KNOWLEDGE REPRESENTATION APPROACH TO CLOSED LOOP

CONTROL SYSTEM - A TANK SYSTEM CASE-STUDY

Lu

´

ıs Rato, Irene Pimenta Rodrigues, Rui Gomes

Universidade de

´

Evora

R. Rom

˜

ao Ramalho, 59, 7000-671

´

Evora

Keywords:

Control, declarative programming, knowledge representation, constraints.

Abstract:

Control engineering problems are dealt within a plethora of methods and approaches depending on the a priori

knowledge, the description of the process to control, and the main control goal. Classical control theory is

mainly based on properties of numerical models. This paper presents an approach that applies to a class of

processes described by numerical and logical relations using inference and a knowledge base system. To attain

this goal an ontology for control systems is constructed. The work presented in this paper is based in a three

tank system benchmark.

1 INTRODUCTION

The knowledge representation as a major impact on

the performance of intelligent systems (Messina et al.,

2001) and the relevance of this fact increases with the

complexity of systems we are dealing with. Thus,

considering the diversity and the potential complex-

ity of control engineering problems one must consider

that control systems are a natural candidate to apply

knowledge bases and inference systems.

Most applications of artificial intelligence algo-

rithms to control problems amount to softcomput-

ing techniques and supervision tasks (Shadbolt et al.,

1989). Nevertheless, the concern on modelization

from the control engineering community has pro-

duced some work on component oriented model lan-

guage as in the Modelica language (Elmqvist et al.,

2001) or CSML (Zagar et al., 2001). In this work we

aim to describe, infer the behaviour, and infer control

actions in a integrated way through a Prolog imple-

mentation using finite domain constraints (Diaz and

Codognet, 2000; Sterling and Shapiro, 1997).

Although the importance of knowledge represen-

tation is recognised and Prolog is used to express

declarative rules about controller properties in (Shad-

bolt et al., 1989), the inference system remains lim-

ited to supervision tasks. This work presents a more

integrated approach from process description to con-

trol tasks and aims to be as general as possible.

The scope broadening of such approach will be at-

tained with a penalty in efficiency when compared to

the very powerfull classical linear system tools. Thus,

in order to illustrate the potential of such approach a

non linear, multi-input multi-output (MIMO) system

is chosen as a test-case. For such systems the power-

full mathematical tools are restricted to very particu-

lar cases. Another possible approach is to combine in-

teger programming with real constraint optimisation

(Bemporad and Morari, 1999). Nevertheless, such

tools do not have a programming framework to sup-

port them as powerful as logic programming has. The

test-case used in this work, a three-tank system, has

been used as a very flexible benchmark system for re-

configurable control techniques (Lunze et al., 2001).

This paper is organised as follows. An introduction

is made in section 1. Section 2 presents the knowl-

edge based control system build around the three tank

system test-case. The model is validated by simula-

tion in Section 3. Section 4 presents the queries that

solve the proposed control problems. Some conclu-

sion are addressed in Section 5.

2 KNOWLEDGE BASED

CONTROL SYSTEM

In this section a knowledge based control system is

build around the three tank system test-case. Though

the knowledge based system presented here does not

113

Rato L., Pimenta Rodrigues I. and Gomes R. (2005).

KNOWLEDGE REPRESENTATION APPROACH TO CLOSED LOOP CONTROL SYSTEM - A TANK SYSTEM CASE-STUDY.

In Proceedings of the Second International Conference on Informatics in Control, Automation and Robotics, pages 113-118

DOI: 10.5220/0001186301130118

Copyright

c

SciTePress

aim to a general purpose solution to process mod-

elling and control it presents solutions that can be eas-

ily extended to other processes and control problems.

Some of the control problems that we aim to ad-

dress are: estimation, fault detection and isolation,

control actuation, and controller optimisation. These

control problems can be define in a declarative way

according to:

• Estimation - given a series of observations of the

process which are the possible internal states at in-

stant t.

