THE PORT-TRANSSHIPMENT SYSTEM DYNAMICS

SOFTWARE SIMULATOR

Josko Dvornik, Ante Munitic, Frane Mitrovic

Faculty of Maritime Studies, University of Split,

Zrinsko frankopanska 38, 21000 Split, Croatia

Abstract. Port is place of interlace of different kindle of cargo, and play

important role in shipping process, connecting different type of traffic in

one united system, and form interrupted traffic chain.

The aim of this paper is: to show the efficiency of System Dynamics

Simulation Modeling during the study of the dynamics behavior of the

Port-Transshipment system, and to find optimal solution for transshipment

with regard to type of the cargo and size of traffic of the cargo, direction

and dynamics of arriving and shipping the cargo. The System Dynamics

Modeling is in essence special, i.e. “holistic” approach to the simulation of

the dynamics behavior of natural, technical and organization systems, and

it contains quantitative and qualitative Simulation Modeling of various

natured realities. The concept of optimization in System Dynamics is

based on belief that the “manual and iterative” procedure, i.e. optimization

by the method “retry and error” can be successfully executed using

“heuristic optimization” algorithm, with the help of digital computer, and

in complete coordination with System Dynamics Simulation

Methodology.

1. Introduction

The System Dynamics Modelling is in essence special, i.e. “holistic” approach to the

simulation of the dynamics behaviour of natural, technical and organization systems.

Systems dynamic comprise qualitative and quantitative simulation modelling, and the

concept of optimization of dynamic systems and processes is based on so call “heuristic”

procedure. Meaning that on the method of manual and iterative procedure, which is

automatized with the help of fast digital computer, named “heuristic optimization” (retry

and error!). This simulation model is only one from the large number of made and

educationally and practically used simulation models for education and training of young

students – mariner, wch use so call “white box” philosophy of investigation of complex

systems, as distinguished from “black box” approach.

Dvornik J. and Munitic A. (2005).

THE PORT-TRANSSHIPMENT SYSTEM DYNAMICS SOFTWARE SIMULATOR.

In Proceedings of the 3rd International Workshop on Modelling, Simulation, Verification and Validation of Enterprise Information Systems, pages

121-125

DOI: 10.5220/0002576401210125

Copyright

c

SciTePress

2. System Dynamics modeling of the Port-transhipment

Mental-verbal model:

Fundamentally, unloading of any kind of cargo can be divided in:

- ship arrival to the berthing position,

- unloading the cargo from the ship to the shore,

- transport of the cargo from the shore to the wagons, trucks and warehouses.

Unloading/loading of the cargo in port is complex dynamics process with two subsystems:

- Unloading/loading of the cargo in port (BUTUL),

- Surrounding environment (OS).

FBL

BUTUL OS

Figure 1. Rudimentary structural model of the Port-Transshipment System

Subsystem BUTUL have at least four sector i.e. subsections:

1. State of occupation of the berth,

2. Number of the cranes (on the ship and on the shore), which are objective at disposal,

3. Number of the fork-lift, which are objective at disposal,

4. Warehouses (number and the area that are at disposal).

Subsystem OS have at least four sector i.e. subsections:

1. Waiting ship (on the berth or in arrival),

2. Engaged wagons capacities,

3. Engaged trucks capacities,

4. Consignee (receiver) of the cargo.

3. Simulation results

This scenario includes putting to shore and unload of the ship on the berth, transshipment

of the cargo on the wagons with subsection of logical management built in it,

transshipment of the cargo on trucks also with subsection of logical management, an at the

end transshipment of the cargo to the warehouse.

In this paper, cause of its largeness, we will present only zero scenarios with initial

conditions:

122

- ship is on the berth 1,

- unloading of the ship have been started in time T=0,

- Transshipment of the cargo with cranes, and the number of cranes are D1=

2+STEP(2,47)-STEP(2,119), i.e. the capacities of the cranes are 50*D1

- Transshipment of the cargo on the fork-lift, and the number of fork-lift are V1=

2+STEP(2,47)-STEP(2,119), i.e. the capacities of the cranes are 50*V1

- Transshipment of the cargo with fork-lift from the berth to the gate and

transshipment on the wagons, and the number of wagons are W1=

56+STEP(40,71)-STEP(40,119)

- transport of the cargo on the trucks, and the number of trucks are K1=

20+STEP(10,47)-STEP(10,95) ,

- transport of the cargo in the warehouse, and capacities of the warehouse are

54000.

