FUZZY PATTERN RECOGNITION BASED FAULT DIAGNOSIS

Rafik Bensaadi, Hayet Mouss and Nadia Mouss

Laboratoire d’Automatique et Productique

Université de Batna , 1 Rue Chahid Med. El. Hadi Boukhlouf, 05000 Batna,

Algeria.

Keywords: Diagnosis, fault detection, pattern recognition, fuzzy control, complex plant, conjugate gradients.

Abstract: In order to avoid catastrophic situations when

the dynamics of a physical system (entity in a M.A.S

architecture) are evolving toward an undesirable operating mode, particular and quick safety actions have to

be programmed in the control design. Classic control (PID and even state model based methods) becomes

powerless for complex plants (nonlinear, MIMO and ill-defined systems). A more efficient diagnosis

requires an artificial intelligence approach. We propose in this paper the design of a Fuzzy Pattern

Recognition System (FPRS) that solves, in real time, the main following problems:

Identif

ication of an actual state,

Identif

ication of an eventual evolution towards a failure state,

Diagnosis and decision-making.

1 INTRODUCTION

There is an increasing interest in the development of

intelligent fault detection and diagnosis in industrial

systems because of increasing requirements for

reliable, safe and efficient operation of the plant and

for maintaining quality of the products.

Many variables, unknown or not directly

measured,

have to be included in the state vector to

better describe the plant behaviour: model accuracy,

a very difficult task, is necessary for the effective

processing of unpredictable and imprecise

information. However, human expert can skilfully

control plants, localise a fault and in many times

make a good diagnosis: the human has the ability to

learn, to manage imprecise data and he acts in terms

of a complex combination of sensoring signals

instead of separate information sources. Because of

complexity in modelling a real plant, we need to

achieve this sophisticated level of information

processing that the brain is capable of, to solve the

difficult task of fault detection and diagnosis.

Pattern Recognition is a field concerned with

mach

ine recognition of meaningful regularities in

noisy or complex environments. It is based upon the

numerical representation of the k

th

object observed in

the process (physical entity such as a DC-motor,

photograph, etc.) as a vector x

k

= [x

k1

, . . . ,x

kq

]

T

,

called the pattern vector or feature vector, where x

kj

the j

th

characteristic (feature) associated with

observation k: temperature, pressure, flow, sound

noise frequency, etc. and q the pattern vector length.

Fuzzy logic concept is included to better manage

uncertainty and make useful quantification of hard

attributes.

In this paper, a technique for membership function

app

roximator design is presented. We discuss some

classification approaches and apply CUSUM

algorithm with additional criterions in fault detection

problem. We propose a general diagnosis and

decision making scheme and give simulation results

for a fictive complex system.

2 FPRS DESCRIPTION

The pattern vector corresponds to a combination of

sensoring signals: temperature at point A, pressure

level at B, incoming flow, etc. It is constructed in

terms of the human expert point of view about the

plant, and the effects listed in an FMEA (Failure

Modes and Effects Analysis). Other mathematical

techniques like PCA (Principal Component

Analysis) help to design the pattern vector.

For each new incoming observation, we need to

id

entify and quantify the actual plant status and any

possible convergence toward an other state: in

particular, a failure state. We have to estimate the

347

Bensaadi R., Mouss H. and Mouss N. (2005).

FUZZY PATTERN RECOGNITION BASED FAULT DIAGNOSIS.

In Proceedings of the Seventh International Conference on Enterprise Information Systems, pages 347-356

DOI: 10.5220/0002510403470356

Copyright

c

SciTePress

speed evolution and execute the necessary safety

actions in acceptable delays. A general fault

detection and diagnosis that meet these requirements

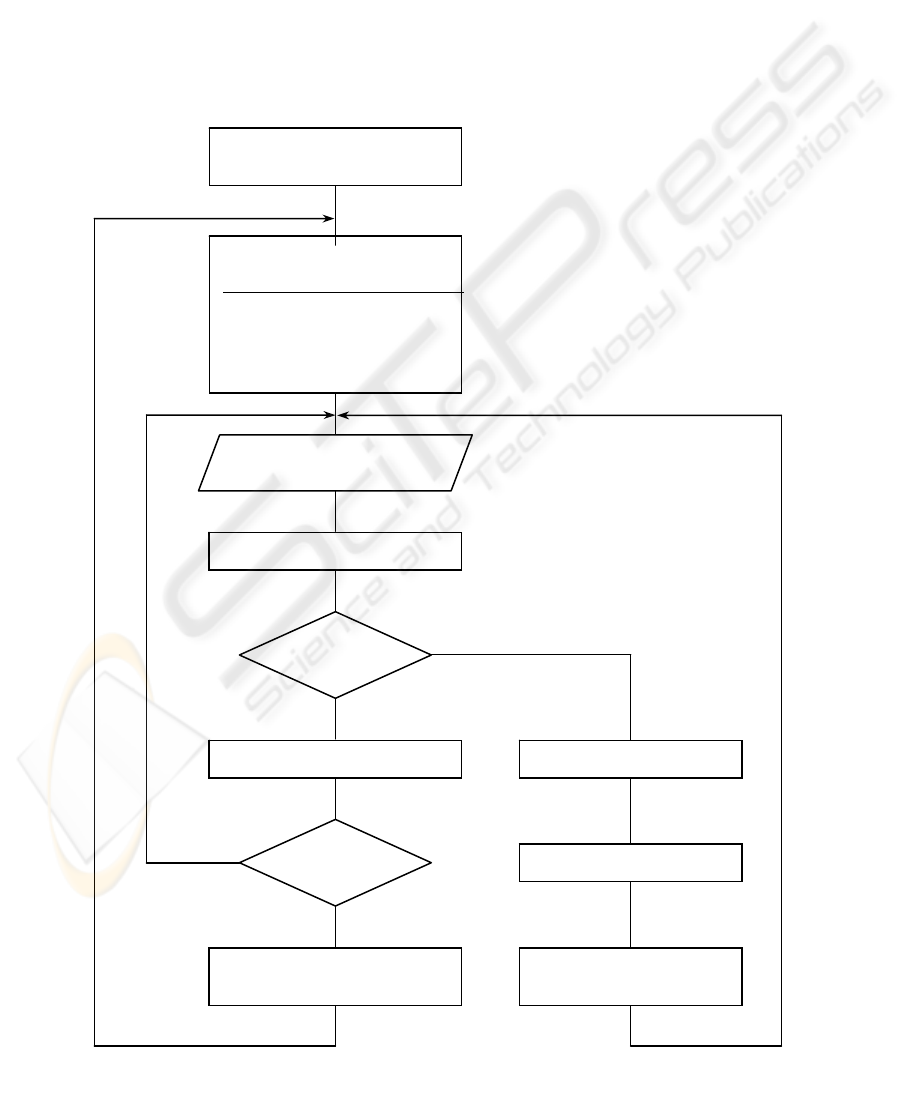

is presented in figure 1.