• Fault detection and diagnosis - given a series of ob-

servations of the process which are the admissible

models or model variations.

• Control actuation - given a series of observations

and a control goal (control reference) which should

be the actuation on the process such that the goal is

attained at an instant t.

• Controller optimisation - given process and con-

troller models which are the controller parameter-

ers such that the closed loop system is optimal ac-

cording to a criteria (penalty function).

These set of classical control problems may be de-

fined with constraints such as internal state variables,

solution space, and time constraints. This fact sug-

gests the use of a constraint oriented programing tool.

2.1 Linear dynamical system

In order to illustrate the potential of the proposed

approach consider a discrete-time linear dynamical

system to be represented in logic programming with

constraints. Discrete-time is considered since the

GnuProlog constraint system applies only to integer

domain.

x(t +1)=Ax(t)+Bu(t) (1)

y(t)=Cx(t)+Du(t) (2)

where x(t) is the state; u(t) is the input; y(t) is the

output and A, B, C, D are matrices which parame-

terise the linear system. The following problems will

be considered:

• Simulation - given parameters A,B,C,D, the input

u(t) and initial conditions x(0) what is the state x

or output y at a certain instant t

• Input definition - given parameters A,B,C,D, the

desired output y at time t (with an error marginδ),

initial conditions x(0) what are the possible inputs

u(t) (with some constaints, e.g. constant input).

• Parameterisation - given parameters A,B,C,D, par-

tially defined, the input u(t) and initial conditions

x(0) what should be the parameters such that the

output y is the desired one at time t (with an error

margin

δ)

Prolog Implementation

Two predicates are defined to implement the state and

output equations. The predicate ”state” defines the

state x(t +1)recursively

state(XT1,T1) :- T1 #= T+1, state(XT,T),

input(UT,T),

XT1 #= A

*

XT+B

*

UT.

and the predicate ”output” defines the output y(t)

output(YT,T) :- state(XT,T), input(UT,T),

YT #= C

*

XT + D

*

UT

where A, B, C, D stands for the linear system para-

meters; XT is the state x(t), XT is the input u(t) and

YT is output YT. It should be noted that, in general,

the operators ”*” and ”+” represent the matrix product

and sum, and the variables XT, YT and UT are vec-

tors with compatible dimensions. Furthermore, since

GNU-Prolog constraint solver operates only on inte-

ger positive values, operators ”*” and ”+” and number

representation must be such that positive and negative

limited precision real values are represented through

integer positive values.

To attain this goal negative integer are represented

using tens complements. This is a particular case of

a modular arithmetic (modulo a ten’s power) (Knuth,

1997), just as two’s complements in computer arith-

metic. In order to represent decimal part, variables

are scaled by a constant 10

n

.

Initial contitions may be introduced through a fact

such as

state(0,0).

which stands for x(0) = 0 in a first order system.

Consider the simulation problem. Given zero initial

conditions, and constant input u(t)=1, the value

XT unifies to 1 for any time T .

input(1,_).

the following query defines the output at instant 100.

output(YT,100).

The second proposed problem is input definition.

Given a desired output y = yout with a certain toler-

ance tol, at time t = 100 what should be the input, if

it is constant.

% constant input

input(T1,U) :- T1 #= T+1, input(T,U)

the query could be defined as

input(0,U), output(Y,100),

Y #< yout+tol , y #> yout-tol.

where yout and tol are the desired output value and

tolerance; and U is the variable that unifies with a so-

lution.

