WEB-BASED INTERACTIVE POSITIONING CONTROL OF AN

ELECTRIC FLATCAR VIA WIRELESS NETWORK

Ken Ishii, Koki Abe and Yoshimi Takao

Natl. Res. Inst. of Fisheries Engineering, Fisheries Research Agency,

7620-7, Hasaki, Kamisu city, Ibaraki 314-0408, Japan

Keywords:

Electric flatcar, manipulator probe, model of WEB direct-access monitoring, double exclusive control, con-

troller and multiple-monitor system.

Abstract:

A large tank has been used for target strength pattern measurements of fish. It is equipped with an electric

flatcar. Further an elevation-rotating unit runs on the rails above it. The probe on the top of its elevation unit

is equipped with an attachment for an ultrasonic transducer. The manipulator probe is movable in the four

directions of the x, y, z and θ axes. Installation of a remote control switch has been required for the purpose of

efficient operation of an electric flatcar. A remote control system using a notebook personal computer has been

developed with good cost performance. The PC is equipped with a wireless network interface card. A model

of WEB direct-access monitoring has been designed newly on the basis of the concept that an operator can

control a mechanical device using a WEB Browser via LAN. Furthermore it performs double exclusive control

for access from multi PCs, and has made possible a controller and multiple-monitor system. The mission was

performed for the purpose of evaluation of WEB operation. The result has made clear the specifications for

motion, and an external interface of the electric flatcar is applicable to the new protocol developed for WEB

Browser control.