3 MEMBERSHIP FUNCTION

ESTIMATION

3.1 Fuzzy Clustering

This first step of unsupervised learning is necessary

to produce a logic initialisation of the fault detection

and diagnosis system.

Given the training set X = {x

1

, x

2

, … x

n

}, where x

k

= [x

k1

, . . . ,x

kq

]

T

the pattern vector, the problem of

fuzzy clustering in X is to assign to the objects {x

k

}

labels that identify ‘natural subgroups’ in X. The

membership degrees, are computed as U = [u

ik

] by

the Fuzzy c-Means (FCM) algorithm with the

following considerations:

A class, set of observations that have similar

properties, corresponds to one operating or

failure mode, the number of clusters c is assumed

to be known. It is also initialised in terms of the

expert point of view,

The training set is considered, as representative

of the whole possible clusters, when its size is

large enough. It is obtained by causing the plant

to operate under different modes.

Initialise c, number of known

operating modes

Membership functions

estimation

Fuzzy Clustering

Training a nonlinear

membership function

approximator

Read z

k

, a new observation,

sequence mean/prototype value

Label z

k

Low

membershi

p

Store as rejected data

Max reached

Update c with a higher

estimation

Classify z

k

State change detection

Monitoring update

Launch safety actions

N

o

Yes

N

o

Yes

Figure 1: A general FPRS design strategy

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

348

The FCM algorithm converges from any

initialisation to a local minimum. The prototypes

and membership degrees are iteratively updated by

[3]:

∑

∑

=

=

=

n

k

m

ik

q

k

k

m

ik

i

u

u

1

1

x

v

for i = 1,2,…c (1)

u

ik

= f

(x

k

, v

i

, {v

j

}, m)

where,

u

ik

: the membership degree of object x

k

to class i,

v

i

: prototype of class i,

m ∈ [1, ∞): weight exponent on each fuzzy

membership,

until an error threshold is reached.

Expression (1) is intuitively understood when we

observe the similarity with the ‘centre of gravity’

concept.

3.2 Nonlinear Approximator Design

At this step, X = {x

k

} and U = [u

ik

] feed the input of

a nonlinear approximator optimisation algorithm.

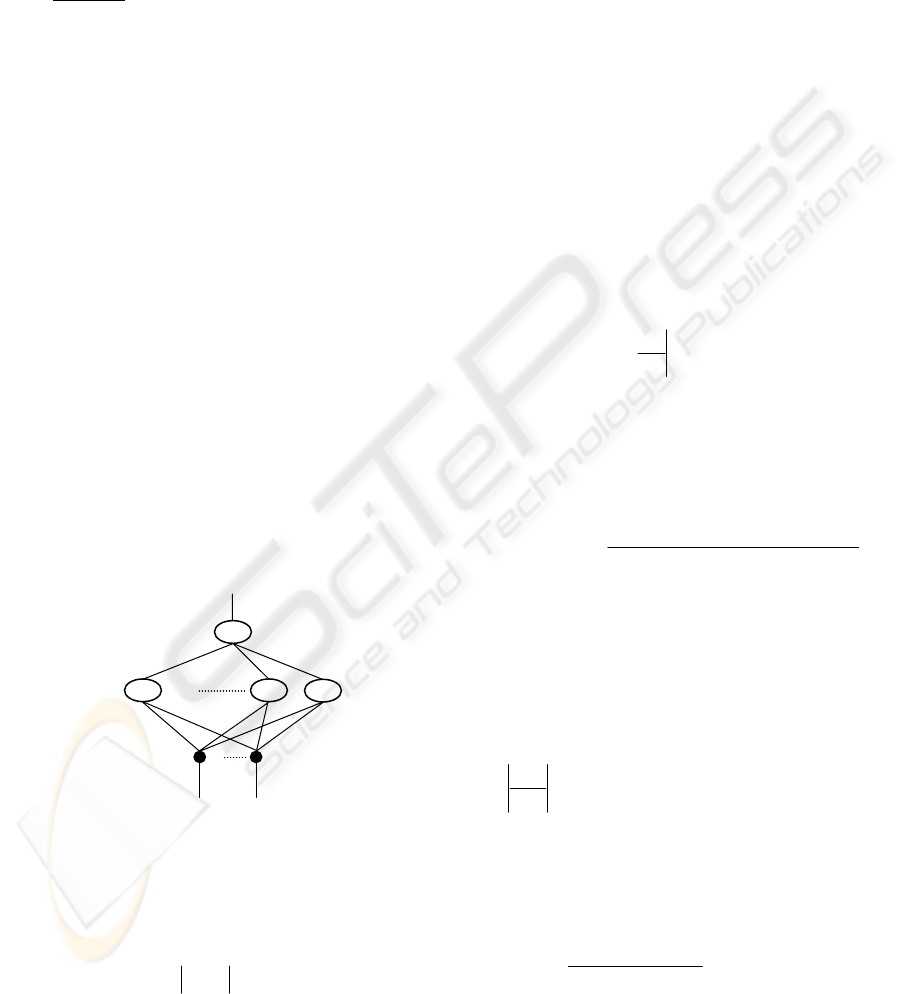

Let’s consider the structure of a Radial Basis Neural

Network (RBNN) as shown in figure 2. The hidden

layer is typically comprised of p radial basis

activation functions with an associated Euclidean

input mapping. The output is taken as a linear

activation function with an inner product

Figure 2: RBNN based nonlinear approximator.

The input-output relationship, with x = [x

1

,. . . ,

x

q

]

T

, is given by

∑

=

−−=

p

j

jjj

wF

1

2

2

)/exp(),(

γ

cxθx

(2)

where,

θ = [w

1

, . . . ,w

p

]

T

: the weight vector to be

adjusted during learning,

c

j

= [c

j1

, . . . ,c

jn

]

T

: the centres of Gaussian

functions.