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

114

2.2 Tank System case-study

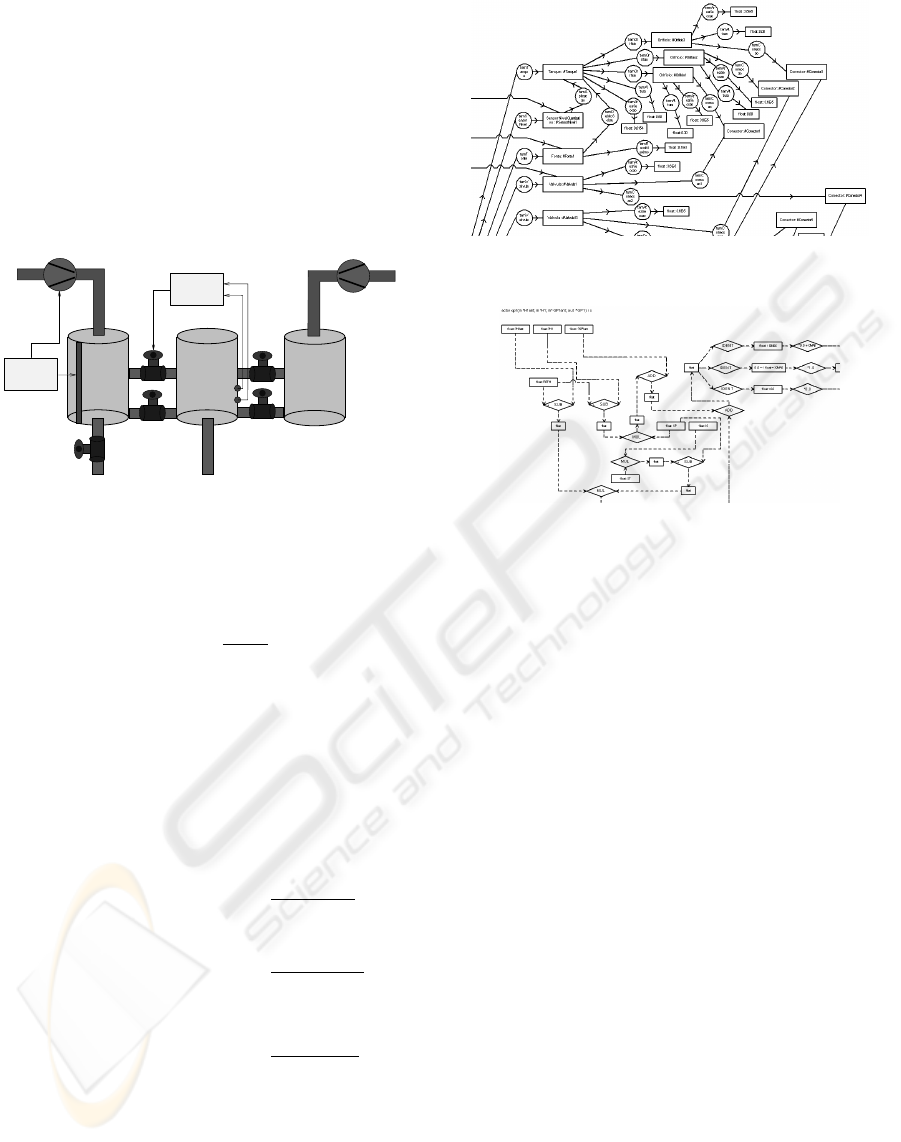

The three tank system, in figure 1, is a rich benchmark

system due to its nonlinear behaviour, actuators and

sensors which can be continuous as well as on-off,

and redundancy which allows to test reconfigurable

control strategies(Rato and Lemos, 1999). Control re-

configuration is a control problem usually tackled by

non classical control tools, thus a good candidate to il-

lustrate the potential of a knowledge based approach.

Tank2

Source1

Source2

Valv13

Valv32

ValvL

Valv2

Valv1

SensorLevel3

SensorLevel1

Controller PI1

Tank1

ControllerON−OFF1

Tank3

PI

controller

ON−OFF

controller

Figure 1: Tree tank system

The mathematical model of tank systems are repre-

sented by the following differential equation for each

tank,

˙

h(t)=

N

i=1

Q

i

(t)

A

T

(3)

where A

T

is the area of the tank base’s, N is the

number of inputs/outputs, and Q

i

is the inflow in each

tank’s input/output. External sources are manipulated

variables.