1 INTRODUCTION

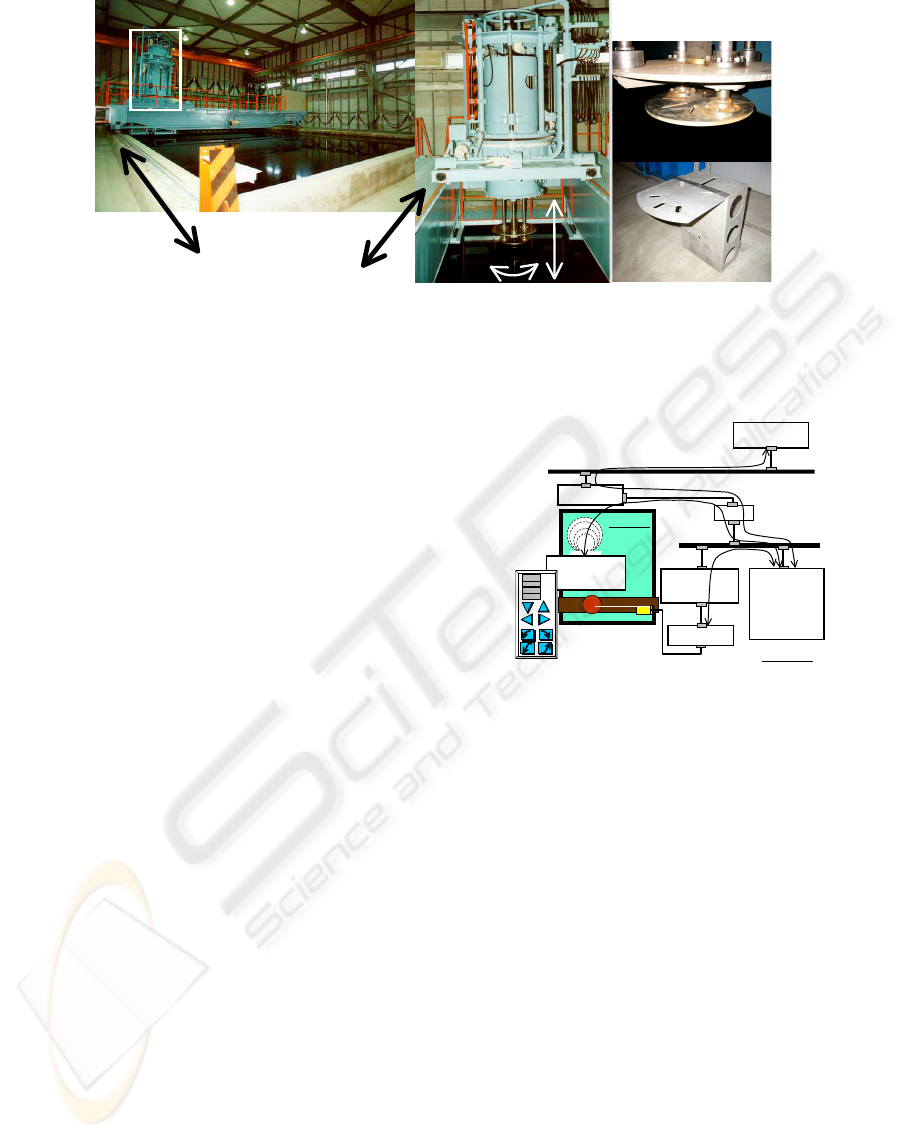

An indoor tank filled with fresh water has been used

for target strength pattern measurements of fish (Ishii

and Takao, 2000), and its shape is 10(W) x 15(L)

x 10(H) m

3

. It is equipped with an electric flatcar.

Further an elevation-rotating unit runs on the rails

above it. The probe on the top of its elevation unit is

equipped with an attachment for an ultrasonic trans-

ducer as shown in Figure 1 (Ishii et al., 1995). Instal-

lation of a remote control switch has been required for

the purpose of efficient operation of an electric flatcar.

A remote control system by a WEB Browser using

a personal computer (PC) has been developed with

good cost performance. Generally, WEB Browser

displays a page from a web sever responding to a re-

quest of a client. A long reply time is not applicable to

WEB Browser. But, the reply time of a target mechan-

ical device accessed by a web server varies widely.

The issue is development of a protocol for receiving

reply messages from a target machine. The commu-

nication method of this system is described in detail

in this paper.

2 METHOD

The probe can move four-dimensionally. The nominal

precision is ±1 cm along the longitudinal and trans-

verse axes, ±2 cm along the elevation axis, and ±0.2

degree around the rotation axis. Resolutions of abso-

lute encoders for positioning are 1 mm and 0.01 de-

gree, respectively. Parameters of velocity are limited

between 1 and 20 cm/s along the longitudinal axis, 1

and 10 cm/s along the transverse axis, and 0.2 and 3.0

degree/s around the rotation axis.

The sequencer (PLC, Programmable Logic Con-

troller) directly controls the electric flatcar every

10ms. Interval of communication between the PC

and the sequencer is one second using DDE (Dy-

namic Data Exchange) protocol via P-LINK (Proces-

sor Link) (Ishii et al., 1999).

323

Ishii K., Abe K. and Takao Y. (2007).

WEB-BASED INTERACTIVE POSITIONING CONTROL OF AN ELECTRIC FLATCAR VIA WIRELESS NETWORK.

In Proceedings of the Fourth International Conference on Informatics in Control, Automation and Robotics, pages 323-326

DOI: 10.5220/0001616103230326

Copyright

c

SciTePress

Longitude

Transverse

Rotation Elevation

(a)

(b)

(c)

(d)

Figure 1: The electric flatcar and its movable directions shown by arrows. (a) The electric flatcar on a large tank. (b) An

elevation-rotating unit on it includes a movable probe. Two devices of (c) and (d) are used in the joint mission. (c) An

attachment on the top of a probe in the electric flatcar. (d) An adaptor for a transducer.

The function of a remote control switch has been

realized by a notebook PC equipped with a wireless

network interface card that is implemented more eas-

ily than a specified low power radio wave unit. The

model of WEB direct-access monitoring has been de-

signed newly on the basis of the concept that mul-

tiple users control or monitor a mechanical device

using a WEB Browser via LAN (Local Area Net-

work). It consists of a main server program that per-

forms exclusive control for access from multi PCs,

and makes possible a controller and multiple-monitor

system (Ishii and Sawada, 2005). Figure 2 shows

its application to the remote control switch function

for an electric flatcar. The driving control command

through the main server program does not access the

database that holds the values, but accesses the device

driver program that operates the instrument instead.