Now, it is desired to cause F

i

(x, θ) to match a

membership function of class i at the data points (x

k

,

{u

ik

}) for i = 1,. . , c, previously estimated by the

FCM. The Conjugate Gradient method, chosen

because of its good convergence properties, is

applied for training the approximator. It is based

upon the minimisation of:

∑

=

=

n

k

kk

i

eeJ

1

T

)(

where,

e

k

= (u

ik

) – F

i

(x

k

, θ), for i = 1,. . . , c

The algorithm is given as follow [10,11]:

1) Calculate

)(

)(

k

i

J

k

θθ

θ

=

∂

∂

=

ζ

. Set the search

direction equal to d(k) = –

ζ

(k).

2) Find θ(k+1) which minimises J

i

(θ) along d(k),

iteratively, by the Secant method:

a) Initialise

σ

< 1, set θ = θ(k)

b) Set

[]

[][]

)()()())((

)()(

TT

T

kdkkdkdk

kdk

ζσζ

ζ

σα

−⋅+

−=

output

c) θ = θ +

α

d(k)

d)

σ

=

α

e) If |

α

⋅d(k)

| < tol

α

then return θ

(k+1) = θ else

go to b

H

idden

layer

3) Calculate

ζ

(k+1).

4) If

θ

ζ

ζ

tol

k

<

)0(

)(

then return θ

(k+1)

x

1

x

q

input

5) Set the next search direction

d

(k+1) = –

ζ

(k+1) +

β

(k+1) d

(k),

where,

[

]

[]

)()(

)1()1(

)1(

T

T

kk

kk

k

ζζ

ζζ

β

++

=+

(Fletcher-Reeves

update), or

FUZZY PATTERN RECOGNITION BASED FAULT DIAGNOSIS

349

[]

[]

)()(

)1()()1(

)1(

T

T

kk

kkk

k

ζζ

ζζζ

β

+−+

=+

(Polak-Ribiere

update)

6) Set k

=

k+1 and goto 2.

c RBNNs are trained to estimate a membership

function for each corresponding class. Note that

F

i

(x, θ) may be outside [0,1] by a very small amount

for the first training, because (2) doesn’t include a

saturation factor. The few false measures must be

corrected (a value that is negative or greater than 1 is

taken, respectively, as 0 or 1) to be processed

correctly for fault detection. An other procedure, that

adds a sigmoid stage to the structure of figure 2, can

be tried in the future.

4 PROCESSING A NEW

OBSERVATION

Once the membership approximator is well defined,

a new observation z is labelled and classified:

The membership value of z to class i is

µ

i

(z) = F

i

(z, θ) (3)

We define a hard classifier on ℜ

q

as a decision

function D imaged in the canonical (unit vector)

basis of Euclidean c-space so that D(z) = e

i

means

that z belongs to class i. This hard attribution is

quantified by (3) to explain how much z is

considered as i

th

fault type and is useful to identify

the actual operating/failure mode. There are many

choices for classifier design:

Criterion 1:

z ∈ i ⇔ µ

i

(z) = max {

µ

j

(z)

}

j = 1, ⋅⋅⋅ c

. (4)

Criterion 2

: crisp nearest prototype rule (NP rule)

z ∈ i ⇔ D

NP,v

(z) = e

i

⇔ || z – v

i

|| ≤ || z – v

j

||

for j = 1, ⋅⋅⋅ c. (5)

Criterion 3

: fuzzy k-nearest neighbor (k-NN) rule

Compute and rank the distances d(z, x

i

) as {d

1

≤ d

2

≤

⋅⋅⋅ d

k

≤ d

k+1

≤ ⋅⋅⋅ d

n

}. Find the columns in U

corresponding to the k nearest neighbor indices {1,

2, ⋅⋅⋅ k}. Calculate the vector u(*|z) = [u(1|z) u(2|z)

⋅⋅⋅ u(c|z)]

T

with the NN labels:

∑

=

=

k

j

ij

k

u

iu

1

) ( z for j =

1, ⋅⋅⋅ c.

And finally decide

z ∈ i ⇔ D

NN,k

(z) = e

i

⇔ u(i|z) = max {

u(j|z)

}

j = 1, ⋅⋅⋅ c

.

(6)