Cargo

receivers

Port Warehouse

wharf

Ship

Fork-lift trucks

Trucks

Vagons

Figure 2. Structural model of material flow of the cargo

Graphic results of simulation:

Time

BIB1

1

BPTSV1

2

0 100 200 300

0

50

100

150

200

1 2

1

2 1

2

1 2

Figure 3. Speed of unloading the ship-BIB1, Speed of shipping of the cargo to the

warehouse-BPTSV1

123

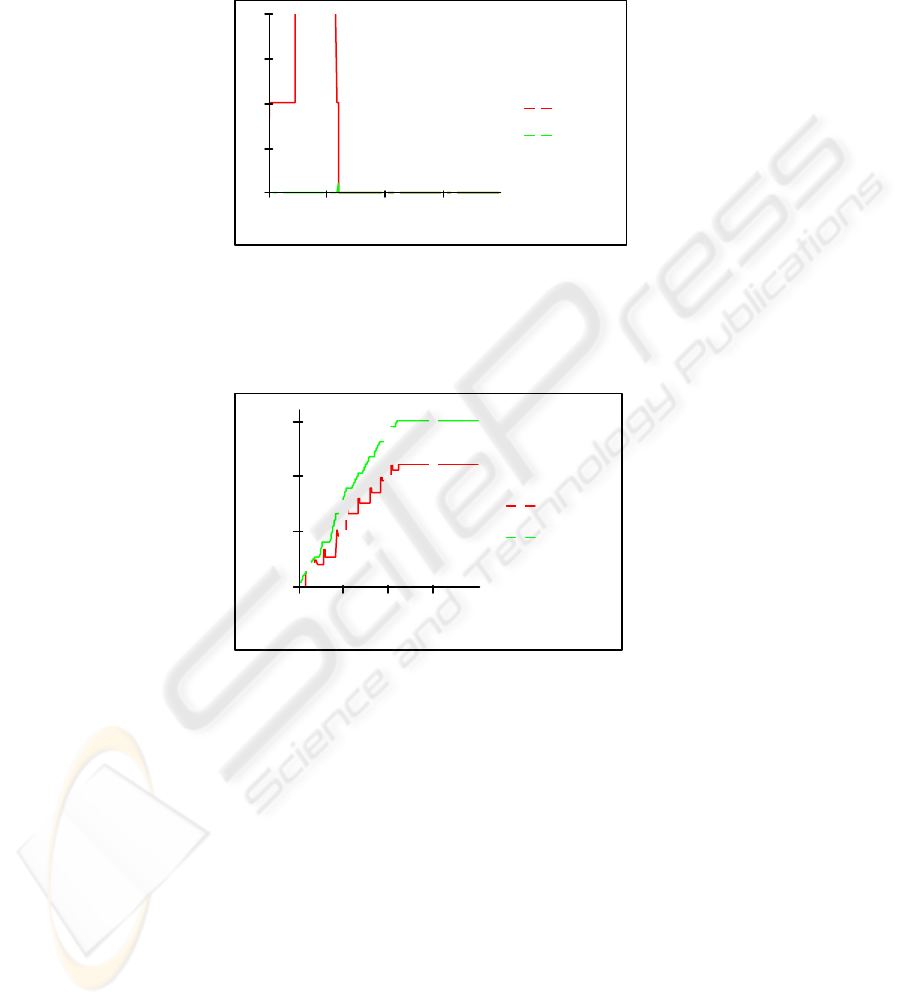

Time

BPTVV1

1

BPTVV11

2

0 100 200 300

0

50

100

150

200

1 2

1

2 1 2 1 2

Figure 4. Speed of shipping of the cargo with fork-lift from the berth1 to the platforms for

loading on the wagons, trucks or warehouse-BPTVV1, Speed of shipping of the cargo with

fork-lift from the berth 1 in the case that SITV1 is multiple of the number of the fork-lift-

BPTVV1

Time

KSOT

1

KPSUKTW

2

0 100 200 300

0

5.000

10.000

15.000

1

2

1

2

1

2

1

2

Figure 5. Cumulative display of the state of the loaded cargo on the wagons-KPSUKTW,