The mission was performed for the purpose of

evaluation of WEB operation. The mission is

achieved by bringing an attachment of a probe close

to an adaptor for a transducer shown in Figure 1. In

this mission, the speed is one or two cm/s in the trans-

verse direction, one cm/s in the elevation direction,

and 0.2 degree/s in the rotation direction (Ishii et al.,

2006).

3 RESULTS

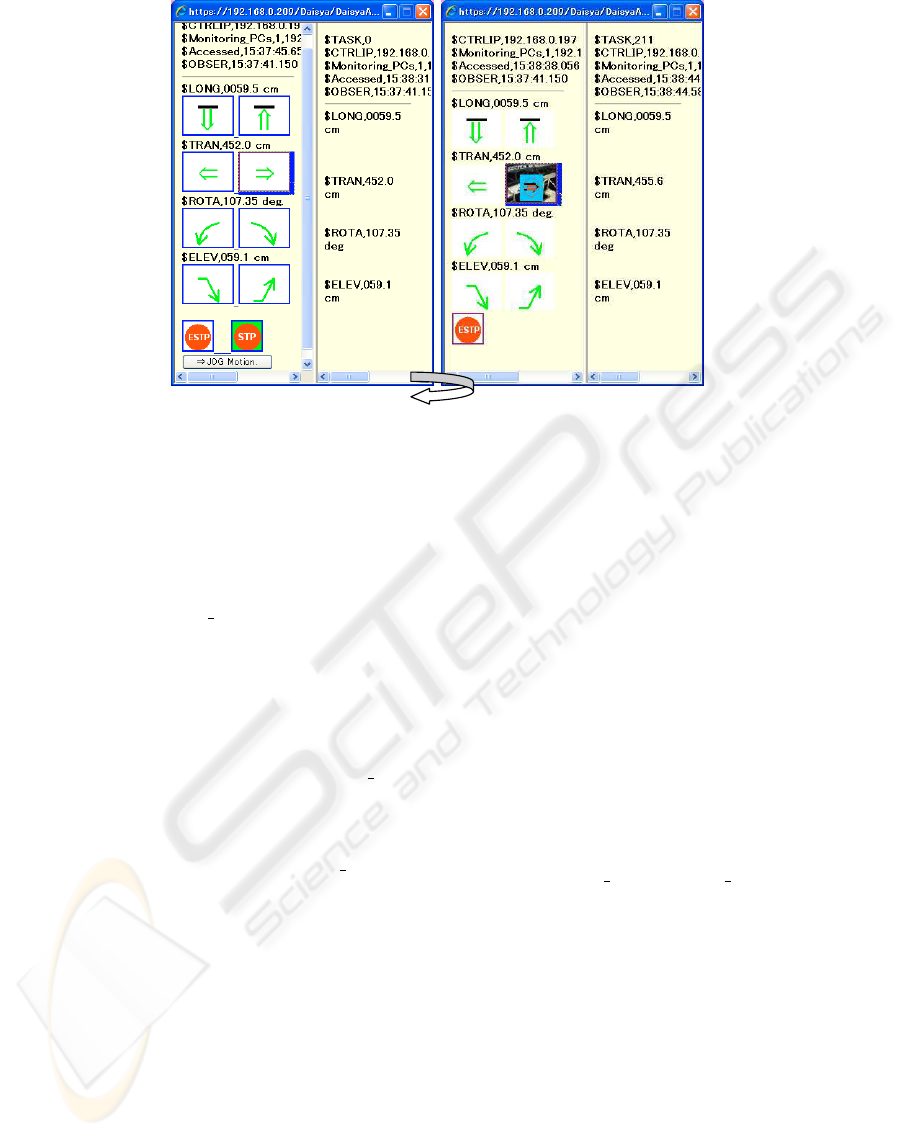

A WEB Browser display of a remote control switch

function has dual modes of ”DRIVE” and ”JOG”.