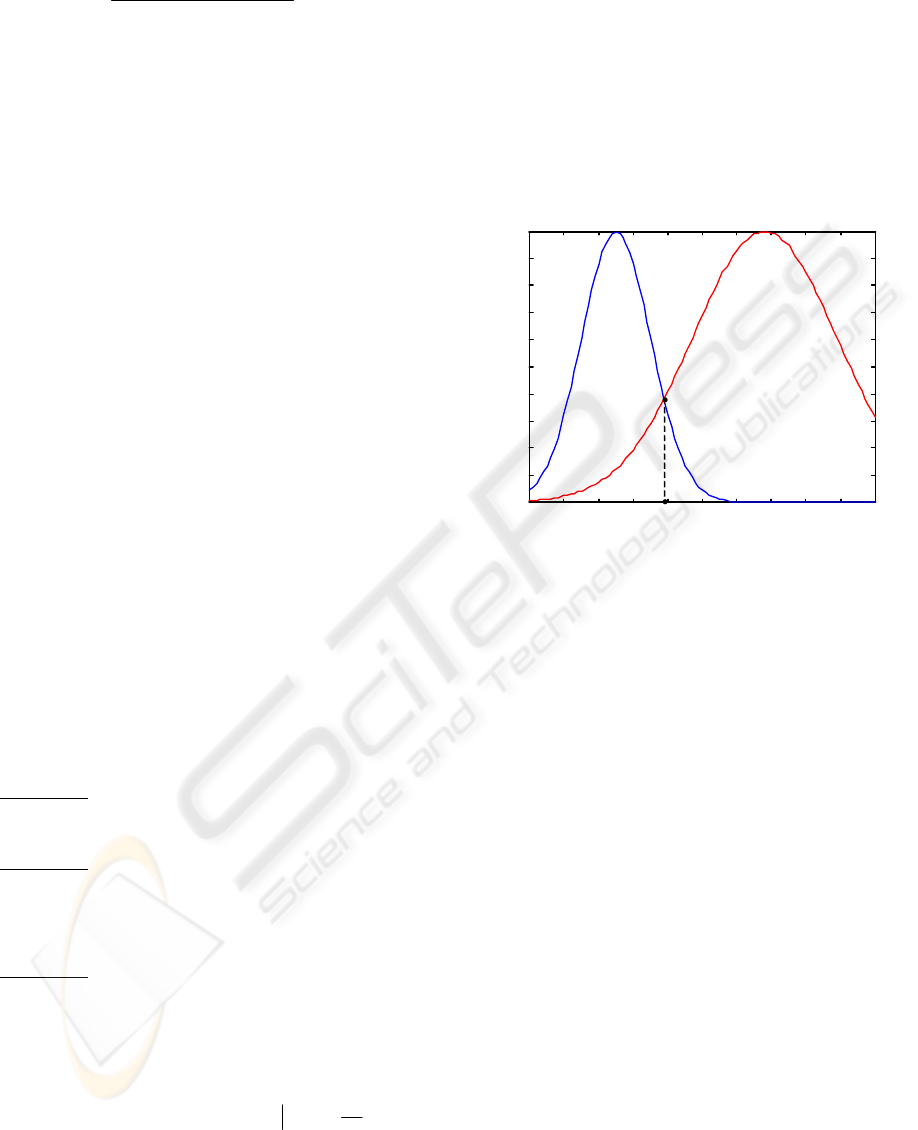

For a long training set and an efficient

approximator, the first criterion is the most adequate.

NP and k-NN may be used as a redundant alternative

to solve ambiguous situations like the example

illustrated in figure 3: it is easy to see that (z

1

<z* ∈

class 1) and (z

2

>z*∈ class 1), but we need an

additional/other criterion to classify (z

2

≈ z*)

0 0.1 0.2 0.3 0.4 0.5

0.6

0.7

0.8

0.9 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

z

membership function

µ1(z)

µ2(z)

z

*

Figure 3: Example of an ambiguous classification

problem

.

We add the constraint

th

c

i

i

uµ >

∑

=1

)(z

(7)

to reject observations with low membership degrees,

u

th

is a small nonzero number taken lower than 0.5.

When a sufficient number of similar (low variance

for a Gaussian pdf approximation) observations are

reached, a new cluster is created. Prototype and

membership function parameters are computed

individually (partial FCM with c=1) or by restarting

a global membership function estimation process.

5 FAULT DETECTION AND

FORECASTS

This is a more ambitious and potentially useful task

in maintenance monitoring. The detection of an

actual or future operating/failure mode requires

getting and processing, in real time, the signals z(t)

and µ

i

(z,t), and taking advantage of their stochastic

properties. If the plant status is efficiently described

by the pattern vector, we note by µ

i

(t) the

membership degree of the plant state to class i at

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

350

time t, and we develop our approach through the

following steps:

1) CUmulative SUM (CUSUM) algorithm is

involved in change detection by processing a

sequence of independent random variables with

probability density function p

Θ

(z) depending

upon one parameter Θ. It relies on a fundamental

concept: the log-likelihood ratio of an

observation z:

)(

)(

ln)(

0

1

z

z

z

Θ

Θ

=

p

p

s (8)

before an unknown change time k

0

, Θ is equal to

Θ

0

. At time k

0

, it changes to Θ = Θ

1

≠ Θ

0

. The

problem is to detect the change time.

The cumulative sum

∑∑

=

Θ

Θ

=

==

k

j

k

j

jp

jp

jskS

1

0

1

1

))((

))((

ln))(()(

z

z

z

(9)

(where, {z(j)}

j = 1, ⋅⋅⋅ k

a sequence of independent

random variables) is expected to exhibit a

negative drift before change, and a positive drift

after change. CUSUM algorithm is derived under

this idea and given as follow:

At each sample time,

a) Acquire the new data z(k),

b) Compute the decision function

g(k)=max{0, g(k-1)+s(z(k))},

c) Compute the number of successive

observations for which the decision function

remains strictly positive:

N(k) = N(k-1) 1

{g(k-1)>0}

+1,

where 1

{x}

=1 when x is true and 1

{x}

= 0

otherwise.

d) If g(k) > h, issue an alarm, (h is a threshold

chosen to meet either a specified mean time

for detection or a specified mean time

between false alarms)

Find the change occurrence time: k

0

= k

a

–

N(k

a

), where k

a

is the alarm time,

Reinitialise the decision function to 0,

In many practical cases, Θ is taken as the mean

value of a Gaussian distribution p

Θ

(z). In our

problem, each typical value Θ

i

indicates a class

prototype v

i

, and the problem of change

detection between failure modes will require a

prior knowledge about the class-statistical

properties. We only own a membership function

database!

2) Because of the fact stated above, CUSUM will

be applied with the following modification:

)(

)(

ln

z

z

j

i

µ

µ

is considered instead of

)(

)(

ln

z

z

j

i

p

p

Θ

Θ

where i and j are class-indexes. A membership

value doesn’t have the same meaning as

probability, but the ratios reflect the same

information, so the ability to apply CUSUM with

taking

)(

)(

ln)(

z

z

z

j

i

µ

µ

s =

(10)

is intuitively concluded.

3) Change time detection between two states is

presented. If the target class prototype remains

far, k

0

may be considered as an evolution

detection occurrence and safety decisions are

executed in acceptable delay. When the radius of

target class membership function is very small,

the safety task will be more difficult, so we need

an other tool to better quantify the evolution

between states and make an earlier alarm.

An evolution towards a fault is described by

dt

td

i

)(

µ

: A negative value means that the plant is

leaving state i, a positive value means that it is

evolving towards this state. The evolution speed

attributes ‘quick’ or ‘slow’ are quantified by

2

2

)(

dt

td

i

µ

: the change in evolution speed is said to

be ‘quick’ for

0

)(

2

2

>

dt

td

i

µ

, an observation may

leave quickly state i while converging slowly to

state j. Information about the fault evolution

direction are extracted from a 3×c matrix defined

by:

⎥

⎥

⎥

⎥

⎥

⎥

⎥

⎦

⎤

⎢

⎢

⎢

⎢

⎢

⎢

⎢

⎣

⎡

=

2

2

2

2

2

2

1

2

21

21

...

...

...

