor (in this case the processor P1). We

calculate the scheduling time segments of the tasks

corresponding to this processor using the following

formulae:

∀ i , for a processor j :

b

ji

= e

ji

– M’a

i

- ⎡(p

ij

/ d

p

)⎤

+ 1

(3)

Where M’a

i

is the remaining margin.

We can assign margins for a task i on a

processor j only if the precedent tasks of the same

job are not already treated. We obtain the C.R.P. and

the control feasibility graph of the processor P1 as

follow:

Per iods

(

we e ks

)

1

2

3

4

5

A1

(

3

)

F1

(

3

)

G1

(

1

)

H1

(

2

)

I1

(

1

)

J1

(

3

)

L1

(

2

)

6

B1

(

2

)

C1

(

3

)

7

22

33

44

55

23

34

45

24

35

25

0

0

5

0

0

3

3

3

2

6

6

-1

0

0 10

3

0

7

9

0

1

0

0 15

12

3 3

12

0 8

Accumulated capacity (days)

5 10 15 20

66

0

0

5

56

8

2

2

46

9

0 6

36

14

0 6

26

14

0

11

25

11

0

0

5

12

5

5

13

5

0 10

14

8

0 12

47

12

0 8

77

1

1

4

67

1

0

9

46

11

0 4

37

15

0

10

15

17

0

8

27

15

0

15

16

19

0

11

17

20

0

15

30

35

5

Figure 7: CRP and PFCG of processor P1 after assigning

all the available margins.

We check then the feasibility condition. If for a

lapse [a,b] in the processor j, the validation

condition is not verified, we should lengthen the

scheduling time segment of the tasks as follows:

- We consider in the duration increasing order the

list of all the tasks included in the lapse [a,b] and

that b

ij

= a or e

ij

= b.

- In order to treat the minimum number of tasks, we

begin to treat in this list the first task in the k

th

position in the list which has a load equal or

superior to the overloading in the lapse.

- We try to regain a margin for this task by

shortening the scheduling time segment of the

precedent task of the same job in a processor

already treated.

- We try this for all the tasks positioned in the (k+1)

th

position in the list until succeeding or arriving to

the end of the list.

- If we arrive to the end of the list, we try with tasks

positioned in the (k-1)

th

, (k-2)

th

… position until

succeeding or arriving to the beginning of the list.

- We must lengthen the scheduling time segment of

as many tasks as necessary to validate the

feasibility of the problematic lapse.

- If the remaining capacity continues to be negative,

we reiterate the treatment of the tasks in the same

order but by trying in this case to move completely

if possible the precedent task of the same job in the

past which allows us to lengthen the scheduling

time segment of tasks of this processor.

- If we do not succeed, we treat the tasks in the same

order by trying to delay the due date on a minimum

number of jobs or by increasing the capacity of the

incriminate lapses.

If we take our example, the control feasibility

graph of the processor P1 indicates that we have a

problem in the lapse [5,5] (Figure 7): the

accumulated capacity requirement is 6 days and the

available capacity is 5 days, so we should lengthen

the scheduling time segment of one of the tasks F1

A NEW LOAD ADJUSTMENT APPROACH FOR JOB-SHOPS

281

or J1. If we lengthen the task in the right, the due

date order will be delayed (F1 or J1 are the last task

of the jobs F and J), so we will try to shorten or

move the scheduling time of F2 or J2 in the

processor P2. F2 can not be shortened (the

scheduling time segment is one period). J2 can be

shortened, the scheduling time segment will be

shortened to the lapse [2,3]. We verify that the

control feasibility graph of P2 remains valid. The

scheduling time segment of J1 will become [4,5].

The control feasibility graph of P1 becomes valid

and we can try to regain margins like done for the

processor P2 in the fourth step. We obtain the C.R.P.

of processor 1 as follow:

Periods

(

weeks

)

1 2 3 4 5

A1

(

3

)

F1

(

3

)

G1

(

1

)

H1

(

2

)

I1

(

1

)

J1

(

3

)

L1

(

2

)

6

B1

(

2

)

C1

(

3

)

7

Periods

(

weeks

)

2 3 4 5

A3

(

2

)

F3

(

2

)

G3

(

1

)

H3

(

2

)

I3

(

2

)

K3

(

4

)

L3

(

3

)

6

B3

(

1

)

E3

(

2

)

Figure 8: C.R.P. of processor P1 and P3 after treatment.

Then, we apply step 5 for the last processor P3

and we obtain the C.R.P. as shown in Figure 8. We

update the beginning and the ending of the

scheduling time segments of the other tasks on the

other processors as explained in step 4 and we obtain

the final CRP of processors P1 and P2:

Periods

(

weeks

)

2 3 4 5

A2(2)

F2(3)

G2(1)

H2(2)

I2(2)

J2(3)

K2(3)

6

B2(3)

D2(2)

Periods

(

weeks

)

2 3 4 5

A1

(

3

)

F1

(

3

)

G1

(

1

)

H1

(

2

)

I1

(

1

)

J1

(

3

)

L1

(

2

)

6

B1

(

2

)

C1

(

3

)

7

Figure 9: Final C.R.P. of processor P2 after treatment and

a possible scheduling solution.

4 SCHEDULING

In case where we admit to interrupt at least one task

by period, the overlapping load adjustment approach

furnishes a necessary and sufficient condition for the

existence of a feasible scheduling solution. The

scheduling will be made in a real time manner.

Indeed, in the end of each task the responsible will

choose the next task between all the tasks that can be

loaded and so on. This load adjustment approach

will be coupled with a scheduling tool which can

function as described below. If we take our example

of Figure 1, the real time scheduling can be made as

follow:

- In the beginning of week 2 we can choose to begin

the task F or B (Figure 1), we choose for instance

task B and then task F.