Furthermore, each mode consists of two inde-

pendent frames of ”SUBMIT COMMAND” and

”POLLING”. An example of ”DRIVE” mode is

shown in Figure 3. The time chart is the following:

Water tank

Electric flatcar

PC_Ctrl

Wireless NIC

Notebook PC

Remote control

switch function

+

+

−

−−

−

−

−−

−

123.8

97.84

473.1

567.4

*1

LAN

WEB Monitoring

PC_Moni

*2

Router

Intranet

*3

Hub

Control room

PC_Log

Main server

program

Logging program

Device driver

program

PC_ Device

DDE, P-LINK

PLC

Figure 2: The model of WEB direct access monitoring ap-

plied to a remote control switch function. Widely located

WEB Browsers post request commands to the main server

program respectively via the routes *1 or *2 on a network.

The main server program directly accesses, via route *3,

a device driver program of an electric flatcar in order of a

session.

• A negotiation command for priority was sub-

mitted from the controller PC at a time of

15:38:38.040, and a transverse driving command

was submitted at 15:38:38.056. The left command

frame was shifted to Figure 3-(b) from Figure 3-

(a).

• During movement, polling is repeated by a moni-

toring frame.

• After a submission of a STOP command at

15:38:51.415, an end flag of driving was detected

at a time of 15:38:52.087.

• By control from a right polling frame, a page

of left command frame was renewal to a waiting

page of Figure 3-(a) at a time of 15:38:52.368.