E

dt

µd

dt

µd

dt

µd

dt

dµ

dt

dµ

dt

dµ

µµµ

c

c

c

(11)

The corresponding alarme time k

e

is computed

in terms of constraints on the elements of E. For

example, k

e

may be defined as the delay time for

which both

⎟

⎠

⎞

⎜

⎝

⎛

dt

td

i

)(

µ

and

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

⋅

2

2

)()(

dt

td

dt

td

ii

µµ

FUZZY PATTERN RECOGNITION BASED FAULT DIAGNOSIS

351

remain positive, and this corresponds to the

alarm time k

a

computed by CUSUM. Other

conditions may be added to make an earlier

alarm (optimisation problem).

Because of external disturbances, a noise is

added to z when reading. We’ll consider mean

values instead of instantaneous values: the

problem is solved by a digital FIR filter, the

frequency bandwidth and sampling time are

chosen in terms of the noise properties and the

response time of all the mechanical/electrical

plant parts considered in the diagnosis design.

6 DIAGNOSIS AND DECISION

MAKING

We completely described a fault detection scheme.

The i

th

fault type effects (symptoms) may be caused

by more than one physical entity, and this fact is

described by conditional probabilities. Diagnosis is

to decide that element e

j

(a valve, transistor, heater,

etc) is (or will be) the cause of the detected (or

expected) fault. Previous fault events feed a

statistical database with class-conditional pdf(s)

{p(i

th

fault | e

j

-fault)}, used to compute p(e

j

-fault | i

th

fault) by Bayes’ rule. The corresponding safety

actions are made according to the diagnosis

conclusion, the fault severity and the decision

making scheme. One powerful solution is built upon

an Inference Engine: this is a software or hardware

system, which gives a conclusion (output) from a

fact (input) and knowledges (production rules). If

knowledges include fuzzy linguistic terms, it is

referred to as Fuzzy Inference Engine (FIE).

A conclusion may deal with:

• A new reference tracking (fuzzy control), the

knowledge base includes rules of the form:

if (mode2) and (low inflow), then (tank 3

temperature should be low)

• Diagnosis / binary logic instructions, a production

rule may be:

if (water outflow > 0.24m

3

/s) and (valve 21

closed), then (shut-off and repair/change element

e

2

),

if (d

2

µ

3

/dt

2

>0.12) or (input control u

1

not set), then

(3

rd

fault type in the next 3 minutes).

Beyond the construction/generation of production

rules, one difficult task when implementing a fuzzy

control algorithm is the accuracy of meaningful

membership functions for all the fuzzy linguistic

terms considered in the knowledge base. We’ll

present later, through an example of temperature

control, the different steps involved in fuzzy control

implementation.

7 SIMULATION RESULTS

For the demonstration of the proposed diagnosis

method, we consider a fictive complex process. We

assumed that a human expert was supervising the

plant state by observing three variables: v

1

(pressure

at point A

1

), v

2

(temperature at point A

2

) and v

3

(sound noise frequency). He makes detection and

diagnosis upon two complex combinations: x

1

=f

1

(v

1

,

v

2

, v

3

) and x

2

= f

2

(v

1

, v

2

, v

3

) (PCA). We want to apply

the designed FPRS to act with a similar reasoning

faculty.

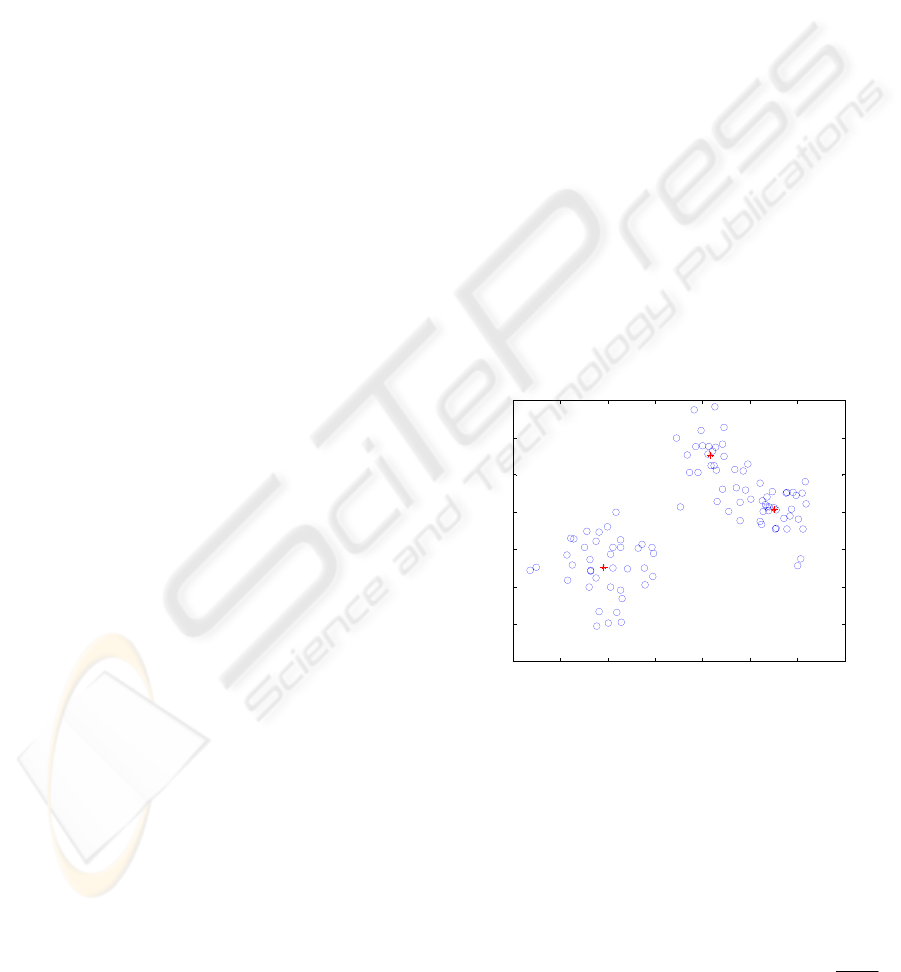

Simulation is run, by causing the plant to operate

during a sufficient time, under one normal (typical)

operating mode and two failure modes (plant

parameters randomly affected). PCA has reduced the

pattern vector to [x

1

, x

2

]

T

. The unsupervised learning

step is applied with a training set of 100 data points.