Q

i

(t)=u(t) (4)

and whenever there is a pipe at height h

p

(only con-

stant section horizontal pipes are considered in this

work) between two tanks the inflow is defined by:

if h>h

p

and h

>h

p

Q

i

(t)=a

Z

Ssgn(h

− h)

2g|h

− h| (5)

if h>h

p

and h

<h

p

Q

i

(t)=a

Z

Ssgn(h

− h

p

)

2g|h

− h

p

| (6)

if h<h

p

and h

>h

p

Q

i

(t)=a

Z

Ssgn(h − h

p

)

2g|h − h

p

| (7)

if h<h

p

and h

<h

p

Q

i

(t)=0 (8)

where h is the level of the tank being modelled; h

is

the level of another tank connected at height h

p

.

The three tank system is composed by three tanks

6m high, with a section surface S =3.610

−5

m

2

,

Figure 2: Catalog of individuals

Figure 3: Model representation

with 2 pipes connecting the central tank to each one

of the other two tanks - one at h =0and an-

other at h =0.3 m - each pipe with section surface

A =0.0154 m

2

has a valve and there are two pumps

that put water into tanks 1 and 2. Maximum flow

for each pump is Q

max

=0.110

−3

ms

−1

Constant

a

z

is assumed unitary. The level of the tanks can be

controlled using the flow from the pumps as well as

through the valves.

A complete model description may be found in

(Lunze et al., 2001). The continuous time model

is obtained discretizing the continuous model using

Euler’s method (

˚

Astr

¨

om and Wittenmark, 1997).

2.3 Three tanks representation as a

Finite Domain Constraint

Satisfaction Problem

To represent the three tanks systems as a constraint

satisfaction problem in Prolog we had to build an on-

tology in order to represent the system entities and its

proprieties.

In figure 2 we present a excerpt of the defined con-

ceptual graph for representing our domain ontology

(three tanks problem). In figure 4 we present the de-

scription of an example according to the ontology de-

fined in figure 2.

In Prolog with finite domain constraints our enti-

ties may be represented by: names, constants values,

KNOWLEDGE REPRESENTATION APPROACH TO CLOSED LOOP CONTROL SYSTEM - A TANK SYSTEM

CASE-STUDY

115

tank(t1,6.0,1.54).

hasHole(t1,hl1).

hasHole(t1,hl2).

hasHole(t1,hl3).

hole(hl1,3.6E-3,3.0).

hole(hl2,3.6E-3,0.0).

hole(hl3,3.6E-3,0.0).

links(hl1,p1).

links(hl2,p2).

links(hl3,p3).

source(s1,0.1).

on(s11,t1).

Figure 4: Representation of a three thanks configuration

variables or constraint variables. Proprieties are rep-

resented by predicates that relate one or more entities.

In this paper we will detail the representation of the

proprieties:

• Tank level height

In our ontology tanks have the propriety of having

a level hight at a time instant, this is represented

by the 3 arguments predicate h where the first ar-

gument represents the tank name, the second one is

a constraint variable that represents the tank hight

and the third one is a constraint variable that repre-

sents a time instant

Example: h(t1,HT,T), represents that tank t1 has

height HT at the time instant T.

The height value, as we can see from equation ??,

at a time instant depends on the flow of the pipes or

sources connected to the tank.

• Pipes and sources flow.

Pipes are connected to tanks and have the propertie

of having a flow at a time instant. The predicate to

represent the flow of a pipe or a source is a 3 argu-

ments predicate q where the first argument repre-

sents the pipe or source name, the second one is a

constraint variable that represents the pipe flow and

the third one is a constraint variable that represents

a time instant.

Example:

q(p1,QT,T), represents that pipe p1 has flow QT at

the time instant T.

q(s1,QT,T), represents that source s1 has flow QT

at the time instant T.