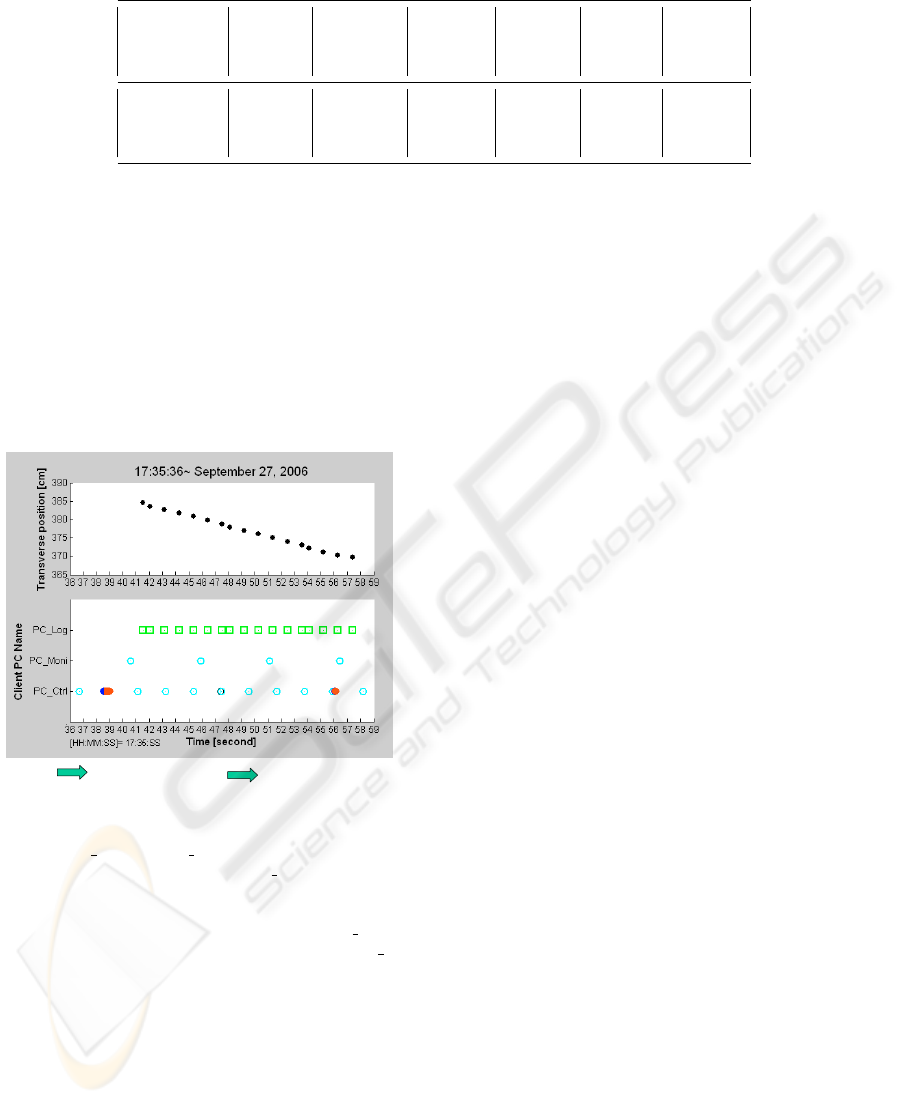

Among the mission for evaluation, access of a

PLC from a remote control switch and monitor PCs

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

324

(a) (b)

Figure 3: Design of the DRIVE mode with START/STOP. From upper icon, control buttons show the four directions ”longi-

tudinal”, ”transverse”, ”rotation”, and ”elevation”. A driven direction is selected by a tab key or a mouse. The left figure (a)

shows a mode of WAITING, and a foreward direction of ”transverse” is focused. The right figure (b) shows a status of driving

operation.

was performed via Intranet or LAN as shown in Fig-

ure 4 for a typical example. In this figure, the X-axis

shows time in seconds. ”PC

Ctrl” of the Y-axis works

as a controller with a remote control switch function.

A WEB Browser performed polling in intervals of five

seconds for the monitoring, or two seconds for the

driving. Each access to a main server is classified by

a session ID, and is ordered by double exclusive con-

trol. A transverse driving command ($DRIVE) was

submitted from the controller PC (named PC

Ctrl)

at a time of 17:35:38.571, and a stopping command

($STOP) was submitted at 17:35:56.096. Positioning

information of the electric flatcar is given per access.

On the other hand, a logging PC (named PC

Log) re-

ceives renewal data at an interval of about one second

linked with changing of values of position. The probe

of the electric flatcar moved from 384.6 cm to 370 cm

at the minimum velocity of one cm/s along the trans-

verse axis. It has been confirmed that a WEB Browser

on the controller PC is available to be performed in

repetition of one second. Furthermore, the number

of PCs for WEB monitoring has been confirmed nor-

mally for Four PCs.

Three kinds of commands such as a negotiation

command for priority, driving commands and a stop-

ping command, are submitted sequentially from a

command frame of a controller PC. On the other

hand, in a monitoring frame, polling is performed for

the purpose of acquisition of positioning information.

Averaged reply times for drive commands are shown

in Table 1 in addition to needed times for acquisition

of moved position information.

4 DISCUSSIONS

Dual modes of motion operation are available to be

changed to the other interactively. The DRIVE mode

with START/STOP is used for driving of long dis-

tance. The JOG mode is useful for short range driv-

ing, about one cm. And Driving of a fixed distance

such as JOG mode is needed for safety of operations.

In Figure 4-(b), it is shown that access timing of

multiple PCs (PC

Moni and PC Ctrl) was success-

fully ordered by double exclusive control of a main

server program.

In Table 1, it takes several seconds for acquisition

of first positioning data owing to lower initial speed.

After second positioning data, it takes about one sec-

ond. It takes about six ms for negotiation of priority.

Positioning data is obtained at the same time of ne-

gotiation of priority. And in the monitoring frame of

a WEB Browser, a negotiation command also works

as a polling command for receiving a reply message

from the mechanical device (PLC). A reply to a mon-

itoring command is performed immediately. The re-

turn time of driving commands is about 30ms.