Samples are labelled; and the prototypes identified

as shown in figure 4.

-2 0 2 4 6 8 10 12

-6

-4

-2

0

2

4

6

8

x1

x2

Figure 4: Fuzzy clustering with c=3, q=2. The prototypes

are marked as red stars: v

1

=[1.823, -0.935]

T

, v

2

=[9.006,

2.151]

T

, v

3

=[6.297, 5.078]

T

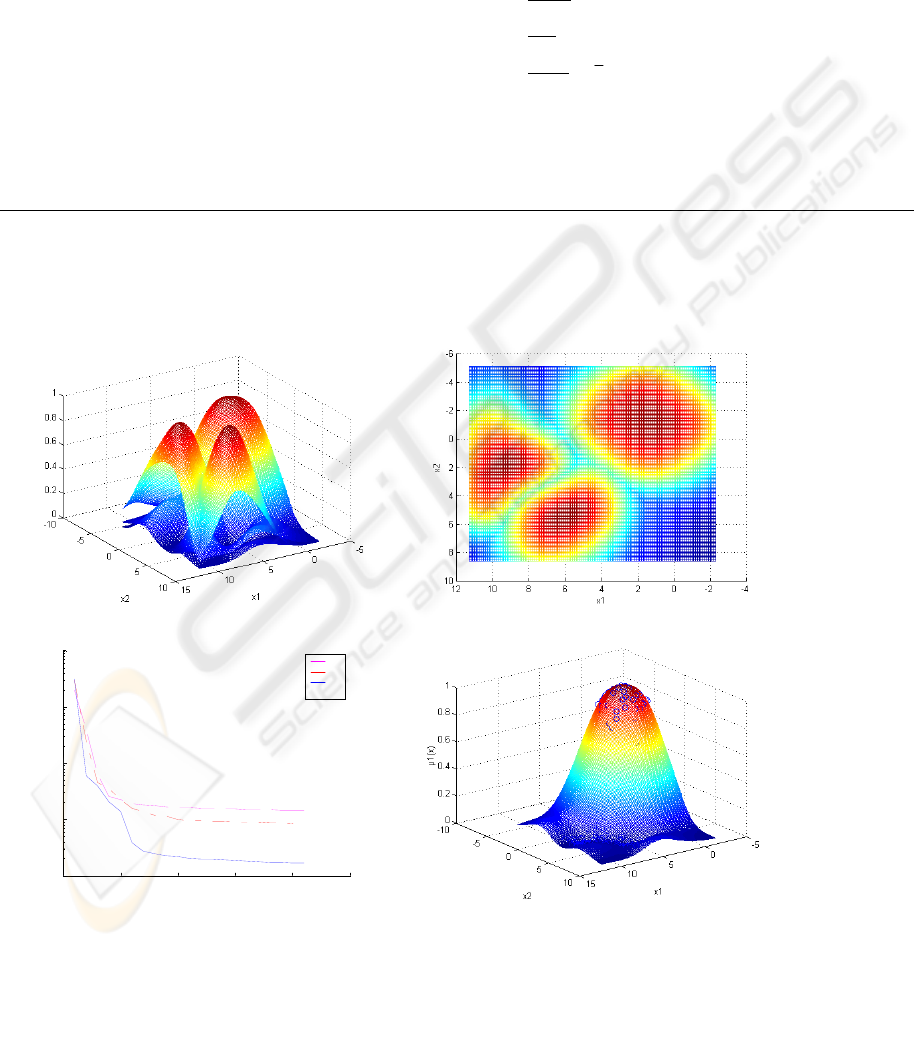

The method of Conjugate Gradients is successfully

applied to train an RBNN based membership

function approximator for each class (figure 5).

For classification and fault detection test, we

caused the system to evolve towards mode 3 by

generating a linear path sequence {z

k

=[z

k1

, z

k2

]