In order to model the behaviour of three tanks rep-

resented in figure 1 we had to define a set of rules such

has the following ones:

• rule to model Tank t1 level height

h(t1,HT,T):- T1#= T-1, h(t1,HT1,T1),

q(s1,Fs1,T1),

q(hl1,Fhl1,T1),

q(hl2,Fhl2,T1),

area(t1,A),

HT #= HT1 + (Fs1+Fhl1+Fhl2) /|/ A.

The operator //— represents the integer division

between integer represented in ten-complement.

Flow and height values are represented in ten-

complement since flows in pipes may be positive

or negative.

• rule to model Tank1 t1 initial conditions

Supposing that the initial conditions where that

thank 1 has a level less then 10until 5 seconds. The

following rule represents this initial conditions.

h(t1,H,T):- H#<10,T#<5.

• rule to model flow in source s1

The following rule states that source s1 has a flow

of 20 from t=0 until t=10.

q(s1,FT,T):- FT#=20, T#>=0,T#=10.

• rule to model flow in pipe p1.

This rule will be obtain from the general equations

presented in the previous subsection taking into ac-

count that pipe p1 connects tank t1 and tank t2.

For instance the translation of the rule:

if h>h

p

and h

>h

p

Q

i

(t)=a

Z

Ssgn(h

− h)

2g|h

− h| (9)

q(p1,FT,T):- T1 #= T-1,

h(t1,HT1,T1),

h(t2,HT2,T1),

height(p1,H),

HT1#>H, HT2#>H,

HD#= HT1-HT,

module(HD,HDM),

FT1

*

FT1 #= 2

*

10

*

HDM,

signal(HD,FT1,FT).

3 CONTROL AND DIAGNOSIS

QUERIES

In this section we present some examples in order to

illustrate the results of our modulation of the three

tanks using logic programing with finite domain con-

straints.