- We arrive at the end of day 1 of week 3 and we see

that we can choose between three tasks: A or D or

E (Figure 1). The scheduling tool will inform the

user if he could really choose one task and during

how much time without breaking the feasibility

condition. If the user chooses for example task A,

the scheduling tool will tell him that the task A can

be scheduled for only one day until the end of the

second day of the week because there are two tasks

E and D with a total duration of 3 days that must be

scheduled on week 3. So, if the user decides to

choose A, he must interrupt A after one day,

schedule E and D and after that, continue with the

task A, but the user can choose to schedule E and D

without interruption. We suppose that the user

chose the task E and so we obtain the partial

scheduling described in Figure 10.

- We continue in the same way the scheduling and

we can obtain for example the final scheduling of

Figure 10.

Periods (weeks)

W eek 2

W 3

E(2)

F(2)

B

(

4

)

Periods

(

weeks

)

W2

W3

W4 W5

E(2) F(2)

C(4)

A(2)

D(2)

B(4)

G(4)

Figure 10: the partial and final scheduling.

In our opinion, this original approach of

scheduling presents many advantages in comparison

with the automatic calculation of a schedule. First,

the approach is really dynamic, each decision is

taken in the last moment and we do not produce

plans which will be out of date. Moreover, the user

can have its own reasons to choose one task or

another. A system that proposes and does not impose

but exposes the consequences of each choice in

regard to the scheduling which allows the user to

decide with full knowledge of the facts and

integrates his own criteria. This characteristic could

promote the scheduling performance, and allow in

all cases the responsibility of the user and his

comprehension of the system.

5 EXPERIMENTATION

An experimentation has been carried out on a set of

examples. We’ll describe very briefly (due to edition

constraints) the conditions and the results of this

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

282

experimentation. We have constructed 20 examples

where we varied the number of jobs (5 to 20) and the

number of processors (2 to 4). The total load is

always near or superior to the capacity. We

compared our approach with the classic approach of

placement. For each example, we apply our

approach and the placement approach. This

placement is applied in two steps: first an earliest

placement to determine the earliest due dates and

second a latest placement using job’s due dates as

the maximum between the requested due dates and

the earliest ones. We have compared the two

approaches in terms of number of jobs delayed. The

percentage of jobs delayed with the placement is

about 25 % whereas it is equal to 8 % with our

approach. This fact proves really the efficiency of

our approach. However, we should experiment and

compare our approach with other approaches.

6 CONCLUSIONS

We think that the most common approach used in

production planning remains MRP II

(Manufacturing Resource Planning). The proposed

approach in this paper works in a hierarchical

production planning and scheduling and constitutes

an alternative to the traditional load adjustment

approaches used in the CRP (Capacity Requirement

Planning) modules in software based on MRP II

philosophy. The new heuristic presented in this

paper, in comparison with the usual middle and/or

long-term planning and scheduling approaches, has

the following advantages:

- not setting a long-term tasks scheduling to assure

that the planning can be properly carried out;

- exploiting the intrinsic margins of each job to

obtain their loading time segments guaranteeing the

production planning feasibility under the

assumption of pre-emptive tasks;

- distributing judiciously the job’s margins on their

tasks and trying to respect the just-in-time

principles;

- splitting up the production planning into jobs

subsets making thus its analysis and its exploitation

easier;

- permitting the postponement of the final scheduling

jobs problem until the short term at the order

release phase and/or the scheduling phase;

- delaying, if necessary, the due dates of some jobs

or increasing the capacity in some lapses for

guaranteeing in every case the feasibility of the

production planning.

We can extend and improve our work by

studying the possibility of introducing the

overlapping of the scheduling time segments of

consecutive tasks. We can also improve our heuristic

accordingly since we want to minimize the average

tardiness or the max tardiness or the number of

delayed jobs.

REFERENCES

Bahroun, Z., Jebali, D., Baptiste, P., Campagne, J-P. and

Moalla, M.,

1999. Extension of the overlapping

production planning and application for the cyclic

delivery context, in IEPM ‘99 Industrial Engineering

and Production Management, Glasgow

.

Bahroun, Z., Campagne, J-P. and Moalla, M., 2000a. The

overlapping production planning: A new approach of a

limited capacity management

. International Journal of

Production Economics

, 64, 21-36.

Bahroun, Z., Campagne, J-P. and Moalla, M., 2000b. Une

nouvelle approche de planification à capacité finie

pour les ateliers flow-shop. Journal Européen des

Systèmes Automatisés

, 5, 567-598.

Dauzere-Peres, S., and Lassere, J-B., On the importance of

scheduling decisions in production planning and

scheduling. International Transactions in Operational

Research, 9(6), 779-793.

Dillenseger, F., 1993. Conception d'un système de

planification à moyen terme pour fabrications à la

commande. PhD thesis, INSA Lyon, France.

Drexl, A. and Kimms, A., 1997. Lot sizing and scheduling

- Survey and extensions. European Journal of

Operation Research, 99, 221-235.

Fleischmann, B. and Meyr, H., 1997. The general lot

sizing and scheduling problem. Operation Research

Spektrum, 19(1), 11-21.

Gunther, H.O., 1987. Planning lot sizes and capacity

requirements in a single stage production system.

European Journal of Operational Research, 31(1),

223-231.

Hillion, H. and Proth, J-M., 1994. Finite capacity flow

control in a multi-stage/multi-product environment.

International Journal of production Research, 32(5),

1119-1136.

Néron, E., Baptiste, P. and Gupta, J.N.D., 2001. Solving

Hybrid Flow Shop problem using energetic reasoning

and global operations. Omega, 29, 501-511.

A NEW LOAD ADJUSTMENT APPROACH FOR JOB-SHOPS

283