T

},

each observation is well labelled and classified

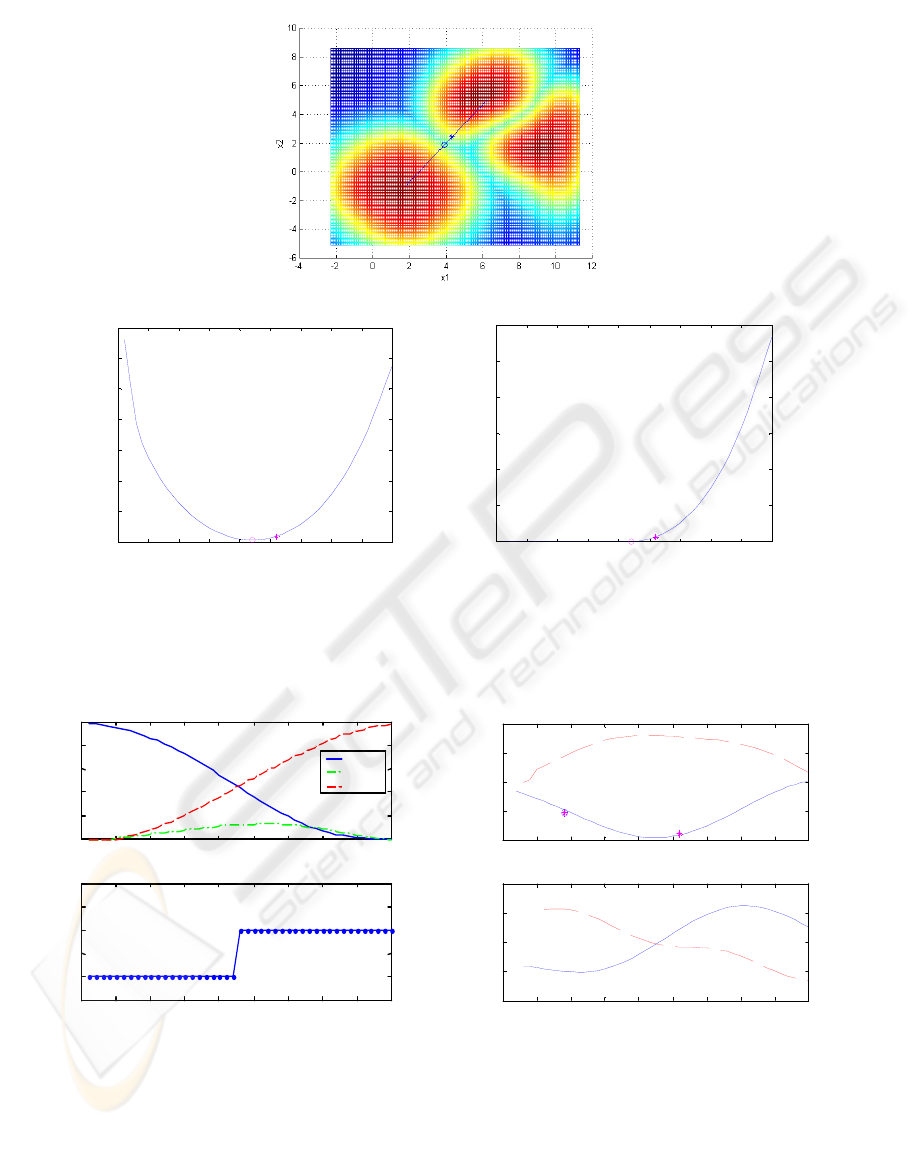

(Figure9-a). CUSUM is applied with

)(

)(

ln)(

1

3

z

z

z

µ

µ

s =

(figure 6). Evolution towards fault 3 is detected

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

352

The fuzzy linguistic term ‘mode i’ is described by

the corresponding membership function F

i

(x,θ). The

membership function for each other fuzzy linguistic

term is initialised as shown but may be modified by

learning to update the shape form and parameters.

earlier when membership function derivatives are

considered (figure 7-b).

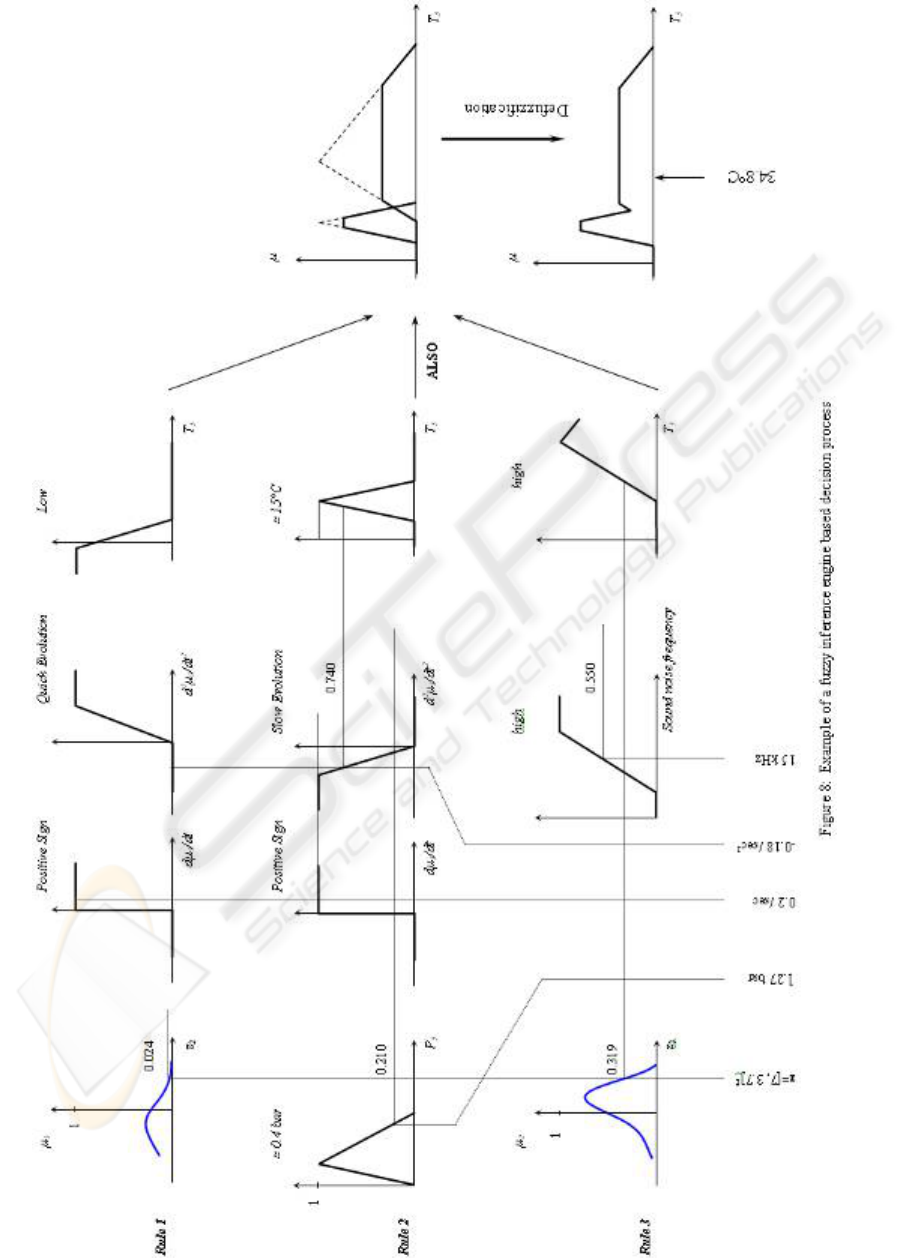

Temperature control problem is presented to

describe an exemple of a fuzzy inference engine

(figure 8). A part of the knowledge base is given as

follow:

The basic operators, involved in fuzzy control, are

defined as follow:

R1: if (mode1) and (quick evolution toward mode3),

then (T

5

should be low)

R2: if (P5 ≈ 0.4 bar) or (slow evolution toward mode3)

, then (T

5

should be around 15°C)

R3: if (mode2) and (high sound noise frequency),

then (T

5

should be high)

…..

Fact: z=[7, 3.7]

T

, P

5

= 1.27 bar, dµ

3

/dt

= 0.2 /sec, d

2

µ

3

/dt

2

= -0.18 /sec

2

, f

sn

= 15 kHz

Conclusion: T

5

should be ?