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

116

3.1 Model validation

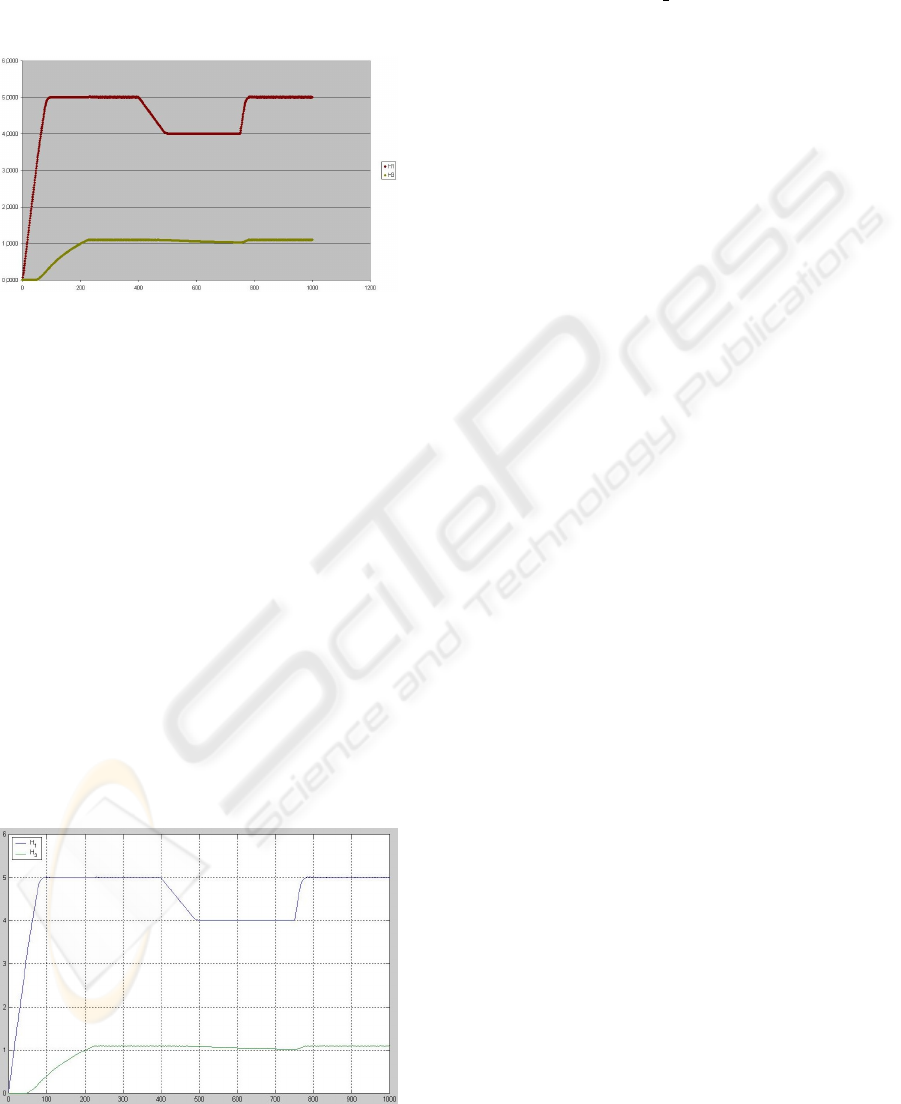

The generated declarative model of the tank system

is validated comparing simulation results in figure 5

with results from a MATLAB implemented model ac-

cording to (Lunze et al., 2001), in figure 6

Figure 5: Three tank system simulation - GNU-Prolog

The results of the generated declarative model im-

plemented in PROLOG with finite domain constraints

are according to those from the MATLAB simulation.

3.2 Example 1 - A diagnosis problem

Consider the tank system and admit that a leakage

may occur. This fault is simulated by opening of

valve 1L which is in the bottom of tank 1, at instant

t = 160. One may wish to find in which instants such

a fault may occur considering the observations. This

amounts to a diagnosis problem.

The following constraints were considered: the

fault occurs in the interval 150s<t<175s;

the model is admissible if the simulated tank level

h

s

imul and the observations are such that |h

simul

−

h

obs

| < 10mm. The query is,

| ?- findall(T,(T#<300,

h(t1,HT,T),

Figure 6: Three tank system simulation - MATLAB

h_obs(t1,HobsT,T),

(HT-HobsT)#<10) ,LS).

LS = [159,160,161]

Where the predicate h obs is in the database de-

fined for all relevant time instants, 0 to 300.

If the solutions are ordered by decreasing error

then,

| ?- setof(DT-T,(T#<300,

h(t1,HT,T),

h_obs(t1,HobsT,T),

DT#= HT-HobsT,

DT#<10),LSO).

LSO = [0-160,7465-161,8099-159]

the instant t = 160 is the most likely to be the correct

answer. It should be noticed that in this simulations

there is not addition of noise on sensor signals so, ex-

act answers are found.

3.3 Example 2 - control problem

with constraints

Consider the goal is to have the tank level at 205mm

at instant t =60s. We should define the input flow Q

(from a pump) considering this flow to be constant

in the interval 0s<t<60s with the constraint

75000mm/s < Q < 80000mm/s.

This constraints could be stated by the following

rules:

q(s1,FT,T):- FT#<80000, FT#>75000, T#<60,T#>60.

h(t1,205,T):- T#=60,!.

This amounts to a control problem with constraints,

whose solution is obtained by the query,

| ?- findall(FT,q(s1,FT,60),LS).

LS = [75844,75845,75846,75847,75848,

75849,75872,75873,75874,75875]

where the predicate h(t1,HT,T),T#=60cal-

culates the tank level at t =60s. This results depends

on the initial conditions of the tank system. Thus, one

of those solutions can be applied in a received strat-

egy. Which means that after the solution is obtained

and applied, new observations are made and a new

solution is calculated.