Furthermore, submission of a driving command

hardly coincides with the renewal of a WEB page

for polling, because of the two independent frame

WEB-BASED INTERACTIVE POSITIONING CONTROL OF AN ELECTRIC FLATCAR VIA WIRELESS NETWORK

325

Table 1: Reply times for commands and needed times for position information.

Drive axis Priority $DRIVE First Priority $STOP Last

position position

ms ms sec. ms ms sec.

Transverse 6 32 2.5 6 31 1.6

Elevation 6 28 1.5 7 28 1.0

Rotation 7 30 3.2 7 27 1.2

architecture. Therefore retry of the selection is not

required. Consequently remote control by a WEB

Browser has been working well.

Residual issues are the following:

• A notebook PC lacks solidity.

• It takes longer time in a FORCED STOP oper-

ation on a wireless PC than in an operation by

an EMERGENCY STOP button on an operation

desk.

(a)

(b)

Waiting

$DRIVE

command

$STOP

command

Figure 4: Ordered accesses by three PCs to a main server

PC via LAN. The lower figure (b) shows access timing from

multi PCs. PC

Mon and PC Ctrl use WEB Brower with an

interval time of two or five seconds. PC

Log uses an exclu-

sive application program for logging positioning data with

an interval time of about one second. The upper figure (a)

shows positioning information acquisitioned by PC

Log. In

the lowest row, a transition of motion modes about PC

Ctrl

is shown.

5 CONCLUSION

The development of a remote operation system via a

wireless PC didn’t require editing of a complex se-

quencer program in the electric flatcar, so that this

system starts working well as soon as possible. Using

a function of PRESET DRIVE and a simple commu-

nication protocol that are implemented in the electric

flatcar, the server program for WEB pages that are

available for control and monitoring of a machine has

developed in a sever PC. Usage of a WEB browser

makes possible a flexible constitution of the remote

terminal system. Then it has a merit of a smaller task

to a terminal PC.

This system has been developed on the basis of

two contents such as a WEB direct-access model, and

a controller / multi-monitor system model. It was

clear by the above-described mission that the commu-

nication speed of the electric flatcar is applicable to

the model of WEB direct-access control and monitor-

ing, in the case of attainability of the electric flatcar.

An attachment of a probe is also available for in-

stallation of underwater cameras. The optical calibra-

tion of an underwater observation bench is scheduled

using an electric flatcar. It is hopeful that the wireless

operation on the spot instead of a push button opera-

tion on an operation desk is effective.

REFERENCES

Ishii, K., Abe, K., and Takao, Y. (2006). Positioning control

of the electric flatcar using web browser via wireless

lan. In Abstracts of 2006FY Autumn Annual Meeting.

AMSTEC.

Ishii, K. and Sawada, K. (2005). Network-integrated control

program for a transducer-rotating mechanism to mea-

sure target strength (ts) pattern of squid. In Journal

of Advanced Marine Science and Technology Society.

AMSTEC.

Ishii, K., Sawada, K., and Miyanohana, Y. (1999). Design

of transducer-positioning system scanning around an

aquatic target in a tank. In Collected Papers of FO-

RUM ACUSTICUM BERLIN 99. ASA and DEGA.

Ishii, K., Sawada, K., Takao, Y., Miyanohana, Y., and Oku-

mura, T. (1995). Control system of electric flat-car

equipped above an acoustic tank. In Proceeding of

the Annual Meeting. the Marine Acoustics Society of

Japan.

Ishii, K. and Takao, Y. (2000). Evaluation of transducer-

positioning system scanning around an aquatic target

in a tank. In Abstracts of 2000FY Spring Annual Meet-

ing. Advanced Marine Science and Technology Soci-

ety.

ICINCO 2007 - International Conference on Informatics in Control, Automation and Robotics

326