AND

: µ

A∩B

=

MIN(µ

A

, µ

B

) (12)

OR

: µ

A∪B

=

MAX(µ

A

, µ

B

) (13)

NOT

:

A

A

1

µ

µ

−

=

(14)

(a) (b)

0 5 10 15 20 25

10

-2

10

-1

10

0

10

1

10

2

number of iterations

J3

J2

J1

(c) (d)

Figure 5: membership approximator, p=25, γ = 2.5. (a) Plant status membership functions. (b) Projection of (a) on

x

1

-x

2

plane, the similarity with the plot of figure 4 is proved. (c) Cost function during learning. There is a trade-off

between the learning time and accuracy requirements. (d) F

1

(x, θ) matches the data pairs considered in training the

RBNN

.

FUZZY PATTERN RECOGNITION BASED FAULT DIAGNOSIS

353

(a)

0 5 10 15 20 25 30 35 40 45

-80

-70

-60

-50

-40

-30

-20

-10

time in number of samples

CUmulative SUM: S

(b)

0 5 10 15 20 25 30 35 40 45

0

10

20

30

40

50

60

time in number of samples

cusum decision function: g

(c)

Figure 6: Fault change detection by CUSUM, h=1.2. The estimated change occurrence is marked as circle; the alarm

time as star. (a) New observation-path, plant is leaving mode1 towards mode3 (b) Cumulative Sum plot, (c) decision

function plot

.

0

5

10

15

20

25

30

35

40

45

0

0.2

0.4

0.6

0.8

1

time in number of samples

Membership

µ1(z(k))

µ2(z(k))

µ3(z(k))

0

5

10

15

20

25

30

35

40

45

0

1

2

3

4

5

time in number of samples

Class number

(a)

0 5 10 15 20 25 30 35 40 45

-0.04

-0.02

0

0.02

0.04

time in number of samples

membership first derivative

0 5 10 15 20 25 30 35 40 45

-4

-2

0

2

4

x 10

-3

time in number of samples

membership second derivative

(b)

Figure 7: Future fault detection strategy with additional derivative based criterions. (a) Criterion 1-classification. (b)

1

st

and 2

nd

derivatives of µ

1

(t) and µ

3

(t), the filled circle indicates an earlier change detection.

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

354

FUZZY PATTERN RECOGNITION BASED FAULT DIAGNOSIS

355

For each rule, the compatibility of the fact to the

antecedent is obtained by projecting the fact to the

corresponding membership function. The resulting

membership degrees are combined by a conjunction

‘AND’ (rules 1, 3) or ‘OR’ (rule 2). An individual

conclusion is obtained by truncating (minimising)

the consequent membership function. All the rules

are combined by conjunction ‘ALSO’ (maximisation

of individual conclusions) to construct a relatively

complicated membership function ‘µ’ characterising

the final conclusion. The final step is

defuzzification: the new reference

that must be

tracked, given the fact: (z=[7, 3.7]

T

, P

5

=1.27 bar,

dµ

3

/dt = 0.2 /sec, d

2

µ

3

/dt

2

=-0.18 /sec

2

, f

sn

=15 kHz),

is computed by the center-of-gravity method:

*

5

T

()

()

C8.34

55

555

*

5

°==

∫

∫

dTTµ

dTTµT

T

(15)

and T

5

remains continuously under this control.

8 CONCLUSION

We have proposed a general FPRS design scheme

for fault detection and diagnosis in industrial

systems. This approach involves fuzzy clustering as

a first partition of the training set into a number of

classes initialised by the known operating/failure

modes, and the conjugate gradient method as the

learning tool for training membership function

approximators. Incoming observations will be

classified and new created classes are taken into

account.

Fault detection efficiency is first tested by

applying CUSUM with modified expression of the

log-likelihood ratio: membership degrees are

considered instead of probabilities. Then, an other

proposed method that takes advantage of

membership function derivatives is investigated,

evolution towards a fault type target is quantified

and safety actions will be executed in acceptable

delays.

There are many ways to design the decision

system, we proposed a knowledge based approach

and presented a ‘temperature fuzzy control’ as an

example of a safety action based on information

about fault change forecasts, extracted from the

matrix E.

The designed FPRS is successfully tested for a

fictive plant. Its proficiency will be more proven

when tested in a real environnement, this involves

additional hardware and software implementation

and will be the subject of a future work.

REFERENCES

Mogens Blanke, Michel Kinnaert, Jan Lunze and Marcel

Staroswiecki, 2003. Diagnosis and fault tolerant

control, Berlin: Springer.

L. H. Chiang, E .L. Russell and R. D. Braatz, Fault 2001.

Detection and Diagnosis in Industrial Systems,

London: Springer.

J. C. Bezdek, 1996. a review of probabilistic, fuzzy, and

neural models for pattern recognition. In C. H. Chen

(ed), Fuzzy logic and neural network handbook,

chapter 2, New York: McGraw Hill.

L. A. Zadeh, 1965. Fuzzy sets. Information and Control,

vol. 8, pp. 338-353.

L. A. Zadeh, 1973. Outline of a new approach to the

analysis of complex systems and decision processes’,

IEEE Trans. Syst., Man, Cybern., vol. SMC-3, no. 1,

pp. 28-44, jan.

S. Zieba, 1995. Une méthode de suivi d’un système

évolutif. Application au diagnostic de la qualité

d’usinage, Thèse de doctorat, Université de

Technologie de Compiègne, juin.

Takeshi Yamakawa 1993. A Fuzzy Inference Engine in

Nonlinear Analog Mode and Its Application to a

Fuzzy Logic Control. IEEE trans. on Neural

Networks, vol. 4, no. 3, pp. 496-522, May.

I. S. Torsum, , 1995 Foundations of Intelligent

Knowledge-Based Systems, London: Academic Press.

Bernard Dubuisson, Diagnostic et reconnaissance des

formes, Paris: Hermès, 1990.

Jonathan Richard Shewchuk, 1994. An Introduction to the

Conjugate Gradient Method Without the Agonizing

Pain (e-article), August.

Jeffrey T. Spooner, Manfredi Maggiore, Raúl Ordóñez and

Kevin M. Passino, Stable 1996. Adaptive Control and

Estimation for Nonlinear Systems. –Neural and Fuzzy

Approximator Techniques, New York: John Wiley and

sons, Inc.

David J. DeFatta, Joseph G. Lucas and William S.

Hodgkiss, 1988. Digital Signal Processing: A System

Design Approach, New York: John Wiley and sons,

Inc.

ICEIS 2005 - ARTIFICIAL INTELLIGENCE AND DECISION SUPPORT SYSTEMS

356