Cumulative book -keeping state of the shipped cargo-KSOT

124

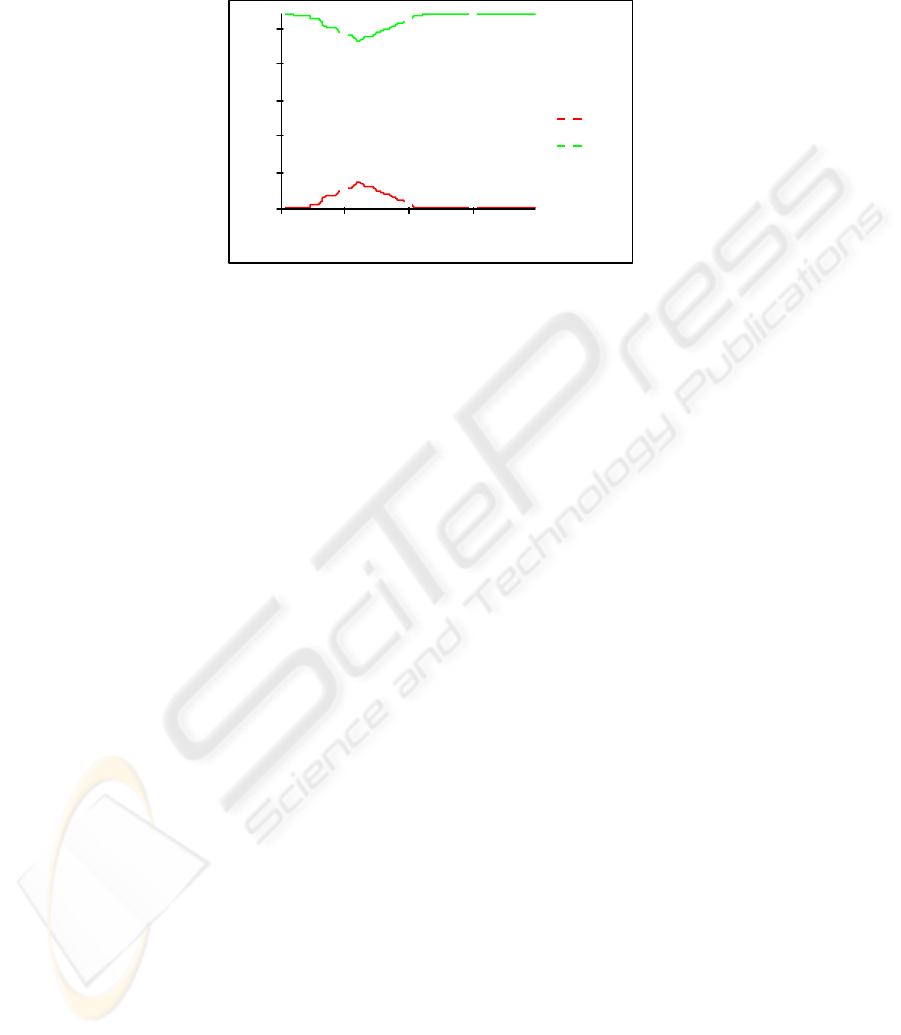

Time

SUTS1

1

SSKS1

2

0 100 200 300

0

10.000

20.000

30.000

40.000

50.000

1

2

1

2

1

2

1

2

Figure 6. State of available warehouse capacities-SSKS1, State of the loaded cargo to the

warehouse-SUTS1

REFERENCES

1. Forrester, J.W., Principles of Systems, MIT ,Press, Cambridge Massachusetts, USA (1973)

2. Munitic, A., Application Possibilities of System Dynamics Modelling, System Dynamic, Edited

by Susan Spencer and George Richardson, Proceedings of the SCS Western Multiconference,

San Diego, California, A Society for Computer Simulation International, San Diego, USA

(1989)

3. Munitic, A., Computer Simulation with Help of System Dynamics, Croatia, BIS Split, p. 297,

(1989)

4. Munitic, A., Bilic, M., Dvornik, J., System Dynamics Simulation Model of the

PorTranshipments System, The Modern Information Technology in the Innovation Processes

of the Industrial Enterprises (MITIP 2002), Savona, Italia, (2002), 171-176.

5. Munitic, A., Bilic, M., Dvornik, J., System Dynamics Simulation Model of the Port-

Transhipments System, First International Congress on Mechanical and Electrical

Engineering and Technology / Fourth International Conference on Marine Industry,

(MEET/MARIND'02), Varna, October, (2003), 169-176.

6. Munitic, A., Milic, L., Dvornik, J., System Dynamics Simulation Modelling of the Port

Manager Planer, European Concurrent Engineering Conference, (ECEC 2003), 14-16 April,

Plymouth, UNITED KINGDOM, (2003), 51-54.

7. Munitic, A., Simundic, S., Dvornik, J., System Dyanamics Modelling of Material flow of the

Port cargo system, ISDC 2003, 21st System Dynamics Conference in New York City,

International System Dynamics Conference,, NEWYORK,USA, (2003).

125