3.4 Example 3 - calculating optimal

gains

Consider the tank water level in closed-loop con-

trolled by a fixed structure controller such as a PI

controller. We want to determine the controller para-

meters under the following constraints: the controller

gains (proportional gain k

p

and integral gain k

i

) are

in the intervals 1 <k

i

< 10 and 10 <k

p

< 100; the

tracking error (the difference between the goal and the

actual level) is bounded to 5mm ref − h| =< 5mm;

KNOWLEDGE REPRESENTATION APPROACH TO CLOSED LOOP CONTROL SYSTEM - A TANK SYSTEM

CASE-STUDY

117

and there is no overflow in the tank h<600mm

within the following time interval 25s<t<100s.

which is solved by the following query, whose set of

solutions is over 200.

| ?- findall((KP,KI),sim(KP,KI,_),LS).

LS = [(25,2),(26,2),(27,2),(30,3),...]

where sim(KP,KI,ERR TOTAL) is a predicate

that calculates the tracking error of the closed loop

system with gains K

i

and K

p

.

An optimal parameterisation is obtained with a in-

creasing error ordered list

| ?- setof(ET-(KP,KI),sim(KP,KI,ET),LSO).

LSO = [3330-(75,10),3337-(74,10),....]

resulting in the optimal gains K

i

=10and K

p

=75.

4 CONCLUSIONS AND FUTURE

WORK

A declarative approach to control problems that ap-

plies to a class of processes described by numerical

and logical relations using inference and a knowledge

base system as been presented. Logic programming

with constraints has been applied. The followed ap-

proach makes possible not only to represent the con-

trol system in declarative way but also to query the

knowledge base system using the same declarative

language. The complete system is described using

the same description language no matter we are deal-

ing with logical or numerical variables. A further step

in the research will be to explore constraint logic pro-

gramming using other solvers that cope with real vari-

ables (positive or negative) possibly using mixed inte-

ger quadratic optimisation and compare the precision

gains versus the computational complexity increase.

Another problem that should be carefully analysed,

in the presence of quantisation, is the propagation of

quantisation error across the inference process.

REFERENCES

˚

Astr

¨

om, K. and Wittenmark, B. (1997). Computer Con-

trolled Systems. Prentice-Hall.

Bemporad, A. and Morari, M. (1999). Control of systems

integrating logic, dynamics, and constraints. Automat-

ica.

Diaz, D. and Codognet, P. (2000). The gnu prolog sys-

tem and its implementation. In ACM Symposium on

Applied Computing-SAC, Villa Olmo, Como, Italy.

ACM.

Elmqvist, H., Mattson, S., Otter, M., and Astrm, K. (2001).

Modeling complex systems. In Astrm, K., Albertos,

P., Isidori, A., Schaufelberger, W., and Sanz, R., edi-

tors, Control of Complex Systems, chapter 2. Springer.

Knuth, D. (1997). The Art of Computer Programming -

Seminumerical Algorithms. Addison-Wesley.

Lunze, J., Askari-Marnani, J., Cela, A., Rato, L., Lemos,

J., and Staroswiecki, M. (2001). Three-tank control

reconfiguration. In Astrm, K., Albertos, P., Isidori,

A., Schaufelberger, W., and Sanz, R., editors, Control

of Complex Systems, chapter 2. Springer.

Messina, E. R., Evans, J. M., and Albus, J. S. (2001). Eval-

uating knowledge and representation for intelligent

control. In 2001 PerMIS Workshop, Mexico.

Rato, L. and Lemos, J. M. (1999). Multimodel based fault

tolerant control of the 3-tank system. In Proceedings

of European Control Conference ECC99, Karlsruhe,

Germany.

Shadbolt, N. R., Robinson, B. D., and Stobart, R. K. (1989).

knowledge represebtation for closed loop control. In

SIGART: ACM Special interest group on AI.ACM

Press.

Sterling, L. and Shapiro, E. (1997). The Art of Prolog. MIT

Press.

Zagar, K., Plesko, M., G.Tkacik, and Vodovnnik, A.

(2001). The control system modelling language. In

ICALEPCS-2002, San Jose CA.

ICINCO 2005 - INTELLIGENT CONTROL SYSTEMS AND OPTIMIZATION

118